Have you ever wondered what makes 60/40 brass such a versatile material in various industries? This technical deep – dive is crafted for intermediate learners seeking in – depth knowledge. 60/40 brass is primarily composed of copper and zinc, with copper playing a key role in conductivity and zinc contributing to strength. These elements give it unique physical properties like good corrosion resistance and ductility.

In the following sections, we’ll explore its exact chemical makeup, physical traits, and diverse applications. Curious about how it stacks up against other materials? Read on to find out.

60/40 brass, also known as cartridge brass, is an alloy primarily composed of copper and zinc, with additional elements like lead and trace amounts of other metals. This alloy combines excellent machinability, good corrosion resistance, and balanced mechanical strength.

Copper (Cu) makes up between 59.0% and 61.5% of 60/40 brass. Copper is known for its excellent electrical and thermal conductivity, as well as its ductility and corrosion resistance. In this alloy, copper enhances the overall mechanical properties by contributing to the material’s strength and durability. This makes 60/40 brass an ideal choice for applications where both electrical conductivity and structural integrity are important.

Zinc (Zn), comprising between 34.5% and 40% of the alloy, plays a critical role in improving strength and hardness. Zinc also contributes to the alloy’s ductility, allowing it to be easily worked and formed. The presence of zinc helps balance the mechanical properties of 60/40 brass, making it robust enough to withstand significant stress while remaining ductile enough to be formed into intricate shapes.

Lead (Pb) is included in smaller amounts, typically ranging from 0.8% to 3.0% by weight. Lead improves the alloy’s machinability. It acts as a lubricant during machining processes, reducing friction and wear on cutting tools. This makes 60/40 brass ideal for manufacturing components requiring precise machining, such as fittings and fasteners. However, lead can negatively impact environmental properties and electrical conductivity, so its content is carefully controlled.

In addition to copper, zinc, and lead, 60/40 brass may contain trace amounts of elements such as iron (Fe), nickel (Ni), aluminum (Al), and tin (Sn). These elements are present in very small quantities, usually less than 0.35% by weight. Each trace element influences the alloy’s properties in specific ways:

The precise control of these trace elements ensures 60/40 brass maintains desirable properties while minimizing any negative effects.

The chemical composition of 60/40 brass can be summarized as follows:

This balanced composition allows 60/40 brass to offer a combination of strength, ductility, machinability, and corrosion resistance, making it a versatile material for a wide range of applications.

60/40 brass has a density of about 8,520 kg/m^3. This relatively high density is attributed to the alloy’s significant zinc content, which contributes to its overall mass.

60/40 brass exhibits a tensile yield strength of around 140 MPa. This measures the stress level where the material starts to deform permanently, providing a measure of its ability to withstand applied forces without permanent deformation.

The ultimate tensile strength of 60/40 brass ranges from approximately 360 MPa and can be higher depending on the specific application and any additional elements present in the alloy. This strength reflects the maximum stress the material can endure before failure, making it suitable for components subjected to high loads.

With a Rockwell hardness of B78, 60/40 brass offers considerable resistance to wear and surface deformation, which is beneficial in applications where the material must maintain its integrity under mechanical stress and frequent contact.

60/40 brass can elongate up to 53% before breaking. This high ductility indicates the material’s ability to absorb significant deformation before breaking, making it ideal for forming and machining processes.

60/40 brass has a thermal conductivity of approximately 117 W/m·K, making it effective for heat transfer applications such as radiators and heat exchangers. This property ensures efficient thermal management in various industrial settings.

The thermal expansion coefficient of 60/40 brass is around 20.3 x 10^-6/K. This indicates how much the material expands or contracts with temperature changes, ensuring dimensional stability in environments with fluctuating temperatures.

60/40 brass has an electrical conductivity of roughly 26% IACS (International Annealed Copper Standard). While not as high as pure copper, this level of conductivity is adequate for many electrical components, balancing conductivity with mechanical strength.

Young’s modulus for 60/40 brass is approximately 105 GPa, which measures the material’s stiffness and resistance to elastic deformation. This property is crucial for applications where rigidity and structural integrity are required.

60/40 brass has a Poisson’s ratio of around 0.35, indicating its behavior under mechanical loading. This ratio helps predict the material’s stability and deformation characteristics when subjected to stress.

60/40 brass may include additional elements such as lead, tin, and aluminum, which enhance its machinability, strength, and corrosion resistance. Lead, in particular, improves machinability by reducing friction during machining processes, while tin and aluminum contribute to forming a protective oxide layer that enhances corrosion resistance.

The physical properties of 60/40 brass make it suitable for a wide range of applications, including plumbing fixtures, electrical components, precision engineering, and musical instruments. Its combination of strength, ductility, and corrosion resistance ensures reliability and performance in various environments, especially those exposed to moisture and chemicals.

60/40 brass is highly valued in industrial applications because it offers an excellent balance of strength, ductility, and machinability. It can withstand mechanical stress and remain formable, making it ideal for manufacturing.

In manufacturing, 60/40 brass is widely used to produce components that demand high precision and durability. This includes gears, bearings, and bushings, where the alloy’s wear – resistance and mechanical properties ensure long – term performance. Moreover, its machinability enables the production of complex parts with tight tolerances, which is crucial in high – precision industries.

60/40 brass is a preferred material for plumbing fixtures and electrical components because of its corrosion resistance and moderate electrical conductivity.

The machinability of 60/40 brass is one of its most notable properties, making it an excellent choice for various machining and forming processes.

Several industries have successfully used 60/40 brass in critical applications, demonstrating its versatility and reliability.

When compared to other materials, 60/40 brass offers a unique combination of properties that make it suitable for a wide range of applications.

Turning is a fundamental machining process for 60/40 brass. The chips from turning 60/40 brass break easily, avoiding entanglement with the cutting tool. High-speed steel or carbide tools are commonly used. For rough turning, a relatively large depth of cut and feed rate can be employed to remove material quickly. In finish turning, lower feed rates and depths of cut are used to achieve a smooth surface finish. The cutting speed should be carefully selected based on the tool material and the diameter of the workpiece.

Milling 60/40 brass allows for the creation of complex shapes. End mills, face mills, and ball-nose mills can be used depending on the required geometry. For example, intricate shapes like gear teeth can be milled with high precision. The lead in the alloy reduces tool wear during milling operations. When using a CNC milling machine, the programmer can take advantage of the alloy’s good machinability to create parts with high precision.

Drilling holes in 60/40 brass is relatively straightforward. Standard twist drills can be used, and the drill bit should be sharp to ensure clean holes. The lead content in the brass acts as a lubricant, reducing friction between the drill bit and the workpiece. This results in less heat generation and longer drill bit life. When drilling multiple holes, a proper peck-drilling technique can be used to clear chips from the hole and prevent chip clogging.

Hot forming of 60/40 brass is often used when significant deformation is required. Specific grades like CZ129/CW611N are well-suited for hot forming processes. At elevated temperatures, the alloy becomes more ductile, allowing it to be shaped more easily. Forging is a common hot-forming method where the heated brass is hammered or pressed into the desired shape. Extrusion is another option, where the heated alloy is forced through a die to create long, uniform shapes such as rods or tubes.

Cold forming can also be performed on 60/40 brass, although it has some limitations. The alloy’s good ductility allows for cold heading, cold rolling, and cold bending to a certain extent. However, there is a risk of work hardening during cold forming, which can make the material brittle. Intermediate annealing, which involves heating the material to a specific temperature and then cooling it, can be used to restore ductility if multiple cold-forming operations are needed. Cold-formed parts often have better dimensional accuracy and surface finish compared to hot-formed parts.

One of the main challenges in machining 60/40 brass is the presence of lead. While lead improves machinability, it can reduce the electrical conductivity of the final product, which is a concern for electrical applications. To address this, the lead content can be carefully controlled during the alloy production process. Another challenge is the potential for built-up edge formation on the cutting tool. This can be reduced by using appropriate cutting fluids and optimizing the cutting parameters.

In hot forming, controlling the temperature is crucial. If the temperature is too low, the alloy may not be ductile enough, leading to cracking or incomplete forming. If the temperature is too high, the alloy may oxidize, affecting its surface quality. For cold forming, work hardening is a significant challenge. Intermediate annealing can help restore the ductility of the material. Additionally, proper lubrication is essential in both hot and cold forming to reduce friction and prevent surface damage.

The high machinability of 60/40 brass significantly enhances its material efficiency. During machining processes, this alloy produces chips that break easily, reducing waste significantly. This efficiency in material usage not only conserves resources but also streamlines manufacturing operations, leading to a more sustainable production cycle. For instance, in the production of small, intricate components, the ease of machining 60/40 brass allows for precise shaping with minimal material loss.

This alloy’s components can endure harsh environments, like plumbing systems or marine applications, without significant degradation. This resistance reduces the need for frequent replacements, which in turn decreases the overall maintenance costs and downtime.

Brass, including 60/40 brass, is highly recyclable. Recycling brass uses much less energy than producing new brass from raw materials. Recycling brass also helps in conserving natural resources, as it reduces the demand for mining copper and zinc. This closed-loop recycling system contributes to a more sustainable and environmentally friendly production cycle.

The ease of machining 60/40 brass, aided by the lead that reduces friction, directly translates into cost savings during manufacturing. This results in less tool wear, which means lower tool replacement costs. Additionally, the high machinability allows for faster production cycles, increasing the overall efficiency of manufacturing operations.

The durability and corrosion resistance of 60/40 brass contribute to its long lifespan. Components made from this alloy require less frequent maintenance and replacement, which reduces long-term costs. In industrial applications, such as machinery parts, the extended service life of 60/40 brass components can lead to substantial savings in maintenance and replacement expenses.

The wide range of applications of 60/40 brass makes it a cost-effective choice across various sectors. From industrial components to architectural and decorative hardware, this alloy can be used in multiple contexts. This versatility means companies don’t need to source various materials for different uses, cutting procurement costs and simplifying inventory management.

Below are answers to some frequently asked questions:

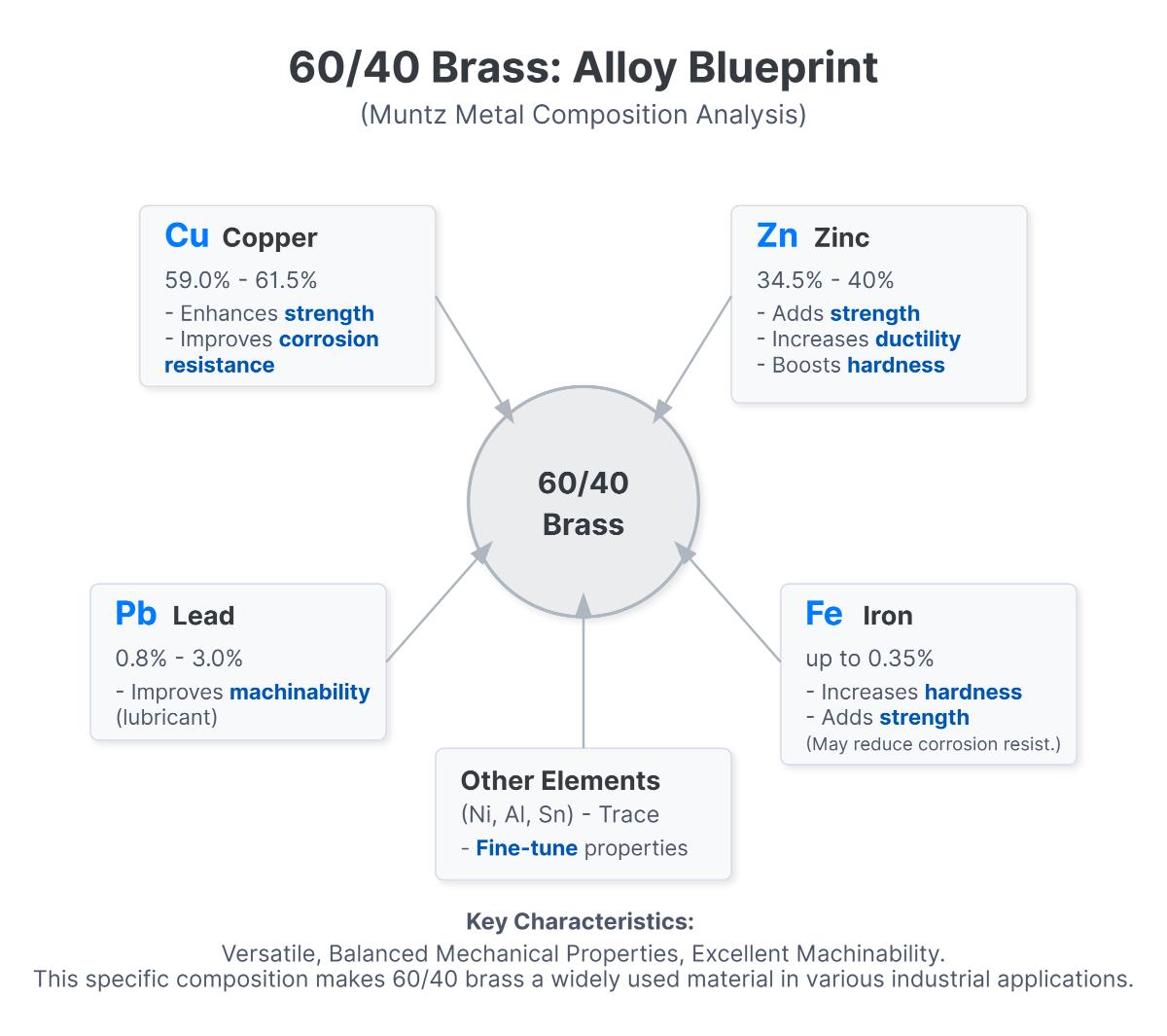

60/40 brass, also known as Muntz metal, is an alloy composed primarily of copper and zinc, with smaller amounts of other elements. The typical chemical composition includes 59.0% to 61.5% copper and 34.5% to 40% zinc by weight. Copper in the alloy enhances its strength and corrosion resistance, while zinc contributes to its strength, ductility, and hardness. Additionally, 60/40 brass contains 0.8% to 3.0% lead, which improves machinability by acting as a lubricant. Trace amounts of iron (up to 0.35%) are present to increase hardness and strength, though they may slightly reduce corrosion resistance. Small quantities of other elements such as nickel, aluminum, and tin might also be included to fine-tune the alloy’s properties. This specific composition makes 60/40 brass a versatile material suitable for various industrial applications due to its balanced mechanical properties and excellent machinability.

60/40 brass, an alloy consisting of 60% copper and 40% zinc, exhibits balanced physical properties suitable for a variety of applications. It has a tensile strength ranging from 338 to 469 MPa, which indicates strong structural integrity. The material’s elongation at break is approximately 53%, allowing for significant deformation without failure. Its hardness is measured at Rockwell B78, contributing to its wear resistance. The yield strength typically falls between 124 and 310 MPa, while the modulus of elasticity is about 14,100 ksi, enabling the material to return to its original shape after deformation.

Thermally, 60/40 brass has a conductivity of 117 W/m·K, making it efficient for heat transfer applications like heat exchangers. Its thermal expansion coefficient is 20.3 x 10^-6/K, ensuring dimensional stability under varying temperatures. Electrically, it has a conductivity of 26% IACS, which is adequate for many electrical components. The alloy also offers excellent corrosion resistance due to its high copper content, making it suitable for harsh environments. Additionally, the presence of lead enhances its machinability, allowing for precise and intricate shapes. The density of 60/40 brass is approximately 8.5 g/cm³, and its Poisson’s ratio is 0.31, indicating stability under mechanical loads. These properties collectively make 60/40 brass a preferred material in industries such as plumbing, electrical components, and precision engineering.

60/40 brass, composed of approximately 60% copper and 40% zinc, is utilized across various industries due to its excellent machinability, balanced mechanical properties, and corrosion resistance. In industrial applications, it is commonly used for manufacturing locks, metal fittings, keys, hinges, bearing cages, valve bodies for refrigeration, oil strainers, plumbing fixtures, and various valves and fittings. The material’s strength and durability make it ideal for these uses.

In marine environments, 60/40 brass is favored for shipbuilding and propellers due to its resistance to seawater corrosion. It is also popular in decorative and architectural applications, such as fireplace screens, door frames, and furniture hardware, due to its aesthetic appeal and workability.

In the electrical and RF components sector, 60/40 brass is used for electrical contacts and RF amplification because of its moderate electrical conductivity. Additionally, it finds applications in liquid filtration and particle separation, particularly in wire mesh forms, owing to its strength and corrosion resistance.

Other notable uses include components in aerospace and power plants, where its mechanical properties and workability are highly valued.

60/40 brass, also known as leaded brass, is distinguished by its composition of approximately 60% copper, 40% zinc, and 0.8-2% lead. Compared to other brass types, 60/40 brass offers a unique balance of properties. It excels in machinability due to its lead content, making it one of the easiest brasses to machine. This is particularly advantageous in applications requiring precision engineering and mass production of components.

In comparison, 65/35 yellow brass, with a slightly higher zinc content, is stronger but less ductile and less machinable than 60/40 brass. It is often used in decorative and mechanical components. On the other hand, 70/30 brass, with a higher copper content, provides greater ductility and formability but lower machinability, making it suitable for applications requiring extensive forming and shaping.

60/40 brass, consisting of 60% copper and 40% zinc, is prized for its excellent machinability, which is further enhanced by the inclusion of lead. The primary machining techniques for this alloy include CNC milling and CNC turning. CNC milling involves using rotating cutting tools to remove material from a stationary workpiece, allowing for the creation of complex shapes with high precision. CNC turning, on the other hand, involves rotating the workpiece while a stationary cutting tool shapes it, making it ideal for producing cylindrical parts with precise tolerances.

Key considerations in machining 60/40 brass include optimizing tool geometry, particularly using a 0° back rake angle to minimize tool wear and simplify regrinding. Proper speed and feed rates are crucial for maximizing tool life and part quality, while cooling systems, such as coolants or lubricants, are essential to manage temperature and chip evacuation.

The lead content in 60/40 brass significantly improves machinability by reducing friction and facilitating discontinuous chip formation, which helps maintain tool integrity. While the alloy has good corrosion resistance, it is not suitable for extreme environments due to the risk of dezincification.

Surface finishing techniques such as polishing, brushing, and coating are commonly used to enhance the appearance and functionality of brass parts, ensuring dimensional accuracy and high-quality finishes.

To enhance the corrosion resistance of 60/40 brass, several methods can be implemented. Adjusting the alloy composition is one approach; increasing the copper content can improve corrosion resistance as copper forms a protective patina. Adding alloying elements like tin, aluminum, and nickel can also enhance resistance, with tin preventing dezincification, aluminum creating a self-healing oxide film, and nickel boosting Protective coatings such as varnish, powder coating, and PVD coating can shield the brass from environmental factors. Cathodic protection methods, including sacrificial anodes and impressed current systems, offer additional defense by preventing the brass from corroding. Applying chemical inhibitors to fluids in contact with the brass can form a protective film, reducing corrosion.

In manufacturing, heat treatment, forging, and annealing processes can improve the alloy’s uniformity and reduce stress concentrations, mitigating stress corrosion cracking. Regular maintenance, including cleaning and inspection, ensures the integrity of protective measures and minimizes exposure to corrosive environments, thereby extending the lifespan and performance of 60/40 brass components.