Imagine a steel that combines exceptional strength, toughness, and versatility, becoming a cornerstone in industries ranging from automotive to aerospace. This steel is none other than SAE AISI 4140. Known for its remarkable mechanical properties, such as high tensile strength and impressive hardness, SAE AISI 4140 stands out among its peers. But what truly sets it apart is its response to heat treatment, which can tailor its properties to meet specific requirements. In this comprehensive guide, we’ll delve deep into the chemical composition and mechanical attributes of SAE AISI 4140, explore various heat treatment techniques, and uncover its widespread applications. Whether you’re a seasoned engineer or a curious enthusiast, this article will equip you with essential knowledge and practical insights about one of the most reliable steels in modern engineering. Ready to unlock the full potential of SAE AISI 4140 steel? Let’s dive in.

SAE AISI 4140 steel, often referred to as “chromoly” steel, is a low-alloy steel with chromium and molybdenum as its primary alloying elements. This combination gives the steel exceptional mechanical properties, making it highly suitable for a wide range of industrial applications.

These properties are critical for components that must endure high stress and impact, making 4140 steel an excellent choice for heavy-duty parts in the automotive and aerospace industries.

SAE AISI 4140 steel also exhibits superior wear resistance. This characteristic extends the lifespan of parts, reducing the need for frequent replacements and maintenance, and enhancing the overall efficiency and cost-effectiveness of machinery and equipment.

The adaptability of SAE AISI 4140 steel to various heat treatment processes is another significant advantage, allowing it to be hardened and tempered to achieve a wide range of mechanical properties. This flexibility allows engineers to tailor the material to specific requirements, optimizing performance for different applications.

The key alloying elements in SAE AISI 4140 steel are:

The specific proportions of these elements (e.g., 0.38-0.43% carbon, 0.80-1.10% chromium, 0.15-0.25% molybdenum) result in a balanced combination of strength, toughness, and wear resistance. This balance is crucial for components that must perform reliably under varying stress conditions.

In the automotive industry, SAE AISI 4140 steel is used for high-stress components such as crankshafts, gears, and axles. Its ability to withstand significant forces without deforming makes it ideal for these critical parts.

The aerospace sector relies on SAE AISI 4140 steel for structural components like landing gear and engine parts. The material’s high strength-to-weight ratio and excellent fatigue resistance are vital for ensuring the safety and performance of aircraft.

In the oil and gas industry, SAE AISI 4140 steel is used for drill collars, tool joints, and other equipment that must endure harsh environments and high pressures. Its durability and resistance to wear and corrosion are essential for maintaining operational integrity.

The construction and defense sectors also benefit from the properties of SAE AISI 4140 steel. It is used in the manufacturing of heavy machinery parts, armor plating, and firearm components, where strength and reliability are paramount.

The chemical composition of SAE AISI 4140 steel is crucial as it determines the steel’s properties and suitability for various applications. The primary alloying elements are:

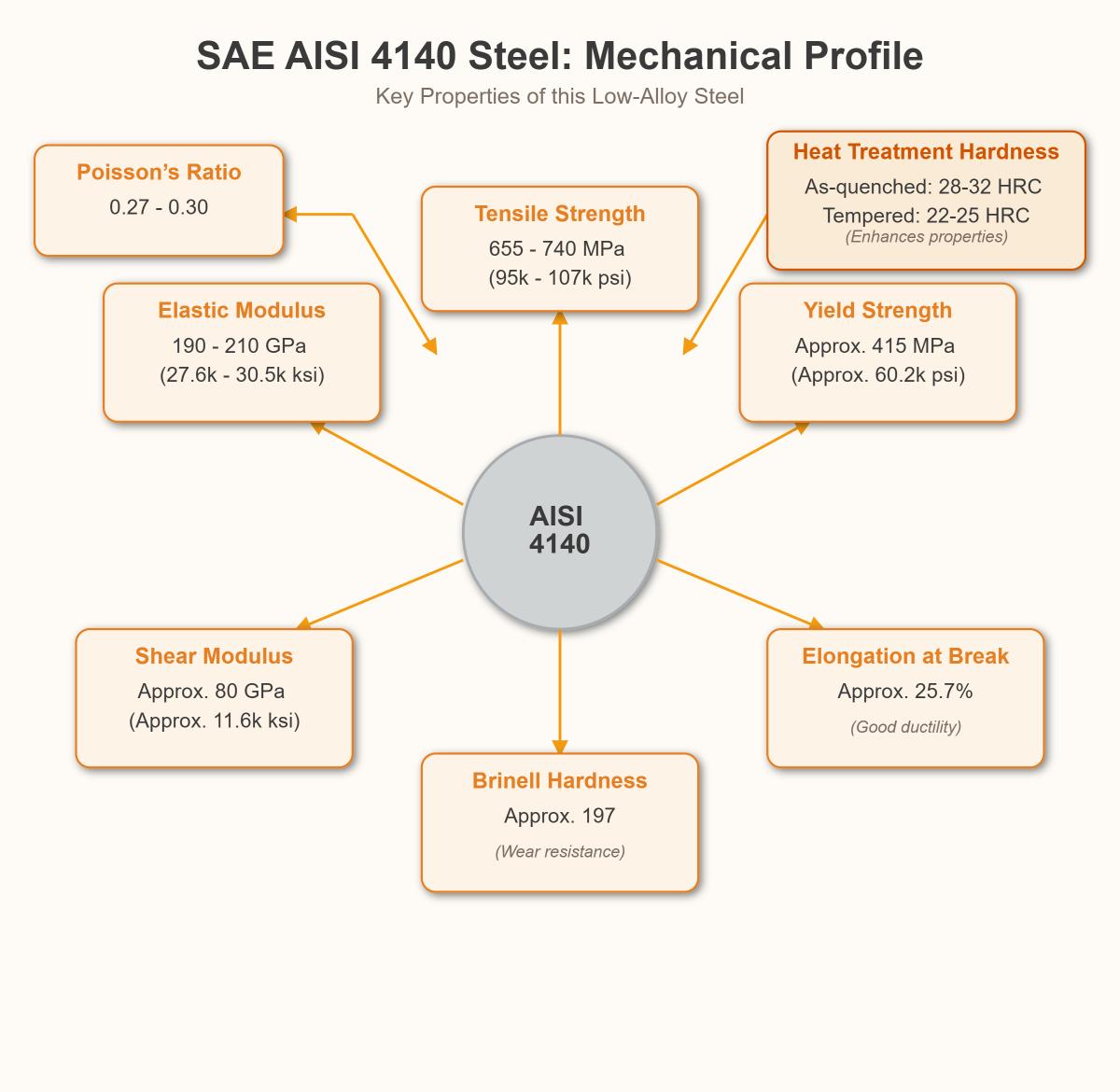

SAE AISI 4140 steel exhibits a combination of mechanical properties that make it versatile and valuable in engineering applications. These properties include:

Tensile strength measures the maximum stress SAE AISI 4140 steel can withstand before breaking, typically ranging between 655 – 740 MPa (95,000 to 107,000 psi).

Yield strength is the stress level at which SAE AISI 4140 steel begins to deform plastically, with an approximate value of 415 MPa (60,200 psi). This is important for applications where the material must maintain its shape under high stress.

The hardness of SAE AISI 4140 steel is an indication of its resistance to deformation and wear. The Brinell hardness of this steel is approximately 197. This level of hardness makes it suitable for components that are subject to wear and tear, such as gears and shafts.

The elastic modulus of SAE AISI 4140 steel ranges between 190 to 210 GPa (27,557 to 30,458 ksi), the shear modulus is about 80 GPa (11,600 ksi), and the bulk modulus is approximately 140 GPa (20,300 ksi), all of which indicate the material’s resistance to deformation.

When comparing SAE AISI 4140 steel with other similar steels, its balance of strength, toughness, and hardenability stands out. For example:

Heat treatment is a critical process for SAE AISI 4140 steel, capable of significantly altering its mechanical properties to suit various applications. By precisely controlling heating and cooling rates, the steel’s microstructure can be manipulated, leading to improvements in strength, hardness, toughness, and ductility.

The initial step in quenching is austenitizing, where the steel is heated to a temperature range of 1550–1650°F. At this temperature, a uniform austenitic microstructure forms, which is essential for subsequent hardness development. A homogeneous austenitic phase ensures consistent properties throughout the steel.

After austenitizing, the steel is rapidly cooled, typically by immersing it in a quenching medium such as oil or water. Oil quenching is often preferred for SAE AISI 4140 steel as it offers a more controlled cooling rate than water. This controlled cooling reduces the risk of cracking and warping that can occur with overly rapid cooling.

After quenching, tempering is carried out to relieve internal stresses and adjust the hardness and toughness of the steel. The steel is heated to a temperature between 300–1200°F. Lower tempering temperatures result in higher hardness and tensile strength but lower ductility. Conversely, higher tempering temperatures reduce hardness and strength while increasing ductility and toughness.

Annealing involves heating the steel to a temperature range of 1450–1650°F and then cooling it slowly. This process relieves internal stresses from manufacturing, like forging or machining, reduces the steel’s hardness, and increases its ductility, making it more machinable. The slow cooling rate allows the steel’s microstructure to transform into a more stable and uniform state.

After annealing, normalizing is another important heat treatment process. The steel is heated to 1600–1700°F and then air – cooled. This process refines the grain structure of the steel, improving its mechanical properties. A finer grain structure generally leads to higher strength, better toughness, and improved fatigue resistance.

Forging and hot working of SAE AISI 4140 steel can be performed at temperatures between 1550–2200°F. At these elevated temperatures, the steel becomes more malleable, allowing it to be easily shaped into various forms. This process also helps to align the grain structure of the steel, enhancing its mechanical properties.

Heat treatment can significantly increase the strength of SAE AISI 4140 steel. Quenching followed by low – temperature tempering can result in high tensile and yield strengths, making the steel suitable for applications requiring high – stress resistance.

The hardness of the steel is directly affected by heat treatment. Quenching generally increases hardness, while tempering can be used to adjust the hardness to the desired level. Higher tempering temperatures lead to lower hardness values.

Annealing and high – temperature tempering increase the ductility of the steel. By reducing internal stresses and altering the microstructure, these heat treatment processes allow the steel to deform more easily without fracturing, which is important for applications where the material needs to be formed or shaped.

SAE AISI 4140 steel is popular in the automotive industry because of its strength and ability to resist fatigue. This steel is particularly suited for components that endure significant stress and wear, including:

The aerospace industry relies on SAE AISI 4140 steel for critical components due to its excellent strength-to-weight ratio and high fatigue resistance. Key applications include:

In the oil and gas industry, SAE AISI 4140 steel is utilized for equipment that operates in harsh environments and under high pressures. Key applications include:

SAE AISI 4140 steel is also prominent in the construction and mining industries, where equipment must endure heavy loads and abrasive conditions. Applications include:

The defense industry leverages the properties of SAE AISI 4140 steel for various applications requiring high strength and durability. Examples include:

In the manufacturing of machine parts, SAE AISI 4140 steel is used for components that require high hardness and resistance to stress. Typical applications include:

SAE AISI 4140 steel’s versatile properties make it indispensable across numerous industries, ensuring reliable performance in applications where strength, toughness, and wear resistance are paramount.

Selecting the appropriate material for a specific application involves evaluating several criteria to ensure the material meets the required performance standards. For SAE AISI 4140 steel, these criteria include mechanical properties, heat treatment adaptability, cost, availability, and compatibility with manufacturing processes.

SAE AISI 4140 steel is known for its excellent mechanical properties, such as high tensile strength, yield strength, and hardness. These properties make it ideal for high-stress applications needing durability and resistance to wear and deformation. When selecting this steel, it’s essential to consider:

These properties ensure that components made from SAE AISI 4140 steel can perform reliably under demanding conditions.

One of the significant advantages of SAE AISI 4140 steel is its adaptability to various heat treatment processes, such as quenching, tempering, and annealing. Quenching and tempering enhance hardness and strength, annealing improves ductility and machinability, and normalizing refines the grain structure and improves toughness. This adaptability allows for tailoring the mechanical properties to meet specific requirements.

The cost and availability of materials are crucial factors in material selection. SAE AISI 4140 steel is widely available and cost-effective, making it a practical choice for large-scale manufacturing and engineering projects. Factors to consider include:

The widespread availability of SAE AISI 4140 steel ensures that it can be sourced efficiently for various applications.

SAE AISI 4140 steel’s compatibility with common manufacturing processes, such as machining, welding, and forging, is another critical consideration. This compatibility ensures that the material can be processed efficiently and to the required specifications. Key points to consider are:

When selecting SAE AISI 4140 steel, it’s essential to compare it with alternative materials to ensure it is the best fit for the application. Alternatives may include other alloy steels, carbon steels, or even non-ferrous materials. Consider the following comparisons:

Several factors influence the choice of material for a specific application. These factors include:

Below are answers to some frequently asked questions:

SAE AISI 4140 steel is a low-alloy steel with notable mechanical properties. Its tensile strength ranges from 655 MPa to 740 MPa (95,000 psi to 107,000 psi), and yield strength is about 415 MPa (60,200 psi). It has an elongation at break of around 25.7%, indicating good ductility. The Brinell hardness is approximately 197, providing wear resistance. The shear modulus is about 80 GPa (11,600 ksi), and elastic modulus ranges from 190 GPa to 210 GPa (27,557 ksi to 30,458 ksi). Poisson’s ratio is between 0.27 and 0.30. Heat treatment can further enhance these properties, with as-quenched hardness from 28 – 32 HRC and tempered hardness from 22 – 25 HRC.

SAE AISI 4140 steel, a chromium-molybdenum alloy steel, is widely used across various industries due to its exceptional strength, toughness, and wear resistance. In the automotive industry, it is commonly used for gears, shafts, crankshafts, connecting rods, and high-performance engine components. In aerospace, it is utilized for structural components like landing gear and turbine shafts, as well as engine parts such as piston rods and crankshafts. The oil and gas industry employs this steel in drilling equipment, including drill collars and stabilizers, due to its toughness and ability to withstand harsh environments. Additionally, SAE AISI 4140 steel is used in heavy equipment and construction for excavator teeth and crane components, in defense for armor plating and rifle barrels, and in machinery for spindles and lead screws. Its versatility extends to farming equipment like cultivator teeth and disc blades, as well as gear racks, sprockets, bolts, nuts, mold bases, tooling, and conveyor parts.

Heat treatment significantly influences the mechanical properties of SAE AISI 4140 steel, a low-alloy steel noted for its strength and toughness. Key heat treatment processes for 4140 steel include normalizing, annealing, quenching, and tempering.

Normalizing involves heating the steel to 850-900°C and cooling it in air to refine its grain structure and relieve internal stresses. Annealing, heating the steel to 800-872°C followed by slow cooling, softens the steel and makes it easier to machine. Quenching, heating to 815-880°C and rapidly cooling, dramatically increases hardness and strength due to the formation of martensite. Tempering, reheating quenched steel to 200-700°C, adjusts the balance between hardness and toughness, enhancing ductility and elongation.

These treatments can elevate the hardness of 4140 steel to 54-59 HRC and adjust it to 28-48 HRC with tempering. Consequently, heat-treated 4140 steel exhibits high tensile strength (≥1100 MPa), yield strength (≥950 MPa), improved toughness, and fatigue resistance, making it ideal for demanding applications in automotive, aerospace, and oil and gas industries.

When selecting SAE AISI 4140 steel for a project, several key considerations must be evaluated to ensure optimal performance and cost-efficiency.

Firstly, assess the mechanical properties required for the application. SAE AISI 4140 steel is known for its high tensile and yield strength, toughness, and wear resistance, making it suitable for high-stress and dynamic loading conditions. This steel’s chromium and molybdenum content also provide moderate corrosion resistance, although additional protective measures may be necessary for highly corrosive environments.

Next, consider the heat treatment and processing requirements. 4140 steel offers flexibility in heat treatment, allowing it to be annealed, quenched, and tempered to achieve desired mechanical properties. However, its machinability is best in the annealed state and becomes more challenging when hardened. Its weldability is lower than 4130 steel due to its higher carbon content, necessitating preheating and post-weld heat treatment to avoid cracking.

Application-specific considerations are also crucial. SAE AISI 4140 steel is widely used in industries such as automotive, aerospace, oil and gas, and manufacturing for components like gears, shafts, and structural elements that demand strength and durability. Cost and availability should be factored into the decision, as 4140 steel generally commands a higher price than alternatives like 4130 steel.

SAE AISI 4140 steel is a chromium-molybdenum alloy steel known for its high tensile strength, toughness, and wear resistance. Compared to other steels, 4140 exhibits superior mechanical properties. For instance, its tensile strength can reach up to 850 MPa when heat-treated, which is higher than that of 1040 and 1018 steels. Its yield strength, ranging from 415 to 990 MPa, surpasses steels like 8620 (360-570 MPa) and 1018 (around 370 MPa).

While 4140 steel offers good ductility with elongation at break between 11% and 26%, it is not as ductile as 8620 steel (13-31%). Its chromium content (0.8-1.1%) provides better corrosion resistance than non-alloy steels like 1018, although it does not match the corrosion resistance of stainless steels or Inconel 718 in highly corrosive environments.

4140 steel requires careful pre-heating and post-weld heat treatment due to its high carbon content, which can lead to welding challenges. Despite this, it is more weldable than steels like 1141.

SAE AISI 4140 steel is extensively used in various industrial applications due to its high strength, toughness, and wear resistance. In the automotive industry, it is utilized for gears and crankshafts, which require durability under extreme operating conditions, as well as for connecting rods and high-strength bolts and fasteners essential for structural integrity. In the aerospace sector, it serves in landing gear and engine parts, where reliability and strength are critical.

The oil and gas industry employs SAE AISI 4140 steel for drill collars and downhole components that must withstand harsh environments and mechanical loads. In heavy equipment and construction, it is used for excavator teeth, crane booms, and bulldozer blades, which endure significant wear and tear. The defense industry benefits from its application in rifle barrels and armor plating due to its resistance to stress and toughness.

Furthermore, agricultural machinery such as cultivator teeth and plow shares rely on this steel for its wear resistance. Additionally, machine parts like spindles and gears benefit from its strength and resistance to stress, making it suitable for high-stress components. These examples highlight the versatility and reliability of SAE AISI 4140 steel in demanding industrial applications.