Have you ever stared at a pile of fasteners and wondered which one to use for your project? Bolts, screws, and studs might seem interchangeable, but they each serve distinct purposes and have unique characteristics. Understanding these differences can make a world of difference in the success of your endeavors. In this article, we’ll delve into the specific definitions, uses, and features of bolts, screws, and studs. We’ll explore their physical characteristics, threading, head types, and functional differences to help you confidently choose the right fastener for any job. Ready to demystify the world of fasteners? Let’s get started!

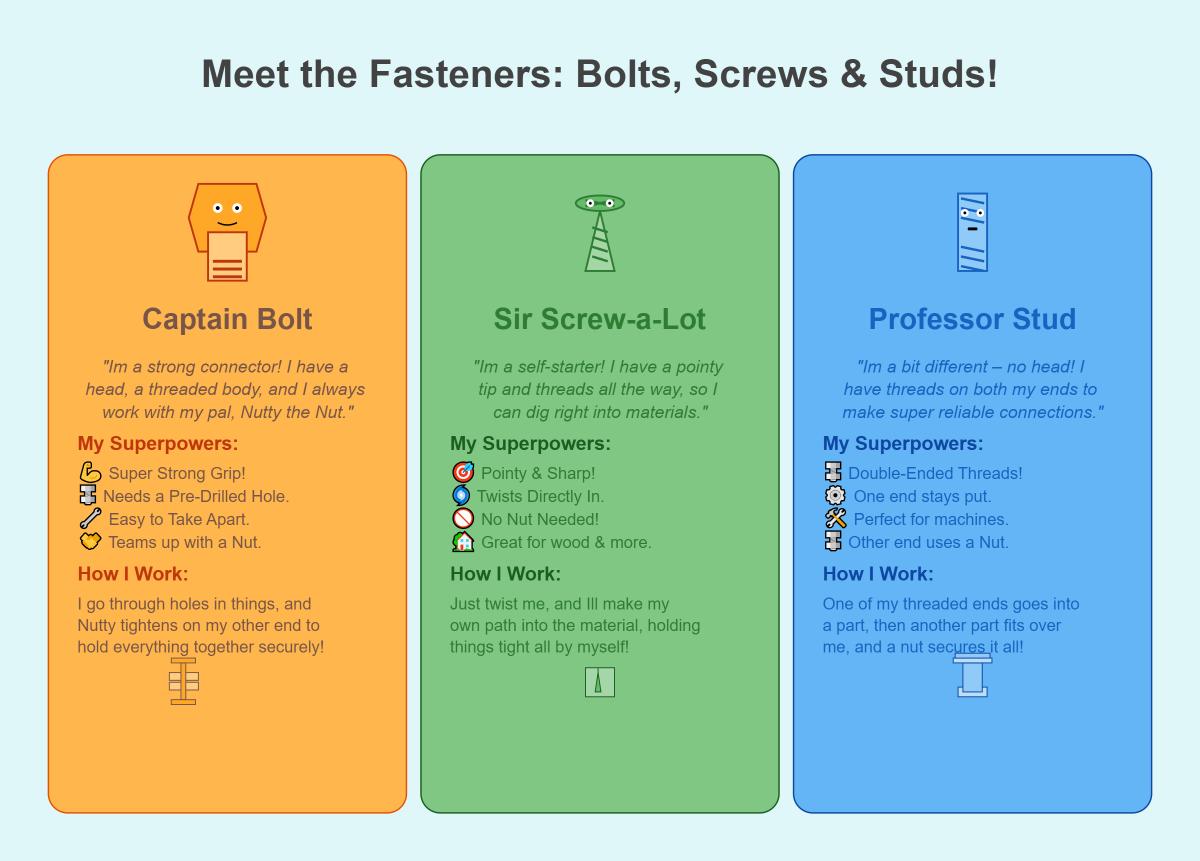

Bolts are fasteners with a cylindrical body and external threads. At one end, there’s a head that can be turned using tools like a wrench or pliers. Bolts are designed to connect two or more unthreaded components and are typically paired with a nut. For example, in building a large metal structure, bolts are used to hold different parts together firmly. They are ideal for high-tension applications requiring a strong, secure connection. Additionally, since they can be easily removed and replaced, bolts are perfect for situations where disassembly might be needed later.

Screws are also threaded fasteners. They have a pointed end and helical threads running along their length. A key feature of screws is their ability to be driven directly into materials, often without the need for a nut. Screws come in various head shapes such as flat, round, or pan, and they are tightened using a screwdriver. They are commonly used in materials like wood, plastic, or thin metal. For instance, when assembling a wooden bookshelf, screws are a popular choice as they can penetrate the wood easily and hold the parts together in low-tension applications.

Studs are metal rods that have threads on both ends but no head. They are used to provide a strong connection between two parts. Usually, nuts are used on both ends of the stud. Studs are frequently found in heavy-duty applications, like engine components or flange connections. Without a head, they don’t require external force for tightening. They can be fully or partially threaded depending on how they will be used. For example, in an engine block, studs help to securely attach different components with consistent clamping forces.

Bolts are fasteners with a cylindrical, threaded body and a head on one end. The head, typically hexagonal or square, is designed to be turned with a wrench. Bolts usually feature a smooth, unthreaded section of the shank near the head. They are primarily used in conjunction with nuts to secure two or more parts together.

Screws generally have threads along most of their length and often feature a pointed or self-tapping tip. They come with various head designs such as flat, round, or pan, which are driven by tools like screwdrivers or drills. Unlike bolts, screws are designed to be driven directly into materials, creating their own threads.

Studs are headless cylindrical rods threaded on both ends or throughout their entire length. One end is screwed into a tapped hole in the base material, while the other end is secured with a nut. This configuration allows for strong, reliable joints without the need for a bolt head.

Bolts generally have a more substantial diameter and length compared to screws and studs, making them suitable for heavy-duty applications. Screws vary widely in size, suitable for both lightweight and medium-load tasks. Studs are typically longer than bolts and screws, designed for applications requiring precise clamping forces.

Bolts may have partial external threads, with a smooth shank near the head for added shear strength.

Screws are usually fully threaded or mostly threaded, with some designed to cut their own threads into the material.

Studs have threads at both ends or sometimes along their entire length. They provide secure, strong joints by embedding one end in the base material and securing the other with a nut.

Bolts come with various head types, including hexagonal, square, or other shapes designed for wrench tightening.

Screws offer a wide range of head types, including flat, pan, round, and countersunk, each suited for different applications and driving tools.

Studs do not have heads, allowing for torque to be applied through the nuts used at each end, making them ideal for applications requiring consistent clamping force.

| Feature | Bolt | Screw | Stud |

|---|---|---|---|

| Shape | Headed fastener with cylindrical shaft and threads, often with unthreaded shank | Threaded shaft, pointed or self-tapping tip, headed for screwdriver | Headless threaded rod with threads on both ends |

| Threading | External threads, often partially threaded | Fully or mostly threaded, sometimes self-tapping | Threads at both ends, sometimes partially threaded in the middle |

| Usage | Used with nuts to clamp two or more parts | Driven into material, creating or engaging internal threads | One end screwed into base, nut used on other end to secure parts |

| Installation | Requires access to both sides, tightened with wrench and nut | Tightened from one side with screwdriver or drill | Installed by screwing one end, nut on other end |

| Typical Applications | High-strength joints, machinery, automotive | Woodwork, plastics, sheet metal, appliances | Engine heads, flanges, heavy equipment, cable ties |

| Removal & Reuse | Easy to remove and replace by loosening nut | Can be difficult if embedded or damaged threads | Studs allow repeated assembly with consistent clamping force |

| Head Types | Hex, square, or other wrench heads | Flat, pan, round, countersunk, or none (set screws) | No head |

Bolts are designed to be used with nuts, inserted through pre-drilled holes in the materials to be joined. The nut is then threaded onto the bolt’s end to clamp the parts together securely. This design provides a strong clamping force and allows easy removal and replacement.

Screws are designed to be driven directly into materials, either creating their own threads or engaging existing ones. They do not generally require a nut and can be installed and removed from one side of the assembly.

Studs provide a strong joint by embedding one end into a base material and securing the other end with a nut. This design allows for precise torque control and is ideal for applications where consistent clamping force is needed.

Bolts are best used for joining two or more pre-drilled or unthreaded parts when you can access both sides of the material. They are commonly used in high-tension applications, such as machinery and automotive assembly, where strong, secure connections are essential. For example, bolts are used to hold engine parts together in a car. In construction frameworks, bolts connect structural steel joints, ensuring the stability of large buildings and bridges. Since bolts can be easily removed by loosening the nut, they are also suitable when disassembly and reassembly might be required, such as during equipment maintenance or modification.

Screws are ideal for fastening materials when you can only reach one side. They are commonly used in wood, plastic, thin metal, drywall, and light-duty assemblies. In furniture assembly, screws are often used as they can penetrate wood easily and hold the parts together. For cabinetry, screws provide a neat and secure way to attach doors, drawers, and other components. In electronics, small screws are used to hold the casing together, and in drywall installation, screws attach the drywall to the studs. They are also great for household repairs, like fixing a loose hinge or attaching a small bracket.

Studs are used when precise alignment and strong clamping are needed, but a bolt head isn’t practical. They are common in engine cylinder heads, flanges, and heavy machinery. In automotive engine assembly, studs attach various components to the engine block, allowing for accurate torque control and consistent clamping force, which is crucial for the proper functioning of the engine. In turbine flanges and pressure vessels, studs ensure a tight seal and can withstand high pressures. Industrial pipe flanges also use studs to connect pipes securely, allowing for easy disassembly for maintenance or replacement of pipes.

Threading is a crucial design feature of fasteners, impacting their performance and application. Threads are helical structures wrapped around the cylindrical body of a fastener, enabling it to be driven into materials and secure parts together.

Threading affects how well a fastener can hold materials together and withstand forces. Coarse threads are more resistant to damage and are easier to install and remove, making them suitable for applications where speed and durability are critical. Fine threads, on the other hand, provide better clamping force and precision but may require more effort to install and are more prone to cross-threading.

The head of a fastener is the top part designed to be engaged by a tool, such as a wrench or screwdriver, and it affects both installation and material interaction.

Choosing the right head type depends on the specific requirements of the project. For high-strength and high-torque applications, hex heads are preferred due to their robust design and ease of use with wrenches. Flat and countersunk heads are ideal for projects where a flush surface is necessary, such as in woodworking or cabinetry. Pan and round heads are chosen for their aesthetic appeal and are suitable for visible applications where a smooth, finished look is important.

Fasteners are made from various materials, each offering unique properties and benefits depending on the application.

When selecting a material for fasteners, consider the following factors:

By understanding the design features of threading and head types, as well as the material options available, you can select the right fastener for your specific application, ensuring strength, durability, and ease of installation.

Fasteners like bolts, screws, and studs are made of different materials, each with distinct properties for specific uses. Understanding these materials can help you choose the right fastener for your project.

Carbon steel and stainless steel are two commonly used materials for fasteners. Carbon steel is popular due to its strength and durability, often used in construction and industrial applications where high tensile strength is needed. It can be further treated with coatings to enhance corrosion resistance, making it suitable for both indoor and outdoor use. Stainless steel fasteners, on the other hand, are known for their excellent corrosion resistance. They are ideal for applications exposed to moisture or harsh environmental conditions, such as marine or outdoor structures. Stainless steel also offers good strength and aesthetic appeal, which is beneficial for visible fixtures that require both durability and a clean finish.

Brass is used for fasteners that need to resist corrosion and provide a decorative finish. It is commonly found in applications such as plumbing, electrical components, and ornamental hardware. Brass fasteners are also known for their good electrical conductivity, making them suitable for use in electronic devices.

Nickel alloy fasteners are selected for their high – strength and ability to withstand extreme temperatures. These properties make them ideal for demanding applications in the aerospace, automotive, and chemical industries. Nickel alloys provide superior performance in environments where both high mechanical stress and temperature fluctuations are prevalent.

Aluminum alloy fasteners are lightweight and corrosion-resistant, making them suitable for applications where weight reduction is crucial, such as in the aerospace and automotive industries. Aluminum fasteners also offer good mechanical properties and can be used in environments where exposure to corrosive elements is a concern.

Choosing the right material for fasteners involves considering several factors that can impact the performance and longevity of the fastener in its application.

Assess the mechanical properties required for the application, like tensile and shear strength. For high-load applications, materials like carbon steel or nickel alloy may be preferred due to their robustness.

Consider the environmental conditions where the fastener will be used. Stainless steel and brass are excellent choices for environments exposed to moisture or chemicals, as they offer superior corrosion resistance.

For visible applications, the appearance of the fastener can be important. Brass and stainless steel fasteners provide a clean, attractive finish suitable for decorative purposes.

Balance the material’s performance benefits with its cost to ensure it meets the project’s budget. Carbon steel is often the most cost-effective option, while materials like stainless steel and nickel alloy may be more expensive but offer additional advantages.

When selecting fasteners for specific applications, it’s essential to match the material properties with the requirements of the task.

By considering these factors and understanding the properties of different materials, you can make informed decisions when selecting fasteners for your projects.

When choosing a fastener, it’s crucial to match its material with the materials you’re joining; for example, stainless steel fasteners resist corrosion and are ideal for moist environments. In contrast, carbon steel might be a better choice for dry, protected areas where strength is the main requirement. Also, understand the application method. Some fasteners, like self-clinching ones, require a specific installation process using a parallel-acting press instead of a quick impact tool.

Evaluate the load your fastener needs to bear, including its tensile strength (pulling force), shear strength (cutting force), and tightening torque. Select the right thread size and length to ensure the fastener can handle the load without breaking. For thin sheet materials, self-clinching fasteners can be a good option if the panel is ductile and softer than the fastener.

Pick fasteners with the appropriate hardness and strength for the application; for instance, use stainless steel fasteners for outdoor use to prevent rust, or high-tensile bolts for heavy machinery. Also, think about environmental resistance. If the fasteners will be exposed to moisture, saltwater, or chemicals, they should be corrosion-resistant.

Choose reputable fastener suppliers with industry expertise, as they can provide quality products and valuable guidance. They can help you select the right fastener based on your specific needs, ensuring the correct strength, material, and application method.

You’ll need a bolt of the appropriate size and material, a corresponding nut, a wrench or socket set that fits the bolt head and nut, and possibly a drill if you need to create holes in the materials to be joined.

Ensure the surfaces of the materials are clean where the bolt will be installed. If they aren’t pre-drilled, use a drill bit of the correct size to create holes in both materials. Make sure the holes are aligned properly.

Slide the bolt through the holes in the materials. Ensure that the bolt’s head is on the accessible side and the threaded end protrudes through the other side.

Place the nut on the threaded end of the bolt. Use a wrench or socket set to start turning the nut clockwise. Tighten the nut gradually, applying even pressure, until the materials are firmly held together. Avoid over-tightening, which can damage the bolt or the materials.

Choose a screw that is suitable for the material you’re working with. For example, wood screws are designed for wood, while sheet metal screws are for thin metal. Also, consider the length and diameter of the screw based on the thickness of the materials.

If you’re working with wood, you may want to make a small guide hole. This helps prevent the wood from splitting and makes it easier to drive the screw. For other materials, ensure the surface is clean and free of debris.

Insert the tip of the screw into the guide hole or the material. Use a screwdriver or a drill with a screwdriver bit. Hold the screw straight and apply downward pressure while turning it clockwise. Keep driving the screw until it is flush with or slightly below the surface of the material.

You’ll need a stud of the correct size, a nut for each end of the stud, a wrench or socket set, and a tap if you need to create threads in the receiving hole.

If the receiving hole in the base material isn’t threaded, use a tap to create the threads. Clean the hole to remove any debris or metal shavings.

Apply a small amount of thread-locking compound if required. Line up the threaded end of the stud with the threaded hole in the base material. Use a wrench or socket set to turn the stud clockwise and screw it into the hole until it is fully seated.

Position the components on the other end of the stud. Then, place a nut on the exposed threaded end of the stud. Use a wrench or socket set to tighten the nut, applying the appropriate torque to secure the components firmly.

Below are answers to some frequently asked questions:

Bolts, screws, and studs are all types of fasteners, but they have distinct characteristics and uses. A bolt is a fastener with a cylindrical shaft and external threads, typically with a plain section near the head, designed to be used with a nut. Bolts are inserted through pre-drilled holes and secured with a nut, making them ideal for strong, reliable joints that can be easily disassembled.

A screw, on the other hand, has a fully threaded shaft and usually a pointed tip designed to cut or engage threads in the material itself. Screws do not require a nut; they are inserted directly into the material, making them suitable for fastening when only one side of the assembly is accessible.

A stud is a headless metal rod with threads on both ends. One end is screwed into a tapped hole in one component, while the other end receives a nut to secure a second component. Studs provide a permanent threaded connection, often used in applications requiring repeated assembly and disassembly, such as engine cylinder heads and heavy machinery.

When deciding whether to use a bolt instead of a screw, consider the specific requirements of your project. Bolts are ideal for situations where high load-bearing capacity and strength are needed. They provide a more secure connection due to the bolt-nut-washer combination, which distributes the load over a larger area and allows for greater clamping force. This makes bolts suitable for heavy-duty structural applications like construction, machinery, and automotive suspension.

Bolts are also advantageous when adjustability and easy disassembly are required. They allow for easy tightening, loosening, and reassembly, which is beneficial for projects needing regular maintenance or adjustments. Additionally, bolts are preferable for joining materials that require through-holes, offering superior performance in aligning parts and resisting shear forces.

Studs are metal rods with threads on both ends and no head, distinguishing them from bolts and screws, which have heads. They often have a non-threaded middle section, though some can be fully threaded. Studs are typically used by screwing one end into a base or component, then securing the other part with a nut on the opposite end, creating a strong joint. This makes studs ideal for applications where nuts are required on both sides of the joined materials, such as engine cylinder heads or flange connections.

Studs provide the advantage of more accurate torque application during tightening because no rotational force is applied to the stud itself, only to the nut(s), reducing the risk of inaccurate torque readings. They are usually larger and longer than bolts or screws and can be designed with various thread lengths and profiles to suit specific applications. Being headless, studs simplify maintenance and disassembly as only the nuts need to be removed.

Bolts generally require nuts to secure them in place. Bolts are externally threaded fasteners designed to be used with a nut, which threads onto the bolt from the opposite side of the assembly to provide clamping force and stability. This makes bolts ideal for applications requiring high strength and where both sides of the assembly are accessible, such as in building frames and bridges.

On the other hand, screws do not require nuts. Screws are also externally threaded but are designed to create their own mating threads in the material they are driven into, or to fit into pre-tapped holes. Screws are tightened by turning their head, making them suitable for applications where only one side of the assembly is accessible, such as in woodworking or drywall installation.

Bolts, screws, and studs are fasteners made from various materials. Bolts are commonly made from carbon steel, which offers good strength and is cost – effective, often coated for corrosion resistance. Stainless steel bolts (304, 316 grades) are great for corrosion – prone environments, while alloy steel is used for high – strength needs. Screws are typically made of stainless steel for its corrosion resistance and durability, and brass or aluminum for lighter or decorative uses. Studs are usually manufactured from stainless steel (304, 316, 410), carbon steel, and alloy steel. Different grades of stainless steel offer varying levels of corrosion resistance and strength, and carbon/alloy steel is used in heavy – duty applications. The choice of material depends on the application’s environment and mechanical requirements.

When using bolts, screws, and studs, avoid several common mistakes. For bolts, don’t use the wrong size or material as it can lead to joint failure, and follow proper installation techniques to prevent over – or under – tightening. Also, ensure material compatibility to avoid galvanic corrosion. With screws, select the right type and length for the material, don’t over – tighten, and use the correct driver bits. For studs, choose the right size, perform pre – installation checks, and don’t use damaged ones. Generally, avoid galvanic corrosion by not mixing dissimilar metals, use the correct torque, and don’t opt for low – quality fasteners.