In the world of plumbing and piping systems, choosing between reducing couplings and bushings can be a daunting task. These two components may seem similar at first glance, but they have distinct differences that can significantly impact your project. Reducing couplings are designed to connect pipes of different sizes, while bushings are used to adapt a larger fitting to a smaller pipe. But how do these differences translate into real-world applications? And which one is the right choice for your specific needs?

As you continue reading, you’ll uncover the nuances between these two fittings, including their installation processes, space requirements, and impact on flow rates. By the end, you’ll be well-equipped to make an informed decision for your next project. So, are you ready to find out which fitting reigns supreme?

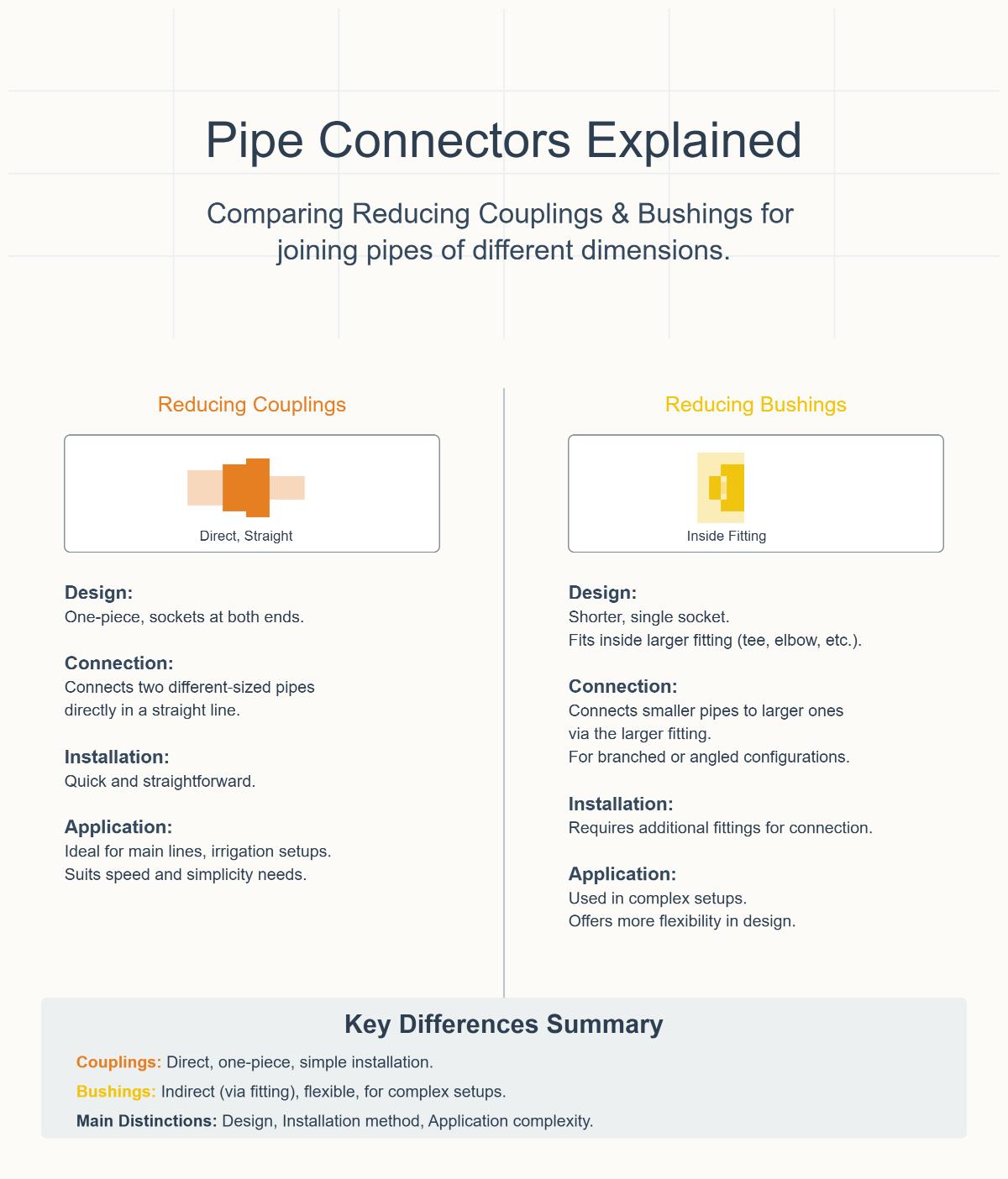

Reducing couplings are fittings that connect two pipes of different diameters directly. These one-piece fittings provide a seamless transition between different pipe sizes, which is essential in various fluid transportation applications.

Reducing bushings are compact fittings designed to reduce the size of a pipe opening by fitting into a larger fitting and connecting to a smaller pipe. Unlike reducing couplings, bushings are inserted into existing fittings, making them a more versatile option for complex configurations.

Reducing couplings and bushings play crucial roles in plumbing and piping systems by enabling the connection of pipes with different diameters. This capability is vital for both residential and industrial applications, where varying pipe sizes are often necessary to accommodate different flow rates, pressures, and system designs.

Reducing couplings are longer fittings that provide a gradual transition between pipe sizes, maintaining stable flow and minimizing turbulence. Their straightforward design also allows for easy and quick installation with minimal disruption. They are commonly used in main water lines, irrigation systems, and other setups requiring stable and extended connections.

Reducing bushings are compact and fit well in tight spaces. They need precise installation, as they must be threaded and aligned into larger fittings. This makes them suitable for retrofit projects and complex configurations such as branched or angled connections.

| Feature | Reducing Couplings | Reducing Bushings |

|---|---|---|

| Design | One-piece, longer, suitable for straight-line connections | Shorter, inserted into larger fittings |

| Installation Complexity | Straightforward, quick installation | More precise, can be complex in certain configurations |

| Space Requirements | Suitable for more spacious environments | Ideal for confined spaces |

| Maintenance | Less maintenance due to fewer connections | Requires precise alignment, more potential leak points |

| Flow Characteristics | Suitable for stable flow in straight lines | Can reduce turbulence, improve flow in complex setups |

Choosing the right material for reducing couplings and bushings is crucial for the system’s durability and performance. Selecting materials compatible with the pipes helps prevent problems like galvanic corrosion, ensuring the system lasts longer and remains reliable.

Reducing couplings and bushings are indispensable components in modern plumbing and piping systems, each offering unique advantages tailored to specific applications and installation requirements.

Reducing couplings are fittings designed to join two pipes of different diameters. They require some additional length to accommodate the transition between pipe sizes. This means that while they can be used in space-constrained environments, some linear space is necessary to install them properly.

Reducing couplings simplify the connection process in tight spaces due to their compact design. Their ability to accommodate slight misalignments and size variations helps mitigate installation challenges in narrow spaces, making the connection process simpler.

However, telescoping, where the smaller pipe slides into the larger one, can complicate the installation process in tight vertical spaces. This requires additional measures to secure the connection, potentially complicating the installation process.

Reducing bushings are designed to step down from a larger pipe to a smaller one by fitting into an existing larger fitting. This design makes them inherently compact, which is a significant advantage when working in confined spaces.

The primary advantage of reducing bushings in space-constrained installations is their compact size. Their design allows them to fit neatly into existing fittings, reducing the overall footprint of the installation. This compact form factor is particularly beneficial in environments where space is at a premium, such as in urban infrastructure, aerospace applications, or compact electronic devices.

Despite their compact size, reducing bushings require precise installation. This precision can be challenging in tight spaces, as aligning and threading the bushing into the larger fitting must be done accurately to ensure a proper seal. This requirement can make the installation process more time-consuming and difficult in confined areas.

When selecting fittings for installations with space constraints, several factors need to be considered:

| Feature | Reducing Couplings | Reducing Bushings |

|---|---|---|

| Ease of Installation | Easier to install due to their accommodating design | Needs precise alignment during installation |

| Space Efficiency | Suitable for tight spaces due to compact design | Less suitable for very tight spaces due to precision needs |

| Misalignment Tolerance | Can handle slight misalignments and size variations | Requires precise alignment to function correctly |

Reducing couplings are generally more advantageous in space-constrained installations due to their ease of installation and flexibility. However, reducing bushings are preferable in environments where compactness and precise connections are critical, despite the challenges in installation precision.

Reducing couplings are easy to install thanks to their simple design. First, align the ends of the two pipes with different diameters and insert the larger pipe end into the coupling’s gasket. After that, place the coupling housing halves over the gasket. Make sure the housing keys engage the pipe grooves. Then, tighten the nuts on the housing alternately to achieve metal – to – metal contact. This process is relatively quick and can accommodate minor misalignments and size variations in the pipes.

Installing reducing bushings is a more precise task. It begins with taking accurate measurements to ensure a perfect fit between the bushing and the pipe ends. Precise alignment is crucial at this stage to maintain proper flow control and prevent leaks. Once the alignment is correct, insert the bushing into the larger pipe. After that, connect the smaller pipe to the bushing. Seal carefully to prevent leaks.

In terms of installation speed, reducing couplings have a clear advantage. Their simple design and the ability to tolerate misalignments allow for a quicker installation process, which is ideal for projects with tight schedules or those requiring temporary fixes.

Regarding difficulty, reducing bushings are more challenging to install. The need for precise measurements and alignment means that installers must be more meticulous. Any small error in the installation can lead to leaks or improper flow.

Reducing couplings are versatile and fit well in various spaces. Although they need some linear space for the transition between pipe sizes, their ability to handle misalignments helps in tight spaces. Although compact, reducing bushings are challenging to install in tight spaces due to the need for precise alignment.

Reducing couplings are essential in residential plumbing for main water lines. These lines often need a stable connection between pipes of different diameters to ensure a consistent water supply. For example, when linking a larger main pipe to a smaller branch pipe leading to a specific fixture, a reducing coupling offers a reliable joint. This component is also crucial in residential irrigation systems, where maintaining steady water pressure and flow is vital. The secure connection provided by reducing couplings helps prevent leaks and ensures efficient water distribution.

In industrial settings, reducing couplings play a key role in systems that handle high pressures. Industries like chemical processing, oil and gas, and power generation often deal with fluids under significant pressure. The robust, threaded connection of a reducing coupling offers the strength and security needed for these conditions. Additionally, these couplings are ideal for permanent connections, maintaining system integrity over long periods without frequent disassembly. They are indispensable in critical systems, such as the cooling systems in power plants, where reliability is paramount.

Reducing bushings are particularly useful in residential plumbing retrofit projects. When upgrading an existing plumbing system or adding new fixtures, space can be limited. The compact size of reducing bushings allows them to fit into tight spaces where a reducing coupling might be too bulky. They also come in handy for complex configurations. For instance, when connecting a smaller pipe to a larger one at an angle, a reducing bushing can be inserted into the larger fitting to create the necessary connection, providing design flexibility.

In industrial settings, reducing bushings are often employed in non-critical systems. These systems may not require the same level of security and stability as high-pressure or critical systems. For example, in secondary ventilation or low-pressure fluid transfer systems, the simplicity and cost-effectiveness of reducing bushings make them a preferred choice. They are also commonly used in industrial irrigation systems for the same reasons of ease and efficiency.

Reducing couplings are designed as one-piece components, making them straightforward to install. Their straightforward design makes it easier to connect pipes of different sizes and requires minimal tools. This simplicity reduces the number of potential leak points, enhancing reliability and decreasing maintenance needs. Their design is particularly advantageous in applications where ease of installation is critical.

Reducing bushings are compact components that fit within existing fittings, providing size adaptations in confined or angled setups. However, their installation is more complex due to the need for precise alignment and additional fittings, which can increase labor time and costs.

Reducing couplings ensure a secure, direct connection that maintains consistent flow with minimal interruption. They are particularly beneficial in applications where space is not a major concern, such as residential plumbing and irrigation systems. The design minimizes the risk of leaks and reduces maintenance needs, contributing to higher efficiency and reliability of the overall system. By using reducing couplings, the transition between different pipe sizes is smooth, which helps in maintaining optimal pressure and flow rates. This can lead to cost savings over time due to fewer repairs and replacements.

Reducing bushings are suited for complex or space-restricted configurations, offering necessary size adjustments without requiring larger fittings. However, using a bushing instead of a coupling when it’s not suitable can cause more leaks and turbulence, negatively affecting system flow efficiency. Therefore, while bushings are versatile, they may not always be the best choice for maintaining optimal flow rates.

Reducing couplings are generally more durable due to their threaded connections, which provide a tighter seal. This greater resistance to pull-out ensures secure and leak-resistant connections, making them suitable for long-term applications in various environments.

Reducing bushings, especially those made from robust materials like polyurethane, offer superior environmental durability. They resist chemicals, UV light, and high temperatures, making them suitable for harsh environments where impact resistance is crucial. This makes bushings a preferred choice in settings where environmental factors play a significant role in the system’s longevity.

| Feature | Reducing Couplings | Reducing Bushings |

|---|---|---|

| Structure | One-piece, linear | Compact, fits within fittings |

| Installation Complexity | Simple, minimal tools | More complex, precise alignment needed |

| Cost | Generally higher initial cost | Lower initial cost but added labor |

| Application Flexibility | Best for straightforward connections | Ideal for confined or angled setups |

| Durability | More durable for secure connections | Superior environmental durability |

Reducing couplings and bushings each have their unique advantages. Reducing couplings are preferred for straightforward, linear connections where installation speed and simplicity are prioritized. Conversely, reducing bushings are optimal for complex, space-restricted configurations requiring size adaptations. The choice between the two should align with project requirements, spatial constraints, and applicable code regulations.

Reducing couplings are one-piece fittings that directly connect two pipes of different diameters. They simplify installation and minimize potential leak points, making them ideal for straightforward, in-line reductions where ease of installation and long-term reliability are crucial.

Reducing bushings fit within existing fittings, offering size reduction in a compact form. They are typically used with other fittings, providing flexibility in complex piping configurations. However, their installation requires precise alignment and additional fittings, which can increase both labor time and the potential for leaks.

When choosing between reducing couplings and bushings, consider the specific needs of your project. For straightforward installations where reliability and speed are crucial, reducing couplings are the better choice. Conversely, in complex or space-constrained environments, reducing bushings offer the necessary flexibility and initial cost savings, despite the higher labor and maintenance costs.

Below are answers to some frequently asked questions:

Reducing couplings and reducing bushings are both used to connect pipes of different sizes, but they have distinct differences in design, installation, and application.

Reducing couplings are one-piece fittings with sockets at both ends, designed to connect two pipes of different sizes directly in a straight line. They offer quick and straightforward installation, making them ideal for main lines or irrigation setups where speed and simplicity are crucial.

On the other hand, reducing bushings are shorter fittings with a single socket that fit inside a larger fitting like a tee, elbow, or union. They are used to connect smaller pipes to larger ones, often in branched or angled configurations. Bushings require additional fittings to complete the connection, offering more flexibility in complex setups.

Choose a reducing coupling for straightforward, in – line pipe connections when installation speed is a priority. It’s great for main water lines and irrigation setups, offering a secure and durable connection with less maintenance. However, it’s bulkier and can cause more flow turbulence.

Opt for a reducing bushing in tight spaces or complex piping configurations like branch lines. It’s more compact, cost – effective, and widely available. Its chamfered edges also improve flow by reducing turbulence. But installation is more complex, and it’s less secure than a reducing coupling.

Reducing couplings and reducing bushings both play a significant role in plumbing and piping systems, particularly when it comes to connecting pipes of different diameters. Their impact on flow rates differs due to their design and installation.

Reducing couplings offer a smooth, linear transition between pipes, which minimizes turbulence and pressure loss. This design helps maintain consistent flow rates, making them ideal for applications that require high flow efficiency. However, they still introduce some resistance, potentially decreasing flow rates by 23% to 54% depending on the specific design and application.

On the other hand, reducing bushings are more compact and typically used in confined spaces. Their abrupt transitions can cause minor flow restrictions, leading to increased turbulence and reduced flow efficiency compared to reducing couplings. However, some bushings with chamfered edges can improve flow characteristics slightly by reducing turbulence.

Space constraints play a significant role in choosing between reducing couplings and bushings. Reducing couplings, designed for straight-line connections between pipes of different diameters, are ideal for open areas where space is abundant, such as basements or external water lines. Their linear design requires more space and is less suited for confined or complex piping systems.

Conversely, bushings are compact fittings that reduce pipe diameter by fitting inside larger fittings. Their design, featuring internal and external threads, makes them highly suitable for tight spaces, such as under sinks or within machine frameworks. Bushings can be inserted into existing fittings like tees or elbows, allowing for size adjustments without adding extra length, making them more versatile in space-constrained environments.

In residential plumbing, reducing bushings often offer a better cost-benefit ratio. They are less expensive and easier to install as they don’t require threading the pipe into the fitting. However, reducing couplings provide a more secure and leak-resistant connection, which is crucial for maintaining system integrity and reducing maintenance needs. If a more durable and secure connection is necessary, despite the higher cost and installation challenges, reducing couplings might be the better choice. The decision depends on specific plumbing requirements such as system pressure, flow rate, and environmental conditions.

In industrial piping, the cost-benefit analysis between reducing couplings and reducing bushings hinges on several factors. Reducing couplings offer a more secure and durable connection due to their threaded design, making them suitable for high-security applications where resistance to pull-out forces is crucial. However, they can be more challenging to install and maintain, potentially leading to higher labor costs and the risk of leaks if not properly installed.

Reducing bushings, on the other hand, are easier to install and generally more cost-effective, particularly for applications where extreme security is not a priority. They rely on a socket connection, which can be less secure and potentially restrict flow more than couplings, but they offer significant savings in installation time and material costs.

Ultimately, if the priority in an industrial setting is long-term durability and security, reducing couplings provide a better cost-benefit despite higher upfront costs. For simpler applications where ease of installation and lower costs are more critical, reducing bushings may offer a more favorable cost-benefit ratio.