When it comes to choosing the right metal for your project, the decision between stainless steel and iron can be a tough one. Both materials have unique properties that make them suitable for various applications, but understanding their differences is crucial. Stainless steel boasts excellent corrosion resistance and high tensile strength, while iron, especially cast iron, offers cost – effectiveness and great heat retention. But which is truly more durable in different environmental conditions?

In this comprehensive comparison, we’ll delve into material properties, advantages, and industrial applications of these metals. So, are you ready to discover which metal reigns supreme for your needs?

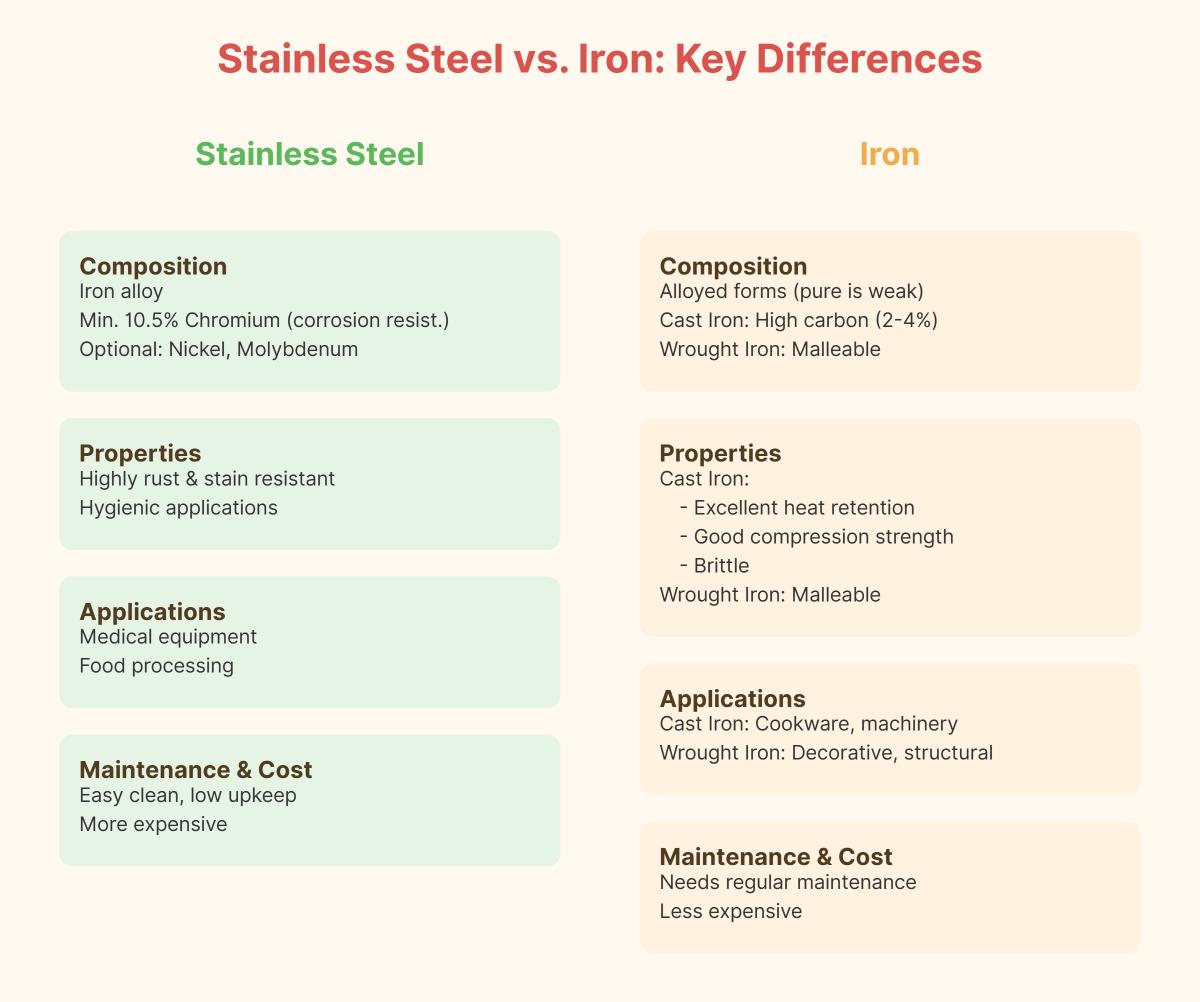

Stainless steel is a high-alloy material primarily composed of iron, with at least 10.5% chromium. Other elements such as nickel and molybdenum are also added to enhance its strength and corrosion resistance. The chromium in stainless steel forms a protective oxide layer on the surface, which is the key to its excellent anti-rust and anti-corrosion properties.

Pure iron has weak mechanical properties, so it is rarely used industrially in its pure form. Instead, it is often alloyed with carbon to form different types of materials. For example, cast iron has a high carbon content, which makes it hard but brittle. Wrought iron, on the other hand, has a low carbon content and is more ductile.

Cast iron is an alloy of iron and carbon, with a relatively high carbon content (usually 2-4%). This high carbon content gives it unique properties compared to other forms of iron and stainless steel. Cast iron has a lower tensile strength compared to stainless steel and is highly susceptible to corrosion without proper surface treatment.

| Material | Tensile Strength | Corrosion Resistance |

|---|---|---|

| Stainless Steel | High (500 MPa – over 2,000 MPa) | Excellent, due to self-healing chromium oxide layer |

| Iron (Cast) | Low (150 – 200 MPa) | Prone to rust, needs surface treatment |

| Iron (Wrought) | Lower than stainless steel, more ductile | Some resistance due to low carbon content |

Stainless steel is typically more durable than iron. Thanks to its chromium content, which forms a protective layer, stainless steel resists corrosion effectively. This protective layer can self – heal when damaged, ensuring long – term integrity, whereas iron, especially in its pure or wrought forms, is much more vulnerable to corrosion.

In terms of mechanical stress, stainless steel’s high tensile strength, which can range from 500 MPa to over 2,000 MPa depending on the grade, allows it to withstand stretching and pulling forces with ease. Cast iron has lower tensile strength, around 150 – 200 MPa, and is more prone to cracking under impact.

Stainless steel’s resistance to corrosion makes it ideal for harsh environments. It can be used in moist environments or applications involving corrosive substances without significant degradation. Iron, however, deteriorates rapidly in the presence of moisture and oxygen. For instance, in coastal areas where the air is salty and humid, stainless steel structures will maintain their integrity for much longer than iron structures.

Stainless steel requires minimal maintenance. Its corrosion resistance and durability mean that it can last for a long time with little upkeep. In contrast, cast iron requires more maintenance. For example, it needs regular seasoning to prevent rust, and wrought iron may need periodic application of protective coatings. Over time, the maintenance costs of iron can be significantly higher than those of stainless steel.

Stainless steel’s durability edge over cast iron is quite evident. Cast iron is brittle, making it prone to cracking under impact. In applications where there is a risk of mechanical shock, stainless steel is a far better choice. Stainless steel’s ability to resist corrosion also gives it an advantage over cast iron, which rusts easily without proper treatment.

In outdoor environments or areas with high humidity, stainless steel maintains its durability. Cast iron, however, will start to rust if not protected. Even with protective coatings, these can wear off over time, leaving the cast iron exposed to the elements.

Cast iron requires more maintenance. Regular seasoning is necessary to prevent rust, and any chips or scratches in the surface must be addressed promptly to avoid corrosion. Stainless steel, with its self – healing oxide layer, can withstand normal wear and tear without the need for frequent maintenance.

Stainless steel is commonly used in chemical plants and oil refineries because it resists corrosion and is highly durable. Specific grades like 304 and 316 are preferred as they can withstand harsh chemical environments without degrading, ensuring the longevity and safety of equipment such as storage tanks, pipelines, and reactors.

In the food and beverage industry, stainless steel is ideal for making equipment, containers, and utensils because it’s easy to clean and non-porous. Its resistance to rust and ability to maintain hygiene standards are crucial for preventing contamination and ensuring the safety of consumable products.

Stainless steel is popular in architecture and construction for its strength and aesthetic appeal, used in beams, columns, and facades. Additionally, it is employed in decorative elements such as railings, cladding, and sculptures due to its modern appearance and resistance to weathering.

Stainless steel’s ability to resist corrosion and withstand high temperatures is highly valued in the medical and aerospace industries. It is used to manufacture surgical instruments, medical devices, and implants due to its biocompatibility and durability. In aerospace, stainless steel is utilized in components that require high strength and corrosion resistance, such as fasteners, exhaust systems, and structural parts.

Iron, particularly in its cast form, is extensively used in construction and heavy machinery. Cast iron’s high compressive strength makes it suitable for engine blocks, gearboxes, and machine bases. Its durability under compressive forces is essential for these applications, where structural integrity and longevity are paramount.

In the automotive sector, iron is utilized for manufacturing various components due to its strength and cost – effectiveness. Cast iron is commonly used for engine blocks, brake rotors, and other parts that require high wear resistance and heat retention.

Cast iron is perfect for cookware like skillets, pots, and pans because it retains heat well. Additionally, its durability and aesthetic appeal are appreciated in decorative items like benches, lampposts, and fences.

Cast iron is perfect for cookware like skillets, pots, and pans because it retains heat well.

Cast iron pipes are used in plumbing and drainage because they are durable and wear – resistant. In the automotive industry, cast iron is employed for engine blocks, cylinder heads, and other components that benefit from its high strength and ability to withstand thermal stress.

| Application Area | Stainless Steel | Iron (Cast and Wrought) |

|---|---|---|

| Chemical and Oil Industries | High corrosion resistance; used in reactors, storage tanks | Limited use; prone to corrosion |

| Food and Beverage Sector | Non – porous, easy to clean; used in equipment and utensils | Limited use; requires protective coatings |

| Architecture and Construction | Strong and aesthetic; used in structural and decorative elements | Cast iron used in heavy – duty applications |

| Medical and Aerospace Industries | Corrosion – resistant and durable; used in instruments and components | Limited use; not suitable for high – stress applications |

| Cookware | Limited use; generally too expensive for everyday cookware | Excellent heat retention; used in skillets and pots |

| Automotive Industry | High – strength components for specific applications | Widely used in engine blocks and brake rotors |

Stainless steel production is notable for its high recyclability. Typically, stainless steel contains 60% to 70% recycled content, which significantly reduces the need for primary raw materials. Recycling stainless steel uses much less energy than producing it from raw materials. Additionally, advancements in manufacturing practices have led to further reductions in energy use, with some mills achieving up to a 70% decrease in energy consumption over the past two decades.

In contrast, iron production, particularly primary steelmaking, is highly energy-intensive. The iron and steel industry is a major contributor to global greenhouse gas (GHG) emissions, accounting for about 7% of global GHG emissions and 11% of CO2 emissions. Traditional iron production heavily relies on fossil fuels, making it challenging to cut emissions. However, emerging technologies such as using clean hydrogen for the direct reduction of iron ore offer promising pathways for decarbonization, potentially reducing the environmental impact of iron production.

Stainless steel is 100% recyclable without losing its inherent properties, making it an ideal material for a circular economy. This high recyclability significantly reduces waste and conserves natural resources. When stainless steel products reach the end of their life, they can be easily recycled, reducing environmental impact and landfill use.

Iron-based products, including cast and wrought iron, are also recyclable, but their recycling processes are often less efficient compared to stainless steel. While steel products have high recycling rates, the recycled material may not always retain the original quality and properties. Proper recycling of iron products is crucial for effective end-of-life management. If not managed correctly, iron products can contribute to environmental degradation through rust and pollution.

| Material | Production Energy Intensity | Emissions | Recyclability | End-of-Life Impact |

|---|---|---|---|---|

| Stainless Steel | Lower (due to recycling) | Lower | High | Minimal |

| Iron | Higher (energy-intensive) | Higher | Moderate | Potential for degradation if not recycled properly |

Below are answers to some frequently asked questions:

Stainless steel and iron are both widely utilized materials in various industries, but they differ significantly in composition, properties, and applications.

Stainless steel is an alloy primarily composed of iron, with at least 10.5% chromium added to enhance corrosion resistance. Additional elements such as nickel and molybdenum can be included to further improve strength and durability. This composition makes stainless steel highly resistant to rust and staining, which is why it is favored in applications requiring high hygiene standards, like medical equipment and food processing.

Iron, on the other hand, is typically used in its alloyed forms, such as cast iron or wrought iron, due to its inherent weakness in pure form. Cast iron, with a high carbon content (2-4%), is known for its excellent heat retention and compression strength but is brittle. It is commonly used in cookware and heavy machinery parts. Wrought iron, which is malleable, is often used for decorative and structural purposes.

In terms of maintenance, stainless steel is easier to clean and requires less upkeep due to its corrosion resistance. However, it is generally more expensive than iron. Iron, particularly cast iron, needs regular maintenance to prevent rust and ensure longevity.

Stainless steel is generally more durable than cast iron due to its superior corrosion resistance and lower maintenance requirements. Stainless steel, with its high chromium content, resists rust and staining effectively, making it ideal for environments with high moisture or exposure to corrosive substances. This characteristic ensures longevity with minimal upkeep. Cast iron, while highly durable and excellent in heat retention, is more prone to rust if not properly seasoned and maintained. It requires regular care to prevent corrosion and maintain its non-stick properties. Additionally, cast iron is heavier and can crack under sudden temperature changes or mishandling. Therefore, for most applications, stainless steel offers greater durability, particularly in terms of corrosion resistance and ease of maintenance.

Stainless steel and iron each have distinct advantages and disadvantages based on their composition and properties.

Stainless Steel: Advantages:

Disadvantages:

Iron (Cast and Wrought): Advantages:

Disadvantages:

Choosing between stainless steel and iron depends on the specific requirements of the application, considering factors like cost, maintenance, durability, and environmental conditions.

Stainless steel and iron perform differently under various environmental conditions due to their distinct compositions and properties. Stainless steel, which contains chromium, nickel, and sometimes molybdenum, is highly resistant to corrosion. The chromium forms a protective oxide layer that prevents rust, making stainless steel ideal for use in environments with high moisture, such as coastal areas and industrial facilities. This resistance to localized corrosion, including pitting and crevice corrosion, is particularly notable in grades like 316 stainless steel.

Iron, on the other hand, is more susceptible to corrosion because it lacks a protective oxide layer. When exposed to oxygen and moisture, iron rusts quickly, especially in humid or wet environments. This susceptibility is exacerbated by exposure to salts or acids. To mitigate corrosion, iron often requires protective coatings, such as galvanization or painting.

In terms of durability, stainless steel is highly durable, resistant to warping and high temperatures, and requires minimal maintenance. It can be easily cleaned and does not need special care. Iron, particularly cast iron, is also durable when properly maintained, but it requires regular seasoning to prevent rust and is prone to cracking under sudden temperature changes.

Stainless steel, iron, and cast iron each have distinct applications due to their unique properties.

Stainless steel is highly valued for its corrosion resistance, durability, and ease of maintenance, making it ideal for applications such as kitchen utensils, cookware, and appliances in the food and catering industry. It is also widely used in medical equipment, surgical instruments, and environments with harsh conditions like offshore and marine settings. Additionally, its strength and resistance to environmental factors make it suitable for aerospace and automotive components, as well as chemical and power plant systems.

Iron, in its various forms, is fundamental in construction, where it is a key component of steel used for building frameworks and structural elements due to its strength and cost-effectiveness. It is also essential in transportation for manufacturing vehicle parts, including engines, and in electrical systems for wiring and components like transformers.

Cast iron is prized for its excellent heat retention and durability, making it perfect for cookware such as skillets and Dutch ovens, which are ideal for slow cooking and searing. It is traditionally used in manufacturing engine blocks due to its strength and durability. In plumbing, cast iron was historically used for pipes, although modern systems often prefer other materials.

When comparing the costs of stainless steel, iron, and cast iron, iron is generally the least expensive due to its simpler extraction and production processes and the abundance of iron ore. Cast iron is also relatively affordable as its casting process is less complex than steel production, and it’s often cheaper than stainless steel upfront. Stainless steel is more costly because of additional production steps like alloying with elements such as chromium and nickel to enhance corrosion resistance. Different grades of stainless steel can vary significantly in price. In practical terms, for cookware, cast iron is budget – friendly initially, while stainless steel, though a larger initial investment, may offer better long – term value. For industrial applications, the choice depends on specific needs, with iron and cast iron being more cost – effective upfront, and stainless steel a better long – term investment due to its durability and corrosion resistance.