Imagine a metal that combines excellent machinability with high ductility and strength, making it a preferred choice for various industrial applications. SAE AISI 1117 carbon steel, also known as UNS G11170, is precisely that material. This versatile steel alloy boasts a unique chemical composition, featuring key elements like carbon, manganese, and sulfur, which contribute to its impressive mechanical properties. But what exactly are these properties, and how do they translate into practical benefits for industries ranging from automotive to general engineering? In this article, we’ll delve into the intricate details of SAE AISI 1117’s composition, uncover its mechanical performance characteristics, and explore its widespread applications. By the end, you’ll have a comprehensive understanding of why SAE AISI 1117 stands out among carbon steels and how it can enhance your manufacturing processes. Ready to uncover the secrets behind this remarkable alloy? Let’s dive in!

SAE AISI 1117 is a type of carbon steel classified by the Society of Automotive Engineers (SAE) and the American Iron and Steel Institute (AISI). Also known as UNS G11170, this resulfurized carbon steel has added sulfur to enhance machinability. The steel is primarily used for wrought products, including bars, forgings, and tubing, offering improved machinability and hardenability due to its unique chemical composition.

The Unified Numbering System (UNS) provides a systematic method for identifying metals and alloys. UNS G11170 corresponds to SAE AISI 1117, ensuring uniformity across different standards and specifications. This designation helps maintain consistency in material properties and quality, facilitating ease of reference and procurement for engineers and manufacturers globally.

Standard classifications by SAE, AISI, and UNS are essential in the metal industry for several reasons:

SAE AISI 1117 conforms to a range of U.S. military and industrial specifications, reflecting its wide applicability. Some key standards include:

These specifications govern the chemical composition, mechanical properties, and manufacturing processes, ensuring that SAE AISI 1117 meets stringent requirements for various applications.

SAE AISI 1117 provides several benefits thanks to its unique formulation and standard classification:

By adhering to established standards and classifications, SAE AISI 1117 ensures reliability, quality, and performance across its various applications.

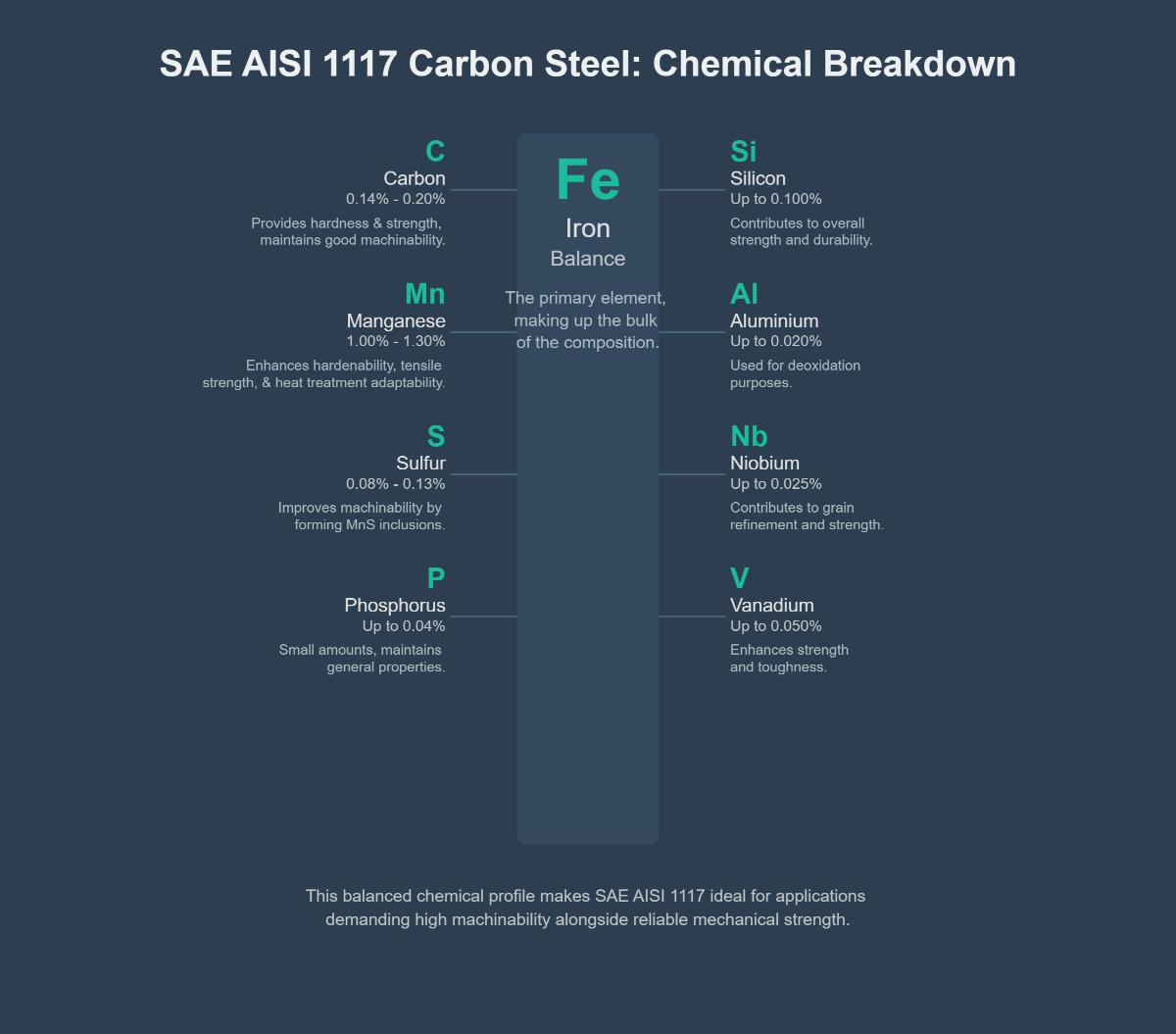

SAE AISI 1117 carbon steel is designed with a specific chemical composition to improve machinability and hardenability, while also maintaining strong mechanical properties. Its main components are iron, carbon, manganese, sulfur, phosphorus, with small amounts of silicon, aluminum, niobium, and vanadium.

Carbon, present in the range of 0.14–0.20%, is the principal hardening element in SAE 1117. This relatively low carbon content provides moderate tensile strength and maintains reasonable ductility and machinability. The carbon content allows the steel to be heat-treated to improve hardness, but without the brittleness associated with higher carbon steels.

Manganese (1.00–1.30%) boosts the steel’s ability to harden uniformly during heat treatment. It also enhances tensile strength and wear resistance, ensuring better mechanical performance and toughness, which counteracts the brittle effects of sulfur.

Sulfur (0.08–0.13%) enhances machinability by forming manganese sulfides that break chips during cutting. This significantly improves the efficiency of machining processes, although excessive sulfur can reduce impact toughness and ductility.

Phosphorus is kept very low, typically ≤ 0.040%, to avoid brittleness. While trace amounts of phosphorus can increase strength, excessive phosphorus can embrittle the steel. Therefore, it is tightly limited to maintain toughness and ductility.

These elements are present in trace amounts and primarily act as deoxidizers and grain refiners. Silicon (≤ 0.10%) slightly improves strength and hardness. Aluminum (≤ 0.020%) controls grain size and improves overall steel cleanliness. Niobium (≤ 0.025%) and vanadium (≤ 0.050%) contribute to grain refinement, improving strength and toughness without sacrificing ductility.

The balanced chemical composition of SAE AISI 1117 results in a steel that offers good machinability, moderate strength, and toughness suitable for various engineering applications.

The low carbon content provides a good balance between strength and ductility. It enables the steel to be heat-treated to achieve higher hardness levels, which is beneficial for applications requiring wear resistance.

Manganese improves hardenability, allowing the steel to achieve uniform mechanical properties through heat treatment. It also enhances tensile strength and wear resistance, making SAE 1117 suitable for parts that require moderate strength and good wear resistance.

Controlled sulfur content significantly improves machinability, making SAE 1117 ideal for manufacturing components that require extensive machining. The formation of manganese sulfides ensures efficient cutting and reduces tool wear.

Keeping phosphorus content low helps maintain toughness and prevents brittleness. Trace elements like niobium and vanadium refine grain size, improving mechanical properties without compromising workability. Silicon and aluminum further enhance strength and cleanliness.

The chemical makeup of SAE 1117 results in desirable mechanical properties, such as:

These properties make SAE 1117 versatile for diverse manufacturing processes, allowing it to be cold worked or heat treated to achieve desired strengths and hardness levels.

SAE AISI 1117 carbon steel is known for its balanced mechanical properties, making it suitable for a variety of engineering applications. These properties include tensile strength, yield strength, elongation, hardness, and impact resistance.

The tensile strength of SAE AISI 1117 carbon steel usually ranges from 430 MPa to 540 MPa, influenced by heat treatment and processing. This moderate strength is suitable for many engineering applications requiring durability and reliability.

Yield strength is the stress at which a material begins to deform plastically. Beyond this point, the material will deform permanently and will not return to its original shape. SAE AISI 1117 has a yield strength ranging from 230 MPa to 460 MPa. This range indicates that the steel can endure significant stress before undergoing permanent deformation, which is critical for structural and load-bearing applications.

Elongation, expressed as the percentage increase in length before breaking, measures the ductility of a material. For SAE AISI 1117, the elongation at break typically falls between 15% and 32.8%. This high elongation percentage indicates good ductility, meaning the material can absorb significant energy and deform plastically before fracturing, which is beneficial for applications where flexibility and toughness are essential.

Hardness is a measure of a material’s resistance to deformation, typically assessed using the Brinell hardness test for SAE AISI 1117. The Brinell hardness (HB) of this steel ranges from 121 to 190 HB, with cold-drawn conditions reaching up to 190 HB. This hardness level is adequate for applications needing wear resistance and surface durability.

Impact resistance, often evaluated using the Izod impact test, measures a material’s ability to withstand sudden, shock loading. SAE AISI 1117 exhibits an impact strength of approximately 93.6 J in the annealed condition, indicating good toughness and the ability to resist shock loads without fracturing.

One of the standout features of SAE AISI 1117 carbon steel is its excellent machinability. The addition of sulfur significantly enhances its machinability by forming manganese sulfides, which act as chip breakers during machining. This results in smoother cutting, reduced tool wear, and the ability to achieve high-speed and complex machining operations efficiently. Compared to similar low-carbon steels like AISI 1018, SAE 1117 offers superior machinability, making it ideal for precision-machined components.

Hardenability refers to the ability of steel to harden deeply and uniformly during heat treatment. SAE AISI 1117 responds well to carburization processes, which involve introducing carbon into the surface layer to increase hardness. This ability enables the creation of a hard, wear-resistant surface with a tough core, making the steel ideal for parts such as gears, camshafts, and king pins, which need both surface hardness and core toughness.

SAE AISI 1117 carbon steel’s performance characteristics are influenced by its mechanical properties and composition:

SAE AISI 1117’s mechanical properties and performance characteristics make it a versatile and reliable choice for a wide range of engineering and manufacturing applications.

SAE AISI 1117 and AISI 1018 are low-carbon steels ideal for machining. Their slight differences in chemical composition affect their properties and performance.

Both SAE AISI 1117 and AISI 1018 have similar carbon content, ranging from 0.14% to 0.20%. This low carbon content provides moderate tensile strength and maintains ductility, essential for machining and forming processes.

The higher manganese content in SAE 1117 (1.00–1.30%) compared to AISI 1018 (0.60–0.90%) improves its hardenability and tensile strength, making it better suited for heat treatments like carburization and case hardening.

Higher sulfur content in SAE 1117 (0.08–0.13%) enhances machinability by forming manganese sulfide inclusions, which act as lubricants during machining, leading to better tool life and surface finish. AISI 1018, with sulfur content up to 0.04%, does not offer the same level of machinability.

Both steels maintain similar phosphorus levels (up to 0.04%), which is controlled to prevent brittleness while slightly enhancing strength.

SAE AISI 1117 generally exhibits higher tensile and yield strengths due to its higher manganese content, making it more suitable for applications requiring greater mechanical performance. The enhanced sulfur content in SAE 1117 also contributes to superior machinability, making it advantageous for precision machining, reducing tool wear, and improving production rates. Additionally, SAE 1117’s higher hardenability allows it to respond better to carburizing and case hardening processes, resulting in a hard, wear-resistant surface with a tough core. AISI 1018, with lower manganese and sulfur content, offers moderate strength and toughness, making it ideal for parts that do not require extensive heat treatment or complex machining operations.

SAE AISI 1117 is commonly used in automotive components, valve bodies, pump shafts, and general engineering parts due to its superior machinability, strength, and case hardening ability.

AISI 1018 is ideal for structural components and general-purpose parts requiring moderate strength and toughness.

SAE AISI 1117 carbon steel is versatile and well-suited for various manufacturing processes, including forging, hot-rolling, and cold-finishing. Each process offers specific advantages depending on the desired final product and application.

Forging shapes the steel by applying compressive forces, often through hammering or pressing. This process enhances the strength and durability of the steel by refining its grain structure.

Hot-rolling involves heating the steel above its recrystallization temperature and then rolling it into the desired shape. This process is widely used for producing large sections and complex profiles.

Cold-finishing methods, like cold drawing or rolling, shape the steel at room temperature. These processes enhance the surface finish and dimensional accuracy of the final product.

SAE AISI 1117 can be manufactured into various product forms, each suited for different applications:

SAE AISI 1117 carbon steel is widely used in various industries because it is easy to machine and has good mechanical properties. Its balanced composition makes it suitable for several high-demand applications across different sectors.

In the automotive sector, SAE AISI 1117 is commonly used for precision-machined components with high surface finish quality, such as gears, shafts, and threaded fasteners. The steel’s hardenability and strength make it ideal for gears, which demand a combination of surface hardness and core toughness. Both drive shafts and steering shafts benefit from the material’s machinability and mechanical properties. Additionally, its machinability allows for the efficient production of studs and bolts with precise dimensions.

SAE AISI 1117 is often chosen for valve bodies and stems because it can be machined precisely and meet tight tolerances. This ensures that the valves operate reliably under different pressures and temperatures.

Its ease of machining allows for the production of complex, precise parts essential for efficient pump operation in hydraulic and fluid systems. Components such as shafts and impellers benefit from this material’s properties, facilitating the manufacture of intricate shapes and precise parts.

Beyond specific industries, SAE AISI 1117 is a go-to material for general engineering applications. This includes the production of machine parts that require extensive machining and precise tolerances. The steel’s properties make it suitable for forging into various shapes and sizes, enhancing its versatility.

One of the primary benefits of SAE AISI 1117 is its enhanced machinability, which significantly reduces manufacturing time and tool wear. The presence of sulfur forms manganese sulfide inclusions that act as lubricants during cutting, facilitating smoother machining processes.

SAE AISI 1117 can undergo carburization, which allows for a hard, wear-resistant surface while maintaining a tough core. This makes the steel ideal for components that need both surface durability and internal strength.

This steel can be forged, hot-rolled, and cold-finished, making it highly versatile. This adaptability ensures that SAE AISI 1117 can meet diverse application requirements across multiple industries.

The efficient machinability and reduced tool wear translate to lower production costs. This cost-effectiveness, combined with the material’s reliable performance, makes SAE AISI 1117 a preferred choice for many manufacturers.

Adherence to established standards and classifications ensures that SAE AISI 1117 maintains consistent quality across different batches and suppliers. This reliability is crucial for industries where material performance directly impacts the safety and functionality of the final products.

SAE AISI 1117 carbon steel’s combination of machinability, hardenability, and versatility makes it a valuable material for a wide range of industrial applications, ensuring both performance and cost-efficiency.

Annealing is a vital heat treatment process for SAE 1117 carbon steel that helps relieve internal stresses, improve ductility, and enhance machinability.

Heat the steel to a temperature range of 850–870°C and then cool it slowly, typically within a furnace.

Normalizing is another important heat treatment for SAE 1117, refining the grain structure and improving overall mechanical properties.

Heat the steel above its critical temperature, approximately 900°C, and then allow it to cool in air.

Though SAE 1117 isn’t typically hardened for high-strength uses due to its sulfur content, some cases may still require hardening and tempering.

Heat the steel to the austenitizing temperature of approximately 850°C, followed by rapid quenching in water or oil.

Reheat the quenched steel at 140–180°C to reduce brittleness and relieve internal stresses.

The machinability of SAE 1117 is one of its standout features, primarily due to the sulfur content which promotes chip breakage.

Forming operations benefit from the steel’s ductility, especially when it has been annealed beforehand to reduce the risk of cracking.

Below are answers to some frequently asked questions:

SAE AISI 1117 carbon steel has a well-defined chemical composition that enhances its machinability, strength, and performance. The key elements and their typical ranges are as follows:

This specific composition makes SAE AISI 1117 suitable for applications requiring high machinability and reliable mechanical performance.

SAE AISI 1117 carbon steel is known for its excellent machinability and favorable mechanical properties. The key mechanical properties of SAE AISI 1117 carbon steel include:

These properties make SAE AISI 1117 carbon steel suitable for applications such as automatic screw machine parts, gears, shafts, studs, pinions, and various carburized parts like king pins and camshafts.

SAE AISI 1117 carbon steel is known for its excellent machinability and good mechanical properties, making it suitable for a range of applications. In the automotive industry, it is commonly used for manufacturing shafts, gears, and steering components due to its higher tensile strength and ability to undergo deep case hardening, which is essential for parts requiring precision and durability. Additionally, its machinability makes it ideal for fasteners and studs that need close tolerances and smooth finishes.

In general engineering applications, SAE AISI 1117 is utilized in the production of valves and pump components that demand good machinability and mechanical performance under stress. It is also suitable for carburized parts, such as gears, where surface hardness and a tough core are necessary for wear resistance.

Manufactured in various forms like bars, wire rods, plates, strips, sheets, and tubing, SAE AISI 1117 supports diverse production methods including hot-rolling, cold-finishing, and forging. This versatility allows it to meet a wide range of industrial requirements. However, its high sulfur content, while enhancing machinability, reduces weldability, making it less suitable for welded constructions.

SAE AISI 1117 carbon steel primarily differs from AISI 1018 in its composition and resulting properties. SAE AISI 1117 has higher manganese content (1.00–1.30%) and is resulphurized, containing elevated sulfur levels (0.08–0.13%) to enhance machinability. These inclusions act as lubricants during cutting, making 1117 much easier to machine compared to 1018, which has lower manganese (0.60–0.90%) and sulfur levels.

Mechanically, 1117 exhibits better hardenability and tensile strength due to its higher manganese content, making it suitable for components that require carburization and case hardening. In contrast, AISI 1018 is better suited for general applications requiring good weldability and moderate strength, as it is not specifically designed for enhanced machinability or case hardening.

SAE AISI 1117 carbon steel is highly adaptable to several manufacturing processes due to its excellent machinability and suitability for carburizing. Key processes include:

These manufacturing processes make SAE AISI 1117 a versatile material for various industrial applications, especially where machinability and carburizing are crucial.

When processing SAE AISI 1117 carbon steel, several techniques and treatments can optimize its properties for specific applications. Firstly, heat treatment is crucial: annealing the steel by heating it and then cooling slowly can relieve internal stresses and increase ductility, making the material easier to machine and form. Normalizing involves heating the steel above its critical temperature (approximately 900°C) and cooling it in air to refine the grain structure, enhancing toughness and overall mechanical properties.

Cold drawing is another effective method, reducing the steel’s diameter to improve its strength, hardness, and surface finish, which is ideal for producing precise components. Due to its high sulfur content, SAE AISI 1117 exhibits excellent machinability, making it suitable for high-speed cutting and intricate part production. Case hardening techniques such as carburizing and nitriding can be used to increase surface hardness while maintaining core toughness, essential for parts subjected to high wear.

These processing tips ensure that SAE AISI 1117 carbon steel achieves the desired mechanical properties and performance for specialized industrial applications.