In the world of engineering, the choice between socket weld and threaded flange connections can be pivotal, influencing both the reliability and efficiency of a system. As professionals navigate the intricacies of these options, key considerations such as sealing under high pressure, vibration resistance, and ease of maintenance become crucial. Socket weld flanges offer robust sealing, ideal for high-pressure applications, while threaded flanges provide flexibility and ease of installation. But which is better suited for your specific needs? This article delves into a detailed comparison, exploring the advantages and disadvantages of each connection type, and offering insights into their performance in various industrial applications. As we uncover the nuances of socket weld versus threaded connections, we’ll address the burning question: when should you choose one over the other? Join us as we dissect these engineering staples, providing clarity on which might be the optimal choice for your next project.

Socket weld flanges create a strong, leak-proof connection by inserting a pipe into a recessed area of the flange and welding it in place.

This welding process ensures a strong, leak-proof connection, making socket weld flanges ideal for high-pressure and high-temperature applications, and their design provides better flow characteristics compared to other flange types. The long socket length facilitates easier and more accurate pipe alignment and welding.

Socket weld flanges are widely used in industries where high-pressure and high-temperature conditions are common. Some common applications include:

Socket weld flanges offer high sealing efficiency because the welded connection minimizes the risk of leaks, providing a more reliable seal compared to threaded flanges. The weld provides a robust connection that can withstand high pressures and temperatures. The smooth bore design improves flow efficiency, reducing pressure drops and turbulence.

Installation can be complex and costly, requiring skilled labor and specialized equipment for welding, which may increase both installation time and costs. Although durable, welded connections are more challenging to disassemble and reassemble compared to threaded connections. Welded joints may require regular inspections to ensure the integrity of the connection, particularly in critical applications.

Threaded flanges are essential components in piping systems, connecting pipes through threaded holes. This design is particularly advantageous in scenarios requiring frequent assembly and disassembly, such as residential plumbing and small-scale industrial applications.

Threaded flanges are characterized by their ease of installation and maintenance, making them a preferred choice for systems that do not require specialized skills or equipment. The threaded connection eliminates the need for welding, facilitating quick and straightforward assembly—especially beneficial in low-pressure systems where simplicity is key.

These flanges are mainly used in low-pressure systems and smaller pipe diameters, such as residential plumbing, air conditioning, and small-scale industrial setups.

The primary advantage of threaded flanges is their simplicity and cost-effectiveness. Installation does not require welding, which reduces labor costs and the need for skilled workers. Maintenance is flexible, allowing easy disassembly for repairs or part replacement. This aspect reduces downtime and costs, crucial for systems needing frequent updates.

However, threaded flanges are less suitable for high-pressure applications where leak-proof connections are critical. Threads can loosen over time, especially with vibration or thermal expansion. They are generally used for small-diameter pipes, limiting their use in larger systems.

Pressure rating is the maximum pressure a flange can safely withstand under specific conditions. It is essential for ensuring the safety and reliability of piping systems, especially in high-pressure scenarios.

Socket weld flanges are designed for high-pressure systems due to their welded connections, which create a strong, unified structure capable of withstanding significant pressure without leaks. This robust design is ideal for applications where maintaining high-pressure integrity is crucial.

Threaded flanges are generally limited to low-pressure applications. They are less capable of handling high pressures because the threads can loosen or degrade over time, increasing the risk of leaks. This limitation confines their use to environments where pressure demands are moderate.

Socket weld flanges are known for their ability to create leak-proof connections, thanks to the continuous, solid seal formed by the fillet weld during installation. This welding process ensures a durable seal that withstands high pressures and thermal expansion.

Threaded flanges, on the other hand, depend on the integrity of the threads and the effectiveness of sealants. These connections are more susceptible to leaks, particularly under high pressure, vibration, or thermal cycling. The potential for thread loosening over time further compromises their sealing efficiency.

When comparing sealing mechanisms, socket weld flanges offer superior performance in high-pressure applications due to their welded design, which significantly reduces the risk of leaks. This makes them more reliable for critical systems. Threaded flanges, while easier to install and maintain, do not provide the same level of sealing efficiency and are better suited for low-pressure, non-critical applications.

Corrosion resistance is crucial for the performance and longevity of flanges in various industrial settings. It reflects a material’s ability to withstand degradation from chemical reactions, typically involving environmental elements like moisture, acids, and salts.

Socket weld flanges generally resist corrosion better than threaded flanges because the welding process creates a smooth, continuous surface that reduces crevice formation. This design minimizes areas where corrosive agents can accumulate, thereby enhancing the flange’s resilience.

Threaded flanges are more susceptible to corrosion due to the presence of threads, which create crevices where corrosive substances can accumulate.

Durability under operational stress is another key factor when comparing socket weld and threaded flanges.

Socket weld flanges exhibit superior mechanical strength and durability under operational stress conditions.

Threaded flanges offer dynamic adaptability but have limitations in high-stress environments.

| Factor | Socket Weld Flanges | Threaded Flanges |

|---|---|---|

| Crevice Corrosion | Moderate risk (dependent on weld quality) | High risk (thread geometry) |

| Fatigue Resistance | High (welded joint integrity) | Low (thread wear under cyclic loading) |

| Installation Complexity | High (requires skilled welding) | Low (simple threading) |

| Maintenance Frequency | Low (permanent joint) | High (routine thread inspection) |

Socket weld flanges require precise installation because they use welding to ensure a strong connection. The pipe is inserted into a flange socket and secured with a fillet weld around the rim, creating a robust, leak-proof joint. A small gap (usually 1/16″) between the pipe and socket base is needed to allow for thermal expansion and prevent stress. Although the setup time is longer and costlier due to the welding process, the resulting joint is permanent and offers high structural integrity, making socket weld flanges suitable for demanding environments.

Threaded flanges offer a simpler and faster installation process. They connect pipes by screwing onto the threads, eliminating the need for welding. This makes them ideal for applications in confined spaces or low-pressure systems where quick assembly is required. Careful thread compatibility checks are necessary to prevent cross-threading, which can compromise the connection’s integrity. Sealants like Teflon tape or thread compound are crucial to prevent leaks. The ease of installation makes threaded flanges a cost-effective option for systems that do not require the high-pressure resilience provided by socket weld flanges.

Socket weld flanges boast superior durability, particularly under conditions of vibration and thermal cycling, thanks to their welded joints. Maintenance can be labor-intensive, as disassembly requires cutting and rewelding, increasing downtime and repair costs. Although inspections often require non-destructive testing methods like X-ray, the reliability of socket weld flanges under high-pressure and high-temperature conditions is unmatched. Despite the challenges, the reliability of socket weld flanges under high-pressure and high-temperature conditions is unmatched, making them a preferred choice for critical applications.

Threaded flanges offer more straightforward maintenance due to their easy disassembly. They can be unscrewed for repairs, significantly reducing service interruptions. Visual inspections are generally sufficient to assess thread integrity, but frequent re-tightening may be necessary to maintain a secure connection, particularly in environments subject to vibration or thermal stress. Although more prone to leaks than socket weld flanges, threaded flanges provide flexibility and ease of maintenance, making them suitable for systems requiring regular updates or part replacements.

| Factor | Socket Weld Flanges | Threaded Flanges |

|---|---|---|

| Installation Complexity | High (requires skilled welding) | Low (simple threading) |

| Maintenance Effort | High (cutting and rewelding needed) | Low (easy disassembly) |

| Durability | High (superior leak resistance) | Moderate (prone to thread wear) |

| Cost | Higher initial cost due to welding labor/materials | Lower upfront cost |

Socket weld flanges are preferred in high-pressure steam lines, chemical processing systems, and hydrocarbon applications where the risk of leaks outweighs maintenance convenience. Their installation complexity and high durability make them suitable for critical systems. On the other hand, threaded flanges are ideal for temporary setups, low-risk plumbing, and systems requiring frequent disassembly. Their ease of installation and maintenance suits budget-sensitive projects where skilled threading personnel are available.

Choosing between socket weld and threaded flanges depends on the application’s pressure needs, space constraints, and maintenance frequency.

Socket weld flanges are highly resistant to vibration due to their welded joints, which provide a strong, stable connection that minimizes movement. This characteristic makes them particularly suitable for environments with significant vibration, such as those involving pumps and compressors. Additionally, these flanges maintain alignment under thermal expansion, reducing the risk of loosening from vibration. Despite these advantages, it’s crucial to ensure high-quality welding to prevent stress cracks in high-frequency vibration settings.

In high-vibration environments, threaded connections may loosen unless thread-locking compounds are applied. This susceptibility can lead to misalignment or back-out under mechanical stress. Moreover, contaminants can become trapped between threads, accelerating corrosion and weakening the joint. Therefore, threaded flanges are most effective in low-to-medium vibration applications, such as HVAC systems and light industrial setups.

Socket weld flanges are ideal for high-pressure, high-temperature applications like oil and gas pipelines and chemical reactors, despite requiring skilled installation. Their durability and reliability make them a preferred choice in sectors such as petrochemical and heavy manufacturing.

Threaded flanges are better suited to low-to-medium pressure environments, such as water supply systems and compressed air lines. They offer the advantage of easy maintenance and quick disassembly, which is beneficial for systems requiring frequent access, such as residential plumbing and HVAC systems. Their lower initial costs and straightforward installation make them appealing for cost-sensitive projects.

Recent trends show a growing preference for socket weld flanges in high-purity systems, such as those in the semiconductor and pharmaceutical industries, due to their leak-proof capabilities. These industries demand the highest standards of cleanliness and reliability, which socket weld flanges can provide effectively.

In parallel, the use of advanced non-destructive testing methods, such as ultrasonic inspections, is on the rise for socket welds in vibration-heavy systems. These methods help detect micro-cracks early, ensuring the integrity and safety of the piping systems in demanding applications.

When comparing socket weld and threaded flanges, initial installation costs are a major factor to consider. Socket weld flanges require skilled labor and specialized equipment for welding, which increases both the time and expense involved in their installation. This precise execution is necessary to create a leak-proof seal, making them ideal for high-pressure systems but costly upfront. In contrast, threaded flanges offer a more economical installation process. They do not require welding, reducing the need for specialized skills and equipment, thus making threaded flanges a cost-effective choice for projects where budget constraints are a priority.

The maintenance costs associated with socket weld and threaded flanges vary considerably. Socket weld flanges, once installed, are difficult to disassemble, necessitating cutting or re-welding for maintenance. This complexity can lead to higher maintenance costs over time. Conversely, threaded flanges allow for easier disassembly and reassembly, facilitating quicker repairs and modifications. This ease of maintenance results in lower long-term costs, making threaded flanges advantageous in systems that require frequent updates or part replacements.

Socket weld flanges are known for their superior sealing efficiency and strength, making them reliable in high-pressure and high-temperature environments. Their welded connections minimize leakage risks and withstand operational stresses better than threaded flanges. However, the complexity of maintaining socket weld flanges can sometimes outweigh their benefits. Threaded flanges, while potentially less reliable in high-pressure scenarios due to thread vulnerabilities, offer simplicity in maintenance and replacement, which can prolong system usability in low-pressure settings.

Comparative Analysis:

Choosing between socket weld and threaded flanges requires careful consideration of both initial and long-term costs, as well as the specific demands of the system in question. Factors such as pressure requirements, maintenance frequency, and budget constraints play critical roles in determining the most suitable flange type for any given application.

Socket weld flanges are crucial in high-pressure applications, with standards defined by ASME and ISO ensuring their reliability and performance.

Threaded flanges are governed by standards set by organizations like ANSI and ASME, focusing on their application in low-pressure systems. These standards ensure compatibility with various threaded pipe systems and maintain safety and reliability.

| Aspect | Socket Weld Flanges | Threaded Flanges |

|---|---|---|

| Material Standards | ASME, ISO (high-grade alloys) | ANSI, ASME (cast iron, carbon steel) |

| Dimensional Compliance | Strict (socket depth, flange thickness) | Moderate (thread dimensions) |

| Pressure Ratings | High (for demanding environments) | Low (for residential or small-scale) |

| Installation Standards | Requires skilled welding per ASME guidelines | Easy threading, per ANSI standards |

Both socket weld and threaded flanges are designed to meet specific standards, ensuring their suitability for various applications. Socket weld flanges offer superior strength and are compliant with stringent high-pressure standards, making them ideal for industrial applications. In contrast, threaded flanges are simpler to install and comply with standards suitable for low-pressure environments, offering ease and cost-effectiveness for less critical systems.

In the oil and gas industry, choosing the right type of flange—socket weld or threaded—is crucial due to the challenging conditions involved.

Socket weld flanges are preferred for high-pressure pipelines and critical connections where leak prevention is paramount. Their welded joints offer strong resistance to the high pressures and temperatures common in oil and gas extraction and transport, making them ideal for mainline connections and high-pressure sections.

Threaded flanges are used in less critical applications within the industry, where ease of maintenance and installation is more important than high-pressure performance.

Pharmaceutical manufacturing demands strict hygiene and precision, influencing the choice between socket weld and threaded flanges.

Socket weld flanges are preferred for maintaining sterility, which is essential in pharmaceutical production.

Threaded flanges are used in non-sterile areas where flexibility and ease of maintenance are prioritized.

Water treatment facilities require robust and reliable connections to handle varying pressure and chemical exposure.

Socket weld flanges are employed in high-pressure and critical sections of water treatment plants.

Threaded flanges are used in areas where ease of access and flexibility are more important than pressure handling.

Below are answers to some frequently asked questions:

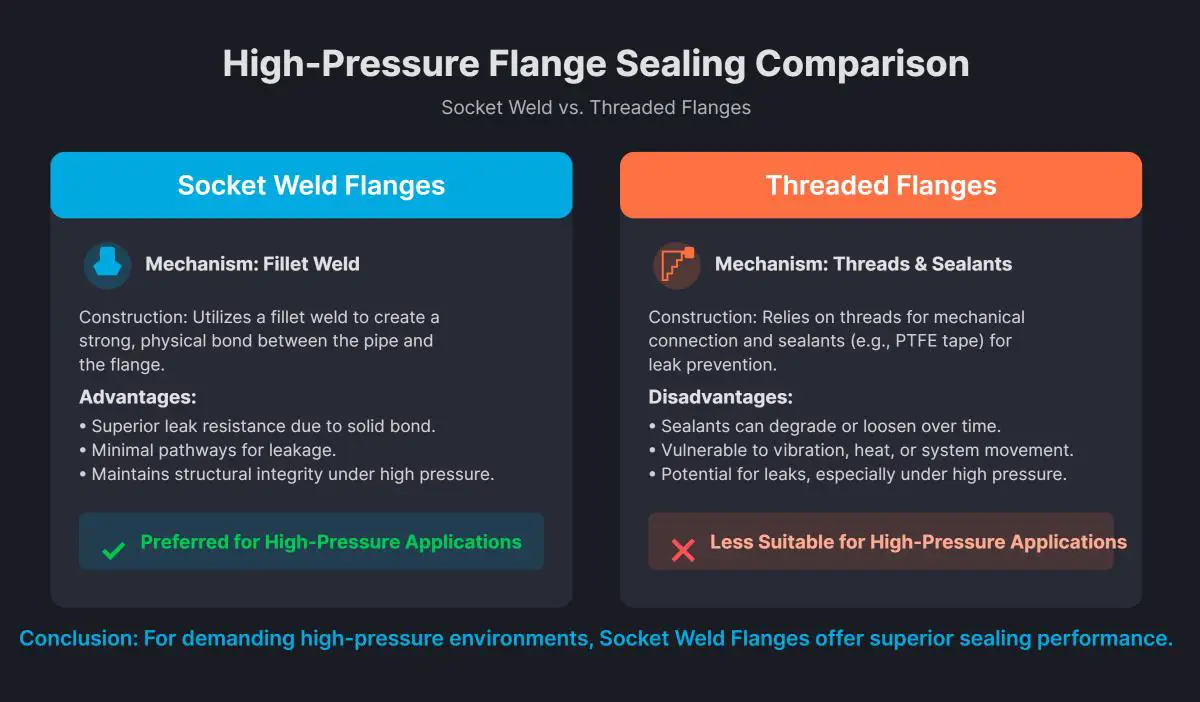

Socket weld flanges provide better sealing under high pressure compared to threaded flanges. This is due to the nature of their construction: socket weld flanges use a fillet weld to create a strong, leak-resistant connection that physically bonds the pipe to the flange. This method ensures minimal pathways for leakage and maintains integrity under high-pressure conditions. In contrast, threaded flanges rely on threads and sealants such as PTFE tape, which can degrade or loosen over time due to vibration, heat, or system movement, potentially leading to leaks. Therefore, for high-pressure applications, socket weld flanges are generally the preferred choice.

Threaded connections should be chosen over socket weld connections when the operational conditions involve low-pressure systems, typically with small diameters (≤2 inches), where frequent disassembly and maintenance are necessary. This is common in applications like HVAC systems or residential plumbing. Threaded flanges offer advantages in ease of installation and maintenance, as they require no specialized welding equipment or skills, making them cost-effective for temporary setups or systems needing regular access. They are ideal for scenarios where quick assembly and disassembly are needed without compromising system integrity. However, they are not suitable for high-pressure, high-temperature, or critical environments where leak-proof performance is essential, as these conditions favor the use of socket weld connections. Additionally, threaded connections are beneficial in environments where avoiding thread galling or seizing is crucial, such as in moderate chemical exposure situations.

Vibration affects threaded and socket weld connections differently due to their inherent design characteristics. Socket weld connections are generally more resistant to vibration because the welded joints create a rigid, monolithic structure that can withstand dynamic stresses and pressure surges effectively. Proper welding techniques, such as maintaining optimal weld geometry and avoiding defects, are crucial to enhancing fatigue resistance and preventing premature cracking under cyclic loads.

In contrast, threaded connections are more susceptible to loosening when exposed to vibration. The mechanical engagement of threads can lead to wear and galling, especially under repeated vibrational fretting. This can create leak paths and necessitate frequent maintenance, such as torque checks and the use of locking compounds or secondary seal welds to mitigate failures. Consequently, in high-vibration environments, socket weld connections are preferred for their durability and reliability, while threaded connections might be suitable for less critical applications or where ease of disassembly is required.

Socket weld and threaded flanges have specific compliance standards that guide their use in piping systems. Socket weld flanges typically adhere to ASME B16.5, which covers dimensions and weights for flanges from Class 150 to Class 1500, and ASME B31.1, which outlines installation and welding procedures. This ensures they are suitable for high-pressure applications, especially for smaller-diameter pipes up to NPS 4, where precise installation is critical for performance.

Threaded flanges generally follow ASME B16.5 for dimensions, although they are not explicitly covered under this standard for threading. MSS SP-44 provides additional guidance, though it is less commonly referenced. Threaded flanges are suitable for lower-pressure applications where welding is impractical, and frequent disassembly is required. Understanding these standards helps engineers choose the appropriate flange type based on system requirements, pressure levels, and installation practices.

Installation costs for threaded flanges are generally lower compared to socket weld flanges due to differences in labor, materials, and technical requirements. Threaded flanges require minimal skilled labor as they are installed by simply aligning and tightening threads, which is faster and involves basic tools. This reduces labor hours significantly since no welding or post-installation processes are necessary. Additionally, threaded flanges avoid the costs associated with welding consumables and equipment, and they are ready for immediate use after installation without further testing.

In contrast, socket weld flanges necessitate certified welders for installation, which increases labor costs due to the time-intensive welding process, inspection, and potential heat treatment. They also require additional materials like electrodes and welding machines, further elevating costs. Despite the higher upfront costs, socket weld flanges may be justified in high-pressure systems where superior leak resistance is crucial, whereas threaded flanges are more cost-effective for low-pressure, non-critical systems. Overall, threaded flanges can offer installation cost savings of approximately 30-50% compared to socket weld flanges.

Socket weld flanges are most beneficial in industries such as chemical and petrochemical, oil and gas, and power generation. These industries demand high-pressure, high-temperature resistance, and robust, leak-proof connections, which socket weld flanges provide. Their ability to handle harsh environments and prevent moisture accumulation makes them ideal for critical applications where reliability and corrosion resistance are paramount.

Threaded flanges, on the other hand, are best suited for industries with low to medium pressure requirements, such as HVAC, water treatment, and food processing. Their ease of installation and disassembly, along with cost-effectiveness, makes them suitable for systems requiring frequent maintenance or modifications. They are also advantageous in the pharmaceutical industry, where cleanliness and the ability to quickly adjust or inspect connections are critical.