Imagine a material so robust it can extend the life of industrial machinery, resist extreme wear and corrosion, and enhance overall performance—welcome to the world of tungsten carbide coatings. This comprehensive guide delves deep into the technical marvels of tungsten carbide, known for its exceptional hardness and durability. We will explore the myriad benefits these coatings offer, from superior wear resistance to enhanced corrosion protection, and how they are applied through advanced processes like High-Velocity Oxy-Fuel (HVOF) and Detonation Gun (D-Gun) techniques.

Our journey will take you through a detailed comparative analysis of these coating methods, shedding light on their unique advantages and limitations. Whether you’re looking to improve machinery lifespan, boost performance in aerospace applications, or simply understand the best practices for applying these coatings, this guide has you covered. Ready to uncover the key factors in selecting the perfect tungsten carbide coating process for your needs? Let’s dive in and transform your understanding of industrial coatings.

Tungsten carbide (WC) is a composite material made by combining tungsten and carbon atoms in equal parts. It is renowned for its exceptional hardness and durability, making it invaluable in various industrial applications. Tungsten carbide appears as a fine gray powder in its raw form but is typically processed into dense, solid shapes through pressing and sintering techniques.

First, tungsten ore is processed into tungsten oxide. This oxide is then reduced to tungsten metal powder. The powder is mixed with a carbon source, such as graphite, and heated in a high-temperature furnace (1300–1600°C) to form tungsten carbide. The material is then milled and sieved to achieve specific particle sizes before being compacted into desired shapes and sintered at around 1500°C. The result is a homogeneous, dense cemented carbide with superior mechanical properties.

Tungsten carbide is ideal for enhancing the surface properties of tools and components due to its durability and resistance to wear. Common applications include cutting tools, high-performance drills, turbine blades, and industrial machinery parts. These components benefit from extended service life by resisting abrasion, corrosion, and thermal damage. Its toughness and scratch resistance also make it a popular choice for high-end jewelry, like wedding bands and fashion rings.

One of the primary advantages of tungsten carbide coatings is their exceptional wear resistance, as tungsten carbide’s hardness is second only to diamond. This property significantly extends the service life of components, reducing maintenance costs and downtime.

Tungsten carbide coatings also offer excellent corrosion resistance, particularly when combined with a suitable binder material. This makes them suitable for use in environments where chemical exposure or high humidity could otherwise degrade uncoated materials. The corrosion resistance can be further enhanced by selecting specific binder compositions tailored to the operating environment.

By applying tungsten carbide coatings, the overall performance of industrial components can be significantly improved. These coatings provide a hard, durable surface that maintains precision tolerances, even under extreme conditions. This leads to better operational efficiency, reduced wear and tear, and longer intervals between maintenance cycles.

Tungsten carbide coatings exhibit a combination of properties that make them highly desirable for various industrial applications:

In the aerospace industry, tungsten carbide coatings protect critical components like turbine blades, engine parts, and landing gear from wear and thermal stress, ensuring reliability and longevity under extreme conditions.

Tungsten carbide coatings are essential in power generation equipment, where they protect parts exposed to high temperatures and abrasive environments. This includes components like valves, pump impellers, and turbine blades, which benefit from the enhanced wear and corrosion resistance provided by the coatings.

In the metal production industry, tungsten carbide coatings are used on tools and dies to extend their lifespan and maintain precision. The coatings help withstand the high pressures and abrasive conditions typical in metal forming and cutting processes.

The HVOF process sprays a mixture of tungsten carbide powder and a binder through a high-velocity gas stream onto the substrate, creating dense, well-adhered coatings with excellent wear resistance.

The D-Gun process uses controlled detonations to accelerate tungsten carbide particles to supersonic speeds. The particles impact the substrate, forming a coating with low porosity and high adhesion. This process is known for producing exceptionally dense and durable coatings.

The HVAF process is similar to HVOF but uses air instead of oxygen as the oxidizing agent. This method can produce coatings with comparable properties to HVOF, often with lower oxidation and higher deposition efficiency.

Proper surface preparation is crucial for optimal coating adhesion. This involves cleaning the substrate to remove contaminants and roughening the surface through grit blasting, ensuring a strong mechanical bond.

Post-coating treatments, such as grinding and polishing, are often necessary to achieve the desired surface finish and dimensional accuracy. Additionally, sealing treatments may be applied to enhance the corrosion resistance and overall performance of the coatings.

The High-Velocity Oxygen Fuel (HVOF) process is a popular thermal spray method for applying tungsten carbide coatings. In this method, fuel gases like hydrogen, propane, or kerosene combust with oxygen in a high-pressure chamber, producing hot gases expelled at supersonic speeds, reaching up to 3,093°C (5,600°F). Tungsten carbide powder is injected into the gas stream, accelerating the particles to velocities up to 900 m/s (approximately 3,000 feet per second). Upon impacting the substrate, the particles deform and bond instantly, forming a dense, cohesive coating layer.

Typical applications include wear-resistant piston rods, process rolls in the paper industry, impellers and mixing equipment, and steel rolls and conveyor screws.

The Detonation Gun (D-Gun) process uses controlled explosions to propel tungsten carbide particles at supersonic speeds. In this method, a mixture of fuel gas and oxygen is ignited within a barrel, producing a detonation wave that propels the powder particles toward the substrate. The particles impact the surface at high velocities, forming a coating with minimal porosity and high adhesion.

The High-Velocity Air-Fuel (HVAF) process is similar to HVOF but uses air instead of oxygen as the oxidizing agent. This method involves combusting fuel gas, such as propane, with air to create a high-velocity jet. Tungsten carbide powder is injected into the jet, accelerating the particles to high speeds before they impact the substrate.

The formulation of tungsten carbide powders is critical to achieving desired coating properties. Factors such as particle size, composition, and binder content must be optimized to ensure hardness, toughness, and corrosion resistance.

Proper surface preparation is essential for coating adhesion. This involves cleaning the substrate and roughening the surface through grit blasting to enhance mechanical interlocking.

Key parameters such as combustion gas ratio, spray distance, powder feed rate, and substrate temperature must be controlled to achieve consistent coating thickness and microstructure.

Typical coating thickness ranges from 100 to 500 microns, depending on application requirements. Post-coating treatments, such as grinding and polishing, may be necessary to achieve precise dimensions and smooth surfaces.

Process Characteristics:

Applications:

Process Characteristics:

Coating Properties:

Applications:

Process Characteristics:

Coating Properties:

Applications:

Process Characteristics:

Coating Properties:

Applications:

Process Characteristics:

Coating Properties:

Applications:

Tungsten carbide coatings are highly valued for their exceptional durability and wear resistance. These coatings, typically applied through the High Velocity Oxygen Fuel (HVOF) process, are crucial for applications where strength and longevity are paramount.

Proper surface preparation is essential for effective tungsten carbide coating application. Start by thoroughly cleaning the surface to remove any oils, greases, or contaminants using solvents or alkaline solutions. Follow this by shot blasting, where abrasive materials such as steel grit or aluminum oxide are propelled at high speeds to create a rough texture and induce compressive stress, enhancing coating adhesion.

Prepare the HVOF equipment by mixing fuel (like kerosene, propane, or hydrogen) with oxygen in a combustion chamber. Ignite the mixture to produce a high-pressure, high-temperature gas stream, capable of melting the tungsten carbide powder.

Inject the tungsten carbide powder into the HVOF gun nozzle. The high-speed gas stream accelerates the particles to velocities of up to 3,000 feet per second, ensuring they impact the substrate with significant force. Spray the particles onto the prepared surface, where their high-velocity impact causes them to deform and bond strongly with the substrate, creating a dense and cohesive coating.

After applying the coating, post-spray treatments may be necessary for a smooth finish and precise dimensions. Use diamond wheels for grinding to achieve a microhardness of 1,000 to 1,400 HV and bonding strength over 150 MPa. Optionally, apply a sealant like epoxy resin to fill micropores, reducing porosity below 0.05% and enhancing corrosion resistance.

Tungsten carbide coatings are used in various industries due to their superior properties:

Ensuring the component material is compatible with tungsten carbide is essential for optimal coating performance. Tungsten carbide coatings are versatile and can be applied to various metals, including steel, stainless steel, and nickel alloys. However, ensuring optimal bonding and performance requires careful consideration of the substrate material. Some metals may need specific surface treatments or pre-coating processes to enhance adhesion.

To ensure that the coating will adhere properly, compatibility testing should be conducted. This might involve surface roughening, cleaning, and applying a thin test layer to evaluate adhesion strength and uniformity.

The level of wear resistance required depends on the application environment, including factors such as abrasion, erosion, and sliding wear. Tungsten carbide’s exceptional hardness makes it ideal for environments where high wear resistance is essential.

Different industries have varying requirements for wear resistance. For example, the mining and drilling industries, which deal with abrasive materials, benefit significantly from the hardness of tungsten carbide coatings. Heavy machinery and manufacturing sectors also demand coatings that can withstand intense wear and prolong component life.

Tungsten carbide coatings are suitable for applications up to 500°C (930°F). Beyond this temperature, the performance may degrade due to the formation of brittle phases. It is essential to consider the operating temperature to ensure the coating maintains its properties under thermal stress.

For components in corrosive environments, selecting tungsten carbide formulations with added corrosion resistance is important. This can be achieved by incorporating additives like chromium, which can improve the coating’s ability to withstand chemical exposure and high humidity.

In applications such as turbine engines, where components are subjected to high thermal stress, the coating must maintain its structural integrity and performance. Selecting the appropriate tungsten carbide formulation and coating method is critical to ensure durability under such conditions.

High-Velocity Oxygen Fuel (HVOF) and High-Velocity Air Fuel (HVAF) methods are preferred for producing dense, well-bonded coatings with low porosity and high bond strength. These methods are ideal for demanding applications where coating quality is paramount.

Other coating methods, such as plasma spraying or combustion powder spraying, can also be used. However, HVOF and HVAF generally offer superior performance in terms of coating density and adhesion, making them the preferred choice for critical applications.

The choice of tungsten carbide formulation depends on the specific requirements of the application, such as wear resistance, corrosion resistance, or thermal stability. Customizing the formulation to meet these needs ensures optimal performance.

Incorporating additives like chromium can enhance the coating’s impact resistance and corrosion protection. These additives are selected based on the operational environment and the specific challenges the coated components will face.

Applying tungsten carbide coatings can be more economical than replacing worn components, especially in high-value applications where downtime is costly. Coatings can extend the service life of components, reducing the need for frequent replacements.

The superior wear resistance and durability of tungsten carbide coatings contribute to their cost-effectiveness over time. By minimizing wear and prolonging component life, these coatings can lead to substantial savings in maintenance and replacement costs.

Tungsten carbide coatings are an eco-friendly alternative to traditional coatings like hard chrome plating, as they do not involve hazardous materials and reduce the need for frequent replacements.

In the oil and gas sector, tungsten carbide coatings are crucial for their exceptional resistance to wear and corrosion. Equipment used in drilling and production is often subjected to extreme conditions, including high pressures, abrasive materials, and corrosive environments. Common applications of tungsten carbide coatings in this industry include:

These coatings significantly reduce maintenance costs and operational downtime by protecting critical components from rapid wear and corrosion.

Tungsten carbide coatings are vital in aerospace and aviation for their ability to withstand extreme stress, high temperatures, and corrosive environments. Key applications include:

These coatings ensure that aircraft components remain reliable and efficient, even in the toughest conditions.

Manufacturing industries benefit greatly from the use of tungsten carbide coatings, particularly in metal forming and cutting applications. These coatings are used on:

In the paper industry, tungsten carbide coatings are used on process rolls to improve grip and wear resistance, enhancing the efficiency and longevity of the equipment.

In power generation, tungsten carbide coatings are applied to protect components exposed to high temperatures and abrasive environments. Typical applications include:

These coatings enhance the efficiency and lifespan of power generation equipment, minimizing the need for frequent maintenance and replacements.

The mining industry relies heavily on tungsten carbide coatings to extend the lifespan of tools and machinery exposed to extreme wear and impact. Applications include:

Applying tungsten carbide coatings to mining equipment ensures efficient and reliable operation, even in the harshest conditions.

Below are answers to some frequently asked questions:

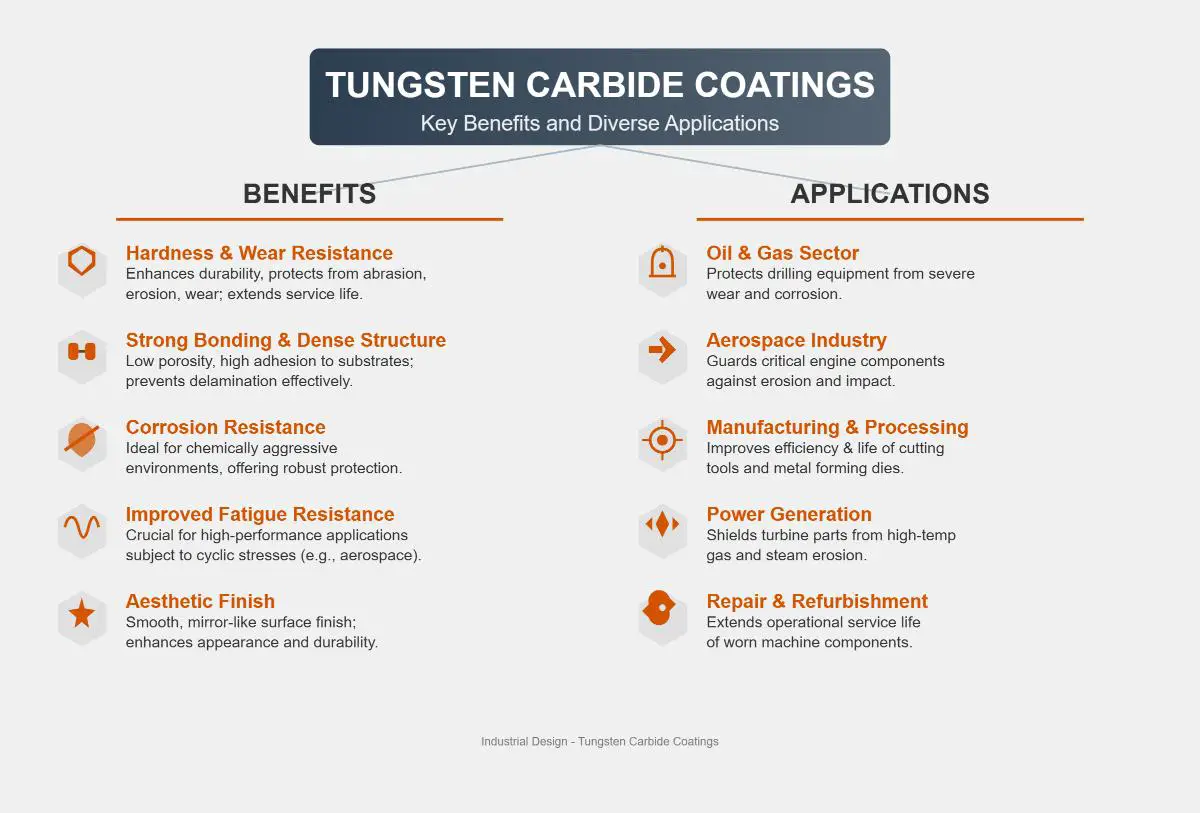

Tungsten carbide coatings offer numerous benefits, primarily due to their exceptional hardness and wear resistance. These coatings significantly enhance the durability and performance of components exposed to harsh conditions. They provide superior protection against abrasion, erosion, and mechanical wear, which helps extend the service life of tools and machine parts. Additionally, tungsten carbide coatings exhibit strong bonding and dense structures, resulting in low porosity and high adhesion to substrates, which prevents delamination.

The corrosion resistance of tungsten carbide coatings is another key advantage, making them suitable for use in chemically aggressive environments. They also improve fatigue resistance, essential for high-performance applications like aerospace, where components are subject to cyclic stresses. Aesthetically, these coatings can be finished to a smooth, mirror-like surface, enhancing the appearance and durability of tools and parts.

Applications of tungsten carbide coatings are diverse, spanning various industries. In the oil and gas sector, they protect drilling equipment from wear and corrosion. In aerospace, they are used on critical engine components to guard against erosion and impact damage. Manufacturing and industrial processing benefit from these coatings on cutting tools and metal forming dies, improving efficiency and tool life. In power generation, they protect turbine components from erosion caused by high-temperature gases and steam. Additionally, tungsten carbide coatings are used for repairing and refurbishing worn parts, extending their service life.

Different processes like High-Velocity Oxy-Fuel (HVOF) and Detonation Gun (D-Gun) significantly influence the properties of tungsten carbide coatings. HVOF utilizes a high-temperature combustion process to propel particles at velocities exceeding 3,000 ft/s, resulting in dense coatings with minimal porosity (<0.5%). This process ensures high bond strength and low residual stress, making HVOF coatings ideal for applications requiring abrasion resistance and moderate corrosion protection.

On the other hand, D-Gun employs controlled detonations to achieve supersonic particle speeds within a water-cooled barrel. This technique produces coatings with ultra-low porosity and superior adhesion due to precise energy delivery. The resulting microstructure is finer, with minimized thermal degradation, enhancing fatigue resistance and making D-Gun coatings suitable for extreme wear environments like aerospace and oil drilling.

Comparatively, D-Gun coatings typically offer better bond strength and lower porosity than HVOF coatings, providing exceptional performance in critical applications where coating integrity is paramount. HVOF, however, remains cost-effective and widely used for high-volume industrial applications.

When selecting a tungsten carbide coating process, several key factors need to be considered to ensure optimal performance and cost-effectiveness. Firstly, material compatibility is crucial; the substrate material must be able to bond effectively with the tungsten carbide coating. The operational environment of the component is another critical factor, as coatings must be tailored for conditions such as corrosion, abrasion, or high temperatures.

The grain size and volume fraction of tungsten carbide particles influence the coating’s properties, with finer grains typically providing smoother finishes and higher wear resistance. Binder selection, such as cobalt or nickel, affects toughness and oxidation resistance, which is essential for specific applications. Temperature limitations of both the coating and the process must be considered to ensure durability under operational conditions.

The coating method itself, whether High-Velocity Oxy-Fuel (HVOF), Detonation Gun (D-Gun), or High-Velocity Air-Fuel (HVAF), impacts the coating quality, with each method having its own advantages and limitations. Lastly, cost considerations play a role, as tungsten carbide coatings are an investment, but they can extend the life of high-value components significantly, thereby justifying the expense.

Tungsten carbide coatings, especially those applied using advanced methods like High Velocity Oxygen Fuel (HVOF) and Chemical Vapor Deposition (CVD), generally have a lower environmental impact compared to traditional coatings such as hard chrome plating and chrome carbide weld overlays. Key advantages include the elimination of hazardous substances, as tungsten carbide coatings do not use toxic hexavalent chromium found in hard chrome plating. Additionally, these coatings meet stringent environmental regulations like REACH, reducing ecological risks and regulatory compliance issues.

The HVOF process generates significantly less waste compared to chrome plating, simplifying disposal and reducing environmental contamination. The exceptional durability and wear resistance of tungsten carbide coatings extend component lifespans, reducing the need for frequent replacements and thus lowering the overall consumption of raw materials and energy over time. This results in a smaller environmental footprint. Moreover, the CVD process is energy-efficient, producing coatings without toxic by-products and minimizing secondary waste.

Effective surface preparation is crucial for ensuring strong adhesion and optimal performance of tungsten carbide coatings. The best techniques include:

These techniques ensure that the surface is adequately prepared, clean, and roughened to achieve optimal coating performance, making tungsten carbide coatings highly effective in applications requiring wear resistance and durability.

Tungsten carbide coatings are renowned for their exceptional hardness, wear resistance, and ability to protect components in demanding environments. However, they cannot be universally applied to all materials. These coatings are primarily suited for metallic substrates such as steel, stainless steel, cast iron, and various alloys. These materials can withstand the thermal and mechanical stresses of coating processes like High-Velocity Oxygen Fuel (HVOF) thermal spraying and provide good adhesion.

Non-metallic substrates, such as plastics, ceramics, or composites, pose challenges. The high temperatures and kinetic energy involved in the coating processes can damage or deform these materials, and adhesion is typically poor without specialized surface treatments or intermediate bonding layers. Some advanced ceramics or composites might be coated under specific conditions, but this is not common practice.

Successful application of tungsten carbide coatings relies on proper surface preparation, including grit blasting or chemical cleaning, and sometimes the use of intermediate layers to enhance adhesion and accommodate thermal expansion differences. Thus, while tungsten carbide coatings are highly effective for metallic substrates, their application to non-metallic materials is limited and generally impractical.