In the world of industrial engineering, aerospace innovation, and cutting-edge automotive design, the materials that build our future must be as resilient as they are versatile. Steel, a cornerstone of modern engineering, stands out for its strength and adaptability, particularly when the heat is on. But not all steel is created equal—especially when it comes to withstanding extreme temperatures.

Whether you’re designing components for a jet engine or selecting materials for a high-performance furnace, understanding the temperature resistance of various steel types is crucial. This article delves into the fascinating realm of heat-resistant steels, unraveling the secrets behind their impressive performance. We’ll explore the chemical compositions that empower steels like 304, 316, and Chrome Moly to thrive in scorching environments, and uncover the specific applications where they excel.

From the interplay of chromium and nickel to the impact of titanium and other elements, discover how these metals maintain their integrity under relentless heat. Join us on a journey through the fiery trials these steels endure, and learn how to choose the right material for your high-temperature needs.

304 stainless steel is highly versatile and widely used across various industries due to its excellent balance of corrosion resistance, durability, and affordability.

The alloy primarily consists of iron, with approximately 18% chromium and 8% nickel, which enhances its corrosion resistance and strength; it also includes carbon, manganese, silicon, phosphorus, sulfur, and nitrogen to refine its mechanical properties.

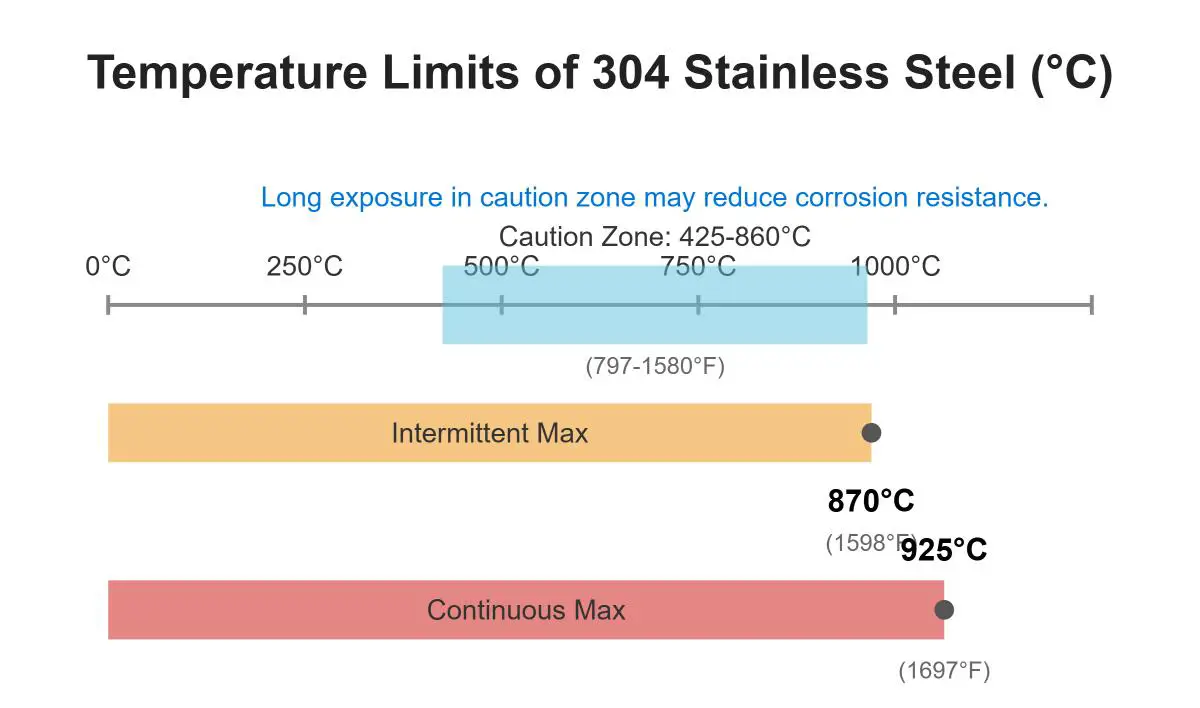

304 stainless steel can handle intermittent temperatures up to 870°C and continuous temperatures up to 925°C, making it suitable for varying temperature exposures.

Commonly found in home appliances, heat exchangers, and food processing equipment, 304 stainless steel is ideal for environments requiring oxidation and corrosion resistance.

Thus, it’s important to consider the specific operating conditions when using this material in high-temperature environments.

309 stainless steel is specifically designed to withstand high temperatures, making it a superior option for heat-intensive applications.

Containing higher levels of chromium (around 23%) and nickel (approximately 13%) than 304, 309 stainless steel offers enhanced heat resistance.

309 stainless steel can tolerate temperatures up to 980°C intermittently and 1095°C continuously. This high-temperature resilience makes it suitable for components exposed to extreme heat.

Often used in high-temperature machinery, oven linings, and furnaces, 309 stainless steel excels in environments exposed to extreme heat.

310 stainless steel excels in applications requiring superior high-temperature strength and oxidation resistance.

310 stainless steel, with about 25% chromium and 20% nickel, is designed to perform in extreme heat conditions.

This steel grade can endure temperatures up to 1035°C intermittently and 1150°C continuously, making it one of the most heat-resistant stainless steels available.

310 stainless steel is perfect for burner tips, heat exchangers, and other high-heat equipment, ensuring reliability under intense thermal stress.

316 stainless steel is known for its enhanced corrosion resistance, especially in chloride environments.

With around 16% chromium, 10% nickel, and 2% molybdenum, 316 stainless steel offers superior resistance to pitting and crevice corrosion.

This alloy can handle intermittent temperatures up to 870°C and continuous temperatures up to 925°C, similar to 304, but with added corrosion resistance.

316 stainless steel is extensively used in medical equipment, chemical manufacturing, and marine environments due to its excellent corrosion resistance.

321 stainless steel is stabilized with titanium, which enhances its resistance to intergranular corrosion.

Containing similar chromium and nickel levels as 304, 321 stainless steel includes titanium for added stability at high temperatures.

321 can be used intermittently up to 870°C and continuously up to 925°C, providing reliable performance in high-temperature conditions.

321 stainless steel is commonly used in aerospace, chemical processing, and heat exchangers for its durability and high-temperature oxidation resistance.

410 stainless steel is a martensitic grade known for its high strength and moderate corrosion resistance.

410 stainless steel, with about 12% chromium, balances hardness and corrosion resistance, enhanced by its carbon content.

This steel can be used intermittently up to 815°C and continuously up to 705°C, suitable for moderate temperature applications.

410 stainless steel is utilized in cutlery, steam turbine blades, and other high-strength, wear-resistant applications.

420 stainless steel is a high-carbon variant of 410, offering increased hardness.

420 stainless steel, a high-carbon variant of 410, offers increased hardness and strength.

It withstands intermittent temperatures up to 735°C and continuous temperatures up to 620°C, suitable for applications where hardness is crucial.

420 stainless steel is commonly used in surgical instruments, cutlery, and other applications requiring sharpness and durability.

Chrome Moly steel is an alloy known for its exceptional strength and heat resistance.

Chrome Moly steel contains chromium and molybdenum, which enhance its strength, toughness, and high-temperature resistance.

Chrome Moly can withstand extreme temperatures, making it ideal for power plants and petrochemical industries where high thermal stability is required.

Chrome Moly steel is extensively used in power generation, petrochemical, and oil and gas industries for its performance under severe service conditions.

304 stainless steel is an austenitic alloy primarily made of iron, with significant amounts of chromium and nickel. The typical composition includes about 18% chromium and 8% nickel, providing corrosion resistance and enhanced mechanical properties. It also contains small amounts of carbon, manganese, silicon, phosphorus, sulfur, and nitrogen, which contribute to its stability and performance.

304 stainless steel can resist oxidation in intermittent service up to 870°C (1,598°F). This makes it suitable for environments where it is occasionally exposed to high temperatures without significant degradation.

For continuous use, 304 stainless steel can withstand temperatures up to 925°C (1,697°F). However, continuous exposure between 425-860°C (797-1,580°F) may reduce its corrosion resistance.

304 stainless steel is widely used in various industries due to its versatility and robustness. Common applications include:

While 304 stainless steel offers excellent corrosion resistance, high temperatures, especially with chlorides, can compromise its performance. Stress corrosion cracking can occur in environments over 60°C (140°F). For higher strength at elevated temperatures, 304H, the high-carbon variant, is recommended. Evaluate the specific conditions of use to ensure the material maintains its integrity and functionality.

309 stainless steel is an austenitic alloy known for its high resistance to heat. Its composition includes 22-24% Chromium, 12-15% Nickel, up to 0.08% Carbon, 2% Manganese, 1% Silicon, 0.045% Phosphorus, and 0.03% Sulfur. The high levels of chromium and nickel help it resist oxidation and corrosion, making it suitable for high-temperature environments.

309 stainless steel can withstand temperatures up to 1093°C (2000°F) in intermittent use and up to 1038°C (1900°F) in continuous use. This makes it highly effective for applications where the material is exposed to extreme heat conditions.

This material is ideal for high-temperature machinery, oven linings, industrial furnaces, and heat exchangers due to its exceptional heat resistance. Its ability to perform reliably under these conditions makes it a preferred choice in many industrial settings.

The high chromium and nickel content provide strong oxidation resistance, preventing scale formation and maintaining surface integrity, even in sulfur-containing environments. This ensures longevity and durability in various challenging conditions.

309 stainless steel retains significant mechanical strength at high temperatures, with a tensile strength around 150 MPa at 850°C, maintaining structural stability and mechanical properties. This makes it suitable for demanding applications that require both strength and heat resistance.

Compared to other grades, 309 stainless steel offers better temperature resistance than 304, is nearly as good as 310, and surpasses 321 stainless steel. This makes it a versatile and reliable option for high-temperature applications.

In summary, 309 stainless steel’s combination of high-temperature resistance, corrosion and oxidation resistance, and mechanical strength makes it a reliable choice for industrial applications involving extreme heat.

310 stainless steel is a high-performance austenitic chromium-nickel alloy known for its exceptional temperature and oxidation resistance. The chemical composition typically includes:

310 stainless steel can withstand continuous exposure to temperatures up to 1100°C (2000°F) in oxidizing environments. This makes it highly suitable for environments where the material is consistently exposed to high heat without significant degradation.

For intermittent service, the material can handle temperatures up to 1038°C (1900°F). Its resistance to rescaling and low coefficient of thermal expansion contribute to its ability to endure thermal cycling without warping or losing structural integrity.

Due to its high-temperature properties, 310 stainless steel is ideal for various demanding applications, including:

The tensile strength decreases with rising temperature, such as approximately 50 MPa at 1000°C (1832°F) and around 9 MPa at 1050°C (1922°F).

In low sulfur oxidizing environments, it operates continuously at up to 1050°C (1922°F) and intermittently at up to 1100°C (2012°F). In higher sulfur conditions, the maximum temperature limit is reduced to 950°C (1742°F).

In low oxygen environments, the maximum service temperature is approximately 1000°C (1832°F), making it versatile for various industrial applications.

310 and 310S stainless steels are weldable using common techniques such as fusion and resistance welding, although oxyacetylene welding is not recommended. Annealing involves heating the material to 1050-1150°C (1922-2102°F) followed by water quenching. For hot working, initial temperatures should be 1150-1200°C (2102-2192°F) with finishing temperatures above 950°C (1742°F) to maintain its mechanical properties and prevent brittleness.

Overall, 310 stainless steel’s high-temperature resistance and mechanical durability make it an excellent choice for industrial applications involving extreme heat.

316 stainless steel is an austenitic alloy primarily made of iron, with key elements like chromium, nickel, and molybdenum. Its typical chemical composition includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, with smaller amounts of carbon, manganese, silicon, phosphorus, and sulfur. Molybdenum enhances the alloy’s resistance to corrosion, especially in chloride environments.

316 stainless steel can withstand various temperatures depending on the type of service. It can resist oxidation up to 870°C (1,598°F) in intermittent service and up to 925°C (1,697°F) in continuous service, though prolonged exposure at high temperatures may affect its corrosion resistance.

316 stainless steel is widely used in medical, chemical, marine, food processing, and pharmaceutical industries. It is ideal for surgical instruments, chemical processing equipment, boat fittings, food processing machinery, and pharmaceutical manufacturing.

High temperatures can reduce corrosion resistance, especially above 425°C (797°F), leading to chromium carbide formation. Using 316L, a low-carbon variant, can prevent this.

316 stainless steel has a melting point between 1,371°C and 1,399°C (2,500°F to 2,550°F). It has low thermal conductivity (16.3 W/mK) and a significant coefficient of thermal expansion (16.5 x 10^-6/°C between 20°C and 200°C).

316 stainless steel is used in high-temperature environments where corrosion resistance is essential, such as chemical processing equipment, medical sterilization tools, and marine applications.

While 310 and 330 stainless steels offer higher temperature resistance, 316 stainless steel’s excellent corrosion resistance and mechanical properties make it versatile for both high-temperature and corrosive conditions.

321 stainless steel is an austenitic alloy mainly composed of iron, with around 18% chromium and 8% nickel. The addition of titanium, in a quantity of at least five times the carbon content, stabilizes the alloy, preventing chromium carbide precipitates during welding or high-temperature exposure. This stabilization is crucial for maintaining resistance to intergranular corrosion.

321 stainless steel can handle intermittent temperatures up to 900°C and continuous temperatures up to 925°C. The titanium addition ensures the material retains its mechanical properties and corrosion resistance even at these high temperatures.

321 stainless steel is widely used in industries that require materials to maintain their properties at high temperatures. In the aerospace sector, it’s used in aircraft exhaust systems and jet engine parts due to its excellent high-temperature stability. In chemical processing, it’s ideal for heat exchangers and other components in chemical plants where high-temperature resistance is essential. In the automotive industry, it’s used in exhaust systems and other components exposed to high temperatures. Additionally, it is employed in the construction of furnace components that operate under high thermal stress.

321 stainless steel offers excellent resistance to intergranular corrosion, which is particularly beneficial in high-temperature environments. However, it is less resistant to pitting and crevice corrosion in chloride-rich environments compared to other stainless steels. Therefore, it’s more suitable for high-temperature applications rather than environments with high chloride exposure.

321 stainless steel maintains good mechanical properties even at elevated temperatures, with a proof stress of 205 MPa, tensile strength of 515 MPa, elongation of 40%, and hardness of HB 217, HRB 95. Its physical properties include a density of 0.29 g/cm³, modulus of elasticity of 193 GPa, thermal expansion coefficient of 16.6 µm/m°C at 1-100°C, and thermal conductivity of 16.1 W/mK at 100°C and 22.2 W/mK at 500°C.

321 stainless steel has good forming and welding characteristics, making it versatile for various fabrication methods. However, the titanium in 321 does not transfer well across a high-temperature arc, which can complicate welding. In such cases, using Type 347 stainless steel, stabilized with niobium, is preferred for welding applications involving 321 stainless steel.

410 stainless steel is a martensitic alloy primarily made of iron, with about 12% chromium. It also contains small amounts of carbon, manganese, silicon, phosphorus, and sulfur. The chromium enhances corrosion resistance, while the carbon contributes to the material’s hardness and strength.

410 stainless steel can handle intermittent temperatures up to 815°C (1499°F) and continuous temperatures up to 705°C (1301°F). These limits make it suitable for applications exposed to high temperatures periodically or consistently.

Its properties make 410 stainless steel ideal for cutlery, steam and gas turbine blades, petroleum refining equipment, and valves and pump parts. These applications benefit from the alloy’s balance of strength, hardness, and moderate corrosion resistance.

Heat treatment processes like hardening and tempering can enhance its heat resistance. These processes involve heating the steel to high temperatures followed by rapid cooling (quenching) and then reheating to a lower temperature (tempering) to improve toughness. Prolonged exposure to very high temperatures can reduce toughness and hardness, so specific operating conditions and heat treatments are important.

410 stainless steel maintains good corrosion resistance in mild environments and retains significant tensile strength and hardness at elevated temperatures, though ductility may decrease. This balance of properties makes it a versatile choice for applications requiring moderate heat resistance and mechanical strength.

Compared to other stainless steels, 410 stainless steel has moderate heat resistance, higher than some but lower than high-performance alloys like 309 or 310. This positions it as a practical option for many industrial applications.

Welding 410 stainless steel requires preheating and post-weld heat treatment to prevent cracking and ensure structural integrity. Proper handling during welding ensures the material’s performance and durability in various applications.

420 stainless steel is a martensitic alloy renowned for its exceptional hardness and strength.

The chemical composition of 420 stainless steel includes:

This composition gives the alloy its characteristic wear resistance and moderate corrosion resistance.

420 stainless steel can handle moderate temperatures but has limits in extreme conditions: up to 735°C (1355°F) for intermittent service and 620°C (1148°F) for continuous service.

420 stainless steel is ideal for cutlery, surgical instruments, shear blades, and automotive exhaust systems due to its strength, hardness, and moderate corrosion resistance.

Heat treatment significantly enhances 420 stainless steel’s properties. The typical process includes hardening at 980-1030°C followed by oil or air quenching, achieving up to 57 HRC hardness. Tempering at 100-600°C adjusts hardness and toughness, depending on the specific temperature used.

Key thermal properties include:

Compared to other stainless steels, 420 offers higher hardness and wear resistance due to its greater carbon content. However, it has lower temperature resistance than grades like 310 or 316, which are better for extreme temperatures. Thus, 420 stainless steel is preferred when hardness and wear resistance are more critical than high-temperature stability.

Chrome Moly steel, also known as Chromium-Molybdenum steel, is an alloy primarily made of iron, with notable amounts of chromium (Cr) and molybdenum (Mo). The typical composition includes 0.50% to 9.00% chromium, 0.20% to 1.00% molybdenum, 0.05% to 0.15% carbon, up to 1.00% manganese, up to 0.50% silicon, and up to 0.03% each of phosphorus and sulfur. This composition gives Chrome Moly steel its distinctive properties, making it suitable for high-stress, high-temperature applications.

Chrome Moly steel can withstand very high temperatures, keeping its strength and stability under tough conditions.

For intermittent use, Chrome Moly steel can handle temperatures between 540°C and 870°C (1004°F to 1598°F). This makes it suitable for applications with fluctuating thermal cycles.

For continuous use, Chrome Moly steel can endure temperatures from 540°C to 815°C (1004°F to 1499°F), making it ideal for prolonged high-heat environments.

Chrome Moly steel is widely used in various industries due to its excellent performance in high-temperature and high-pressure conditions.

In power generation, Chrome Moly steel is used for components like boilers, steam turbines, and pressure vessels because it resists thermal and mechanical stress.

The petrochemical sector uses Chrome Moly steel in refinery equipment, such as catalytic cracking units, heat exchangers, and reactor vessels, due to its resistance to high temperatures and corrosive environments.

In the oil and gas industry, Chrome Moly steel is essential for offshore drilling rigs and production platforms, providing durability against harsh marine environments and high operational temperatures.

In the automotive and aerospace industries, Chrome Moly steel is used for high-strength, lightweight components like roll cages, fuselages, and engine parts, benefiting from its excellent mechanical properties and heat resistance.

Chrome Moly steel offers high tensile strength, which remains even at high temperatures. This property is crucial for applications involving high mechanical stress and thermal loads.

The chromium content provides excellent resistance to corrosion and oxidation, making Chrome Moly steel suitable for chemical exposure and high temperatures.

Chrome Moly steel has excellent hardenability, allowing it to achieve desired mechanical properties through heat treatment, and it is easy to fabricate and weld, with TIG welding being a preferred method.

The performance of Chrome Moly steel varies with its grade, defined by standards like ASTM A387 and ASME SA387. Common grades include P5 (5% Cr, 0.5% Mo), P9 (9% Cr, 1% Mo), P11 (1.25% Cr, 0.55% Mo), P22 (2.3% Cr, 1% Mo), and P91 (9% Cr, 1% Mo). Each grade offers specific advantages in temperature resistance, mechanical properties, and corrosion resistance, tailored to particular applications.

Chrome Moly steel’s high tensile strength, corrosion resistance, and high-temperature durability make it ideal for demanding industrial applications.

Austenitic heat-resistant steels have high levels of chromium and nickel, which help them withstand high temperatures and resist oxidation. Typical compositions include:

Other elements include:

These elements work together to enhance the steel’s heat resistance, corrosion resistance, and mechanical properties at high temperatures.

| Steel Type | Intermittent Service | Continuous Service |

|---|---|---|

| 304 | Up to 870°C (1,598°F) | Up to 925°C (1,697°F) |

| 309 | Up to 980°C (1,796°F) | Up to 1095°C (2,003°F) |

| 310 | Up to 1035°C (1,895°F) | Up to 1150°C (2,102°F) |

| 321 | Up to 870°C (1,598°F) | Up to 925°C (1,697°F) |

| 330 | Up to 1093°C (2000°F) | Recommended limit of 1038°C (1900°F) |

Due to their exceptional properties, austenitic heat-resistant steels are used in various high-temperature applications, such as:

Austenitic heat-resistant steels derive their high-temperature properties from their chemical composition and crystalline structure, offering key characteristics such as:

Recent advancements in austenitic heat-resistant steels, like the “AH” series by Nippon Steel, have enhanced temperature resistance and mechanical performance. These advanced grades withstand temperatures up to 1000°C (1832°F) and beyond, offering improved oxidation resistance, creep rupture strength, and microstructural stability.

Heat-resistant steels are specially designed to endure high temperatures while maintaining their structural integrity. The specific chemical composition of these steels is crucial to their performance.

Chromium, typically ranging from 5% to 30%, enhances corrosion resistance by forming a stable oxide layer on the steel surface, which protects it from oxidation and scaling at high temperatures.

Nickel, often found in significant amounts, especially in austenitic and nickel-based alloys, improves high-temperature strength, creep resistance, and toughness.

Aluminum is added to some heat-resistant steels to enhance oxidation resistance by forming a protective aluminum oxide layer, which is particularly beneficial in oxidizing environments.

Titanium helps stabilize the steel’s microstructure and improve high-temperature properties, preventing the formation of chromium carbides that can cause intergranular corrosion.

Silicon contributes to forming a stable oxide layer, enhancing the steel’s heat resistance, strength, and oxidation resistance.

The carbon content in heat-resistant steels is generally low to avoid embrittlement, but in some grades, higher carbon levels can enhance hardness and abrasion resistance.

Elements like molybdenum, vanadium, tungsten, cobalt, and cerium are added to increase the temperature range of recrystallization and melting, enhance atomic bonding, and improve creep resistance.

Heat-resistant steels are designed to resist corrosion in high-temperature environments, with chromium, aluminum, and silicon forming a protective oxide layer that prevents scaling and corrosion.

Creep resistance means the steel can resist deformation under constant stress at high temperatures, thanks to its specific alloying elements.

Heat-resistant steels have high fatigue strength, enduring repeated thermal cycling without cracking, and resist scaling, preventing surface degradation.

These steels can withstand high mechanical loads while maintaining a stable microstructure, thanks to their alloying elements, preventing brittleness even under extreme temperatures.

Austenitic steels like 304, 316, and 321 are known for their high nickel and chromium content, providing excellent resistance to high temperatures and corrosion.

The temperature resistance of different types of steel is largely determined by their specific chemical composition and the resulting material properties. Understanding these factors is crucial for selecting the appropriate steel for high-temperature applications.

Heat-resistant steels are indispensable across numerous industries due to their ability to maintain structural integrity and performance under extreme temperatures. These steels are engineered to resist thermal stress, cracking, fatigue, and corrosion, making them vital for applications where high temperatures are a constant challenge.

In the oil and gas industry, heat-resistant steels play a crucial role. Chrome Moly (chromium and molybdenum alloy) steels are commonly used in pipelines, construction, and equipment. These steels offer:

These properties make them ideal for components such as drilling rigs, production platforms, and refining equipment.

Industrial furnaces, which operate at temperatures up to 3000°C, heavily rely on heat-resistant steels. Chromium and molybdenum-containing steels are preferred for their ability to withstand frequent and prolonged high-temperature exposure. This ensures durability and efficiency in extreme heat environments, making them suitable for furnace linings, heat treatment equipment, and other high-temperature components.

In aerospace and automotive industries, high-temperature resistance is essential for components like engine parts, exhaust systems, and heat exchangers. Stainless steel alloys such as 309, 310, and 321 are frequently used. For instance:

These alloys retain strength and resist corrosion at extreme temperatures, ensuring reliable performance.

The petrochemical and chemical industries demand equipment that can withstand aggressive media and high temperatures. Chrome Moly steel is favored for its:

Stainless steels like 304 and 316 are also used in chemical manufacturing and storage, providing resistance to various liquids and high temperatures.

In mechanical engineering and industrial chemistry, heat-resistant steels are essential for manufacturing furnace equipment, heat-exchange equipment, heat shields, and parts of thermal furnaces and combustion chambers. Alloys such as titanium, chrome-nickel, and molybdenum-based steels are chosen for their ability to perform reliably in high-temperature environments.

The defense and transportation sectors utilize heat-resistant steels in jet technology and high-strength iron alloys. Titanium and chrome-nickel alloys are particularly important due to their:

These properties make them ideal for aircraft components, combustion liners, and turbine exhaust components, ensuring safety and reliability under extreme conditions.

Heat-resistant steels are vital in various high-temperature applications across multiple industries. Their unique properties, such as high-temperature strength, corrosion resistance, and durability, make them indispensable for ensuring the reliability and efficiency of critical components and equipment. As technology advances, the demand for these robust materials continues to grow, highlighting their importance in modern industrial applications.

Industrial engineers frequently deal with high-temperature equipment like furnaces, heat exchangers, and chemical processing units. Selecting the right heat-resistant steel involves evaluating:

In aerospace and automotive sectors, materials must endure extreme temperatures and mechanical stress. Considerations include:

Manufacturers need to balance performance and cost-effectiveness when selecting materials for high-temperature applications:

Understanding the difference between intermittent and continuous temperature limits is vital. Steels exposed to high temperatures for short periods can tolerate higher maximum temperatures, while continuous exposure requires materials that maintain integrity over time. For example, 309 stainless steel can handle intermittent temperatures up to 980°C, whereas 316 stainless steel is suitable for continuous use up to 925°C.

High temperatures can impact corrosion resistance. For instance, chromium carbides can form between 425-860°C, reducing corrosion resistance, but using low-carbon variants like 316L can help. High chromium and nickel content in steels like 310 enhance oxidation resistance, forming protective oxide layers that maintain surface integrity.

Operational environments significantly impact material selection. For example, steels used in chemical processing must resist aggressive chemicals, and high-pressure applications need excellent creep resistance, such as alloys with added vanadium and niobium.

When selecting steel, consider its expected service life and allowable deformation. Choose materials that withstand maximum operating temperatures and stresses without significant degradation, such as 310 stainless steel for long-term high-temperature service. Understanding the material’s creep resistance is crucial for applications involving prolonged exposure to high temperatures.

By considering these factors, professionals can select the most appropriate heat-resistant steel for their specific applications, ensuring optimal performance and durability.

Below are answers to some frequently asked questions:

304 stainless steel can withstand temperatures up to 870°C (1,598°F) intermittently and up to 925°C (1,697°F) continuously. However, long-term exposure in the range of 425-860°C (797-1580°F) may reduce its corrosion resistance.

Grade 310 stainless steel can withstand much higher temperatures compared to Grade 316 stainless steel. Grade 310 can handle continuous service temperatures up to 2000°F (1093°C) and retains its mechanical properties better at elevated temperatures. In contrast, Grade 316 stainless steel is recommended for continuous service up to around 920°F (498°C). Therefore, Grade 310 is more suitable for high-temperature applications due to its superior heat resistance and strength retention.

321 stainless steel is commonly used in high-temperature environments due to its excellent resistance to intergranular corrosion and superior mechanical properties at elevated temperatures. Typical applications include exhaust systems and engine parts in the aerospace industry, heat exchangers and pressure vessels in chemical processing, boiler and superheater tubes in power generation, refinery piping and furnace components in petrochemical and oil & gas industries, exhaust manifolds and catalytic converters in automotive applications, furnace components and thermocouple sheaths in heat treatment equipment, and heat exchangers and piping systems in the food processing industry. These applications benefit from the alloy’s ability to withstand intermittent temperatures up to 900°C (1652°F) and continuous temperatures up to 925°C (1697°F).

The chemical composition of Chrome Moly steel enhances its heat resistance primarily through the presence of chromium and molybdenum. Chromium contributes to corrosion resistance by forming a protective oxide layer on the steel’s surface, which helps prevent oxidation and sulfidation at high temperatures. Molybdenum enhances the steel’s high-temperature strength, allowing it to maintain structural integrity and resist deformation under thermal stress. Together, these elements increase the steel’s tensile strength and ensure uniform hardness, making Chrome Moly steel suitable for demanding high-temperature applications such as in power plants and petrochemical industries.

The difference between intermittent and continuous temperature limits for steel types lies in the duration and pattern of heat exposure. Continuous temperature limits refer to the maximum temperatures a steel alloy can withstand over extended periods without degrading its properties. In contrast, intermittent temperature limits apply to short-term exposures to high temperatures followed by cooling periods. This intermittent exposure causes thermal cycling, leading to expansion and contraction, which can introduce additional stress and potentially cause material failure. Understanding these differences is crucial for selecting the appropriate steel type for specific applications to ensure durability and performance under varying thermal conditions.

High temperatures can significantly affect the corrosion resistance of stainless steel. Elevated temperatures can disrupt the thin passive film that protects stainless steel from corrosion, leading to increased corrosion rates. This effect is more pronounced in the presence of chloride environments, which can exacerbate localized corrosion such as pitting and stress corrosion cracking. Additionally, high temperatures can cause oxidation and scaling, further compromising the protective film and leading to metal wastage. The specific impact varies depending on the type of stainless steel and the environmental conditions, with some grades being more resistant to high-temperature corrosion than others.