Imagine a material that combines exceptional strength, impressive corrosion resistance, and remarkable versatility—Titanium Grade 5, also known as Ti-6Al-4V, is exactly that. As one of the most widely used titanium alloys, it plays a crucial role in industries ranging from aerospace to medical fields. But what makes this alloy so special? In this comprehensive technical reference, we delve into the intricate details of Ti-6Al-4V, exploring its chemical composition, physical properties, and a multitude of applications. Whether you are looking to understand its mechanical prowess or its compliance with ASTM standards, this guide provides the data-driven insights you need. How does Titanium Grade 5 stack up against other alloys, and why is it the preferred choice in high-performance environments? Let’s uncover the answers together.

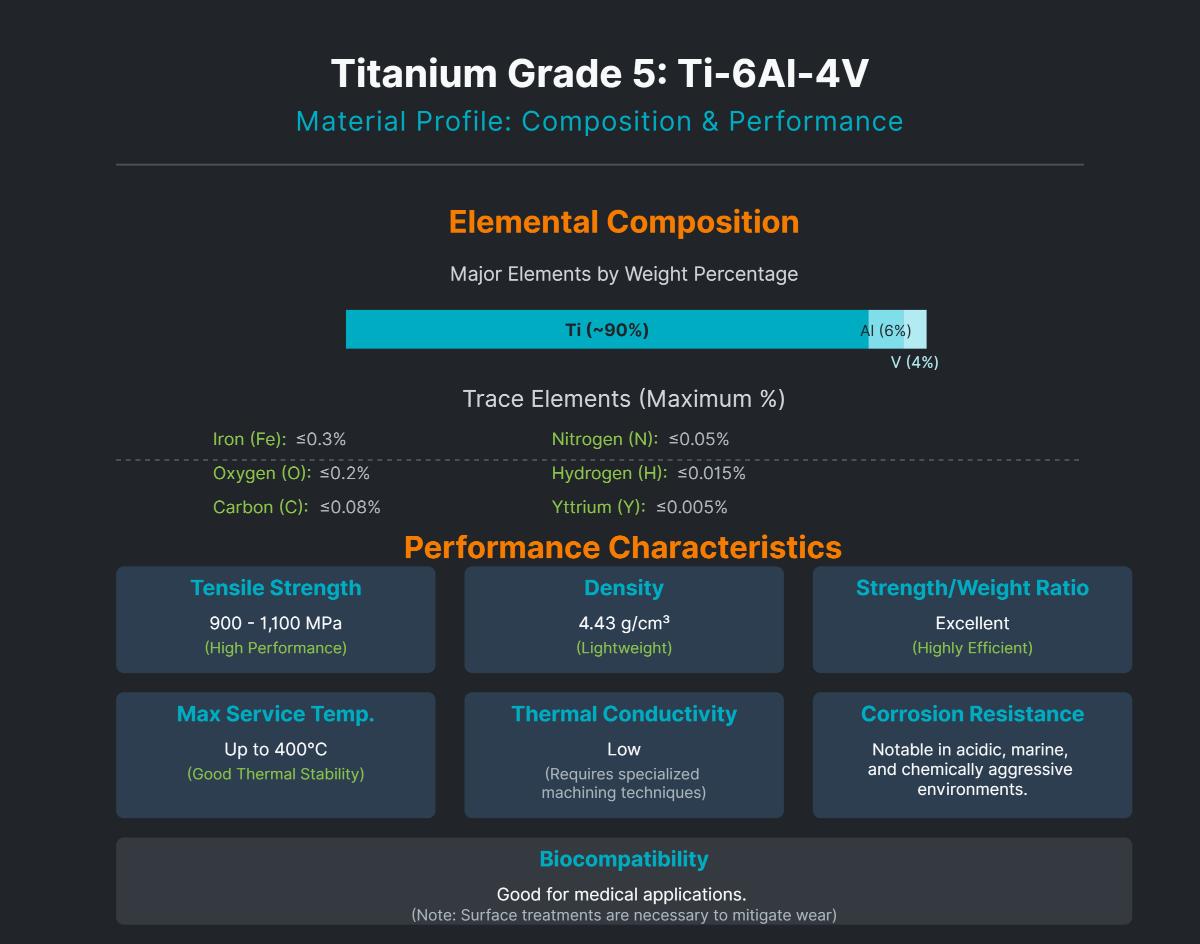

Titanium Grade 5, commonly known as Ti-6Al-4V, is a versatile alpha-beta titanium alloy with a precisely controlled chemical composition. The primary elements and their typical ranges include approximately 90% Titanium (Ti), 5.5% to 6.75% Aluminum (Al), 3.5% to 4.5% Vanadium (V), and trace amounts of Iron (Fe), Oxygen (O), Carbon (C), Nitrogen (N), and Hydrogen (H).

Titanium is the main component, providing natural corrosion resistance and high strength-to-weight ratio. Aluminum, contributing about 6%, strengthens the alloy and improves oxidation resistance while keeping it lightweight. Vanadium, at around 4%, enhances the alloy’s ductility, toughness, and fatigue resistance, making it suitable for high-stress applications.

Iron is considered an impurity in Ti-6Al-4V and is limited to a maximum of 0.3%. While it can enhance strength, excessive iron can negatively impact the alloy’s ductility and toughness. Oxygen, a strong alpha stabilizer, is strictly controlled to a maximum of 0.2%. Higher oxygen levels can significantly increase the alloy’s strength but may lead to embrittlement, reducing ductility. Carbon content is kept to a maximum of 0.08%. It can contribute to the alloy’s strength, but higher levels can adversely affect ductility and toughness. Nitrogen is another minor element controlled to a maximum of 0.05%. Similar to oxygen and carbon, nitrogen can enhance strength but must be limited to avoid compromising ductility. Hydrogen is maintained at a maximum of 0.015%. Excessive hydrogen can lead to embrittlement and degradation of mechanical properties, making its control essential.

Compared to other titanium alloys, Ti-6Al-4V offers a superior combination of strength, ductility, and corrosion resistance. For instance, Titanium Grade 2, primarily composed of commercially pure titanium, has excellent corrosion resistance but lower strength compared to Ti-6Al-4V. Titanium Grade 7, similar to Grade 2 but with added palladium for enhanced corrosion resistance, particularly in reducing environments, does not match the strength and high-temperature performance of Ti-6Al-4V.

The balanced composition of Ti-6Al-4V allows it to perform exceptionally well across various demanding applications, making it the most widely used titanium alloy in critical industries.

Ti-6Al-4V, also known as Grade 5 titanium alloy, offers an exceptional combination of mechanical properties, making it suitable for a wide range of applications.

Ti-6Al-4V is characterized by specific thermal properties that influence its performance in various thermal environments.

Ti-6Al-4V is highly resistant to corrosion in most environments, including seawater and various acids. However, it may be susceptible to stress corrosion cracking in chlorine salts. Its low thermal conductivity can make machining challenging, and its lower shear strength limits its use in applications requiring high shear resistance, like bone screws.

Due to its high strength, low density, and excellent corrosion resistance, Ti-6Al-4V is widely used in aerospace, medical, and marine industries. It’s commonly found in aircraft components, medical implants, and marine hardware.

Titanium Grade 5 (Ti-6Al-4V) is a vital material in the aerospace industry due to its exceptional strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures. It is used in various components such as airframe structures, engine components, landing gear, and fasteners. The material’s ability to maintain structural integrity under high stress and high temperatures makes it ideal for these demanding applications.

In the medical field, Ti-6Al-4V is extensively utilized for its biocompatibility, strength, and resistance to corrosion, making it ideal for surgical implants, including joint replacements, dental implants, and bone plates. The alloy’s compatibility with human tissue and its ability to integrate with bone make it a preferred choice for medical devices. Its durability ensures long-term performance and reliability in medical applications.

Titanium Grade 5 is preferred in marine environments because it resists corrosion, even in seawater. It’s used in subsea equipment, offshore oil and gas platforms, and marine hardware. In chemical processing, it’s employed in heat exchangers and reactors exposed to harsh chemicals. Its ability to withstand harsh chemical exposure without degrading ensures the longevity and safety of the equipment.

Compared to other titanium grades, Ti-6Al-4V stands out due to its superior strength and performance in high-temperature environments. While Titanium Grade 2 offers excellent corrosion resistance, it lacks the high strength of Grade 5. Titanium Grade 7 has enhanced corrosion resistance due to added palladium but is also less strong than Ti-6Al-4V. The unique combination of strength, toughness, and corrosion resistance makes Titanium Grade 5 suitable for more demanding applications.

Advantages include high strength, corrosion resistance, biocompatibility, and lightweight. Disadvantages are higher cost, machining difficulty, and lower shear strength compared to some other materials.

When selecting Titanium Grade 5 for specific applications, several factors should be considered:

The versatile properties of Titanium Grade 5 make it a valuable material across various industries, offering a balance of strength, corrosion resistance, and biocompatibility that is difficult to match with other alloys.

Ti-6Al-4V, also known as ASTM Grade 5 titanium alloy, is regulated by various ASTM standards that ensure its quality and performance in different applications. These standards specify requirements for chemical composition, mechanical properties, microstructure, and testing methods to ensure consistency and reliability.

ASTM F1472 outlines the requirements for wrought Ti-6Al-4V alloy used in surgical implants, addressing its chemical composition, mechanical properties, and microstructure, and specifies testing methods to ensure biocompatibility and mechanical performance, including tensile strength, hardness, fatigue, and corrosion resistance. These provisions are critical for implant reliability and patient safety.

ASTM F2924 focuses on Ti-6Al-4V parts produced through additive manufacturing techniques such as full-melt powder bed fusion and electron beam melting. This standard ensures that the chemical composition, mechanical properties, and post-processing of these parts match those of traditionally manufactured components. This standard is essential as additive manufacturing becomes increasingly prominent for complex aerospace and medical parts.

ASTM F1108 specifies the requirements for cast Ti-6Al-4V alloy used in surgical implants. It includes guidelines for chemical composition, mechanical properties, and quality assurance to ensure that cast components meet the necessary biocompatibility and strength criteria. This standard is crucial for maintaining the integrity and safety of cast medical devices.

Ti-6Al-4V typically contains approximately 6% aluminum and 4% vanadium, with small amounts of iron, oxygen, carbon, and nitrogen as controlled impurities. This composition is optimized to enhance strength and corrosion resistance.

The density of Ti-6Al-4V is around 4.43 g/cm³, which is significantly lower than that of steels, making it ideal for weight-sensitive applications such as aerospace.

Ti-6Al-4V exhibits excellent corrosion resistance in oxidizing environments and bodily fluids, which is particularly advantageous for biomedical implants.

When machining Ti-6Al-4V, it’s important to use low cutting speeds, heavy feed rates, and adequate cooling fluids to prevent tool wear and heat buildup. Avoid using chlorinated cutting fluids to prevent contamination.

Manufacturers must adhere to the specific ASTM standards applicable to their fabrication methods, whether wrought, cast, or additive manufacturing. This adherence ensures:

ASTM standards for Ti-6Al-4V comprehensively cover the alloy’s requirements, ensuring its properties are consistently achieved for reliable performance across various demanding applications. Compliance with these standards is crucial for the safety and effectiveness of Ti-6Al-4V components in industries such as aerospace and biomedical.

Below are answers to some frequently asked questions:

Titanium Grade 5 (Ti-6Al-4V) is an alpha-beta titanium alloy composed of approximately 90% titanium, 6% aluminum, and 4% vanadium. Minor elements include iron (≤0.3%), oxygen (≤0.2%), carbon (≤0.08%), nitrogen (≤0.05%), hydrogen (≤0.015%), and yttrium (≤0.005%).

This alloy is known for its high tensile strength, typically ranging from 900 to 1,100 MPa, and a low density of 4.43 g/cm³, providing excellent strength-to-weight ratios. Ti-6Al-4V retains its mechanical properties at elevated temperatures up to 400°C and has low thermal conductivity, requiring specialized machining techniques. It offers notable corrosion resistance in acidic, marine, and chemically aggressive environments, along with good biocompatibility for medical applications, although surface treatments are necessary to mitigate wear.

Ti-6Al-4V, also known as Titanium Grade 5, is widely used across several industries due to its excellent combination of strength, corrosion resistance, and lightweight properties. In the aerospace industry, it is used for structural components, aircraft engine parts, airframes, and hydraulic systems, contributing to reduced overall mass and improved fuel efficiency. In the biomedical field, Ti-6Al-4V’s biocompatibility makes it ideal for orthopedic implants, dental implants, and cardiac stents. The marine industry benefits from its resistance to seawater corrosion, using it in shipbuilding components, offshore platforms, and subsea equipment. In chemical processing, its stability and corrosion resistance make it suitable for tanks, pipes, and reaction vessels exposed to harsh chemicals. Additionally, the automotive and motorsport sectors leverage its high strength-to-weight ratio for race car components, valves, and suspension parts. Other applications include power generation, where it is used in turbine blades and heat exchangers, and sporting goods, such as bicycle frames and golf clubs.

Ti-6Al-4V, also known as Titanium Grade 5, is a highly versatile titanium alloy notable for its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. Compared to other titanium alloys, Ti-6Al-4V stands out with a tensile strength of up to 1200 MPa, which is significantly higher than that of commercially pure titanium (approximately 500 MPa). Its composition of 90% titanium, 6% aluminum, and 4% vanadium provides a balanced mix of mechanical properties, making it ideal for demanding applications such as aerospace components and medical implants.

In terms of density, Ti-6Al-4V has a typical value of 4.43 g/cm³, which is relatively low and contributes to its lightweight nature. This density is similar to other titanium alloys, maintaining its competitiveness in weight-sensitive industries.

While Ti-6Al-4V excels in tensile strength and corrosion resistance, it has some limitations, such as poor shear strength and surface wear properties. These drawbacks can make it less suitable for applications requiring high shear performance, like certain orthopedic implants.

Titanium Grade 5 (Ti-6Al-4V) is predominantly used in several key industries due to its exceptional properties. The aerospace industry heavily relies on Ti-6Al-4V for structural components such as engine parts and landing gear because of its high strength, corrosion resistance, and ability to withstand mechanical loads. In the medical and healthcare sector, Titanium Grade 5 is favored for medical implants, surgical instruments, prosthetics, and orthotics due to its biocompatibility and high strength. The automotive industry utilizes this alloy for engine parts that require a high strength-to-weight ratio. Additionally, its excellent corrosion resistance makes it suitable for marine and offshore applications, including subsea structures and equipment. The chemical processing industry benefits from its resistance to aggressive chemical environments, making it ideal for processing equipment. Lastly, the power generation and oil & gas sectors use Titanium Grade 5 for components exposed to harsh conditions.

The ASTM standards for Ti-6Al-4V, also known as Titanium Grade 5, provide essential guidelines to ensure its quality and performance across various industries, notably aerospace and biomedical fields. Key standards include:

These standards are critical for maintaining the integrity and performance of Ti-6Al-4V in its respective applications.

Testing Ti-6Al-4V for compliance involves evaluating its mechanical properties, corrosion resistance, and fatigue performance to ensure it meets industry standards, particularly ASTM specifications. Mechanical testing includes uniaxial tensile tests to measure yield stress, ultimate tensile stress, and elongation at failure, and microhardness testing using the Vickers method. Corrosion resistance is assessed by examining the alloy’s ability to form a protective oxide layer and its susceptibility to stress-corrosion cracking and crevice corrosion in environments containing chlorides or halide ions. Fatigue performance is evaluated through fatigue crack growth tests, following ASTM procedures, to determine threshold fatigue crack growth rates. Compliance also requires adherence to material specifications, such as limits on hydrogen content to prevent embrittlement, and standardized production conditions, including heat treatment and surface finishing. These comprehensive testing procedures ensure that Ti-6Al-4V maintains its high strength, corrosion resistance, and durability for various applications.