Welding manganese steel can be a daunting task, even for experienced welders. Known for its high impact strength and resistance to abrasion, manganese steel poses unique challenges that require specific techniques to master. One misstep, and you could end up with cracks or embrittlement, compromising the integrity of your weld. This guide is designed to take you through each step of the process, from preparing the steel to selecting the right electrodes and managing heat input. Whether you’re using Shielded Metal Arc Welding (SMAW) or Gas Metal Arc Welding (GMAW), understanding the nuances of each method will help you achieve the best results. Ready to elevate your welding skills and tackle manganese steel like a pro? Let’s dive in.

Manganese steel, commonly known as Hadfield steel or Mangalloy, is an alloy celebrated for its high impact resistance and ability to harden under stress. This material contains approximately 11-14% manganese and 1.0-1.4% carbon, which gives it remarkable toughness and work-hardening properties. These qualities make manganese steel perfect for durable, wear-resistant applications like construction equipment and rock crushers.

Manganese steel is notable for its strength and ductility, remaining tough even under extreme impact, which is crucial for heavy-duty industrial applications. Additionally, the work-hardening characteristic means that the steel becomes harder and more durable as it is subjected to repeated stress, enhancing its lifespan and performance.

However, welding manganese steel presents distinct challenges that must be carefully managed to preserve its beneficial properties. The material’s sensitivity to heat means improper welding can cause embrittlement and cracking. Therefore, understanding the intricacies of welding manganese steel is essential for achieving optimal results.

Given the unique properties of manganese steel, employing the right welding techniques is critical. Incorrect methods can compromise the steel’s integrity, leading to issues such as reduced ductility, cracking, and failure in service. Using correct welding techniques ensures the steel maintains its toughness and work-hardening properties, keeping it suitable for demanding uses.

To successfully weld manganese steel, welders must pay close attention to several factors, including preparation, temperature control, and electrode selection. Each of these elements plays a vital role in preventing heat-induced damage and maintaining the steel’s performance characteristics.

In the following sections, we will delve into specific techniques and best practices for welding manganese steel, providing a comprehensive guide to help you navigate the complexities of this challenging but rewarding material. Whether you are using Manual Shielded Metal Arc Welding (SMAW) or Gas Metal Arc Welding (GMAW), this guide will equip you with the knowledge needed to achieve strong, durable welds without compromising the steel’s unique properties.

Thoroughly preparing and cleaning manganese steel before welding is crucial to maintain its toughness and work-hardening properties. Contaminants such as oil, dirt, rust, or paint can cause weld defects including porosity, cracking, and embrittlement. Additionally, manganese steel’s sensitivity to heat means precautions must be taken to avoid overheating during cleaning.

Start by eliminating all surface oils, grease, and other organic residues from the weld zone. Use solvent-based degreasers or aqueous cleaners designed for metal surfaces. Apply with lint-free cloths or brushes to thoroughly clean the area. Ensure complete removal—any residual grease can create weld defects or weak spots.

After degreasing, remove any rust, mill scale, or surface coatings. Use wire brushing, grinding, or abrasive blasting to reveal clean metal. For heavy rust, chemical rust removers may be applied. When using chemicals, rinse thoroughly with water and dry immediately to avoid residue interfering with welding. Completely strip paint and coatings from the weld area. Avoid leaving painted surfaces near edges to prevent contamination.

Control the heat generated during grinding or flame cutting to protect the steel’s microstructure. Frequently cool the part by water quenching or partial submersion during mechanical cleaning steps. Use temperature indicators such as Tempilstiks or infrared thermometers to monitor surface temperature. Maintain the temperature below approximately 300°C (572°F) adjacent to the weld zone to prevent carbide precipitation and embrittlement.

Once clean, prepare the joint edges for welding to ensure proper fusion. Grind or bevel the edges to create uniform, clean surfaces for welding. Remove any burrs or sharp edges that could concentrate stress or hinder bead deposition. Ensure that the prepared joint geometry suits the selected welding technique for optimal penetration and strength.

Use small electrode diameters and stringer bead techniques during initial cleaning and preparation welding to minimize heat buildup. Avoid excessive grinding or aggressive cleaning that may thin the base material unnecessarily. If circumstances permit, perform welding in an environment where water quenching or active cooling can follow immediately after preparation to maintain controlled temperatures.

| Preparation Step | Tools/Materials | Purpose |

|---|---|---|

| Remove oils and grease | Solvent-based degreaser, lint-free cloths | Eliminate organic contaminants |

| Remove rust and scale | Wire brush, grinder, abrasive blasting tools | Expose clean, uncontaminated metal surface |

| Chemical rust removal (optional) | Chemical rust remover, rinsing water | Treat heavy rust, followed by thorough rinsing |

| Cleaning temperature control | Water bath/quench, Tempilstiks, IR thermometer | Prevent overheating and embrittlement |

| Joint edge preparation | Grinder, beveling tools | Create uniform, weld-ready joint edges |

Ensuring these preparation steps are carefully executed lays a strong foundation for successful welding of manganese steel, preserving its durability and avoiding common welding pitfalls.

Proper preheat and interpass temperature control is essential in welding manganese steel to avoid problems like carbide precipitation and embrittlement. Aim to keep these temperatures below 204°C (400°F). For highly restrained joints, strictly follow this limit, while for less restrained joints, a lower temperature of around 93°C (200°F) is preferable. Additionally, ensure that the area within 12 mm of the weld does not exceed 250°C to prevent embrittlement.

Use welding methods like Shielded Metal Arc Welding (SMAW) or Gas Metal Arc Welding (GMAW) for precise heat control. Applying the stringer bead technique, which limits the bead width to no more than twice the electrode diameter, can help reduce heat input and control arc energy. Additionally, using low voltage settings to control arc length and heat input will minimize thermal stress and reduce the risk of cracking.

Controlling the cooling rate is crucial to prevent hard, brittle microstructures that weaken the weld. Avoid rapid cooling, as it can lead to embrittlement. Controlled cooling helps preserve the ductility and mechanical strength of the weld. Maintaining the base metal temperature during welding reduces residual stresses and allows diffusible hydrogen to escape, thereby decreasing the risk of hydrogen-induced cracking.

Avoid post-weld heat treatment (PWHT) above the original tempering temperature to prevent strength loss. If PWHT is necessary, it must be carefully controlled with precise temperature monitoring and mechanical testing to ensure the material’s properties are retained. Controlled heating and cooling rates during PWHT are critical to prevent distortion and cracking.

Welders must always wear appropriate personal protective equipment (PPE) to safeguard against potential hazards. This includes welding helmets with suitable filter lenses, flame-resistant gloves, protective clothing, and safety boots. These measures protect against sparks, ultraviolet (UV) radiation, and heat.

Proper ventilation is essential to minimize exposure to manganese fumes and other harmful welding gases. Local exhaust ventilation systems are recommended to capture and remove fumes at the source. Regular air quality monitoring is crucial, as prolonged exposure to manganese fumes can pose significant health risks.

Strict adherence to electrical safety protocols is necessary to prevent electrical shocks or burns. Ensure that welding equipment is properly maintained and grounded. Regular inspections of equipment and adherence to safety guidelines help mitigate electrical hazards during welding operations.

Selecting the right electrodes is vital for maintaining weld toughness and integrity. Nickel-manganese electrodes, such as EFeMn-A (containing 3-5% nickel and 12-14% manganese), are ideal for welding manganese steel. Specialized electrodes like Wearshield® MANGJET® and Super-Mn produce austenitic manganese deposits that work harden during service, providing excellent resistance to abrasion and impact.

Manual Shielded Metal Arc Welding (SMAW), commonly called stick welding, is a versatile technique widely used for manganese steel. This process employs a consumable, flux-coated electrode that generates a shielding gas, protecting the weld pool from atmospheric contamination and ensuring a high-quality weld.

Choosing the right electrode is essential for successful SMAW on manganese steel. The electrode should have a composition that complements the base metal. Electrodes with approximately 13% manganese and a small amount of nickel are ideal. This composition helps in achieving welds with properties similar to those of the base metal, maintaining the toughness and wear resistance of manganese steel.

Gas Metal Arc Welding (GMAW), also known as MIG (Metal Inert Gas) welding, utilizes a continuous wire feed as an electrode and an inert or semi-inert gas to protect the weld pool from atmospheric contamination. GMAW is favored for its speed, versatility, and ease of automation, making it suitable for welding manganese steel.

Choosing the right electrode for welding manganese steel is crucial because it significantly affects the weld’s strength, durability, and wear resistance. The correct electrode ensures the preservation of manganese steel’s inherent properties, such as toughness and work-hardening capability. Using the wrong electrode can lead to issues like embrittlement and cracking, compromising the integrity of the weld.

Manganese steel’s exceptional toughness and ability to harden under stress must be maintained in the weld zone, and the right electrode helps preserve these properties, preventing the weld from becoming brittle and prone to failure. Electrodes designed specifically for manganese steel ensure that the weld area retains its durability and resistance to impact.

Controlling heat is essential when welding manganese steel, as too much heat can cause the base metal to crack. Using electrodes that minimize heat input or act as heat insulators helps maintain the base metal temperature below critical thresholds, preventing cumulative heat damage. This careful management of heat input is vital to avoid compromising the steel’s structural integrity.

For welding high-manganese steel to itself, electrodes like 2850-FCO, 205, or EFeMn-A are ideal. When joining manganese steel to carbon or alloy steels, use stainless steel electrodes such as 304, 308, 309, or 312 to accommodate thermal contraction and reduce cracking.

| Electrode Type | Composition and Features | Application & Benefits |

|---|---|---|

| 2850-FCO / 205 | Designed specifically for manganese steel | Ideal for welding manganese steel base metals |

| EFeMn-A, EFeMn-B | Austenitic manganese electrodes with 12-14% Mn | Provide toughness and work-hardening; suitable for wear parts |

| Nickel-Manganese | Contain 3-5% Ni, 12-14% Mn, sometimes with Mo | Tough welds with good ductility; used in high-impact repairs |

| Stainless Steel (304, 308, 309, 312) | Chrome-nickel alloys with high ductility | Joining manganese steel to carbon or alloy steels; reduce cracking risk |

| 2865-FCO / 207 | Heat-insulating electrodes | Used as buffer layers to protect manganese steel during rebuilds |

Identify whether the base metal is high-manganese steel, low-alloy steel, or carbon steel. The correct electrode depends on the type of base metal, with manganese-specific electrodes used for manganese steel and stainless steel electrodes for mixed metal welds.

Ensure the metal surface is clean and free from contaminants. Proper preparation includes thorough cleaning to remove any oil, grease, rust, or paint. Control the part temperature to prevent overheating above 500ºF (260ºC), which can cause damage to the metal structure.

For manganese steel, use electrodes like EFeMn-A or 2850-FCO for repair and rebuilding. When joining manganese steel to carbon or alloy steel, select stainless steel electrodes such as 309 or 312, which offer ductility and reduce the risk of cracking.

Use low arc power to minimize heat input and avoid cracking. Maintain interpass temperature below 500ºF (260ºC) to prevent embrittlement. Properly set welding parameters are crucial for achieving a strong and durable weld.

Use common welding methods such as Shielded Metal Arc Welding (SMAW) or Metal Inert Gas (MIG) welding. Carefully deposit the weld metal to ensure good fusion without overheating the base metal.

Perform hammering or mechanical peening on the weld while it is still hot to relieve stresses. Follow with water quenching if recommended to enhance toughness and reduce the risk of cracking. Post-weld treatment helps in maintaining the weld quality and durability.

Check the weld for any defects such as cracks, porosity, or improper fusion. Repeat repairs only with appropriate electrodes and controlled heat input to avoid cumulative damage. Regular inspection ensures the weld meets the required standards for strength and durability.

Electrode selection is a fundamental aspect of welding manganese steel, influencing the quality and longevity of the weld. By choosing the correct electrodes and following proper welding techniques, welders can achieve optimal results, maintaining the unique properties of manganese steel and ensuring its performance in demanding applications.

Proper material preparation is essential to prevent embrittlement and cracking when welding manganese steel.

Clean the welding surfaces thoroughly to remove oil, rust, and dirt, which can cause hydrogen-induced cracking. Use solvent-based cleaners or degreasers and ensure the area is completely dry before proceeding.

If the manganese steel has become work-hardened in service, grind away the hardened layer. Work-hardening can increase brittleness, making the steel more susceptible to cracking during welding. Additionally, prepare the edges with smooth fits to minimize stress concentration during welding. Proper edge preparation ensures uniform heat distribution and reduces the risk of localized overheating.

Choose electrodes that match the base metal, like EFeMn-A, to maintain weld toughness and prevent embrittlement.

Employ Shielded Metal Arc Welding (SMAW) or Gas Metal Arc Welding (GMAW). Both processes allow controlled, low arc power, minimizing heat input and avoiding overheating.

Use small diameter electrodes and apply stringer beads instead of wide beads. This technique helps control heat and avoids excessive thermal buildup, reducing the risk of embrittlement and cracking.

Keep interpass temperatures below 500°F (260°C) to avoid forming brittle phases and reduce cracking risk.

Weld short seam lengths and allow cooling between passes. This approach prevents heat accumulation that leads to thermal stress and cracking.

Do not preheat manganese steel, as it can lead to embrittlement by causing carbide precipitation.

Employ rapid cooling techniques such as water or compressed air quenching immediately after welding. Rapid cooling minimizes residual stresses and prevents crack initiation.

Slightly hammer warm weld seams after welding to introduce compressive stresses. These compressive stresses counteract tensile stresses caused by shrinkage during cooling, reducing the risk of crack formation.

During repair welding or flame cutting, keep the parent metal as cool as possible by frequent water cooling or partial immersion in water. This minimizes thermal stresses due to manganese steel’s high thermal expansion and low thermal conductivity.

Maintain low hydrogen levels in the welding environment and consumables. Use dry electrodes and keep moisture away to prevent hydrogen-induced cracks.

Ensure adequate ventilation and use proper personal protective equipment (PPE) including welding helmets, gloves, fire-resistant clothing, and respirators if needed. Proper ventilation reduces exposure to harmful fumes.

Regularly inspect welding equipment to avoid electrical faults or unsafe conditions. Well-maintained equipment ensures consistent weld quality and safety.

Thoroughly inspect welds for cracks or defects. Remove cracks completely by grinding or air carbon arc gouging before rewelding. Complete defect removal ensures the integrity of the weld.

Although preheating is avoided, mechanical stress relief by controlled hammering and allowing the weld to cool naturally can help stabilize the joint. This practice reduces residual stresses and improves weld durability.

Below are answers to some frequently asked questions:

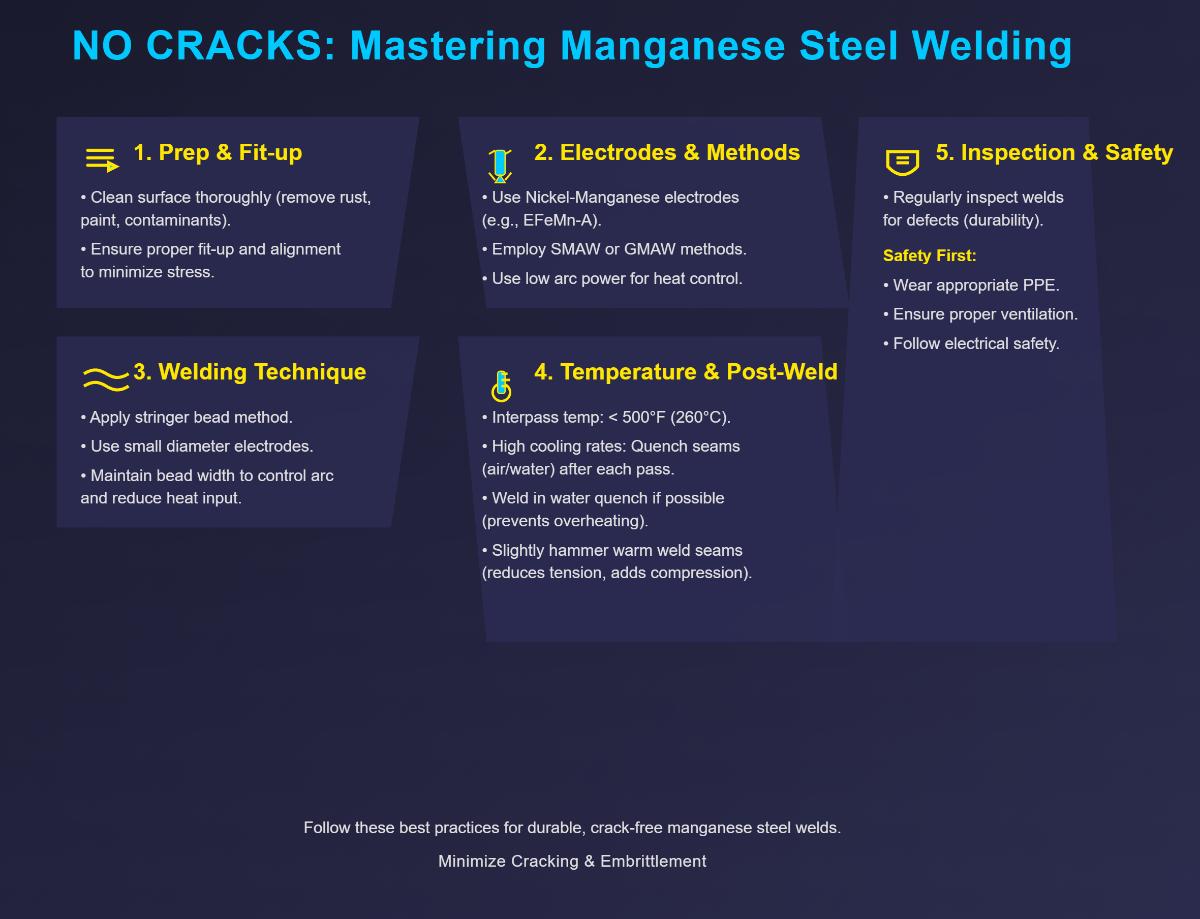

To weld manganese steel without cracking, follow these best practices:

Ensure thorough surface preparation by cleaning the steel to remove rust, paint, and contaminants. Proper fit-up and alignment are crucial to minimize stress concentrations. Select appropriate electrodes, such as nickel-manganese electrodes (e.g., EFeMn-A), and employ techniques like Shielded Metal Arc Welding (SMAW) or Gas Metal Arc Welding (GMAW) with low arc power to control heat input. Utilize the stringer bead method with small electrode diameters, maintaining bead width to control the arc and reduce heat input.

Maintain interpass temperatures below 500°F (260°C) and use high cooling rates by quenching the seams with compressed air or water after each pass. If possible, weld in a water quench to prevent adjacent areas from overheating. Perform slight hammering of the warm weld seams to reduce shrinkage tensions and induce compressive stresses. Regularly inspect welds for defects to ensure durability.

Safety precautions are essential. Wear appropriate personal protective equipment (PPE), ensure proper ventilation, and follow electrical safety measures. By adhering to these practices, you can achieve successful welding of manganese steel while minimizing the risk of cracking and embrittlement.

The main differences between Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW) for welding manganese steel revolve around speed, heat control, and electrode/wire selection.

SMAW is known for its versatility and precise heat control, which is essential for preventing embrittlement in manganese steel. This method uses a consumable, flux-coated electrode that provides a protective shield during welding. Proper electrode selection is crucial, with electrodes containing about 13% manganese and some nickel being preferred. The technique involves using stringer beads to manage heat input effectively.

On the other hand, GMAW offers greater speed and efficiency, making it suitable for larger projects. It utilizes a continuous wire electrode fed through a welding gun, which allows for faster welding but requires careful adjustment of low arc power to avoid excessive heat and reduce the risk of cracking. The wire electrodes used in GMAW should match the manganese steel composition closely.

To effectively control temperature when welding manganese steel, it is crucial to follow several key strategies to prevent defects such as embrittlement and cracking.

First, maintain preheat and interpass temperatures below 400°F (204°C) for highly restrained joints, and even lower, typically below 200°F (93°C), for less restrained joints. This helps avoid overheating, which can lead to carbide precipitation and embrittlement.

Ensure that the temperature in the area 12 mm from the weld does not exceed 250°C during welding to prevent microstructural changes that could reduce ductility and increase hardness. Overall, keep the local temperature below 300°C to avoid embrittlement.

Controlling the cooling rate is essential to minimize residual stresses and prevent the formation of hard and brittle microstructures. This helps retain the toughness of manganese steel and reduces the risk of hydrogen cracking by allowing diffusible hydrogen to escape.

Using appropriate welding processes such as SMAW and GMAW, which allow for effective heat input management, is also important. Proper electrode selection, such as using nickel-manganese electrodes (e.g., EFeMn-A), ensures optimal results and maintains toughness in the weld deposit.

Following these guidelines will help achieve strong, durable, and defect-free welds in manganese steel.

For welding manganese steel, it is essential to use electrodes that produce weld deposits with an austenitic structure capable of work hardening while retaining ductility. Recommended electrodes include:

These electrodes ensure strong, durable welds, maintaining the unique properties of manganese steel such as its impact resistance and work hardening capability. Proper electrode selection and controlled welding techniques are crucial to prevent cracking and ensure optimal weld quality.

To ensure safety while welding manganese steel, it is crucial to manage both the physical hazards of welding and the specific risks associated with manganese exposure. Firstly, use proper personal protective equipment (PPE) such as powered air purifying respirators (PAPRs), welding face shields, gloves, and flame-resistant clothing to protect against fumes, UV radiation, and physical injuries. Secondly, ensure adequate ventilation by using local exhaust ventilation (LEV) systems to capture fumes at the source and maintaining good general ventilation to dilute airborne contaminants. Isolate welding areas to protect other workers from exposure to manganese fumes. Additionally, monitor airborne manganese levels regularly to ensure they remain below occupational exposure limits and conduct health surveillance for early detection of manganese-related health effects. Proper training on manganese hazards and safe work practices is essential for all welders. These measures collectively help minimize health risks and ensure a safer welding environment.

To prepare manganese steel for welding, thorough cleaning is essential to ensure optimal weld quality. The process involves three main stages:

Adhering to these cleaning protocols ensures the integrity and longevity of welds on manganese steel components.