In the realm of metallurgy, AISI 1075 carbon steel stands out for its unique blend of properties that make it invaluable in various industries. With a specific chemical composition, it boasts high tensile strength and excellent hardness, ideal for cutting tools and springs. Understanding how its composition influences these mechanical properties is crucial for manufacturers and metalworkers. Moreover, proper processing and heat treatment are key to unlocking its full potential. Have you ever wondered how AISI 1075 compares to other high – carbon steels in real – world applications? Dive in to find out.

AISI 1075 carbon steel is mainly composed of iron (Fe) and includes several key elements.

The chemical composition of AISI 1075 carbon steel directly influences its mechanical properties and suitability for various applications:

When comparing AISI 1075 to other carbon steels like AISI 1045, AISI 1095, and AISI 1060, the differences in carbon content and resulting properties become evident:

The following table provides a comparative overview of the chemical composition of AISI 1075 and other similar high-carbon steels:

| Element | AISI 1075 | AISI 1045 | AISI 1095 | AISI 1060 |

|---|---|---|---|---|

| Carbon (C) | 0.70% – 0.80% | 0.42% – 0.50% | 0.90% – 1.03% | 0.55% – 0.65% |

| Manganese (Mn) | 0.40% – 0.70% | 0.60% – 0.90% | 0.30% – 0.50% | 0.60% – 0.90% |

| Silicon (Si) | 0.15% – 0.30% | ≤ 0.40% | ≤ 0.40% | ≤ 0.40% |

| Sulfur (S) | ≤ 0.05% | ≤ 0.05% | ≤ 0.05% | ≤ 0.05% |

| Phosphorus (P) | ≤ 0.04% | ≤ 0.04% | ≤ 0.04% | ≤ 0.04% |

| Trace Elements | Present | Varies | Varies | Varies |

This comparative analysis highlights the key differences in chemical composition, helping to understand the unique properties and applications of each type of carbon steel.

AISI 1075 carbon steel is known for its high tensile strength, which typically ranges from 850 to 980 MPa. This strength enables the steel to withstand heavy stress and loads, making it ideal for demanding applications.

The yield strength of AISI 1075 falls between 340 and 510 MPa. Yield strength indicates the stress point where the material starts to deform permanently. This property is essential for applications where the material must maintain its shape and integrity under load.

The elastic modulus of AISI 1075 is approximately 190 to 210 GPa. This measurement reflects the steel’s stiffness and ability to resist deformation under load. A high elastic modulus indicates that the material will not easily bend or flex, which is beneficial for maintaining structural integrity in various applications.

AISI 1075 carbon steel, with a Rockwell C hardness of about 55 after heat treatment, is ideal for high-wear applications like cutting tools and springs. The Brinell hardness for AISI 1075 typically ranges from 180 to 220 HB in its hardened state, indicating its capability to resist indentation and wear.

With a Poisson’s ratio of 0.27 to 0.30, AISI 1075 measures how much the material expands perpendicular to the compression direction. Understanding Poisson’s ratio is important in applications involving dynamic or multi-axial loading conditions.

AISI 1075 exhibits an elongation range of 10% to 20%. Elongation measures the extent to which the material can stretch before breaking, reflecting its ductility. This balance between strength and ductility allows the steel to absorb impact and resist brittle fracture, making it suitable for dynamic and high-stress environments.

The impact strength of AISI 1075 is around 21.7 J at room temperature. This property indicates the material’s ability to absorb energy and withstand sudden forces without fracturing, which is crucial in harsh environments and applications involving dynamic loads.

AISI 1075 demonstrates significant fatigue resistance due to its high carbon content and resultant hardness. This makes it reliable for components such as springs, which are subjected to repetitive stress and need to maintain their mechanical integrity over many cycles.

AISI 1075 has a moderate machinability rating of approximately 50%. It can be machined with standard techniques, but care is needed to minimize tool wear and ensure precision. The steel’s formability is also notable, allowing it to be shaped using conventional methods. However, precise control during forming is necessary to prevent excessive hardening and brittleness.

Due to its impressive mechanical properties, AISI 1075 is utilized in various high-performance applications:

AISI 1075 carbon steel is highly regarded for its high carbon content and superior hardness, making it a top choice in various manufacturing and metalworking applications.

Its high hardness and wear resistance allow it to maintain sharp edges over extended periods, making it ideal for knives used in both culinary and industrial settings, as well as blades commonly utilized in saws and other cutting machinery. Precision cutting tools such as scissors benefit greatly from the steel’s properties, ensuring sharpness and longevity.

AISI 1075 is extensively used for springs due to its good elasticity and ability to withstand repeated stress, making it ideal for vehicle coil springs, spring clamps, and antenna springs. These components require consistent tension and durability, which the steel provides effectively.

The automotive industry uses AISI 1075 for parts that require high strength and wear resistance, such as engine valves and clutch discs, which must endure high temperatures and mechanical stress. This makes the steel particularly suitable for critical automotive components that demand both durability and reliability.

In industries like aerospace and construction, precision components made from AISI 1075 are crucial. The steel’s hardness and wear resistance make it suitable for precision ground bars used in applications demanding tight tolerances and high strength, as well as shafts critical in machinery and equipment.

AISI 1075 is also used in the manufacturing of various industrial equipment components. Rolls and plates made from this steel are employed in machinery that processes materials, requiring high strength and the ability to endure mechanical stress. High-pressure components, including valves and pumps, benefit from the steel’s ability to withstand significant pressure and wear.

The steel’s high carbon content provides the necessary hardness and strength, while its manganese content enhances hardenability and tensile strength, making it crucial for springs and automotive parts. The flexibility in heat treatment allows the steel to be tailored through processes like quenching and tempering to achieve specific hardness and toughness levels.

When compared to other high-carbon steels, AISI 1075 offers a balance of hardness and durability. Versus AISI 5160, which offers better toughness and ductility, AISI 1075 is harder and more durable, making it ideal for precision tools and high-wear applications. Compared to AISI 1095, which has higher carbon content resulting in greater hardness but increased brittleness, AISI 1075 strikes a balance between hardness and workability.

AISI 1075 can be challenging to machine due to its high carbon content. However, its good machinability allows for efficient processing using conventional techniques.

Welding AISI 1075 requires careful handling, including pre-heating and post-heating, to prevent cracking and ensure a strong, durable weld.

The steel can be hardened through quenching and tempering, achieving high hardness levels necessary for various applications. Proper heat treatment is crucial to optimize its mechanical properties for specific uses.

AISI 1075 carbon steel is processed using several key manufacturing techniques, including welding, forging, and heat treatment. Each of these processes plays a critical role in enhancing the material’s properties and making it suitable for various industrial applications.

AISI 1075 can be welded using techniques like shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and gas metal arc welding (GMAW). Due to its high carbon content, the steel is prone to cracking and requires careful handling.

To prevent cracking, pre-heat the steel to 260-315°C (500-600°F). This reduces thermal gradients and minimizes thermal stress. Post-heat at 649-788°C (1200-1450°F) to relieve residual stresses and ensure a strong, durable weld.

During welding, it is crucial to maintain a controlled heat input to avoid excessive hardening of the heat-affected zone (HAZ). Use low hydrogen electrodes to mitigate the risk of hydrogen-induced cracking. Conduct welding in a dry environment to minimize moisture absorption, which can contribute to weld defects.

Forging AISI 1075 typically occurs at 927-1204°C (1700-2200°F). This high-temperature range allows the steel to be shaped effectively, reducing the risk of cracks and defects. The forging process involves heating the steel to the appropriate temperature, then shaping it using hammers or presses. This refines the grain structure and improves strength and toughness.

After forging, perform annealing to relieve internal stresses and soften the material. Heat the steel to around 926°C (1700°F) and allow it to cool slowly in the furnace. This prepares the steel for subsequent machining and heat treatment processes.

Annealing involves heating the steel to 926°C (1700°F) and cooling it slowly in the furnace. This process softens the steel, making it easier to machine and improving its ductility. Annealing also helps to relieve internal stresses accumulated during forging or other mechanical processes.

The hardening process includes heating the steel to 899°C (1650°F) and then quenching it in oil. Quenching rapidly cools the steel, transforming its microstructure into martensite, which significantly increases hardness and strength.

Tempering follows hardening and involves reheating the quenched steel to 371-705°C (700-1300°F). The exact tempering temperature depends on the desired balance between hardness and toughness. Tempering reduces brittleness while maintaining hardness, making it suitable for high-stress applications.

Quenching and tempering are critical steps for achieving the desired mechanical properties in AISI 1075. Quenching creates a hard, brittle martensitic structure, while tempering adjusts this structure to balance hardness with toughness. The tempering temperature and time are carefully controlled to achieve specific property requirements.

Proper heat treatment significantly impacts the mechanical properties of AISI 1075. Hardening and tempering enhance hardness and wear resistance, crucial for cutting tools and springs. Annealing improves machinability and ductility, essential for components requiring precise shaping and forming.

AISI 1075 carbon steel complies with several ASTM standards, which ensure its quality and suitability for various industrial uses. Key standards include:

The chemical composition of AISI 1075, including carbon, manganese, silicon, sulfur, and phosphorus, is tightly controlled to ensure the steel’s desired mechanical properties and performance in specific applications.

AISI 1075 must meet standards for mechanical properties like tensile strength, yield strength, and hardness to ensure reliable performance.

AISI 1075 is recognized by various international standards, making it suitable for use worldwide. Its equivalent grades include:

These equivalent standards allow for the global interchangeability of AISI 1075, facilitating international trade and application.

Industries using AISI 1075 must comply with relevant standards to ensure performance and safety. Applications include:

Manufacturers and suppliers of AISI 1075 provide detailed documentation and certification to confirm compliance with the specified standards. These documents include:

By following these standards and specifications, AISI 1075 carbon steel ensures reliability, performance, and safety in various demanding applications.

Below are answers to some frequently asked questions:

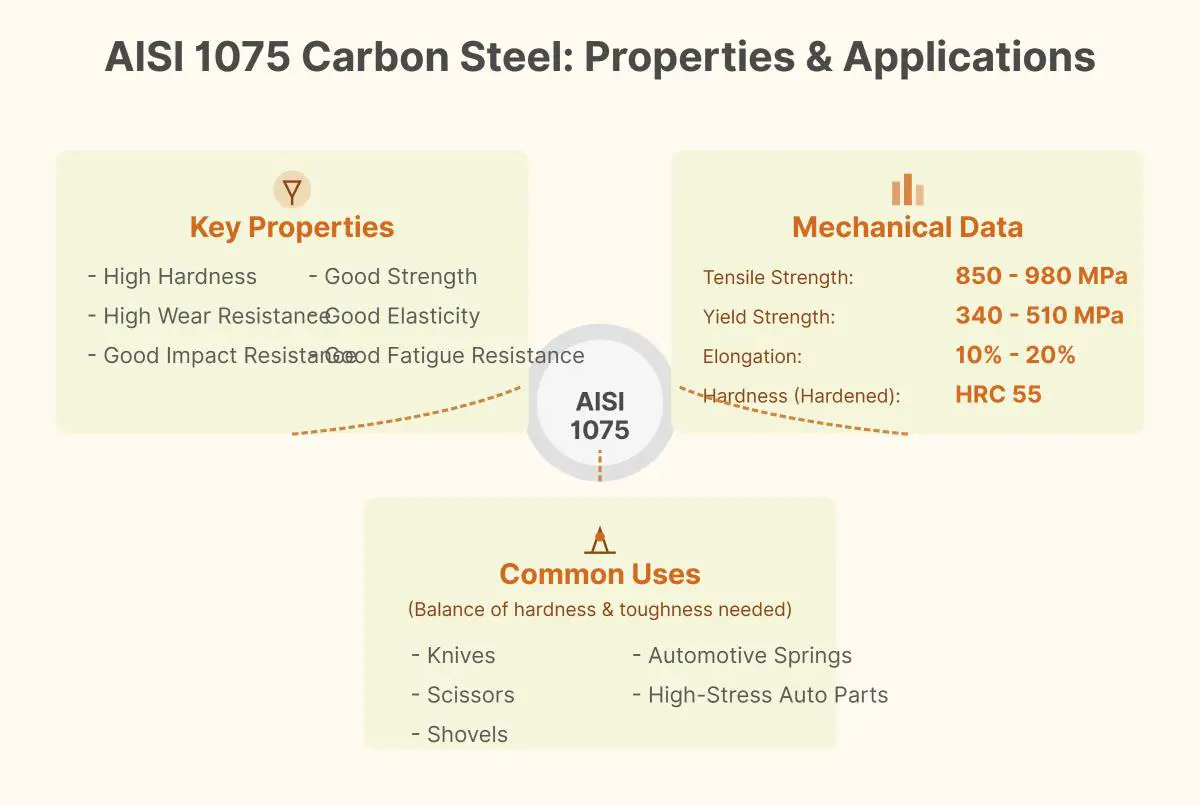

AISI 1075 carbon steel is known for several key properties that make it versatile in various applications. It has high hardness and wear resistance, making it suitable for cutting tools and springs. The steel also offers good strength, elasticity, fatigue resistance, and impact resistance, which are essential for automotive parts and high-stress applications. Its mechanical properties include a tensile strength of 850 – 980 MPa, yield strength of 340 – 510 MPa, and an elongation of 10% – 20%. Hardness can reach Rockwell C 55 when hardened. Common uses include knives, automotive springs, and other tools like scissors and shovels, where a balance of hardness and toughness is required.

AISI 1075 carbon steel is a high-carbon steel known for its excellent hardness and wear resistance. Processing and heat treatment are crucial to achieving the desired properties of this material.

Forging of AISI 1075 is typically performed at temperatures between 927°C and 1204°C, followed by annealing to relieve internal stresses. Welding is feasible using standard techniques, but pre-heating at 260-315°C and post-heating at 649-788°C are necessary to prevent cracking. Machining can be challenging due to the high carbon content, and forming is also difficult but can be managed with conventional methods.

Heat treatment processes for AISI 1075 include annealing, hardening, tempering, and normalizing. Annealing involves heating to 926°C and cooling slowly to soften the steel and reduce internal stresses. Hardening is achieved by heating to 899°C and quenching in oil, which increases hardness and strength. Tempering follows hardening, heating the steel to 371-705°C to balance hardness and toughness. Normalizing at 875°C helps refine the steel’s structure, especially after forging.

These processes are essential for optimizing the performance of AISI 1075 in applications such as cutting tools and springs, where high hardness and wear resistance are critical.

AISI 1075 carbon steel is particularly suitable for cutting tools and springs due to its high carbon content (0.70% to 0.80%) which provides excellent hardness and wear resistance, essential for maintaining sharp edges and durability in cutting applications. The presence of manganese (0.40% to 0.70%) enhances strength and hardenability, crucial for achieving the high tensile strength needed in springs. This composition allows AISI 1075 to undergo heat treatment processes effectively, achieving high hardness levels, typically up to Rockwell C 55, which is vital for both cutting tools and resilient springs. Additionally, the steel’s elasticity and ability to withstand dynamic loads make it ideal for springs that require consistent performance under stress. These combined properties ensure that AISI 1075 delivers the necessary performance characteristics for demanding applications in both cutting tools and springs.

AISI 1075 carbon steel is a high-carbon alloy that offers a balanced combination of hardness, strength, and toughness, making it suitable for various industrial applications. When compared to other high-carbon steels, such as AISI 1095 and 1080, AISI 1075 has distinct advantages and trade-offs.

AISI 1095 steel has a higher carbon content (approximately 0.95%), resulting in increased hardness and edge retention. This makes 1095 ideal for high-performance cutting tools and knives, but it is less tough than 1075, making it more brittle and less suitable for applications requiring impact resistance.

AISI 1080 steel, with a carbon content ranging from 0.75% to 0.88%, offers slightly greater hardness and wear resistance than 1075. However, this also leads to increased brittleness. Therefore, 1080 is favored for applications needing high sharpness without excessive impact, while 1075 provides better flexibility and toughness.

Compared to 5160 steel, which has a lower carbon content (0.56% to 0.64%) and includes about 1% chromium, AISI 1075 offers higher hardness and wear resistance. 5160 is preferred for applications requiring high ductility and toughness, such as automotive springs, due to its enhanced fatigue resistance.

AISI 1075 carbon steel is governed by various standards and specifications to ensure its quality and suitability for different applications. Primarily, it adheres to ASTM standards in the United States, which provide guidelines on its chemical composition, mechanical properties, and processing requirements. Additionally, AISI 1075 is equivalent to European standards such as C75S (1.1248) under DIN EN 10132-4, which specifically addresses its use in spring steel applications.

These standards specify the allowable ranges for elements like carbon (0.70-0.80%), manganese (0.40-0.70%), phosphorus (max 0.04%), sulfur (max 0.05%), and silicon (up to 0.10%), ensuring consistent material properties. Compliance with these standards is critical for achieving the desired performance in applications such as springs, cutting tools, and other high-strength components.