In the world of high-performance materials, few metals hold the prestige of SAE AISI 4340 alloy steel. Renowned for its exceptional strength and toughness, this versatile alloy is a staple in industries where reliability is paramount, such as aerospace and automotive sectors. With its intricate blend of elements, the chemical composition of UNS G43400 endows 4340 steel with unique properties that make it indispensable for critical applications. But what exactly gives this alloy its remarkable characteristics, and how does it stand up to the rigorous demands of modern engineering? In this technical deep dive, we unravel the complexities of 4340 steel, exploring its composition, mechanical properties, and the diverse uses that keep it at the forefront of material science. Join us as we delve into the fascinating world of this alloy, uncovering the secrets behind its enduring success.

SAE AISI 4340 alloy steel, known by its UNS number G43400, is a medium-carbon, low-alloy steel celebrated for its exceptional strength, toughness, and resistance to fatigue. This combination of properties makes it ideal for high-stress applications, particularly in the aerospace and automotive industries, where reliability is paramount.

AISI 4340 steel is highly valued for its impressive strength and versatility. It maintains its mechanical properties under extreme conditions, making it suitable for critical structural components. Its high tensile strength and toughness are achieved through precise alloying and heat treatment processes, enhancing its performance in demanding environments.

Another crucial factor contributing to its widespread use is its fatigue resistance. Components made from this alloy can withstand cyclic loads over extended periods without significant degradation, essential for parts subjected to repetitive stress, such as aircraft landing gear and automotive crankshafts.

AISI 4340 is known for its excellent hardenability, allowing the steel to be hardened deeply and uniformly, even in thick sections. This property is vital for applications requiring consistent mechanical performance throughout the material. The steel’s ability to achieve high hardness levels while retaining toughness is a key advantage in high-strength applications.

The composition of AISI 4340 steel includes chromium, nickel, and molybdenum as its primary alloying elements. Chromium boosts hardenability and corrosion resistance, nickel adds strength and toughness, and molybdenum improves hardenability and high-temperature performance. These elements are carefully balanced to provide the desired mechanical properties.

In the aerospace industry, AISI 4340 steel is used for crucial parts like landing gear, where durability and fatigue resistance are vital. The alloy’s ability to perform reliably under extreme conditions makes it a preferred choice for these demanding applications.

The automotive industry utilizes AISI 4340 steel for components like engine crankshafts and axles, which require high strength and durability. The steel’s excellent mechanical properties ensure the longevity and reliability of these components, even under harsh operating conditions.

AISI 4340 steel is also used in the production of heavy machinery parts, where its strength and resistance to wear and fatigue are crucial. Components such as gears and shafts benefit from the alloy’s robust performance characteristics.

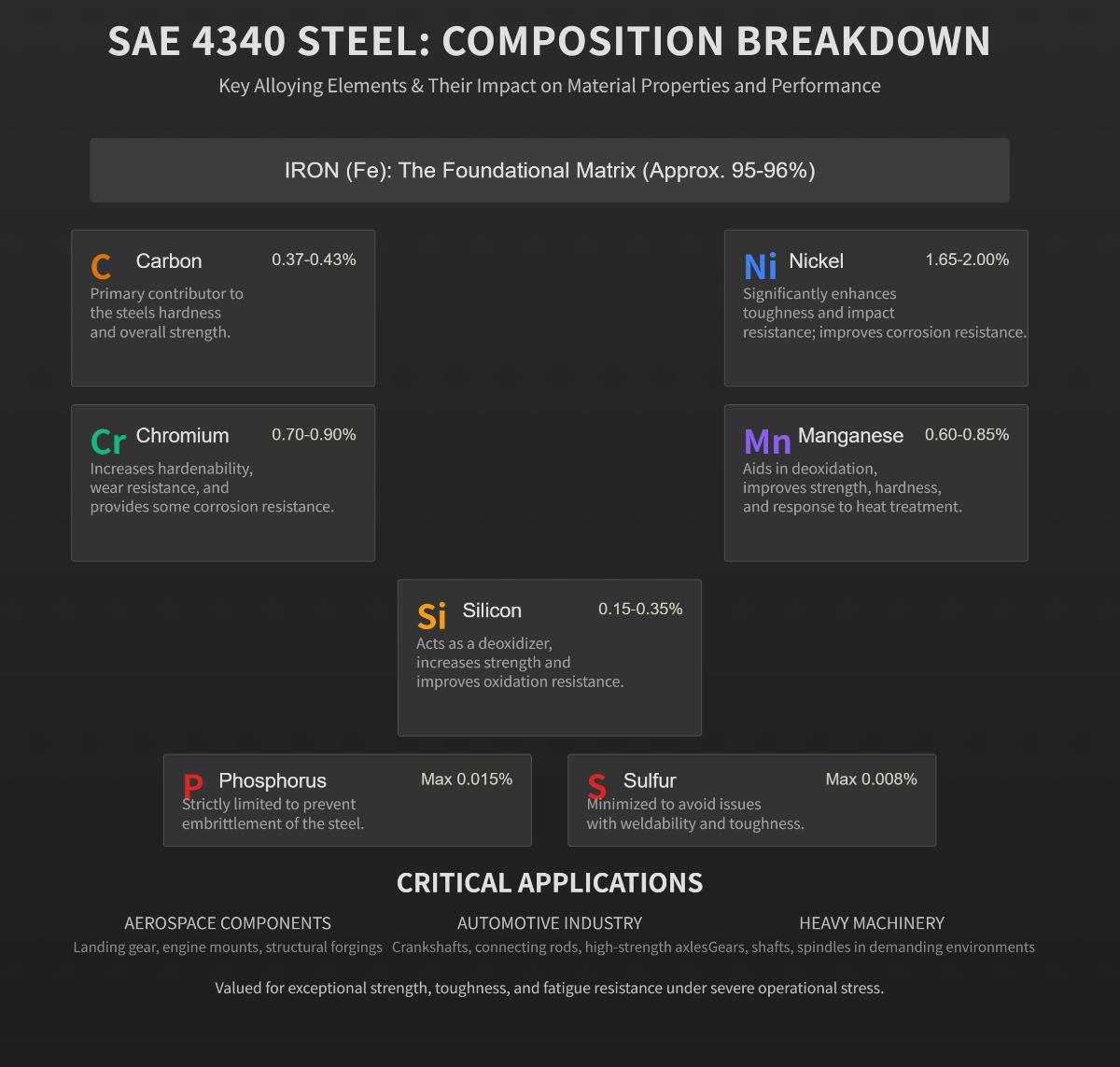

SAE/AISI 4340 alloy steel is renowned for its high strength and toughness, thanks to its carefully balanced chemical composition. The alloy consists of several key elements that contribute to its remarkable mechanical properties.

Carbon is a crucial element, present at 0.37% to 0.43%, which provides a balance between strength and ductility. Manganese, present at 0.60% to 0.80%, enhances the steel’s strength, wear resistance, and helps remove oxygen during production. Silicon, found in amounts between 0.15% and 0.30%, acts as a deoxidizer and adds to the steel’s overall toughness and hardness.

Phosphorus and sulfur are impurities that are kept minimal, with maximum levels of 0.035% and 0.040%, to preserve the steel’s toughness and ductility. Chromium, ranging from 0.70% to 0.90%, significantly boosts hardenability and wear resistance, while also improving corrosion resistance.

Nickel, at 1.65% to 2.00%, is crucial for enhancing toughness, strength, and resistance to impact and fatigue, making 4340 steel ideal for demanding applications. Molybdenum, present from 0.20% to 0.30%, enhances hardenability and high-temperature strength, while reducing temper brittleness.

The precise balance of these elements ensures that 4340 steel can be hardened deeply and uniformly, providing consistent mechanical properties throughout the material. The UNS G43400 designation ensures that 4340 steel meets standardized requirements, guaranteeing its reliability for engineers and manufacturers across various industries.

SAE/AISI 4340 steel is a medium-carbon, low-alloy steel renowned for its outstanding mechanical properties, making it ideal for applications that require high strength, toughness, and wear resistance. This steel’s performance is largely influenced by its chemical composition and heat treatment processes.

The tensile strength of 4340 steel varies significantly depending on its treatment. In its annealed condition, the steel typically exhibits an ultimate tensile strength of approximately 745 MPa (108,000 psi). When subjected to appropriate heat treatment, such as hardening and tempering, the tensile strength can range from 930 to 1080 MPa. The yield strength, indicating the stress at which the material begins to deform plastically, is around 470 MPa (68,200 psi) in the annealed state and increases to approximately 710 MPa (103,000 psi) after heat treatment.

Ductility, which is the ability to deform under stress before breaking, is measured by the elongation at break. For 4340 steel, this is typically around 13.2%. The steel’s hardness, or resistance to deformation and wear, is about 35 HRC when heat-treated. Other hardness metrics include Brinell hardness at 321, Knoop hardness at 348, and Vickers hardness at 339, reflecting the material’s capability to resist deformation and wear, making it suitable for parts that encounter abrasive conditions.

Impact toughness is crucial for applications subjected to dynamic or shock loading. The reduction of area, a measure of how much the material can stretch before breaking, is approximately 36%. This property ensures the material can withstand stress without catastrophic failure.

The mechanical properties of 4340 steel are significantly enhanced by alloying elements like nickel, chromium, and molybdenum. Nickel increases toughness and strength, chromium improves hardenability and corrosion resistance, and molybdenum adds strength and hardenability, especially at high temperatures.

4340 steel’s machinability and formability are important considerations for manufacturers. The material can be machined effectively in its annealed or normalized and tempered conditions. However, as the strength of the steel increases, its machinability decreases, necessitating specialized tooling and techniques.

In forming operations, 4340 steel can be bent or shaped when annealed, thanks to its ductility. This flexibility in manufacturing processes makes it a preferred material for a variety of components in aerospace and automotive industries, among others.

SAE AISI 4340 alloy steel is highly valued for its outstanding mechanical properties, making it ideal for demanding applications across various industries.

In the aerospace sector, AISI 4340 steel is extensively used for critical structural components that require high strength and toughness. Key applications include:

The automotive industry relies on AISI 4340 steel for components that require a balance of strength, toughness, and wear resistance. Its wear resistance and high strength make 4340 steel suitable for transmission gears, shafts, and crankshafts that operate under high loads. Additionally, it is used for axles and drive shafts, which require high strength and toughness to ensure reliable performance and longevity in demanding driving conditions.

In the realm of heavy machinery, AISI 4340 steel is employed for manufacturing parts that need to endure substantial mechanical stress and wear. Its hardness and wear resistance ensure gears and shafts perform reliably in tough conditions. The alloy is used in the production of various machine tool components, such as spindles and tool holders, where high strength and precision are critical. AISI 4340’s toughness and durability are valuable for components in construction machinery, such as excavator arms and bulldozer blades.

The energy sector, particularly the oil and gas industry, benefits from the properties of AISI 4340 steel in several applications. Its strength and fatigue resistance make it perfect for drill collars and tool joints facing mechanical stress in drilling operations. AISI 4340 is also used for pump shafts and valve components, which must endure high pressure and wear, ensuring reliable performance and longevity.

Forging is a key method for shaping AISI 4340 alloy steel, using high heat and pressure to enhance its strength and toughness. This technique improves the steel’s mechanical properties by refining its grain structure. The process typically involves heating the steel to a specific temperature and then deforming it with hammers or presses to achieve the desired shape. Following forging, the steel often undergoes heat treatment to further optimize its properties.

Heat treatment is crucial for achieving the desired mechanical properties of AISI 4340 alloy steel. Common methods include:

These techniques significantly improve the steel’s tensile strength, ductility, and impact resistance, making it suitable for high-stress applications.

AISI 4340 alloy steel can be easily machined, especially when annealed, through processes like turning and milling. Machining techniques such as drilling and grinding are also effective. As the steel’s hardness increases due to heat treatment, specialized tooling and methods may be necessary to maintain precision. The steel’s ductility allows for easy forming and shaping, ensuring that complex components can be manufactured accurately.

The inherent strength and fatigue resistance of AISI 4340 alloy steel contribute to its durability, reducing the need for replacements. This minimizes waste and resource consumption, supporting sustainable practices by extending the lifespan of components.

High-performance materials like AISI 4340 alloy steel enhance energy efficiency in various applications. Components made from this steel can be lighter yet stronger, reducing the overall weight of systems and improving operational efficiency. For instance, in the aerospace and automotive industries, lighter components improve fuel efficiency and reduce emissions.

Steel, including AISI 4340, is recyclable, supporting sustainable practices by conserving resources and reducing environmental impact. At the end of their lifecycle, components made from 4340 steel can be recycled and repurposed, reducing the need for raw material extraction and processing. The high recyclability of steel underscores its role in sustainable manufacturing practices.

SAE and AISI standards play a crucial role in standardizing the specifications of steel alloys like AISI 4340, ensuring uniform quality and performance. These standards provide detailed guidelines on the chemical composition, mechanical properties, and processing requirements, making it easier for engineers and manufacturers to select the appropriate material for their needs.

SAE standards for alloy steels such as AISI 4340 are outlined in documents like SAE J404 and SAE AMS 6414. SAE J404 specifies the chemical composition limits for alloy steels, ensuring that the elements are within specific ranges for optimal properties. SAE AMS 6414 covers requirements for aircraft-quality, low-alloy steel in various forms, including bars and forgings, with guidelines for heat treatment to achieve desired strength and toughness.

AISI standards for 4340 steel provide comprehensive guidelines on the alloy’s composition and properties. Compliance with these standards ensures consistency across different batches, facilitating reliable performance in critical applications.

In Europe and Japan, AISI 4340 is known as 34CrNiMo6 and SNCM439, respectively. European standards such as EN 10083-3 and British standards like BS 970 provide similar guidelines on chemical composition and mechanical properties, ensuring that 4340 steel can be used interchangeably with local equivalents. Japanese standards under JIS G4103 specify requirements for SNCM439, meeting the high-strength needs of the Japanese market.

Industries such as aerospace rely on AISI 4340 for components like landing gear, where high strength is crucial. Various industry standards ensure that the material meets specific requirements for performance and reliability in demanding applications.

ASTM standards like A29 and A322 offer guidelines for the production and quality control of 4340 steel, ensuring its suitability for high-strength applications. ASTM A29 covers general requirements for hot-wrought alloy steel bars, while ASTM A322 specifies requirements for steel bars used in various applications, confirming that 4340 steel is apt for high-stress components.

SAE AISI 4340 alloy steel is renowned among medium-carbon steels for its exceptional mechanical properties and balanced composition. When comparing 4340 to other steel alloys like 4330, 4140, and 300M, key distinctions arise that cater to various engineering needs.

The chemical composition of these alloys significantly influences their mechanical performance and suitability for specific applications. SAE 4340 contains a higher nickel content (1.65–2.00%) compared to 4330, which has around 1%. This difference enhances 4340’s hardenability and toughness, making it more suitable for high-stress applications where fracture resistance is crucial. Unlike 4340, 4140 lacks nickel and instead uses chromium and molybdenum to provide moderate strength and wear resistance. Meanwhile, 300M is enriched with silicon and vanadium, which improve tempering resistance and grain refinement, making it ideal for aerospace applications requiring ultra-high strength.

The mechanical properties of these alloys define their potential uses, with SAE 4340 offering a versatile balance of strength, toughness, and fatigue resistance.

Below are answers to some frequently asked questions:

SAE 4340 steel, also known as AISI 4340, is a medium carbon, low alloy steel notable for its strength and toughness, making it suitable for high-stress applications. Its chemical composition is integral to its properties, featuring the following key elements: Carbon (0.37% to 0.43%), contributing to hardness and strength; Nickel (1.65% to 2.00%), enhancing toughness and corrosion resistance; Chromium (0.70% to 0.90%), improving hardness and wear resistance; Manganese (0.60% to 0.85%), aiding in strength and hardness; Silicon (0.15% to 0.35%), increasing strength and oxidation resistance; Phosphorus (maximum 0.015%) and Sulfur (maximum 0.008%), both kept low to prevent brittleness and welding issues. Iron makes up the majority, about 95% to 96%, providing the foundational matrix for alloying. This composition is crucial for the steel’s applications in aerospace, automotive, and machinery components, where durability and performance under stress are paramount.

AISI 4340 alloy steel is widely utilized in several industries due to its remarkable mechanical properties, including high tensile strength, toughness, and fatigue resistance. In the aerospace industry, it is commonly used for manufacturing aircraft landing gear, where components must endure extreme stress and cyclic loads during takeoff and landing. The automotive sector benefits from AISI 4340 in the production of high-performance shafts, gears, axles, and spindles, which require durability under high torque and stress conditions. In the oil and gas sector, its excellent fatigue strength makes it suitable for drilling equipment exposed to harsh environments. Additionally, AISI 4340 is favored in power transmission systems for gears and shafts due to its hardenability and wear resistance. It is also employed in forging and machine building for heavy-duty forged components and in general engineering for structural parts needing high strength and toughness.

The mechanical properties of SAE AISI 4340 steel, also known as UNS G43400, highlight its suitability for demanding applications. This medium-carbon, low-alloy steel exhibits high strength, toughness, and excellent fatigue resistance. In its annealed condition, 4340 steel has a tensile strength of approximately 745 MPa (108,000 psi) and a yield strength of about 470 MPa (68,200 psi). When heat-treated (quenched and tempered), its tensile strength can reach up to 1,100 MPa (161,000 psi) with a yield strength around 710 MPa (103,000 psi).

The elongation at break in the heat-treated state is roughly 13.2%, and its hardness can be as high as Rockwell C35. The modulus of elasticity is approximately 205 GPa (29,700 ksi), providing a measure of its stiffness. Additionally, 4340 steel is known for its excellent shock and impact resistance, particularly when hardened and tempered, making it ideal for aerospace and automotive components such as landing gear and transmission gears.

SAE AISI 4340 alloy steel is highly regarded for structural applications due to its impressive mechanical properties. Compared to other steel alloys, 4340 stands out with its high yield strength of approximately 125,000 psi and tensile strength ranging from 930 to 1,080 MPa. This makes it stronger than many medium-carbon steels, such as 4140, which lacks the nickel content that enhances 4340’s toughness and fracture resistance. Additionally, 4340’s combination of chromium, molybdenum, and nickel provides superior fatigue resistance, a critical factor in demanding structural applications.

While 300M steel, a modified version of 4340, offers better fatigue strength and ductility, it comes at a higher cost. In comparison, 4340 is more economical and still provides substantial strength, making it suitable for aerospace components like landing gear and engine mounts, as well as automotive crankshafts and suspension parts. Although 4340 requires specific heat treatment processes to optimize its properties and ensure weldability, its overall benefits in strength and durability make it a preferred choice for high-stress environments.

The benefits of using SAE AISI 4340 steel in manufacturing processes are numerous, primarily due to its superior mechanical properties, optimized chemical composition, and versatility in heat treatment. This alloy steel is renowned for its high strength and toughness, achieving tensile strengths of at least 930 MPa post-quenching and tempering, making it ideal for load-bearing components such as crankshafts and aircraft landing gear. Its excellent fatigue resistance makes it suitable for parts subjected to high-cycle stress, like motor shafts and axles.

The chemical composition of 4340 steel, which includes nickel, chromium, and molybdenum, enhances its toughness, hardenability, and wear resistance, while controlled carbon content ensures a balance between hardness and machinability. The steel’s deep hardening capability allows for uniform properties across large cross-sections, which is crucial for heavy-duty forgings.

In terms of processability, 4340 steel performs well in cutting and forging operations compared to higher-alloy steels. Though welding requires preheating and post-weld tempering to minimize cracking, it remains feasible for structural repairs.

These properties make 4340 steel highly valuable in industries such as aerospace, automotive, and oil and gas, where components are often exposed to extreme pressures, impacts, and alternating loads. Additionally, recent advancements, such as improved tempering protocols and hybrid surface treatments, further enhance its performance and extend the service life of components.

SAE AISI 4340 alloy steel is widely recognized for its successful applications across various industries due to its high strength, toughness, and fatigue resistance. In the aerospace industry, it is utilized for high-stress components such as landing gear and critical structural elements, where reliability under extreme conditions is crucial. In the oil and gas sector, 4340 steel is employed in drilling equipment and downhole tools, offering durability and corrosion resistance essential for harsh environments. The automotive industry benefits from its use in machined components like transmission shafts and high-strength applications such as torsion bars and crankshafts, ensuring smooth operation and longevity. Recent research continues to explore the alloy’s strengthening mechanisms and fatigue behavior, further solidifying its role in demanding applications. These case studies highlight the alloy’s versatility and reliability in challenging settings, making it a preferred material for high-performance applications.