When it comes to constructing robust and reliable structures, the choice of steel grade can make all the difference. Have you ever wondered why certain projects call for S235, while others specify S275, S355, or even S420? In this comprehensive guide, we delve into the properties that set these structural steels apart. You’ll discover how their mechanical properties, chemical compositions, and applications vary, and how European standards like EN 10025 influence their production and use. Whether you’re selecting materials for a new construction project or simply seeking to deepen your understanding, this article will provide the insights you need. Ready to explore the nuances of these essential materials? Let’s dive in.

Structural steel is essential in construction and engineering due to its strength, durability, and versatility. As a type of carbon steel, it typically contains up to 2.1% carbon, which significantly influences its mechanical properties and suitability for various applications.

Structural steel is prized for its ability to withstand different types of stresses, including tension, compression, and shear. These qualities make it ideal for building frames, bridges, and marine structures. The intrinsic qualities of structural steel include:

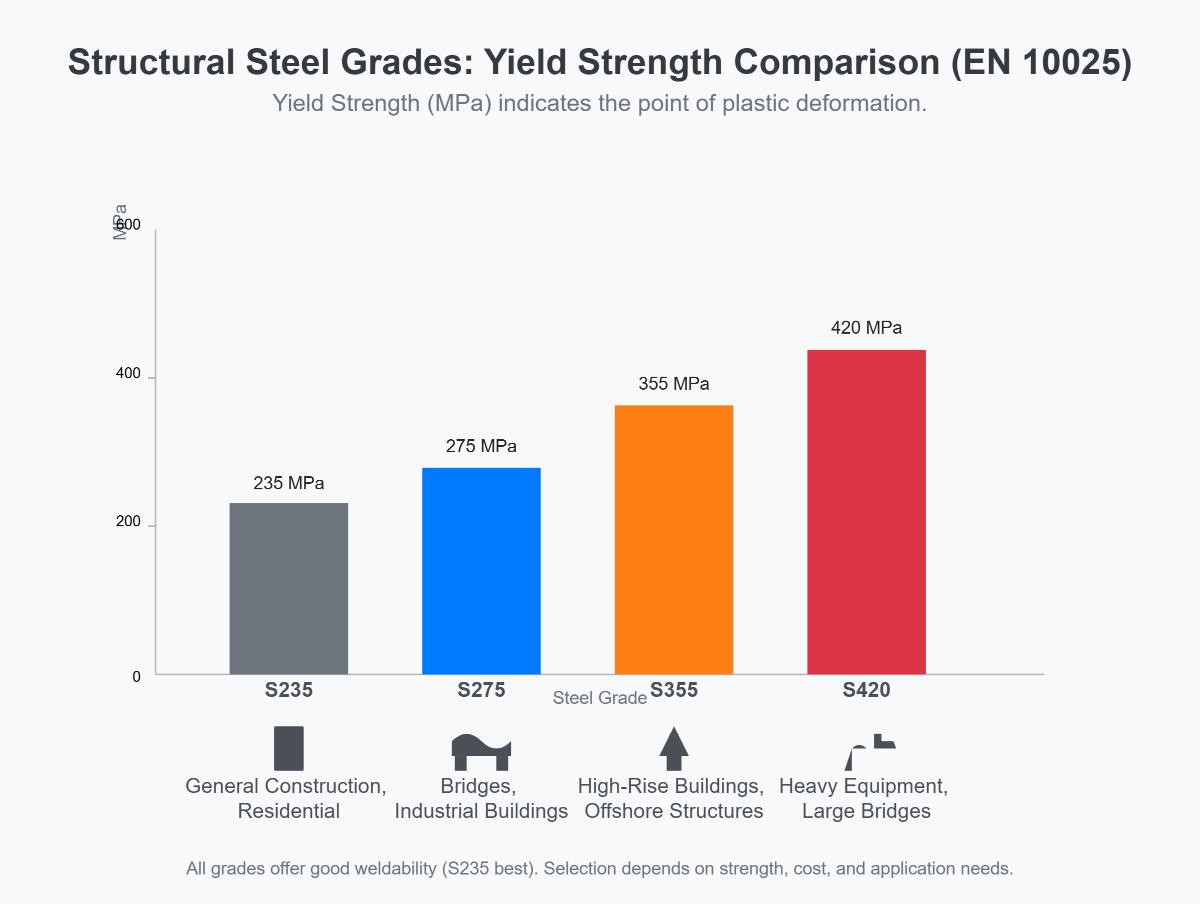

Several grades of structural steel are commonly used, each with specific properties. According to the European Standard EN 10025, the primary grades include S235, S275, S355, and S420. S235, known for its good formability, is popular for general construction projects like building structures and industrial facilities. S275 offers higher strength compared to S235 and is often used in the construction of building frames, bridges, and industrial buildings. S355 is favored for high-stress applications, such as high-rise buildings and offshore structures, due to its superior strength and durability. S420 has the highest yield strength among these grades, making it ideal for heavy-duty construction equipment and large bridges.

Structural steel’s performance depends on its chemical makeup, which usually includes carbon, manganese, phosphorus, sulfur, and silicon. These elements influence its strength, ductility, and toughness. Higher-grade steels, like S355 and S420, generally offer enhanced mechanical strength but may require additional treatments to improve corrosion resistance.

Structural steel is known for its excellent welding properties, allowing it to be processed using various techniques like plasma and laser cutting, edging, welding, and milling. Heat treatments, such as normalizing and thermomechanical processing, can further enhance the steel’s machinability and ductility by refining its crystal structure.

Structural steel’s high strength and versatility make it indispensable in numerous applications. For instance, structural steel is used in the skyscrapers that define city skylines, in bridges that connect communities, and in the infrastructure that supports industrial growth. It is also essential for the construction of solar panel mounts, wind turbine structures, and transmission lines. In marine applications, it is utilized in offshore wind turbines and related equipment due to its robustness and durability.

The design process for structural steel involves meticulous calculations to ensure the selected materials can handle the intended loads. This includes selecting appropriate structural types, designing connections (like bolted or welded joints), and detailing the members. Advanced software tools, such as AutoCAD, are commonly used for detailing and can aid in automating the fabrication process. Fabrication operations typically involve cutting, bending, hole punching, and welding to produce the final structural components.

To ensure consistent quality and performance, structural steel must adhere to established standards like EN 10025 in Europe and ASTM standards in the United States. Compliance with these standards is crucial for maintaining safety and structural integrity in construction projects.

Structural steel remains a cornerstone of modern construction and engineering, providing the essential strength and durability needed for a wide range of applications.

The numbers in the designations of structural steels such as S235, S275, S355, and S420 indicate the minimum yield strength in N/mm² for materials up to 16 mm thick. S235 has a yield strength of 235 MPa, which is relatively lower compared to S420, which reaches 420 MPa, and tensile strength is also crucial in preventing material failure. For instance, S355 has a tensile strength ranging from 470 – 630 MPa, while S235’s tensile strength is between 360 – 510 MPa.

S235 and S275, with their lower carbon content, are easier to shape and form into various structures. In contrast, S355 and S420, which offer higher strength, have reduced ductility. However, their high – strength properties make them ideal for high – stress applications where ductility can be sacrificed to some extent.

Structural steels generally require additional treatments to improve their corrosion resistance. All four grades, S235, S275, S355, and S420, are often coated or galvanized to enhance their durability in harsh environments. This treatment helps protect the steel from rust and other forms of corrosion, ensuring its long – term performance in outdoor or corrosive settings.

The carbon and manganese content in these steels significantly influences their strength and ductility, with S355 and S420 having higher carbon levels that contribute to their greater strength. Different combinations of these elements in S235, S275, S355, and S420 result in their distinct mechanical properties.

Brinell hardness is an important property for structural steels. S235 has a Brinell hardness ranging from 100 – 154 HB, while S275’s range is 121 – 163 HB. S355 and S420 have Brinell hardness ranges of 146 – 187 HB and 143 – 184 HB respectively. This property gives an indication of the steel’s resistance to indentation and wear, which is crucial in applications where the steel may be subject to abrasive forces.

S235 steel, as defined by the EN 10025 standard, is a widely used non-alloy structural steel in construction and engineering. Its composition includes a maximum of 0.22% Carbon, 1.60% Manganese, and 0.05% each of Phosphorus, Sulfur, and Silicon. It also contains up to 0.30% of Chromium, Nickel, and Copper, and 0.012% Nitrogen.

S235 steel has a yield strength of 235 MPa, a tensile strength ranging from 310 to 510 MPa, and an elastic modulus of 210 GPa. It has a density of approximately 7850 kg/m³ and a Brinell hardness of 100-154 HB.

S235 steel is known for its excellent weldability, making it easy to join using various techniques such as Gas Metal Arc Welding (GMAW) and Shielded Metal Arc Welding (SMAW). Its moderate hardness allows for easy cutting, drilling, and machining, and post-processing treatments like galvanization can enhance its corrosion resistance for outdoor use.

S275 steel is crafted with a precise chemical composition that enhances its properties. It contains up to 0.25% carbon, which contributes to its strength. Manganese is present up to 1.60%, enhancing the steel’s hardenability and tensile strength. Silicon, up to 0.60%, helps in deoxidizing the steel during the manufacturing process. Phosphorus and sulfur are each limited to 0.050%, as excessive amounts can negatively impact the steel’s ductility and weldability. The balance is iron, the base element of the steel. Compared to S235, S275 has a slightly higher carbon content, which gives it greater strength. In contrast, S355 and S420 may have different ratios of these elements, resulting in their higher strength properties.

S275 has a minimum yield strength of 275 MPa, which is higher than S235’s 235 MPa, making it more suitable for applications requiring higher load support. However, it is lower than S355 (355 MPa) and S420 (420 MPa), which are used in more demanding applications. Ranging from 370 to 530 MPa, S275’s tensile strength is also greater than that of S235, which has a tensile strength between 310 – 510 MPa. S355 and S420 have even higher tensile strength ranges, reflecting their ability to withstand greater forces before failure. S275’s shear strength, typically between 200 to 250 MPa, is sufficient for many structural applications and higher than S235, but lower compared to S355 and S420. With a Brinell hardness of 140 – 170, Rockwell 75 – 85 HRB, and Vickers 150 – 180, S275 is harder than S235. However, S355 and S420 have higher hardness values, which contribute to their better resistance to wear and deformation. In standard conditions, S275 has an elongation at break of 22 – 26%. This indicates its ductility, or the ability to deform plastically before breaking. It has a good balance of ductility compared to S355 and S420, which sacrifice some ductility for higher strength.

S275’s specific heat capacity of 475 J/kg·K and thermal conductivity of 50 W/m·K make it suitable for applications exposed to heat, similar to other structural steel grades. Ranging from 0.35 to 0.40, S275’s emissivity coefficient indicates its ability to emit thermal radiation. This property is important in applications where heat transfer through radiation is a factor.

S355 steel is a widely used high-strength, low-alloy structural steel, ideal for construction and engineering projects. The chemical composition of S355 steel is designed to provide a balance of strength, weldability, and toughness. The key elements in S355 steel include:

S355 steel stands out for its impressive mechanical properties, which make it perfect for structural uses. These properties include:

S355 steel also has several important physical properties that contribute to its widespread use in structural applications:

S355 steel is widely used in various structural and engineering applications due to its high strength, good weldability, and excellent toughness. Common applications include:

S355 steel is highly regarded for its combination of strength, toughness, and weldability, making it a preferred choice for a wide range of demanding structural applications.

S420 is a type of structural steel, conforming to the European standard EN 10025. This standard ensures its quality and performance in various engineering applications. Compared with grades like S235, S275, and S355, S420 is engineered for more demanding structural needs.

S420 is commonly available in the forms of steel plates and sections. These product forms offer flexibility in fabrication, allowing engineers to create different structural components according to project needs. In contrast, some other steel grades might have more limited product forms, which can restrict their application scope.

The chemical composition of S420 is carefully formulated to achieve its desired properties. The maximum carbon (C) content in S420 is ≤0.20 – 0.25%. Manganese (Mn) is ≤1.60%. Silicon (Si) is ≤0.05%. Phosphorus (P) is ≤0.05%. Sulfur (S) is ≤0.05%. Higher carbon content compared to S235 contributes to S420’s greater strength. However, the relatively low silicon content might affect its deoxidation process during manufacturing compared to some other grades with higher silicon levels.

S420 is suitable for manual and automatic welding processes. Its low-carbon content eliminates the need for pre-heating during welding, and post-welding heat treatment is also not required. This is an advantage over some high-carbon steels that demand complex welding procedures. Gas welding is not suitable for S420.

Although S420 exhibits excellent strength and toughness, its corrosion resistance is inferior to some stainless steels. To enhance its durability in harsh environments, additional protective measures such as powder coating or galvanizing are usually necessary, similar to other structural steel grades.

The mechanical properties of structural steels S235, S275, S355, and S420 differ notably. Yield strength, a key mechanical property, shows a clear gradient among these grades, with S235 at 235 MPa, S275 at 275 MPa, S355 at 355 MPa, and S420 at 420 MPa.

Tensile strength also follows a similar pattern. S235 has a tensile strength ranging from 360 to 510 MPa, while S275’s range is 370 to 530 MPa. S355 offers a wider and higher range of 470 to 630 MPa, and S420 has a tensile strength range of 480 to 620 MPa.

Brinell hardness is another important mechanical property. S235 has a Brinell hardness of 100 to 154 HB, S275’s is 121 to 163 HB, S355’s is 146 to 187 HB, and S420’s is 143 to 184 HB. Higher hardness usually means better wear and indentation resistance.

The carbon content is crucial for determining the strength of these steels. S235 has a maximum carbon content of 0.22%, S275 can have up to 0.25%, and S355 has a maximum of 0.23%. The relatively higher carbon content in S275 contributes to its increased strength compared to S235, and manganese content in all four steels is capped at a maximum of 1.60%.

Phosphorus and sulfur, which can negatively impact the steel’s ductility and weldability, are limited to a maximum of 0.05% in each steel grade. Silicon content is also restricted to a maximum of 0.05% across all the steels.

In terms of strength, S420 clearly outperforms the other three grades due to its high yield and tensile strength. This makes it the top choice for applications where high-stress resistance is crucial, such as heavy-construction equipment. S355 is also highly suitable for high-stress applications like high-rise buildings and offshore structures.

S275 offers a good balance between strength and cost, making it a popular choice for building frames and industrial buildings. S235, with its lower strength, is more suitable for general construction and applications where high strength is not the primary requirement.

Durability is related to both strength and corrosion resistance. All four grades generally require additional treatments like coating or galvanizing to enhance their corrosion resistance. However, the higher-strength steels like S355 and S420 can often withstand more severe mechanical stresses over time, contributing to their overall durability and longevity in demanding applications.

S235 is widely used in general construction, including residential and commercial buildings, infrastructure projects like roads and bridges, and industrial facilities. Its good weldability and formability make it easy to work with in these applications.

S275, with its higher strength, is commonly used in the construction of building frames, bridges, and industrial buildings. It can handle greater loads compared to S235, making it a better option for these more substantial structures.

S355 is favored for high-stress applications such as high-rise buildings, large bridges, and offshore structures. Its superior strength and toughness ensure the long-term stability of these structures under extreme conditions.

S420 is specifically designed for heavy-duty applications like heavy-construction equipment, large bridges, and specialized structures that require high strength and durability. Its high yield strength allows it to support extremely heavy loads.

Yield strength is the maximum stress that can be applied before the steel begins to deform permanently, while tensile strength is the maximum stress the steel can withstand while being stretched or pulled before breaking. The combined yield and tensile strength values for the four grades are:

Ductility is how much the steel can stretch or elongate before breaking. The elongation values for these grades are generally:

Hardness measures the resistance of the steel to deformation and wear. Brinell hardness values for these grades are:

Impact resistance is the steel’s ability to withstand sudden forces or shocks. The Charpy impact test results for these grades are:

Fatigue strength indicates how well the steel can endure repeated stress over time without breaking. This property is crucial for structures subjected to fluctuating loads:

| Property | S235 | S275 | S355 | S420 |

|---|---|---|---|---|

| Yield Strength (MPa) | 235 | 275 | 355 | 420 |

| (Max stress before permanent deformation) | ||||

| Tensile Strength (MPa) | 360-510 | 370-530 | 470-630 | 480-620 |

| (Max stress before breaking) | ||||

| Elongation (%) | 26 | 22-26 | 20-22 | 19 |

| (Measure of ductility) | ||||

| Brinell Hardness (HB) | 100-154 | 121-163 | 146-187 | 143-184 |

| (Resistance to deformation and wear) | ||||

| Impact Resistance (°C) | Performs well at RT | Performs well at RT | Good at -20°C | Good at -20°C |

| (Ability to withstand sudden forces) | ||||

| Fatigue Strength | Lower | Moderate | Higher | Highest |

| (Resistance to repeated stress) |

This comparison of mechanical properties for S235, S275, S355, and S420 helps in selecting the appropriate grade for specific applications based on strength, ductility, hardness, impact resistance, and fatigue strength requirements.

Understanding the chemical composition of structural steels is crucial for determining their mechanical properties and suitability for various applications. The primary elements that influence the properties of S235, S275, S355, and S420 steels include carbon, manganese, silicon, phosphorus, and sulfur.

Carbon is a vital element that enhances the strength and hardness of steel. However, higher carbon content can reduce ductility and weldability. The maximum carbon content varies among the grades: 0.22% for S235, 0.25% for S275, 0.23% for S355, and 0.20-0.25% for S420.

Manganese improves toughness, strengthens the steel, and aids in the deoxidation process during production. The maximum manganese content for all grades is 1.60%.

Silicon acts as a deoxidizer and enhances the hardness and elasticity of steel. The silicon content is generally low in these grades:

Phosphorus and sulfur must be kept low to avoid brittleness and maintain ductility and weldability. The maximum phosphorus content is 0.05% for S235, S275, and S355, and 0.025% for S420. The maximum sulfur content is 0.05% for S235, S275, and S355, and 0.015% for S420.

The chemical composition of these steels is tailored to balance strength, ductility, and other mechanical properties. Below is a comparison of the maximum allowable contents for key elements:

| Grade | Carbon Max (%) | Manganese Max (%) | Silicon Max (%) | Phosphorus Max (%) | Sulfur Max (%) |

|---|---|---|---|---|---|

| S235 | 0.22 | 1.60 | 0.05 | 0.05 | 0.05 |

| S275 | 0.25 | 1.60 | 0.05 | 0.04 | 0.05 |

| S355 | 0.23 | 1.60 | 0.05 | 0.05 | 0.05 |

| S420 | 0.20-0.25 | 1.60 | 0.50 | 0.025 | 0.015 |

Higher carbon and manganese content increases yield and tensile strength. S235 has a yield strength of 235 MPa and tensile strength of 360-510 MPa, while S420 has a yield strength of 420 MPa and tensile strength of 480-620 MPa. Lower phosphorus and sulfur contents improve ductility and weldability, making S235 and S275 more formable compared to S355 and S420.

The chemical makeup of these steels makes them suitable for different applications:

Yield strength measures how much stress steel can endure before it permanently deforms. Among the structural steels:

This progression indicates that S420 is best suited for applications where high stress resistance is essential.

Tensile strength measures the maximum stress that a steel can withstand while being stretched or pulled before breaking:

The higher tensile strengths of S355 and S420 make them ideal for demanding applications requiring significant force endurance.

Brinell hardness is an indicator of a material’s resistance to indentation and wear:

Higher Brinell hardness values indicate better wear resistance, making S355 and S420 more suitable for abrasive environments.

All these structural steels are susceptible to corrosion and typically require protective coatings. Carbon content affects their corrosion resistance:

The processing methods of higher grades like S355 and S420 offer slightly better environmental resistance. These steels can better withstand environmental stresses and mechanical wear over time.

Weldability varies among these grades:

Choosing the right steel grade depends on the specific needs of the application. S235 and S275 are excellent for general construction due to their ease of welding and forming. For more demanding projects, S355 offers a higher strength-to-weight ratio, making it suitable for high-stress applications. S420, with its superior strength, is reserved for the most demanding structural applications, providing both exceptional strength and durability.

S235 steel is commonly used in general construction projects. Its good formability allows it to be easily shaped into various components such as partitions, roofing frames, and simple support structures in residential and commercial buildings. For small-scale infrastructure such as rural bridges and local roads, S235’s cost-effectiveness is practical, whereas S275, with its higher strength, is better suited for medium-sized building frames and bridges. S355 and S420, with their higher strength, are more appropriate for high-stress applications and are not necessary for these general construction projects.

S235 is used in the automotive industry for vehicle chassis and suspension components. Its excellent weldability simplifies the manufacturing process, allowing for efficient assembly of these parts. The material’s good impact resistance also contributes to the structural integrity of the vehicle. Compared to S275, S355, and S420, S235’s lower strength is sufficient for light-duty vehicles, while the higher-strength grades are typically used in heavy-duty or high-performance vehicles.

S235’s versatility makes it essential for fabricating industrial equipment and machinery. It can be used in the construction of conveyor systems, storage racks, and simple machine frames. The steel’s moderate strength and good machinability ensure that it can be easily processed into the required shapes and sizes. In comparison, S275, S355, and S420 are used for more heavy-duty industrial equipment that requires higher load-bearing capacity and greater durability.

S235 is used in the defense industry, especially for armored vehicles and military structures. While S235’s corrosion and impact resistance suit demanding environments, S355 or S420 are preferred for high-strength military applications like high-end armored vehicles or fortified installations.

S235 is suitable for weathering applications like outdoor facades and bridges. Its natural corrosion resistance reduces the need for extensive protective coatings, which can save on maintenance costs. In contrast, S275, S355, and S420, while also having corrosion-resistant properties, may be over-specified for less demanding weathering applications and are more commonly used in harsh marine or industrial environments where higher strength and durability are required.

In the renewable energy sector, S235 can be used in small-scale solar panel mounts and basic wind turbine support structures in less demanding environments. Its cost-effectiveness makes it an economical choice for small-scale projects. S275, with its increased strength, is used for medium-sized wind turbine towers and larger solar panel arrays. S355 and S420 are employed in large-scale and high-stress renewable energy infrastructure such as large-scale wind turbine towers and critical load-bearing components.

S275 steel is widely used in construction, especially for the frames of medium-sized buildings like commercial structures and warehouses. Its higher yield strength compared to S235 makes it suitable for applications that require additional load-bearing capacity. S275’s good weldability ensures that it can be easily joined without the need for preheating, simplifying the construction process.

In infrastructure projects, S275 steel is preferred for building medium-span bridges and overpasses due to its strength and durability. Additionally, S275 steel is used for support structures in roadways and railways, ensuring reliable performance in both urban and rural areas.

S275 steel is widely utilized in the manufacturing of industrial equipment and machinery. It is commonly used to produce machine frames, housings, gears, and shafts due to its excellent machinability and strength. The steel’s ability to withstand mechanical stresses makes it ideal for components that experience significant wear and tear during operation.

In the energy sector, S275 steel is used to build wind turbine towers, whether onshore or offshore, thanks to its high yield strength and good weldability. Additionally, S275 is used in the fabrication of pipelines and storage tanks in the oil and gas industry, where its durability and mechanical properties are critical for safe and efficient operation.

S275 steel is used in marine applications such as the construction of offshore platforms and wind farm infrastructure. Its ability to perform well under dynamic loads and in harsh marine environments makes it a preferred choice for these demanding applications. The steel’s good impact strength at low temperatures, particularly the S275J2 grade, ensures reliability in cold and icy conditions.

In the railway industry, S275 is utilized for manufacturing rail tracks and related components. Its strength and toughness are crucial for enduring the dynamic loads and vibrations of railway tracks. The steel’s excellent weldability also facilitates the construction and maintenance of railway infrastructure.

Compared to S235, S275 offers higher strength and is better suited for applications requiring greater load-bearing capacity. However, S355 and S420 provide even higher strength levels, making them more appropriate for high-stress applications such as high-rise buildings and large bridges. While S275 is a versatile choice for a range of medium-load applications, the selection of steel grade should be based on the specific requirements of the project, including load conditions, environmental factors, and budget constraints.

S355 steel is extensively used in high-rise buildings due to its high yield strength and excellent tensile properties. The ability to withstand significant stress and load without deformation makes it ideal for constructing frameworks that require robust support. In bridge construction, S355 is preferred for its durability and resistance to dynamic and static loads, ensuring long-term structural integrity. Additionally, its weldability allows for the creation of complex designs. This adaptability is crucial for meeting various architectural requirements.

The corrosion resistance and mechanical strength of S355 steel make it suitable for offshore structures such as oil rigs, wind turbine platforms, and other marine applications. These environments demand materials that can withstand harsh conditions, including high humidity, saltwater exposure, and mechanical wear. S355’s properties ensure that these structures maintain their integrity and performance over extended periods, reducing the need for frequent maintenance.

S355 steel is used in the automotive sector for manufacturing vehicle frames, chassis components, and suspension systems. Its high strength-to-weight ratio is crucial for enhancing vehicle safety and performance. For example, the steel’s impact resistance provides additional protection in the event of collisions, making it a reliable choice for critical automotive parts.

In the aviation industry, S355 steel is utilized for producing various aircraft components, including landing gear and structural parts that require high strength and durability. For railway applications, S355 is used in the construction of rail tracks, wagons, and locomotives. The steel’s toughness and ability to withstand dynamic loads ensure the safety and longevity of railway infrastructure.

S355 steel is integral to the construction of wind turbine towers and power plant structures. Its robustness allows it to support heavy loads and endure the stresses imposed by wind forces and operational dynamics. In power plants, S355 is used for building structural supports, pipelines, and pressure vessels, where its mechanical properties ensure safe and efficient operation.

The strength and corrosion resistance of S355 make it suitable for pipeline construction in the oil and gas industry. These pipelines often transport materials under high pressure and through challenging environments. S355 steel’s properties help prevent leaks and failures by providing a sturdy and durable barrier, ensuring reliable and safe transportation of fluids.

S355 steel is widely used in the manufacturing of heavy machinery such as cranes, loaders, excavators, and other construction equipment. The steel’s high strength provides the necessary durability to withstand the demanding conditions of mining and construction sites. The ability to endure heavy loads and resist wear and tear makes S355 an essential material for these applications.

S355 steel’s high recyclability and low carbon content contribute to its sustainability. Its use in construction and industrial applications aligns with modern environmental goals by reducing raw material consumption and waste, while its durability extends the lifespan of structures, minimizing the need for frequent replacements and reducing the overall environmental impact.

In high – strength construction, S420 steel is the workhorse you can rely on. Think of yield strength as the amount of pressure a material can take before it starts to deform. S420 has a yield strength of 420 MPa, which means it can handle a huge amount of weight and force without losing its shape. Its tensile strength, which is how much pulling force it can endure before breaking, ranges from 480 – 620 MPa. This makes it perfect for large bridges, where it has to bear the constant weight of traffic and the stress of changing weather. In contrast, S235, with a lower yield strength (similar to a less tough material), is better for smaller, less demanding bridges. S420 also shines in load – handling equipment and earth – moving machinery. These machines face intense forces during operation, and S420’s strength ensures they can work effectively. While S275 is stronger than S235, it can’t match S420’s power, making S420 the go – to for heavy – duty construction equipment.

When it comes to the marine and offshore industries, S420 is a star performer. Its excellent weldability and corrosion resistance make it ideal for boat and ship construction. It has a fine – grain structure and a well – controlled chemical composition. Variants like S420M have low carbon and phosphorus levels. These features contribute to its corrosion resistance. S355 is also used in marine applications. However, S420 offers higher strength. This is crucial for structures that must endure harsh marine environments and dynamic loads. For offshore platforms, S420 can better resist the mechanical stresses from waves, wind, and ocean currents. In comparison, S235 and S275 may not be as up to the task.

S420’s high strength – to – weight ratio makes it the perfect fit for wind turbine supports and structures. Wind turbines are constantly battered by complex loads. Wind forces push and pull on them, while gravitational forces keep them grounded. S420 can maintain its integrity under these challenging conditions, ensuring the long – term stability of the wind turbine. S235 and S275 are used in smaller – scale or less demanding wind turbine components. But for large – scale, high – performance wind turbines, S420 provides the strength needed to optimize design and performance. S355 is also used in wind turbine construction, but S420 outshines it with its higher strength.

In the rough – and – tumble world of industries like mining and power plants, S420 is the unsung hero. Mining equipment operates in a brutal environment. The ground is filled with hard rocks and abrasive materials. The machinery has to dig, crush, and move large amounts of this material under heavy loads. S420’s high Brinell hardness (143 – 184 HB) gives it excellent wear resistance, like a suit of armor protecting it from the harshness of the mining site. Power plants are no less demanding. They deal with high temperatures, extreme pressures, and intense mechanical stresses. Compared to S235 and S275, S420’s superior mechanical properties make it the top choice for critical components. S355 can be used in industrial settings, but S420 is the preferred option for the most demanding parts of the infrastructure.

High-rise buildings require materials that offer both strength and versatility. In one case study, a construction company opted to switch from S355 to S420 steel for a new skyscraper project. The change enabled a 7.2% reduction in the cross-sectional area of the steel beams, significantly decreasing the structure’s overall weight and material costs. This reduction not only improved the efficiency of the construction process but also allowed for more flexible architectural designs.

In another project, a large-span bridge required materials that could withstand heavy traffic loads and environmental stresses. Engineers initially considered S275 steel but found that it did not meet the necessary strength requirements for the anticipated load and environmental conditions. Instead, they opted for S355 steel, which offers higher yield strength and better performance under stress.

Offshore wind turbines present unique challenges due to their exposure to marine environments and high wind loads. A case study involving the construction of an offshore wind farm demonstrated the benefits of using S355 steel for the turbine foundations. The high yield and tensile strengths of the steel enabled slimmer, more efficient support structures, cutting down material usage and installation costs. S355’s balance of high strength, good weldability, and resistance to corrosion made it an ideal choice. The project’s success highlighted S355’s suitability for renewable energy applications in harsh marine environments.

The manufacturing of heavy-duty machinery, such as cranes and excavators, often demands materials that can withstand significant mechanical stresses. In a notable case, a machinery manufacturer transitioned from using S275 to S420 steel for the production of crane booms. S420’s higher yield strength (420 MPa) offered better load-bearing capacity, enabling the cranes to lift heavier loads safely. This upgrade not only enhanced the performance of the machinery but also extended its operational lifespan, offering better value to the end-users.

A sustainable construction project aimed to minimize the environmental impact of a new residential complex. The project team selected S355 steel for its excellent strength-to-weight ratio, which allowed for the use of less material without sacrificing structural integrity. Choosing high-strength steel led to a 15% reduction in the total steel needed for the project. Additionally, S355’s high recyclability contributed to the project’s sustainability goals, ensuring that the material could be repurposed at the end of the building’s life cycle.

These case studies illustrate the diverse applications and benefits of using different grades of structural steel. S235 is suitable for general construction projects where high strength is not the primary concern, while S275 offers a balance between strength and cost for medium-load applications. S355 is ideal for high-stress environments, such as high-rise buildings and offshore structures, due to its superior strength and durability. S420, with its highest yield strength, is reserved for the most demanding applications, including heavy machinery and large bridges. The choice of steel grade depends on the specific requirements of the project, including load conditions, environmental factors, and sustainability considerations.

The European Standard EN 10025 is crucial for defining the technical delivery conditions of hot-rolled structural steels like S235, S275, S355, and S420. This standard precisely outlines the mechanical properties, such as yield and tensile strength, and the chemical composition of these steels. It specifies the content of carbon, manganese, phosphorus, sulfur, and silicon, which directly influences the steel’s performance. Adhering to EN 10025 ensures that these steels meet consistent quality benchmarks, making them reliable for various structural applications across Europe.

EN 10025 sets strict guidelines for steel manufacturers during production, ensuring careful control of chemical composition and processing parameters to achieve the specified mechanical properties. For example, producing S355 steel with a required yield strength of 355 MPa involves precise adjustments of alloying elements and heat treatment processes. This standardization streamlines production, reduces variability, and enhances In the construction and engineering sectors, EN 10025 provides a clear framework for selecting the appropriate steel grade based on defined properties. For general construction projects, S235, which meets the EN 10025 requirements for lower strength applications, can be used confidently. For high-stress applications like high-rise buildings, S355 or S420, which comply with the standard’s criteria for higher strength, are the preferred choices.

Beyond the European standard, local building codes and regulations must be considered, especially when these steels are used in non-European markets. For example, in the United States, ASTM standards are commonly used. S235 is equivalent to ASTM A283C, and S355 is similar to ASTM A572Gr50. Adhering to local regulations is crucial to ensure the structural integrity and safety of projects, as different regions may have specific requirements regarding seismic resistance, corrosion protection, and fire safety.

All steel products used in European projects must meet European health and safety standards. The CE Mark assures customers that the product adheres to European health and safety laws. It serves as a guarantee of quality and compliance with European standards. For structural steels like S235, S275, S355, and S420, obtaining the CE Mark is a crucial step in the certification process, reassuring customers and regulatory authorities of the product’s reliability.

The EN 10025 standard is a cornerstone in the European steel industry, specifically tailored for hot-rolled structural steels. It ensures the quality, consistency, and performance of steels used across various construction and engineering projects. By adhering to this standard, manufacturers can produce steels that meet the stringent requirements of various projects, from small-scale buildings to large industrial structures.

The EN 10025 standard is divided into several parts, each addressing specific types of structural steels and their delivery conditions:

Different steel grades, such as S235, S275, S355, and S420, are defined and regulated by the EN 10025 standard. Each grade has specific requirements for chemical composition and mechanical properties:

Adhering to the EN 10025 standard is crucial for ensuring the quality and safety of structural applications. The standard sets strict limits for chemical composition, mechanical properties, and other characteristics of the steels. For example, it specifies the maximum allowable carbon, manganese, phosphorus, and sulfur content, which directly affect the steel’s strength, ductility, and weldability. By adhering to these limits, manufacturers can produce steels that perform consistently in different environments and applications, reducing the risk of structural failures and ensuring the long-term safety of construction projects.

EN 10025 ensures structural steels meet specific mechanical and chemical criteria. This standardization enhances reliability and consistency in steel production. Adhering to EN 10025 allows manufacturers to produce high-quality, safe materials that meet precise specifications for various applications.

EN 10025 facilitates the production of steels tailored to specific needs. For example, higher strength grades like S420 are manufactured for heavy-duty applications, while other specialized grades are developed for corrosive environments. This flexibility enables the production of steel products tailored to the unique needs of different industries.

Steels produced under EN 10025 are designed with good weldability and machinability. These steels are easy to process, making the production and assembly of complex structures more efficient and cost-effective.

EN 10025 structural steels are integral to modern construction, supporting the development of high-rise buildings, bridges, and other infrastructure projects. Their reliable strength and durability make them essential for projects that require robust materials capable of withstanding significant loads and environmental stresses.

The high strength and toughness of EN 10025 steels make them ideal for extreme environments like offshore platforms and heavy industrial equipment. These applications demand materials that can endure harsh conditions and mechanical stresses, which EN 10025 steels can reliably provide.

By specifying precise mechanical properties, EN 10025 enables engineers to optimize structural designs, minimizing material usage while ensuring safety and performance. This contributes to more sustainable construction practices by reducing waste and improving the efficiency of resource utilization.

EN 10025-2 focuses on general structural steels like S235, S275, and S355. These steels are commonly used in construction due to their good balance of strength and cost-effectiveness. EN 10025-6 addresses high-strength quenched and tempered steels, which are used in applications requiring exceptional strength.

The standard outlines specific limits for elements like carbon, manganese, and phosphorus to ensure desired mechanical properties such as yield strength and tensile strength. This ensures that the steels produced are consistent in quality and performance.

As technology advances, there is an increasing focus on developing steels with higher strengths, better corrosion resistance, and improved sustainability. These advancements aim to enhance the performance of structural steels without compromising their weldability or machinability.

EN 10025 standards are aligned with international norms like ASTM, facilitating global trade and the application of European structural steels in diverse projects worldwide. This compatibility ensures that steels produced under EN 10025 can be used confidently in international markets.

In shaping the production and use of structural steels, EN 10025 ensures they meet precise standards for strength, durability, and processability, significantly contributing to the safety, efficiency, and sustainability of modern construction and engineering projects.

Selecting the appropriate material is crucial in the design and fabrication of structural steel components. The choice between grades such as S235, S275, S355, and S420 depends on the specific requirements of the project.

When designing with structural steel, engineers must account for various loads to ensure the integrity and safety of the structure.

Ensuring structural stability involves careful design to prevent buckling and maintain the integrity of the structure under various loads and conditions.

The fabrication of structural steel involves several precise processes to achieve the desired shapes and dimensions.

Advanced cutting and shaping techniques ensure precision and minimize material waste.

Achieving the required shapes and connections involves specialized bending and welding techniques.

Quality control is essential to ensure the fabricated steel components meet the required specifications and performance standards.

Applying protective coatings is crucial to enhance the durability and lifespan of structural steel components.

Effective project planning involves detailed blueprints, schedules, and budgets.

Employing a skilled and certified workforce is vital for maintaining high-quality standards in fabrication.

Regular communication with clients ensures their requirements are met and any changes are promptly addressed.

By adhering to these design and fabrication considerations, engineers and fabricators can create robust and durable structures that meet specific project requirements while ensuring safety and efficiency.

In structural steel design, it’s essential to account for various types of loads to ensure the integrity and safety of the structure. The main load types include:

Choosing the right steel grade is critical for meeting the structural requirements of a project. Each grade offers different strengths, ductility, and cost implications:

Ensuring structural stability involves designing to prevent buckling and maintain the integrity of the structure under various loads and conditions.

Connections are critical to the integrity of a structure. Effective design ensures robustness and ease of assembly:

Complex designs can lead to errors and increased costs. Simplification enhances constructability and reduces potential issues:

Consideration of constructability ensures that the structure is easy to build, aligning with fabricator preferences and minimizing the number of framing members:

Using efficient bracing configurations optimizes the structural strength and material usage:

Several optimization techniques can enhance both the cost-effectiveness and structural efficiency of the design:

Maintaining high-quality standards throughout the fabrication process ensures that the final structure meets design specifications:

Applying protective coatings enhances the durability and lifespan of structural steel components:

Cutting is a fundamental technique in steel fabrication, shaping the material into specific lengths and configurations with high precision. Advanced machinery ensures precision and efficiency:

Bending creates curved structural elements necessary for specific architectural designs and structural requirements. Press Brakes use a punch and die to bend steel plates and sheets into various angles and shapes. Bending Rollers utilize a series of rollers to gradually bend steel into smooth curves, suitable for creating cylindrical forms and arches.

Shaping and drilling prepare steel components for assembly:

Welding joins steel parts, enhancing the structure’s strength and stability:

Effective planning and design are essential for successful steel fabrication:

Maintaining high-quality standards throughout the fabrication process ensures the final product meets design specifications. Regular inspections at various stages check for defects and verify dimensions. Non-Destructive Testing (NDT) techniques like ultrasonic and radiographic testing detect internal flaws without damaging the components.

Applying finishing treatments enhances the durability and appearance of structural steel components:

Proper assembly and installation are critical for the stability and safety of the structure:

Welding considerations are vital for ensuring strong and reliable joints:

By adhering to these fabrication techniques and best practices, industries can ensure that structural steel components are produced to meet high standards of quality and performance, supporting a wide range of applications from construction to renewable energy.

S235 is a type of structural steel that has a yield strength of around 235 MPa. It’s well-suited for general construction projects that require moderate strength. Its excellent weldability and formability make it versatile for residential buildings, light industrial structures, and non-load bearing applications. The cost-effectiveness of S235 is one of its primary advantages, as it provides a balance of performance and affordability.

With a yield strength of around 275 MPa, S275 offers enhanced strength over S235, making it ideal for building frames and bridges. The versatility of S275 makes it useful for many structural applications, and it remains cost-effective. This grade provides a good balance between strength and ductility, essential for structures experiencing dynamic loads.

S355 features a yield strength of about 355 MPa and is preferred for high-stress applications, such as high-rise buildings and heavy infrastructure. Although S355 has a higher initial cost, its performance benefits often outweigh this, making it a cost-effective option for demanding projects. Its superior strength-to-weight ratio enables more efficient designs, potentially reducing material costs and construction time.

The highest strength grade among the four, S420 has a yield strength of about 420 MPa. S420’s exceptional strength means less material is needed, leading to long-term savings even though it has a higher upfront cost. This steel is often used in heavy-duty applications where significant loads are expected, such as large bridges and specialized construction equipment.

Material costs for structural steel grades vary, with higher grades like S355 and S420 typically being more expensive due to their superior properties. The increased material costs of these higher grades are often justified by their enhanced performance in demanding applications, leading to potential savings in other areas of the project.

Processing costs can differ based on the grade of steel. Higher grades such as S355 and S420 may require more advanced welding techniques and additional processing steps, which can increase initial fabrication costs. However, the efficiency and durability of these higher grades can result in lower lifetime costs due to reduced maintenance requirements and longer service life.

While higher-grade steels involve a higher upfront investment, their durability leads to lower maintenance and replacement costs over their lifespan. S355 and S420 are less prone to wear and structural failure, which can result in significant long-term savings. The initial higher cost is often balanced by reduced lifecycle costs, making these grades a cost-effective choice for long-term projects.

The use of S355 steel in The Shard, an iconic skyscraper in London, allowed for a significant reduction in structural weight while maintaining strength. This led to lower material costs and faster construction times, demonstrating the economic benefits of opting for high-strength steel grades.

The construction of the Burj Khalifa, the world’s tallest building, utilized high-strength structural steel to reduce the overall weight of the structure while maintaining its stability and strength. This innovative approach allowed the building to reach unprecedented heights, standing at 828 meters (2,717 feet). The design also incorporated advanced engineering techniques to withstand the harsh desert climate and high winds. The Burj Khalifa, completed in 2010, has since become an iconic symbol of modern architecture and engineering prowess, attracting millions of visitors from around the world each year.

All four grades of structural steel – S235, S275, S355, and S420 – are highly recyclable, nearly reaching 100%. Recycling these steels significantly reduces waste, conserves natural resources, and while the energy required might vary slightly due to differences in their chemical compositions, the overall environmental impact is substantially lower compared to producing new steel from raw materials.

The use of recycled steel in construction projects helps reduce environmental impacts such as global warming potential and resource depletion. Environmental Product Declarations (EPDs) can be used to quantify these impacts. S355 and S420, often used in large-scale and high-stress applications, can have a greater positive impact on reducing the carbon footprint of a project due to their high strength-to-weight ratios.

Steel structures made from these grades generally have a longer lifespan compared to many other construction materials. S420, with its high yield strength, can be used in structures that are likely to endure more severe mechanical stresses over time, reducing the need for frequent replacements. S235, while having lower strength, is still durable enough for general construction, which also contributes to long-term material conservation.

Structural steels offer a higher strength-to-weight ratio compared to materials like concrete. S420 has the highest yield strength, which means less material is needed to achieve the same level of strength as the other grades. This can lead to significant reductions in material and foundation costs for heavy-duty applications. S235, on the other hand, is more cost-effective for general construction where high strength is not the primary requirement, as it provides a good balance of strength and cost.

Steel components made from all four grades can be prefabricated off-site, accelerating construction timelines and reducing labor costs. While higher-strength steels like S355 and S420 may require more precise fabrication, their ability to support larger loads can reduce the number of structural components needed, potentially lowering overall material costs.

The durability of steel structures from these grades leads to fewer repairs and replacements over time. S355 and S420, with their ability to withstand high stresses, are less prone to wear and structural failure, resulting in significant long-term cost savings. S235 and S275, while having lower initial costs, may require more maintenance in high-stress applications, which could increase long-term costs.

Below are answers to some frequently asked questions:

S235, S275, S355, and S420 are grades of structural steel defined under the EN 10025 standard. They differ primarily in their mechanical properties, particularly yield strength, which is the stress at which a material begins to deform plastically.

All these grades have good weldability, though S235 is noted for its superior weldability due to its lower carbon content. Understanding these differences helps in selecting the right material for specific construction needs, balancing strength, cost, and environmental considerations.

S235 steel, a low-carbon manganese steel, is used in general construction projects like steel structures and bridges, automotive parts such as frames and suspension components, military applications like armored vehicles, and outdoor facades due to its good weldability, impact resistance, and moderate corrosion resistance. S275, with a higher yield strength of 275 MPa, is suitable for industrial building frames, light steel residential buildings, and large public structures. S355, a high-strength steel with a 355 MPa yield strength, is employed in high-rise buildings, wind and solar energy equipment, and bridge construction. S420, having the highest yield strength of 420 MPa, is used for heavy engineering equipment and offshore structures that require high strength and durability.

The EN 10025 standard significantly impacts the production and use of structural steels, such as S235, S275, S355, and S420, by ensuring uniformity in quality and specifications across Europe. This standard harmonizes the mechanical properties and chemical composition requirements, which enhances the consistency, safety, and performance of structural steel products.

By standardizing these specifications, EN 10025 enables easier international trade and interoperability of steel products, reducing complications associated with varying national standards. It ensures that all structural steel meets specific criteria for yield strength, tensile strength, and elongation, which is crucial for the integrity and durability of construction projects.

Additionally, EN 10025 facilitates efficient production processes and contributes to sustainability by promoting the use of high-quality materials that require less maintenance over time. This standard ensures that manufacturers produce steel that meets rigorous safety and performance standards, thereby supporting the reliability and longevity of structures such as buildings, bridges, and heavy machinery.

When designing with structural steels like S235, S275, S355, and S420, consider the following practical tips:

These tips ensure that your design is both efficient and effective while meeting structural and serviceability requirements.

The cost – effectiveness of different structural steel grades varies based on their properties and applications. S235 and S275 are cost – effective for residential and industrial buildings due to their balance of cost and performance, with S235 having good plasticity and S275 slightly higher strength. S355 and S420, while having a higher initial cost, offer better strength – to – weight ratios for high – demand projects like high – rise buildings and heavy equipment. In comparison with concrete and wood, structural steel, despite a higher upfront cost, has lower long – term maintenance needs, making it more cost – effective over time.

When choosing structural steels such as S235, S275, S355, and S420, several sustainability considerations come into play. Structural steel is highly recyclable and reusable, with nearly 98% recycled into new products, reducing raw material needs and waste. Using recycled materials in production cuts the carbon footprint as it requires less energy. Efficient design and fabrication can minimize material usage and waste. Responsible material sourcing, with suppliers having environmental management systems, is crucial. The industry aims for net – zero carbon emissions by 2050, promoting low – carbon production. Steel structures enhance building energy efficiency and are long – lasting, reducing maintenance. Compliance with standards like EN 10025 ensures environmental performance.