When it comes to high-strength steels, QT 100 stands out for its remarkable balance of toughness, durability, and versatility. Whether you’re an engineer, a manufacturer, or simply someone keen on understanding material properties, QT 100 offers a compelling mix of composition and performance that is hard to ignore. This article delves into the intricate chemical makeup, mechanical properties, and the wide range of applications where QT 100 excels. Furthermore, we’ll compare QT 100 to other high-strength steels like Grade 100, to help you make informed decisions for your projects. Ready to explore the world of QT 100 steel and discover what sets it apart? Let’s dive in.

QT 100 steel, also recognized as TruSTRENGTH 100 QT or ASTM A514/A656 Grade 100, stands out as a high-strength, low-alloy (HSLA) steel. This type of steel is engineered to offer a combination of high strength and good formability, making it suitable for a wide range of industrial applications.

Beyond its basic nature, the relevance of ASTM A514 and CSA standards to QT 100 steel is significant. ASTM A514 is a standard specification for high-yield-strength, quenched, and tempered alloy steel plates. QT 100 steel adheres to this standard, which guarantees its quality and performance in tough applications. This compliance ensures that the steel is good for welded bridges and other structures, providing reliability and strength where it is most needed.

CSA standards offer detailed guidelines on chemical makeup, mechanical traits, and testing methods for QT 100 steel. These standards ensure that the steel meets the necessary safety and performance requirements in the Canadian market and other regions that adopt similar standards. By following these guidelines, QT 100 steel maintains its high-quality attributes, making it a trusted choice in demanding industrial environments.

| The chemical composition of QT 100 steel is carefully designed to achieve its high-strength properties. Each element in the steel alloy contributes uniquely to its element | Maximum Percentage |

| Carbon (C) | Up to 0.24% |

| Manganese (Mn) | Up to 1.60% |

| Phosphorus (P) | Up to 0.020% |

| Sulfur (S) | Up to 0.015% |

| Silicon (Si) | Up to 0.34% |

| Copper (Cu) | Up to 0.25% |

| Nickel (Ni) | Up to 0.45% |

| Chromium (Cr) | Up to 0.65% |

| Molybdenum (Mo) | Up to 0.30% |

Carbon (C) Carbon, present up to 0.24%, balances strength and ductility, making the steel strong yet workable.

Manganese (Mn) Manganese, up to 1.60%, enhances tensile strength, hardness, and resistance to wear and impact.

Phosphorus (P) and Sulfur (S) Phosphorus and sulfur are kept minimal (0.020% and 0.015%, respectively) to prevent brittleness and improve toughness and weldability.

Silicon (Si) Silicon, up to 0.34%, acts as a deoxidizer, which helps in removing oxygen from the molten steel, improving its integrity and strength.

Copper (Cu) Copper, limited to 0.25%, enhances the steel’s resistance to corrosion, making it suitable for applications exposed to harsh environments.

Nickel (Ni) Nickel, up to 0.45%, contributes to the steel’s toughness and impact resistance. It also improves the steel’s ability to withstand low temperatures without becoming brittle.

Chromium (Cr) Chromium, with a maximum content of 0.65%, significantly increases the steel’s hardness and wear resistance. It also enhances corrosion resistance, which is beneficial for outdoor and marine applications.

Molybdenum (Mo) Molybdenum, present up to 0.30%, improves the steel’s strength at high temperatures and enhances its hardenability, making QT 100 steel suitable for high-stress applications.

Carbon equivalent values (CEV) are used to assess the weldability of steel. For QT 100 steel, these values provide insight into how the alloying elements affect its behavior during welding:

These values help in determining the preheating and post-welding treatments required to maintain the structural integrity of the steel during welding processes.

The specific combination of these elements results in a steel alloy that offers:

Understanding the chemical composition of QT 100 steel is crucial for engineers and manufacturers to optimize its use in various applications, ensuring reliability and performance under diverse conditions.

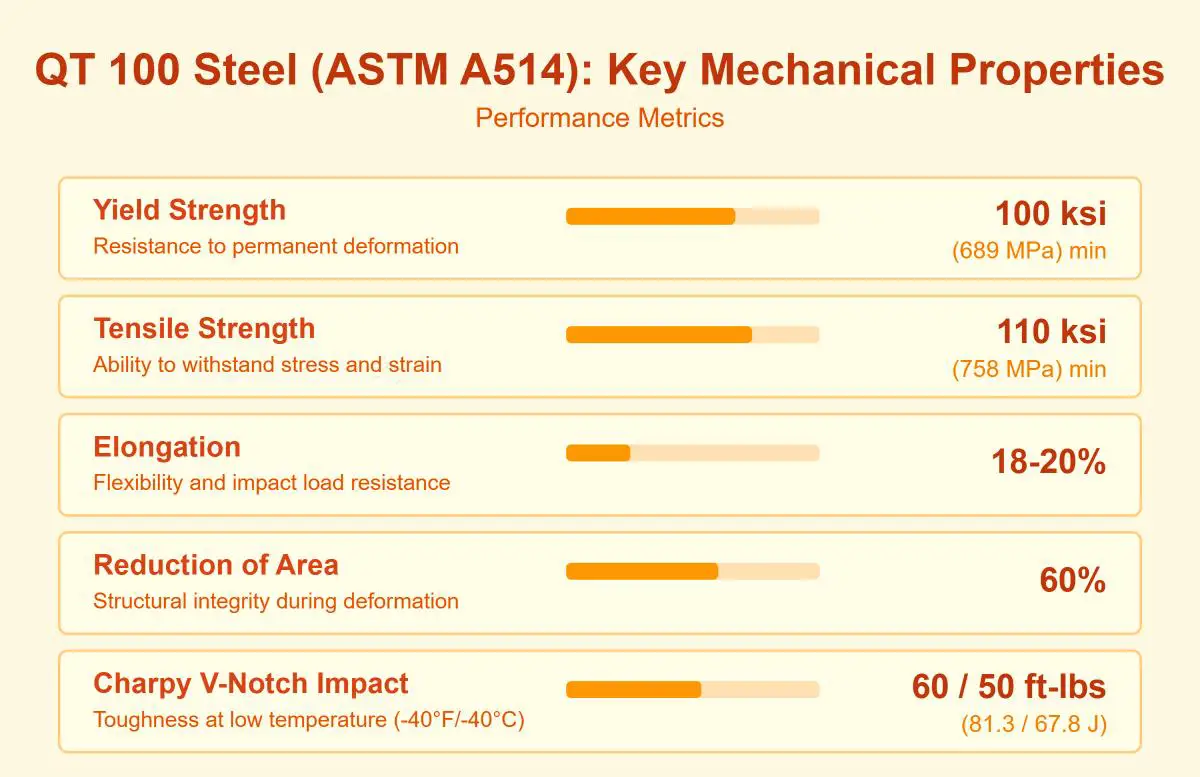

QT 100 steel is known for its high strength. It has a minimum yield strength of 100 ksi (689 MPa) and a minimum tensile strength of 110 ksi (758 MPa). These values are rigorously tested to comply with industry standards, particularly ASTM A370, ensuring the steel can withstand significant stress before deforming plastically. This makes it suitable for applications where structural integrity under load is crucial.

Elongation, which measures how much the steel can stretch before breaking, is up to 18%. The reduction of area, indicating how much the cross – sectional area decreases at the fracture point, is 60%. These properties suggest that QT 100 steel has a good balance between strength and ductility, allowing it to be formed into various shapes without immediate failure.

QT 100 steel has excellent Charpy V – notch impact resistance, even at – 40°F (-40°C). It shows a longitudinal impact resistance of 60 ft – lbs (81.3 J) and a transverse impact resistance of 50 ft – lbs (67.8 J), with a minimum transverse value of 30 ft – lbs (40.7 J). This high impact resistance ensures that the steel can withstand sudden and high – energy impacts, which is essential for applications in harsh environments or those subject to dynamic loading.

The chemical composition of QT 100 steel, with elements like chromium and molybdenum, contributes to its hardness and toughness. Hardness refers to the steel’s ability to resist indentation or scratching, while toughness is the capacity to absorb energy and deform plastically before fracturing. The combination of these properties makes QT 100 steel suitable for high – stress applications where it may encounter wear, abrasion, or impact.

The mechanical properties of QT 100 steel are measured using standardized methods. Tensile and yield strength are assessed through tensile tests, which record the forces and deformations until the sample breaks. Elongation and reduction of area are also measured during these tests. Charpy V – notch impact tests measure the energy absorbed during fracture, while hardness is typically assessed using Brinell or Rockwell methods.

QT 100 steel, also known as TruSTRENGTH 100 QT or ASTM A514/A656 Grade 100, is renowned for its impressive strength, toughness, and weldability. These attributes make it a preferred choice in various demanding applications across several industries. Below are some of the primary uses of QT 100 steel:

QT 100 steel is extensively used in the construction industry for fabricating bridges, buildings, and other structural components. Its high strength-to-weight ratio allows for the construction of robust structures without excessive weight, enhancing the overall efficiency and cost-effectiveness of the projects.

In the transportation sector, QT 100 steel is commonly employed in manufacturing truck and trailer frames, vehicle chassis, and other critical components. Its lightweight yet strong nature is particularly beneficial for heavy-duty transport equipment and railcars, where durability and performance are paramount. The steel’s ability to withstand high stress and impact makes it perfect for these applications.

QT 100 steel is ideal for mining and earthmoving equipment due to its exceptional durability and resistance to harsh conditions. Equipment such as excavators, loaders, and dump trucks benefit from the steel’s high strength, which ensures longevity and reliability even in the harshest environments. This application underscores the material’s capability to endure significant wear and tear.

The oil and gas industry often requires materials that can perform under extreme conditions, making QT 100 steel’s high strength and resistance to environmental stresses a suitable choice for this sector. It is frequently used in the construction of drilling rigs, pipelines, and other infrastructure that must withstand high pressure and corrosive environments.

In agriculture, QT 100 steel is utilized in the manufacturing of machinery and equipment, including tractors, plows, and harvesters. The steel’s strength and durability ensure that these machines can operate efficiently and withstand the rigors of agricultural work. Its robustness reduces the need for frequent maintenance, providing cost savings and reliability for farmers.

QT 100 steel’s high strength and formability make it ideal for heavy equipment used in construction and forestry. Equipment such as bulldozers, cranes, and forestry machinery benefit from the steel’s ability to handle substantial loads and resist impact. This makes it a valuable material for industries that demand both performance and durability in their equipment.

QT 100 steel’s mechanical properties, including a minimum yield strength of 100 ksi (689 MPa) and a tensile strength of 110 ksi (758 MPa), enable it to meet the rigorous demands of these applications. Its elongation of up to 18% also allows for sufficient ductility, making it suitable for various fabrication techniques such as machining, bending, welding, cutting, and heat – treating. Welding is particularly feasible with conventional methods under low hydrogen conditions, ensuring strong and reliable joints.

While QT 100 steel is comparable to other high – strength steels like QT 130, it is often preferred due to its balanced properties of strength, toughness, and weldability. Its high – quality surface finish and corrosion resistance provide additional advantages, making it suitable for a wide range of structural and heavy equipment applications.

Both ASTM A514 (QT – 100) and ASTM A656 Grade 100 share similar strength profiles, but ASTM A656 Grade 100 is more formable. ASTM A656 Grade 100 guarantees a 1.5T inside bend radius, while some A514 suppliers offer a 2.0T radius, making A656 better suited for complex fabrication. Regarding applications, ASTM A514 is mainly used in welded bridges and other structures. In contrast, ASTM A656 Grade 100 finds its use in heavy equipment and construction, leveraging its better formability for more complex fabrication needs.

AR400 is known for its high hardness and abrasion resistance, ideal for impact protection. On the other hand, QT 100 is chosen for its strength and ease of forming into various shapes. AR400 is commonly employed in wear – resistant applications, such as in machinery parts that are subject to constant friction. QT 100 is preferred in construction and transportation due to its balanced properties, making it efficient for use in various structures and vehicles.

QT 100 steel provides notable environmental benefits due to its high strength-to-weight ratio, achieved through a quenching and tempering process. This process enhances the steel’s mechanical properties, allowing for the use of less material without compromising structural integrity, which significantly reduces the environmental footprint of projects using QT 100 steel.

Additionally, QT 100 steel’s corrosion resistance, bolstered by elements such as chromium, nickel, and copper, extends the lifespan of structures and equipment. This longevity reduces the frequency of replacements, thereby minimizing waste and the environmental impact associated with the production and disposal of materials.

Using QT 100 steel in vehicles and structures improves fuel efficiency and reduces emissions due to its lower weight, contributing to a smaller carbon footprint.

QT 100 steel’s natural corrosion resistance significantly cuts down on maintenance needs, especially in harsh environments, leading to long-term cost savings on repairs and replacements.

QT 100 steel is easy to weld and machine, which streamlines fabrication processes and reduces production time and labor costs. Techniques such as laser cutting and plasma cutting can be applied with precision, reducing production time and associated labor costs. The ease of fabrication also means that complex designs can be achieved without excessive expense, further enhancing the material’s cost efficiency.

The high strength-to-weight ratio of QT 100 steel enables the use of less material to achieve the same structural strength as other steels. This characteristic not only reduces material costs but also decreases transportation costs due to the lower weight of the steel. In applications such as heavy equipment and construction, these savings can be substantial.

The durability and strength of QT 100 steel ensure that structures and equipment made from this material have a longer service life. This extended lifespan translates to lower lifecycle costs, as the need for replacements and extensive repairs is minimized. The initial investment in QT 100 steel is often offset by these long-term savings, making it an economically sound choice for various applications.

The Canadian Standards Association (CSA) sets stringent guidelines for the quality and performance of steel used in various applications. These standards ensure that the steel meets specific mechanical properties, chemical composition, and performance criteria to guarantee safety and reliability. For QT 100 steel, compliance with CSA standards involves adhering to the following key requirements:

CSA standards specify the mechanical properties that QT 100 steel must exhibit. These include:

The chemical composition of QT 100 steel is crucial, as CSA standards outline acceptable ranges for elements such as Carbon (C) up to 0.24%, Manganese (Mn) up to 1.60%, Phosphorus (P) up to 0.020%, Sulfur (S) up to 0.015%, Silicon (Si) up to 0.34%, Copper (Cu) up to 0.25%, Nickel (Ni) up to 0.45%, Chromium (Cr) up to 0.65%, and Molybdenum (Mo) up to 0.30%.

These values help predict how the steel will behave during welding and its likelihood of cracking. Typical values for QT 100 steel are:

The production of QT 100 steel involves a quenching and tempering process that enhances its mechanical properties. This controlled heat treatment also enhances the steel’s toughness and ability to withstand impacts.

Manufacturers of QT 100 steel implement rigorous quality control measures to ensure compliance with CSA standards. This includes:

Adhering to CSA standards means following specific testing protocols. These protocols include:

Upon successful testing, QT 100 steel is certified as compliant with CSA standards. This certification assures users that the steel meets the highest quality and performance criteria.

Ensuring compliance with CSA standards is not just a regulatory requirement but a vital aspect of guaranteeing the safety and reliability of QT 100 steel. It provides confidence to engineers and manufacturers that the steel will perform as expected under demanding conditions. This adherence to standards is particularly important in critical infrastructure projects, such as bridges, buildings, and heavy machinery, where material failure can have severe consequences.

Ensuring that QT 100 steel meets CSA standards also facilitates its use in the Canadian market and other regions that recognize these standards, broadening the material’s applicability and acceptance in global projects.

How do you pick the right steel for your project? Choosing the appropriate steel involves evaluating several critical factors to ensure it meets the performance and operational demands of the application.

Understanding the mechanical properties of steel is essential. These properties include tensile strength, which is the ability to resist being pulled apart, yield strength, which indicates the point at which the steel begins to deform, and elongation, which measures how much the steel can stretch before breaking. QT 100 steel, for example, offers high yield and tensile strengths, making it suitable for applications requiring robust structural integrity under significant loads.

Toughness and hardness are crucial for applications where the steel will experience impact or wear. Toughness measures the ability to absorb energy and deform without fracturing, while hardness indicates resistance to indentation and abrasion. QT 100 steel’s high toughness and hardness make it ideal for heavy-duty equipment and machinery subjected to harsh conditions.

For applications exposed to corrosive environments, such as marine or chemical processing, corrosion resistance is vital. Elements like chromium and copper enhance the corrosion resistance of steels like QT 100, extending their service life and reducing maintenance costs.

Weldability is a significant factor when the steel needs to be joined or repaired. QT 100 steel, with its balanced composition, offers excellent weldability using standard methods like SMAW, SAW, and GMAW, provided low hydrogen conditions are maintained. This makes it a practical choice for construction and structural applications where welding is common.

Formability is the ability to shape the steel without cracking or losing strength. QT 100 steel’s good formability allows it to be bent, cut, and machined into complex shapes, which is essential for custom-designed structures and components.

The operational environment, including temperature extremes, influences steel selection. QT 100 steel maintains its mechanical properties at low temperatures, making it suitable for cold climates and applications where temperature fluctuations are a concern.

The type and magnitude of loads the steel will encounter are critical. QT 100 steel’s high strength-to-weight ratio makes it suitable for applications involving dynamic loads, such as in the transportation and heavy equipment industries.

While the initial cost of the steel is a consideration, the total lifecycle cost, including maintenance, repair, and replacement, is more significant. Although QT 100 steel may cost more upfront, like buying a high-quality car, it saves money in the long run on maintenance and replacement.

The availability of the steel and the reliability of the supply chain also affect the selection process. QT 100 steel’s widespread use and compliance with standards like ASTM A514 ensure it is readily available and supported by a robust supply chain.

Modern engineering and manufacturing professionals can leverage interactive tools and software for steel selection. These tools allow users to input specific requirements, such as mechanical properties, environmental conditions, and cost constraints, to identify the most suitable steel grade for their application. By carefully evaluating these factors, engineers and manufacturers can select the right steel for their specific applications, ensuring optimal performance, durability, and cost-effectiveness.

Below are answers to some frequently asked questions:

QT 100 steel, also known as ASTM A514, is notable for its impressive mechanical properties, which make it highly suitable for demanding applications. Key properties include:

These properties are tested and measured using standardized methods to ensure reliability and performance in various high-stress applications.

QT 100 steel is widely used across various industries due to its high strength, toughness, and excellent weldability. Its typical applications include:

These applications leverage the material’s high performance characteristics, making QT 100 steel a preferred choice in demanding environments.

QT 100 steel, also known as ASTM A514 Grade 100, is a high-strength, low-alloy (HSLA) steel that is quench and tempered to enhance its mechanical properties. When compared to other high-strength steels like Grade 100, several key factors come into play.

Both QT 100 and Grade 100 steels offer high yield and tensile strength, making them suitable for demanding applications such as construction, heavy equipment, and transportation. Specifically, QT 100 steel has a minimum yield strength of 100 ksi (689 MPa) and a minimum tensile strength of 110 ksi (758 MPa), with elongation up to 18-20%.

However, QT 100 steel stands out due to its superior weldability and formability, thanks to its balanced composition, which includes elements like chromium, nickel, and molybdenum. These elements not only enhance its strength and toughness but also improve its resistance to wear and corrosion compared to plain carbon steels.

In terms of fabrication, QT 100 steel’s quench and tempering process allows for better control over its mechanical properties, making it versatile for various industrial applications. While both steels are high-performing, QT 100’s specific properties and ease of processing make it a preferred choice in applications where precision and reliability are crucial.

Yes, QT 100 steel complies with CSA Standards, specifically the CSA G40.21 standard for high-strength, quenched, and tempered steels. The equivalent grade in the CSA standard is 100QT, which shares similar mechanical properties and applications as QT 100 steel. Both grades emphasize high yield strength and toughness, making them suitable for demanding structural applications. Compliance with the CSA G40.21 standard ensures that QT 100 steel meets the specific chemical and mechanical specifications required for use in Canadian projects, thus providing reliability and consistency in performance.

The cost-efficiency of QT 100 steel in construction applications is primarily attributed to its high strength-to-weight ratio, excellent formability, and weldability. These properties allow for the design of lighter structures without compromising strength, which can lead to material savings and reduced transportation costs. Additionally, QT 100 steel’s superior weldability reduces fabrication costs by minimizing the need for complex welding procedures and preheating. Its good corrosion resistance further extends the lifespan of structures, leading to lower maintenance costs over time.

To use the interactive tool for steel selection, especially in relation to QT 100 steel, follow these steps:

By following these guidelines, you can effectively leverage the interactive tool to select the most suitable steel for your engineering and manufacturing projects.