When it comes to choosing the right tool steel for your projects, understanding the nuances between different types can make all the difference. S7 and D2 tool steels are two popular choices, each boasting unique properties and advantages. But how do you determine which one is better suited for your needs? Is S7’s superior impact resistance the deciding factor, or does D2’s exceptional wear resistance tip the scales? In this comprehensive comparison, we’ll delve into the chemical compositions, mechanical properties, and specific applications of both S7 and D2 tool steels. By exploring their strengths and weaknesses, you’ll gain a clear understanding of which tool steel stands out for high-impact tasks and other critical uses. Ready to make an informed decision? Let’s dive into the details.

Tool steel is a category of carbon and alloy steels designed to be hard, resistant to wear, and dimensionally stable. These steels are primarily used for machining, cutting, and forming tools. Among the various types, S7 and D2 tool steels are notable for their unique properties and wide range of applications.

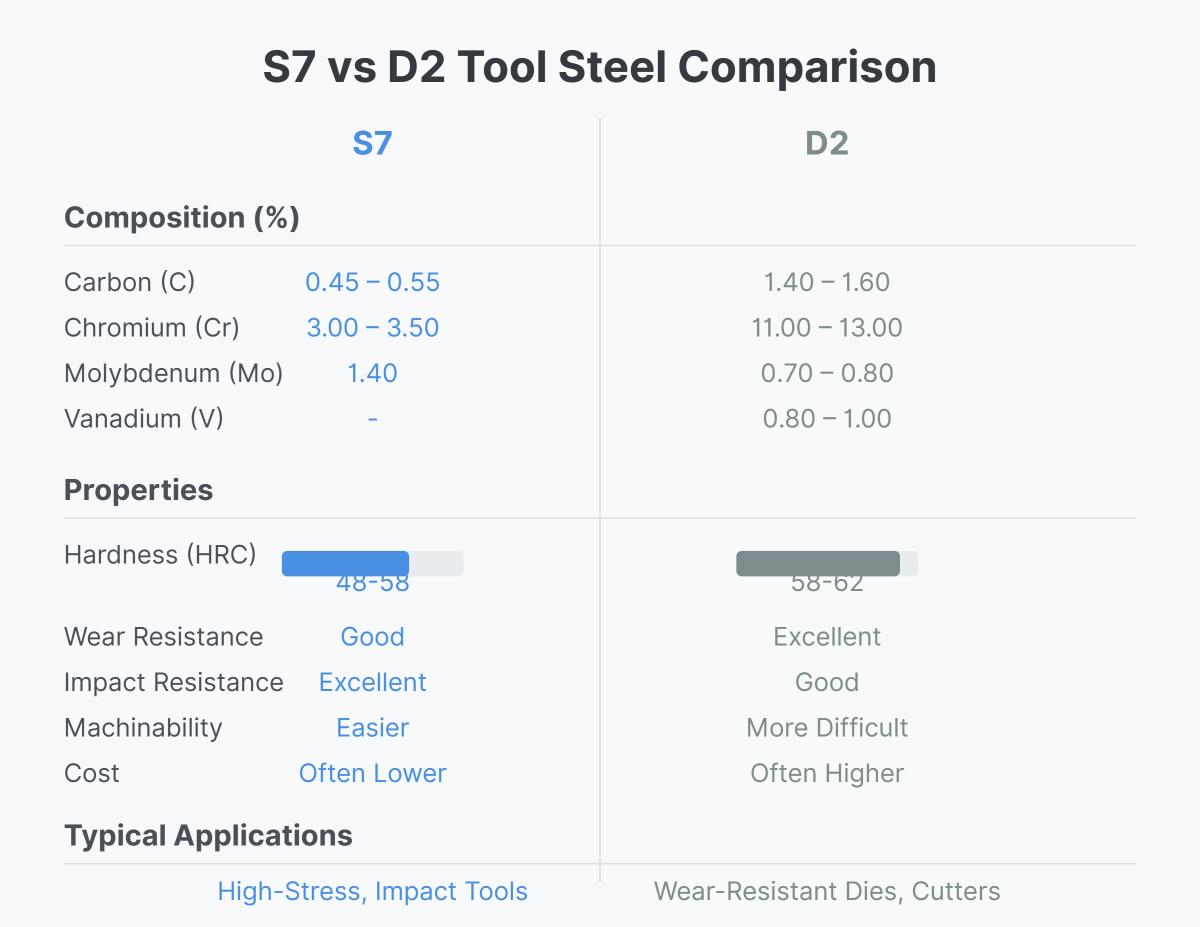

S7 tool steel is known for its excellent impact resistance and toughness. This is due to its relatively low carbon content of 0.45–0.55% and chromium content of 3.00–3.50%. The working hardness range of S7 tool steel is 48–58 HRC, with an ideal hardness of 54–56 HRC.

Applications:

D2 tool steel is distinguished by its high wear resistance and hardness. It contains a high carbon content of 1.50–1.60% and a chromium content of 11.00–13.00%. This composition allows D2 to achieve a hardness range of 58–62 HRC.

Applications:

Choosing between S7 and D2 tool steels depends on the specific needs of the application, such as the requirement for impact resistance, wear resistance, and the operating temperature.

S7 tool steel has a unique chemical makeup that contributes to its exceptional properties. It contains:

Compared to high-carbon tool steels like D2, which have higher carbon and chromium content, S7 is less brittle and offers a better balance of toughness and ductility.

S7 tool steel has several key physical properties:

S7 tool steel can achieve a hardness range of 48 – 58 HRC, with an optimal range of 54 – 56 HRC. This balance allows it to remain tough yet hard enough for various applications. For instance, while D2 tool steel can reach 58 – 62 HRC and is often used for cutting tools, S7 is better suited for impact tools due to its superior toughness.

S7 tool steel is renowned for its excellent toughness and impact resistance. This makes it ideal for tools subjected to heavy impacts, such as chisels and punches. Its chemical composition and heat-treatment process help it withstand high-stress conditions without fracturing, a critical attribute for high-impact applications.

The heat treatment of S7 tool steel is essential for achieving its optimal properties. The process typically involves:

Due to its lower carbon content, S7 is less sensitive to heat treatment compared to high-carbon tool steels, reducing the risk of cracking and distortion.

S7 tool steel is versatile and finds use in various high-impact and high-stress applications:

D2 tool steel is known for its high – carbon, high – chromium makeup, which gives it outstanding properties. Here’s its typical chemical composition:

D2 tool steel has a high hardness range, usually between 58 – 62 HRC. This high level of hardness is vital for applications where the steel needs to keep a sharp cutting edge and resist deformation under stress.

While D2 tool steel is extremely hard, it is also somewhat brittle. For example, in a high – impact application like a drop – forging die, where a heavy hammer repeatedly strikes the metal, D2 may crack. This brittleness means it is not as well – suited for such high – impact jobs compared to S7 tool steel, which is more ductile and can better absorb shock. Its high wear resistance, on the other hand, makes it ideal for applications where surface durability is crucial, such as in cutting tools and dies.

The heat treatment of D2 tool steel is crucial for achieving its best properties. The process can be broken down into the following steps:

Due to its high chromium content, D2 tool steel is relatively stable during heat treatment, reducing the risk of distortion and cracking.

D2 tool steel’s unique combination of hardness and wear resistance makes it suitable for a variety of applications:

Despite its excellent properties, D2 tool steel has some limitations:

S7 tool steel is characterized by its specific chemical makeup, which includes:

D2 tool steel has a distinct chemical composition that includes:

When choosing between S7 and D2 tool steels, consider the following factors:

Selecting the right tool steel depends on the specific needs of the application:

Shear blades face extreme stress during use, so they need to be made from materials that can handle high impact without breaking. S7 tool steel is highly preferred for this application because it is very tough and resistant to impact. The high shock resistance of S7 ensures the blades maintain their integrity and sharpness even under heavy loads, making them ideal for high-stress environments.

Stamping dies require high wear resistance and dimensional stability to produce consistent, precise parts over extended periods. D2 tool steel is ideal for stamping dies because it is very hard and resistant to wear, making it perfect for producing precise parts over long periods. Its ability to maintain sharp edges and resist wear makes it a cost-effective choice for long production runs, ensuring minimal downtime and high-quality output.

Plastic injection molds need materials that can withstand repeated stress and temperature variations. Both S7 and D2 tool steels are used in plastic injection molds, but their applications vary depending on specific needs:

Forging dies must endure significant mechanical stress and high temperatures. S7 tool steel is particularly effective in this role due to its combination of toughness, wear resistance, and thermal conductivity. These properties allow S7 to withstand the repeated impacts and heat cycles typical in forging processes, leading to longer tool life and reduced maintenance.

Cutting tools need materials that stay sharp and resist wear. D2 tool steel is perfect for this because it is very hard and resistant to wear. It is commonly used in applications such as:

Each of these real-world applications highlights the specific strengths of S7 and D2 tool steels, demonstrating their suitability for different industrial needs based on their unique properties.

S7 tool steel contains 0.45–0.55% carbon, 3.00–3.50% chromium, and 1.40% molybdenum. This composition provides excellent impact and shock resistance, making S7 versatile for various applications like shear blades and hot work tools.

D2 tool steel, with its higher carbon (1.50–1.60%) and chromium (11.50–12.00%) content, along with 0.80–1.00% vanadium, offers high wear resistance and hardness, making it ideal for long – lasting cutting tools.

Producing both S7 and D2 tool steels requires a lot of energy, especially during smelting and forging. However, D2’s higher carbon and chromium content means it may need more energy, leading to a greater environmental impact.

D2’s hardness makes it more challenging to machine and grind, potentially generating more waste. In contrast, S7 is easier to machine, which can reduce waste and conserve resources.

S7’s easier machinability allows for more efficient material use and less waste. On the other hand, D2’s high wear resistance means tools made from it last longer, which can offset its higher production impact.

The carbon footprint of D2 tool steel is generally higher due to the energy – intensive processes required for its production, including higher preheating and austenitizing temperatures. S7, which requires lower preheating temperatures, may have a slightly lower carbon footprint during production.

Both S7 and D2 tool steels are recyclable, which significantly reduces their environmental impact. Recycling these materials helps conserve resources, reduce energy consumption, and lower greenhouse gas emissions.

A life cycle assessment (LCA) is beneficial for understanding the full sustainability of these materials. An LCA considers all stages of a product’s life, from raw material extraction through manufacturing, use, and end – of – life recycling or disposal. This comprehensive view helps in making informed decisions about the environmental impacts of using S7 and D2 tool steels.

Choosing between S7 and D2 tool steels involves considering several important factors. Firstly, the nature of the application is paramount. High-impact applications demand a steel that can withstand sudden forces without cracking. S7 tool steel, with its excellent toughness and impact resistance, is ideal for high-impact scenarios, whereas D2 tool steel, with its high hardness and wear resistance, is better suited for continuous wear applications like cutting or stamping.

Machinability is another significant factor. S7 tool steel is more machinable than D2 due to its lower hardness and less brittle nature. This means that manufacturing processes involving S7 can be completed more efficiently, potentially reducing production time and costs. However, D2’s high hardness, while making it more challenging to machine, results in tools with a longer service life in wear-intensive applications.

The heat treatment process differs as well. S7 is air-quenched and needs lower temperatures, reducing the risk of distortion and cracking. D2, on the other hand, typically needs higher heat treatment temperatures and more careful control to achieve the desired properties, which can add complexity and cost to the manufacturing process.

For applications such as rivet sets, chisels, and punches that experience high levels of impact, S7 tool steel is the top choice. Its chemical composition and heat-treatment process endow it with the toughness needed to absorb shock without fracturing. This ensures that tools made from S7 can maintain their integrity and performance over time, even under extreme stress.

When wear resistance is the primary concern, D2 tool steel shines. Applications like cutting tools, stamping dies, and plastic molds benefit from D2’s high hardness and excellent wear resistance. The ability to maintain a sharp edge and resist deformation under stress makes D2 ideal for producing consistent, high-quality parts over long production runs.

When considering cost, the choice between S7 and D2 depends on specific needs. S7, while generally more expensive upfront due to its balanced properties and ease of machinability, can be cost-effective in high-impact applications where tool replacement frequency is reduced. D2, although more challenging to machine, offers long-term cost savings in wear-heavy applications due to its extended tool life.

In a high-volume cutting operation, such as paper cutting or woodworking, D2 tool steel is recommended. Its high hardness and wear resistance allow it to maintain a sharp cutting edge for an extended period, reducing the need for frequent blade replacements. This results in less downtime and increased productivity.

For precision die-casting applications, where dimensional stability and resistance to high-temperature and high-pressure conditions are crucial, S7 tool steel is the better option. Its high thermal conductivity and good dimensional stability under heat and stress ensure that the dies can produce accurate and consistent parts.

For cold-forming metals, D2 tool steel is preferred due to its ability to maintain a sharp edge and resist wear, making it ideal for cold-forming dies and tools. The low distortion during heat treatment of D2 also contributes to the production of precise and consistent parts.

Below are answers to some frequently asked questions:

S7 and D2 are both types of tool steel, used widely in manufacturing. Key differences lie in their composition, properties, and applications. D2 has higher carbon (1.40 – 1.60%) and chromium (11.00 – 13.00%) content than S7 (0.45 – 0.55% carbon, 3.00 – 3.50% chromium), leading to greater hardness (58-62 HRC vs 48-58 HRC) and wear resistance. S7 contains more molybdenum (1.40% vs 0.70 – 0.80% in D2), and D2 has vanadium (0.80 – 1.00%). S7 excels in impact and shock resistance, suitable for high-stress tools. D2 is better for wear-resistant applications. S7 is easier to machine and often less costly.

For high-impact applications, S7 Tool Steel is generally the better choice due to its exceptional impact and shock resistance. Its chemical composition, with lower carbon and chromium content, makes it less hard but significantly more resistant to sudden stresses compared to D2 Tool Steel. S7 achieves a working hardness range of 48 – 58 HRC, which is ideal for high-stress environments.

In contrast, D2 Tool Steel, with its higher carbon and chromium content, offers superior wear resistance and higher hardness (58 – 62 HRC), but it is more brittle and less capable of withstanding impact. This makes D2 more suitable for applications where wear resistance is critical, such as cold forming dies and slitting blades, rather than high-impact scenarios.

Thus, for applications like shear blades, swaging dies, and punches where high impact resistance is crucial, S7 Tool Steel is the preferred option.

Heat treatment significantly affects the properties of S7 and D2 tool steels. For S7 tool steel, annealing at 1500 – 1550°F (816 – 843°C) enhances machining properties. Austenitizing at 1750°F (955°C) followed by air or oil quenching, based on cross – section size, and tempering at 400 – 1000°F (204 – 538°C) achieves high impact resistance and toughness, making it suitable for high – stress and hot work applications.

D2 tool steel requires annealing at 1600 – 1650°F (871 – 899°C) for easier machining. Hardening involves preheating, austenitizing at 1800 – 1850°F (982 – 1010°C), and quenching in oil or air. Tempering at 150 – 200°C (302 – 392°F) optimizes its wear resistance but reduces brittleness.

S7 tool steel is commonly used in applications that require high impact resistance and toughness due to its moderate carbon content and significant amounts of chromium and molybdenum. Typical applications include automotive and aerospace tools such as wheel hub manufacturing tools, punching dies, and camshaft dies. It is also used in die casting dies for aluminum and zinc, mining tools like drill bits and rods, and construction tools such as rock crushing and concrete compaction tools.

D2 tool steel, on the other hand, is highly valued for its exceptional hardness and wear resistance, making it ideal for cutting tools that require a sharp, durable edge. Common applications include cutting and forming tools like punches, forming rolls, knives, and slitters. D2 is also used in stamping dies where high wear resistance is crucial and in thread rolling dies for precision tools requiring minimal distortion.

When comparing the costs of S7 and D2 tool steels, S7 is generally more affordable than D2. S7 tool steel typically ranges from $1,850 to $2,200 per ton, whereas D2 tends to be more expensive due to its higher carbon and chromium content, which enhances hardness and wear resistance. The specific price for D2 can vary significantly, from $115 to over $791 depending on the size and type of bar.

S7’s lower cost is partly due to its excellent impact resistance and machinability, making it a cost-effective choice for high-stress applications like shear blades and punches. D2, while more costly, offers superior wear resistance and longevity, justifying its price for applications requiring minimal distortion and high durability, such as cold work tooling and metal forming.

The environmental impacts of using S7 and D2 tool steels vary across different stages of their lifecycle, including production, usage, and disposal.

Production Phase: D2 tool steel has a higher carbon and chromium content compared to S7, which can make its production more energy-intensive and result in higher emissions. The extraction and processing of chromium are particularly impactful, potentially leading to increased CO2 emissions.

Usage Phase: D2 tool steel is known for its exceptional wear resistance and hardness, which often results in a longer lifespan and less frequent replacements. This can reduce waste and the environmental footprint associated with manufacturing new tools. On the other hand, S7 is easier to machine, which can lower energy consumption during the manufacturing process.

Disposal and Recycling Phase: Both S7 and D2 tool steels are recyclable. However, D2’s higher chromium content can complicate recycling processes due to contamination risks, making it less efficient to recover pure materials compared to S7.

In summary, while D2 tool steel may have higher environmental impacts during production and recycling due to its complex composition, its superior durability can lead to less frequent replacements and potentially lower overall environmental impact in long-term use.