In the intricate world of fluid control systems, choosing the right valve can make all the difference in efficiency and safety. Two of the most pivotal components in this realm are the solenoid valve and the shut-off valve, each with its unique attributes and applications. But what sets these two valves apart, and how do you determine which is best suited for your needs? This article unravels the mysteries surrounding these essential devices, delving into their mechanisms, advantages, and ideal use cases. Whether you’re managing an industrial system or a residential setup, understanding the distinct characteristics and applications of solenoid and shut-off valves can significantly enhance your decision-making process. So, which valve will reign supreme in your fluid control strategy? Let’s explore.

Fluid control systems are essential components in various industries, managing fluid flow, pressure, and direction to ensure efficient and safe operations. These systems play a pivotal role in sectors such as manufacturing, chemical processing, water treatment, HVAC, and automotive engineering. By precisely controlling fluid dynamics, they optimize performance, reduce waste, and enhance safety.

Valves are crucial elements within fluid control systems, responsible for regulating, directing, and controlling fluid flow. Each type of valve serves specific purposes, characterized by unique operational principles and features.

Solenoid valves are electrically actuated devices that utilize an electromagnetic coil to control the opening and closing of the valve. Their rapid response times make them ideal for applications requiring quick and precise control, such as automated systems and emergency shut-offs.

Shut-off valves are designed to completely halt the flow of fluids. They can be either manually or automatically actuated, depending on system requirements. These valves are vital for safety-critical applications and maintenance activities where reliable flow cessation is necessary.

Ball valves control fluid flow using a spherical disc, offering reliable shut-off with minimal leakage. They are commonly used in applications that require tight sealing and efficient flow control.

Gate valves function by lifting a gate to allow fluid flow or lowering it to block the flow. They are typically used in applications where a straight-line flow with minimal restriction is desired, suitable for on/off control but not for throttling.

Needle and globe valves are designed for precise flow control. Needle valves feature a slender, tapered point that allows fine flow adjustments, making them ideal for instrumentation and calibration systems. Globe valves regulate fluid flow by moving a disc or plug against a stationary ring seat, providing precise control in systems requiring accurate flow regulation.

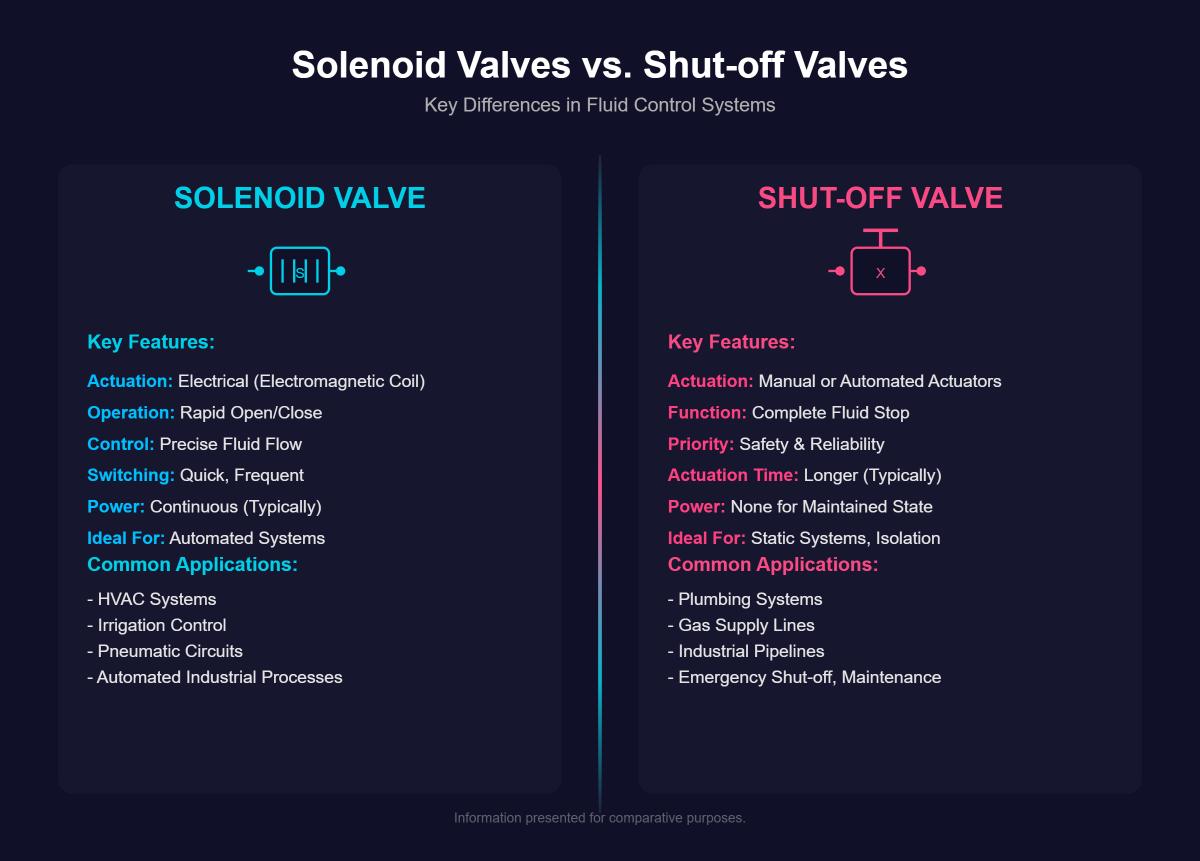

Understanding the differences between various valve types aids in selecting the appropriate valve for specific applications. Below is a comparative analysis focusing on solenoid valves and shut-off valves.

Regular maintenance is crucial to ensure the longevity and performance of valves. For instance, solenoid valves in a factory setting might need regular checks to ensure electromagnetic parts are functioning well, especially in high-use areas. Shut-off valves, being generally simpler and more robust, require less frequent maintenance, making them ideal for applications where reliability and ease of maintenance are critical.

A solenoid valve is an electromechanical device that controls the flow of fluids, including gases and liquids, by using an electric coil to move a plunger. It efficiently manages fluid flow by opening or closing pathways in response to electrical signals.

The operation of solenoid valves is based on electromagnetism. When electricity flows through the coil, it creates a magnetic field that moves the plunger to open or close the valve, controlling the fluid flow. This rapid movement allows for precise regulation in various applications.

Solenoid valves can be either direct-acting or pilot-operated. In direct-acting valves, the plunger directly controls the flow, making them suitable for low flow and pressure scenarios. Pilot-operated valves use a small pilot flow to actuate a larger valve, ideal for managing higher pressures and flows.

Solenoid valves perform essential tasks across diverse industries:

Solenoid valves offer several benefits, including rapid response and precise control, making them perfect for automated systems. However, they require constant electricity to operate, which can increase energy costs. Additionally, their complexity might necessitate more frequent maintenance compared to simpler valve types.

A shut-off valve is an essential component in fluid control systems, designed to regulate the flow of fluids like water, gas, or oil within a pipeline. Its primary function is to isolate sections of a system for maintenance, repair, or emergencies, providing a reliable way to control fluid dynamics without affecting the entire system. Shut-off valves can be manually operated or automatically controlled, depending on the specific requirements of the application.

Shut-off valves operate through a simple mechanical mechanism, which can be manually actuated using handles, levers, or wheels. Some designs incorporate automatic actuation, using electric or pneumatic actuators for remote control. The valve functions by moving a component, such as a disc or gate, into the flow path to stop fluid movement.

Several types of shut-off valves are available, each suited for different applications and system requirements:

Advantages

Disadvantages

Understanding the specific features and capabilities of shut-off valves enables effective selection and integration into fluid control systems, ensuring efficient and safe operation tailored to various industrial and residential needs.

Shut-off valves are used to manually or mechanically control fluid flow, either stopping or allowing it. These valves are operated using a handle, lever, or wheel, providing a simple yet effective method for halting fluid movement. They are crucial for quickly stopping flow during emergencies like pipe bursts, leaks, or equipment failures to minimize damage. Moreover, they enable isolating parts of a system for repair or replacement without shutting down the entire network, crucial for large-scale plumbing systems. Common types of shut-off valves include gate valves, ball valves, butterfly valves, and plug valves.

Solenoid valves use an electromagnetic solenoid coil to open or close the valve, enabling remote and automatic fluid control in automated systems. These valves are integral to applications requiring precise, rapid switching of flow in response to electrical signals, making them prevalent in industrial automation, HVAC, irrigation, and fluid control systems.

Different types of shut-off valves serve various purposes:

Shut-off valves are indispensable in residential plumbing systems, controlling water supply to fixtures and serving as emergency shut-offs in municipal water and gas lines. They are also used in industrial process lines for maintenance isolation and in irrigation systems to segment water delivery efficiently. Their simplicity and reliability, along with the lack of need for electrical power, make them a cost-effective solution for emergency flow control and maintenance isolation. While manual operation can be slower in urgent situations, shut-off valves are a robust and straightforward choice where fast cycling or precise flow control is not required.

Solenoid valves are ideal for applications needing quick, frequent switching and automated control. Their remote operation and easy integration make them perfect for precise, responsive environments.

In manufacturing and chemical industries, solenoid valves play a crucial role in automated process control systems. These environments require precise timing and rapid actuation to regulate fluid flow accurately, ensuring optimal performance and safety. Additionally, in emergency situations such as fire suppression or gas line cut-offs, solenoid valves are invaluable. Their rapid response can quickly halt fluid flow, preventing accidents and minimizing damage.

Solenoid valves are well-suited for pneumatic or hydraulic systems. They operate efficiently under moderate pressures, offering reliable control tailored to specific pressure requirements, ensuring efficient fluid management.

Their compact and lightweight design makes solenoid valves ideal for installations where space is limited. They can be easily integrated into tight spaces without compromising performance.

Solenoid valves equipped with power reduction or latching coils are beneficial in systems that prioritize energy efficiency. These valves reduce power consumption during holding, making them cost-effective for long-term use.

Solenoid valves are also used in specialized applications such as vacuum systems, media-separation valves for corrosive fluids, and scenarios requiring adjustable response times and low noise operation. Their versatility allows them to meet the unique demands of various industries.

Shut-off valves excel in applications demanding reliability, safety, and complete fluid isolation. These valves are straightforward in design and operation, making them ideal for scenarios where manual control is preferred or automation is unnecessary.

In residential and commercial plumbing systems, shut-off valves are essential for controlling water supply at mains and individual fixtures. They are also crucial in gas supply lines, providing reliable shut-off during emergencies to ensure safety.

Shut-off valves are designed to handle higher pressures and larger flow volumes, making them suitable for high-pressure systems and large diameter pipes. Their robust construction ensures they can withstand demanding conditions.

For systems that do not require rapid or frequent switching, shut-off valves are ideal. They provide secure closure and are reliable in applications where fluid flow needs to be stopped infrequently but effectively.

In situations where electrical power may be unavailable, manual shut-off valves serve as reliable backup or emergency isolation mechanisms. They allow for maintenance and repair without the need for automation.

Shut-off valves can be manually operated or fitted with pneumatic or electric actuators for semi-automation. This versatility allows them to be tailored to the specific needs of various systems, providing flexible control options.

Selecting the appropriate valve for a fluid control system requires careful consideration of several factors, including system requirements, environmental conditions, and compliance with safety standards.

Evaluate the operational speed, control precision, pressure and flow conditions, and the degree of automation needed. Solenoid valves are preferable for fast and frequent switching, while shut-off valves are better suited for reliable full isolation.

Consider the installation environment, including space constraints, exposure to corrosive fluids, and temperature variations. Solenoid valves are ideal for compact and automated settings, while shut-off valves excel in rugged and high-pressure environments.

Ensure that the chosen valve meets relevant safety standards and regulations. Both solenoid and shut-off valves have specific applications where compliance with industry standards is critical for safe and efficient operation.

Understanding these factors will help in selecting the optimal valve type for specific fluid control applications, ensuring efficient and reliable system performance.

Automated irrigation systems in large-scale applications, such as parks and gardens, rely heavily on solenoid valves because they can quickly control water flow from a distance. These systems often operate on predetermined schedules or respond to moisture sensors, optimizing water use and conserving energy. The rapid response capability of solenoid valves ensures precise control over watering patterns, allowing for efficient resource management. In contrast, shut-off valves are typically reserved for emergency isolation or maintenance tasks within these systems, providing a reliable method for halting flow when necessary.

In the context of high-pressure natural gas pipelines, shut-off valves, particularly ball valves, are preferred due to their robust mechanical construction and reliability in completely isolating flow. These valves are generally operated manually or via motor-driven actuators, focusing on safety and durability rather than speed. Their design ensures fail-safe operation during emergencies or scheduled maintenance, prioritizing secure fluid isolation. While solenoid valves offer rapid switching, the focus in pipeline applications is on reliability and safety, making shut-off valves the ideal choice.

Solenoid valves are integral to HVAC systems, where they regulate airflow and refrigerant flow dynamically. They can respond within milliseconds, allowing for precise temperature and pressure control, enhancing energy efficiency and system performance. Solenoid valves facilitate automated control, adapting to varying conditions swiftly. However, shut-off valves also play a role in HVAC systems, mainly used as backup isolation points during maintenance. Their reliable closure capability ensures safe operations when sections of the system require servicing.

In chemical processing plants, solenoid valves are pivotal for controlling fluid flow in automated production lines. These valves enable quick responses and easy integration with control systems, essential for managing aggressive fluids and maintaining precise operational conditions. Protective measures are often necessary to shield solenoid coils from corrosive environments. Shut-off valves complement solenoid valves in these settings, providing dependable isolation points for emergency shutdowns or routine maintenance, ensuring system integrity and safety.

When installing valves in fluid control systems, it’s essential to consider space constraints and accessibility to ensure optimal performance. Solenoid valves are particularly suited for environments where space is limited due to their compact and lightweight design. Their small footprint allows for easy integration into automated systems, even in confined areas. This makes them ideal for applications requiring rapid actuation and frequent cycling, such as HVAC systems and automated industrial processes.

In contrast, shut-off valves may require more space due to their typically larger size and manual operation components. While this can be a limitation in tight installations, their simplicity and robustness often compensate for the spatial demands. Shut-off valves are well-suited for applications where manual operation is preferred or where automation is not a priority, such as in plumbing systems and gas pipelines.

Power requirements significantly differ between solenoid and shut-off valves. Solenoid valves, like those used in automated coffee machines, require a constant power supply to operate efficiently. This continuous energy consumption is necessary to maintain the valve’s open or closed position, which is advantageous in applications requiring rapid response and precise control.

Shut-off valves do not require continuous power, making them advantageous in systems where energy efficiency is a priority. Manual shut-off valves need no power source, relying entirely on human intervention for operation. This feature makes them suitable for emergency applications where power may be unavailable or unreliable.

Solenoid valves are generally easy to maintain. They have replaceable components, such as solenoid coils, which can be swapped out quickly. This reduces downtime significantly. However, solenoid valves may require more frequent maintenance due to their electromagnetic components and higher cycle rates.

Shut-off valves, by contrast, are simpler in design, which often results in greater reliability and lower maintenance needs. Their robust construction reduces the likelihood of frequent repairs, making them ideal for applications where minimal maintenance is desired. However, manual shut-off valves may necessitate periodic inspections to ensure proper function, especially in critical safety applications.

The process of replacing components also differs between solenoid and shut-off valves. Solenoid valves typically have internal components that can be replaced easily, such as coils and diaphragms, which can be swapped out with minimal disruption to operations. This ability to replace parts easily is beneficial in systems where downtime must be minimized.

Shut-off valves, while having fewer replaceable components, require physical interaction for maintenance tasks. This can increase maintenance time if adjustments or repairs are needed, particularly in large or complex systems. Despite this, their straightforward design often results in longer service intervals and greater overall durability.

Below are answers to some frequently asked questions:

Solenoid valves and shut-off valves serve distinct functions in fluid control systems, with significant differences in their operation and application. A solenoid valve is an electrically actuated device that uses an electromagnetic coil to rapidly open or close the valve, allowing precise control of fluid flow in automated systems. They are ideal for applications requiring quick, frequent switching, such as in HVAC systems, irrigation, and pneumatic circuits. Solenoid valves require continuous power to maintain their state, except for latching types, and can handle a wide range of temperatures and flow rates.

In contrast, a shut-off valve is designed to completely stop fluid flow and can be manually operated or equipped with automated actuators. These valves prioritize safety and reliability, making them suitable for static systems like plumbing, gas supply lines, and industrial pipelines. Shut-off valves typically have longer actuation times and do not require continuous power, making them effective for emergency shut-off scenarios and maintenance activities.

The primary differences lie in their actuation methods, response times, power requirements, and typical applications. Solenoid valves excel in automated, high-speed environments, while shut-off valves are better suited for safety-critical and manual override situations.

When deciding between a solenoid valve and a shut-off valve, consider the specific application requirements. Solenoid valves are ideal for situations demanding rapid response and automation, such as in industrial process control, HVAC systems, or medical equipment. They are electromechanically actuated and can swiftly regulate fluid flow, making them suitable for automated systems that integrate with programmable logic controllers (PLCs).

On the other hand, shut-off valves are preferable for applications where manual control is sufficient, such as emergency isolation or systems requiring infrequent adjustments. They excel in high-pressure or high-flow environments where durability is paramount. Shut-off valves are typically more cost-effective for manual operations, though motorized variants exist for basic automation needs.

Solenoid valves enhance fluid control in automated systems through their electromagnetic actuation, which provides precise and rapid operation. This mechanism allows solenoid valves to open and close quickly, offering high accuracy in flow modulation and timing, essential for systems requiring precise control. They can be integrated with modern automation technologies like IoT and cloud-based systems, enabling remote operation without manual intervention. This capability not only improves system responsiveness but also facilitates real-time monitoring and maintenance. Solenoid valves are versatile, handling various fluids such as air, water, and gas, and are used across industries from automotive to water treatment. By automating processes, they reduce labor costs and improve efficiency, positioning them as a superior choice for complex fluid control compared to traditional shut-off valves, which primarily offer manual isolation functions.

Solenoid valves and shut-off valves have distinct maintenance requirements due to their different operational mechanisms and roles in fluid control systems. Solenoid valves, being electromechanically operated, demand more frequent and detailed maintenance. Typically, they require inspection every 6 to 12 months, focusing on cleaning internal components to remove debris and corrosion, and checking electrical parts like coils for moisture or damage. Key components such as seals, O-rings, and diaphragms should be inspected for wear and replaced if necessary to prevent leaks and ensure functionality.

In contrast, shut-off valves, which are often manually operated, have simpler maintenance needs. They require less frequent checks, primarily focused on mechanical integrity. Regular operation of the valve can help detect any stiffness or binding, indicating potential issues like corrosion or deposit build-up. Inspecting and replacing worn packing and seals is essential to maintain leak-tight performance. Shut-off valves also benefit from occasional lubrication of moving parts and external cleaning to prevent mechanical wear.

Solenoid valves and shut-off valves are not typically interchangeable due to their distinct design, functionality, and applications. A solenoid valve is electrically operated, allowing for rapid and precise control of fluid flow. It’s ideal for automated systems where quick switching and remote operation are crucial, such as in industrial automation and irrigation systems.

In contrast, a shut-off valve is usually manually or mechanically controlled, making it suitable for applications requiring complete isolation of fluid flow, such as in maintenance or emergency shutdown scenarios. Shut-off valves are preferred for high-pressure environments where safety and reliability are paramount.

While both valves serve the purpose of controlling fluid flow, the choice between them depends on factors like control method, speed of operation, and specific application requirements. Therefore, they should be selected based on the particular needs of the system rather than used interchangeably.

When selecting valves for fluid control systems, ensuring compliance with relevant safety standards is paramount. Key standards include ISO 9001 and ISO 14001, which focus on quality and environmental management, ensuring consistent manufacturing and sustainable practices. The IEC 60534 standard pertains to industrial valve performance, while IEC 61508 and IEC 61511 address functional safety, crucial for solenoid valves due to their electrical components. The Pressure Equipment Directive (PED) 2014/68/EU mandates safety in pressurized systems, ensuring valves can withstand specified conditions without failure. ANSI/ASME B16 standards are essential for understanding pressure-temperature ratings and material compatibility. UL and CSA certifications verify electrical safety, particularly for solenoid valves, while ATEX/IECEx certifications are necessary for valves in explosive environments. These standards collectively ensure that both solenoid and shut-off valves operate safely and reliably in diverse applications, as discussed earlier in the article.