Did you know that aluminum, a metal we encounter daily in cans, foils, and even airplanes, holds fascinating secrets about magnetism? If you’ve ever wondered whether aluminum is magnetic and how it interacts with magnets, you’re not alone. This beginner’s guide will unravel the mystery behind aluminum’s magnetic properties, offering a deep dive into its classification as a paramagnetic material. You’ll learn about the basic principles of magnetism, the unique ways aluminum responds to magnetic fields, and the intriguing applications of these properties in various industries. Ready to explore how aluminum fits into the world of magnetic materials and discover its practical uses? Let’s dive in and uncover the science behind this versatile metal.

Aluminum, symbolized as Al with an atomic number of 13, is a silvery-white, soft, and nonmagnetic metal belonging to the boron group. It is the third most abundant element in the Earth’s crust, making up about 8% by weight. Aluminum is notable for its low density and ability to resist corrosion, largely due to the phenomenon of passivation.

Aluminum’s unique properties make it a vital material in many industries. Here are some of its common uses:

Due to its lightweight and high strength-to-weight ratio, aluminum is extensively used in the aerospace industry. It is used in the construction of aircraft frames, wings, and other critical components. The material’s resistance to corrosion also makes it ideal for use in harsh atmospheric conditions.

In the automotive industry, aluminum is used to manufacture car bodies, engine components, and wheels. Its lightweight nature helps improve fuel efficiency and reduce emissions. Aluminum’s ability to absorb crash energy also enhances vehicle safety.

Aluminum is widely used in the construction industry for window frames, roofing, and cladding. Its durability, corrosion resistance, and ease of maintenance make it a preferred choice for building exteriors and structural components.

Thanks to its excellent electrical conductivity, aluminum is a key material for power transmission and distribution, used in overhead power lines, electrical wiring, and busbars. Aluminum’s lightweight nature also makes it easier to install and handle compared to copper.

Aluminum is used in the packaging industry for making cans, foils, and other containers. It is impermeable to light, air, and moisture, which helps preserve the freshness and quality of packaged goods. Additionally, aluminum packaging is lightweight, recyclable, and cost-effective.

Aluminum is found in a variety of consumer goods, including kitchen utensils, appliances, and electronics. Its thermal conductivity makes it ideal for cookware, while its aesthetic appeal and durability make it suitable for electronics and home appliances.

Aluminum continues to find new applications in emerging technologies and industries, such as in the renewable energy sector for constructing solar panels and wind turbine components. In the transportation sector, aluminum is being explored for use in electric vehicle batteries and lightweight structural components to enhance efficiency and performance.

Understanding the properties and applications of aluminum is essential for appreciating its role in modern industry and technology. As a versatile and sustainable material, aluminum will continue to play a crucial role in various sectors, driving innovation and efficiency.

Magnetism is a fundamental physical phenomenon that describes how materials respond to magnetic fields. It is crucial for understanding how different materials, such as aluminum, behave in magnetic environments.

A magnetic field, represented by the symbol B, is an invisible force that affects materials sensitive to magnetism. It can be visualized using field lines that emerge from the north pole of a magnet and enter the south pole. These lines show the strength and direction of the magnetic field.

Magnets have two distinct poles: north and south. Opposite poles attract each other, while like poles repel. This fundamental property allows magnets to interact with each other and with magnetic materials in predictable ways.

Ferromagnetic materials like iron, nickel, and cobalt are strongly attracted to magnets. They have unpaired electrons whose magnetic moments align parallel to each other in regions called domains, resulting in a strong, permanent magnetization. These materials can retain their magnetic properties even after the external magnetic field is removed.

Paramagnetic materials, including aluminum, exhibit a weak attraction to magnetic fields. These materials have unpaired electrons, but the magnetic moments do not align in the absence of an external magnetic field. When exposed to a magnetic field, their magnetic moments align temporarily, but the magnetization vanishes when the field is gone.

Diamagnetic materials, such as copper and bismuth, are weakly repelled by magnetic fields. They have all their electrons paired, which means they do not have permanent magnetic moments. When exposed to a magnetic field, they induce a weak magnetic field in the opposite direction, resulting in a slight repulsion.

Magnetic fields interact with moving electric charges, such as electrons, causing them to experience a force perpendicular to both the direction of their motion and the magnetic field. This interaction is described by the Lorentz force law and is fundamental to the operation of many electrical devices, including motors and generators.

The magnetic properties of a material are determined by its atomic structure and the alignment of its electrons. Materials with unpaired electrons can exhibit magnetism, while those with paired electrons generally do not. Understanding these properties is crucial for various applications, from designing electronic devices to developing new materials with specific magnetic characteristics.

By grasping the basics of magnetism, one can better appreciate how different materials interact with magnetic fields and the practical implications of these interactions in technology and industry.

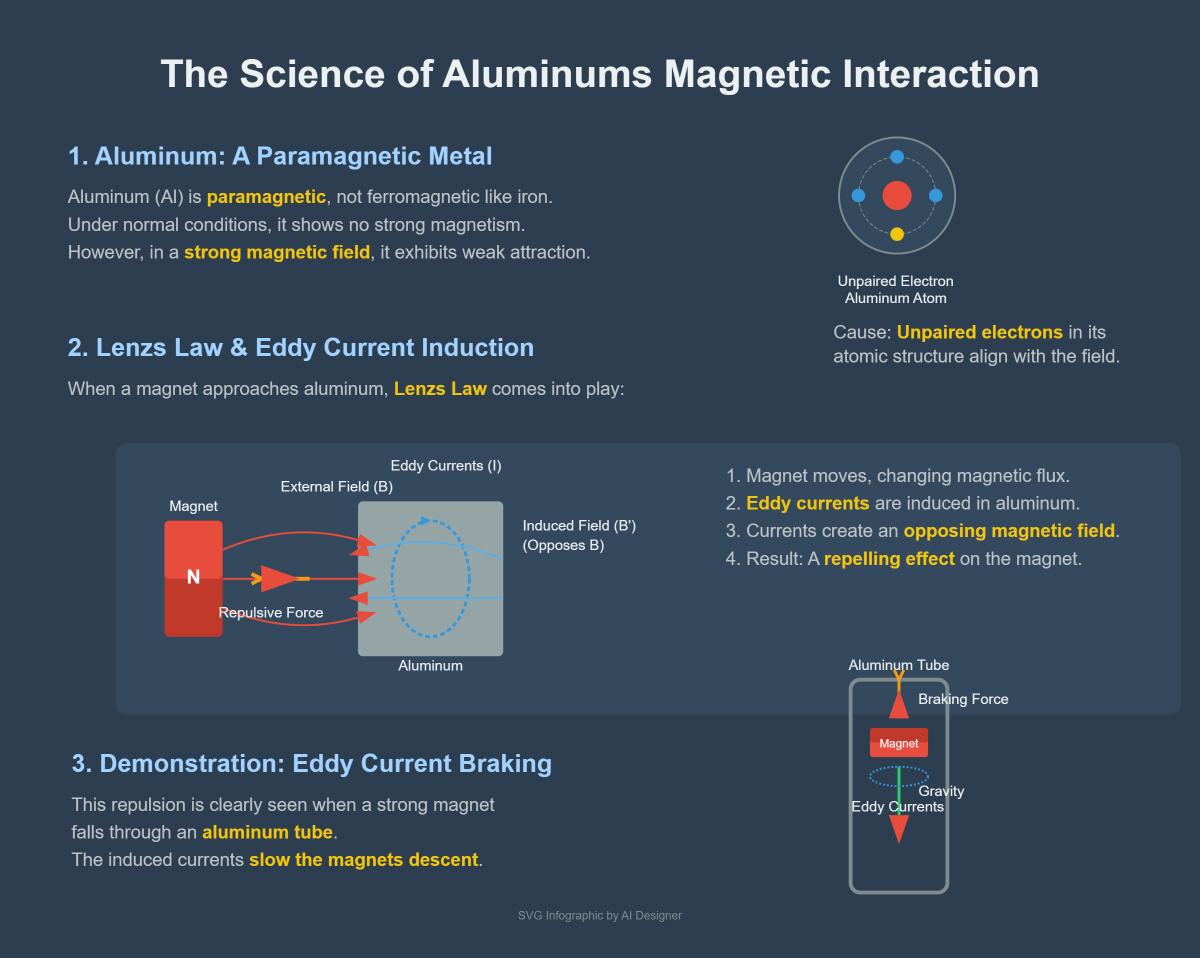

Aluminum is considered a paramagnetic material, which means it has a very weak attraction to magnetic fields. Unlike ferromagnetic materials, such as iron, which are strongly attracted to magnets and can retain magnetization, aluminum’s magnetic behavior is much less pronounced.

Paramagnetic materials have unpaired electrons that align with external magnetic fields, causing a slight attraction that disappears once the field is removed. In aluminum, the magnetic susceptibility is very low, indicating its minimal response to magnetic fields.

Ferromagnetic materials, such as iron and nickel, are strongly attracted to magnets and stay magnetized even after the external magnetic field is gone.

Diamagnetic materials, like copper and bismuth, are weakly repelled by magnetic fields. They have all paired electrons, and when exposed to a magnetic field, they induce a weak magnetic field in the opposite direction, resulting in a slight repulsion.

Aluminum, being paramagnetic, falls between these two extremes. Its response to a magnetic field is weakly positive, unlike the strong attraction seen in ferromagnetic materials or the weak repulsion in diamagnetic materials.

Although aluminum is not magnetic in the traditional sense, it can interact with magnetic fields in interesting ways:

When a magnet is moved near aluminum, it creates electric currents in the aluminum. These currents generate their own magnetic fields that oppose the original magnetic field, in accordance with Lenz’s Law. This phenomenon can be observed in experiments where a magnet falls through an aluminum tube and its descent is slowed by the induced currents.

This interaction has practical applications, particularly in electromagnetic induction processes. Aluminum’s ability to generate opposing magnetic fields when subjected to a changing magnetic environment is utilized in various technologies, including induction cooktops and magnetic braking systems.

Paramagnetism is a type of magnetism that occurs in materials with certain atomic structures, including aluminum. Unlike ferromagnetic materials, which exhibit strong magnetic properties, paramagnetic materials are only weakly attracted to magnetic fields. This section delves into the fundamental aspects of paramagnetism, providing a clear understanding for beginners.

Paramagnetism is the property of materials that causes them to be weakly attracted to an external magnetic field. This attraction occurs because the atoms or molecules in paramagnetic materials have unpaired electrons, which generate magnetic dipoles that temporarily align with an external magnetic field.

The origin of paramagnetism lies in the electronic structure of atoms:

Paramagnetic materials, including aluminum, exhibit several distinctive characteristics:

To better understand paramagnetism, it helps to compare it with other types of magnetic behaviors. Here’s a table summarizing the differences:

| Magnetic Property | Description | Example Materials | Response to External Field |

|---|---|---|---|

| Paramagnetism | Weak attraction due to unpaired electrons aligning with the field | Aluminum, oxygen, lithium, magnesium | Weakly attracted; magnetization disappears when the field is removed |

| Diamagnetism | Weak repulsion due to induced magnetic fields opposing the external field | Copper, silver, gold | Weakly repelled; inherent in all materials but overshadowed if paramagnetic/ferromagnetic |

| Ferromagnetism | Strong attraction due to spontaneous alignment of magnetic moments | Iron, cobalt, nickel | Strongly attracted; retains magnetization even after the field is removed |

The magnetic susceptibility (χ) of a material quantifies how much it will become magnetized in an external magnetic field. For paramagnetic materials, (χ) is positive but much less than one, indicating a weak magnetic response.

The magnetic behavior of paramagnetic materials is influenced by temperature. As temperature increases, thermal motion disrupts the alignment of magnetic moments, reducing the material’s overall magnetization. This relationship is often described by the Curie or Langevin functions, which show that magnetization is inversely proportional to temperature.

Aluminum is a well-known paramagnetic material. Other examples include:

Understanding paramagnetism helps explain why aluminum, despite being a metal, does not exhibit strong magnetic properties like iron. Instead, its weak interaction with magnetic fields is temporary and only present under the influence of an external magnetic field.

Lenz’s Law explains how a changing magnetic field induces a current in a conductor. This induced current generates its own magnetic field, which opposes the change in the original magnetic field. This phenomenon can be observed in many practical applications and experiments involving conductive materials like aluminum.

Mathematically, the law is represented as: (E=−dΦB/dt) where (E) is the induced electromotive force (emf), and (dΦB/dt) is the rate of change of the magnetic flux (ΦB). The negative sign indicates that the direction of the induced emf (and hence the current) opposes the change in magnetic flux.

Although aluminum is not traditionally magnetic, its excellent conductivity allows it to exhibit interesting behavior under Lenz’s Law.

When a magnetic field near aluminum changes, it induces currents within the aluminum. These currents, known as eddy currents, flow in loops within the material. The eddy currents generate their own magnetic fields, which oppose the change in the original magnetic field.

A clear demonstration of Lenz’s Law is dropping a strong magnet through an aluminum tube. As the magnet falls, it induces eddy currents in the walls of the aluminum tube. These currents create a magnetic field that opposes the motion of the magnet, causing it to fall slower than it would in the absence of the tube. This experiment vividly shows how aluminum interacts with changing magnetic fields.

In some roller coasters and trains, magnets and aluminum plates are used together in braking systems. When the vehicle moves, the magnets induce eddy currents in the aluminum plates, creating a magnetic field that opposes the motion and slows the vehicle down. This application of Lenz’s Law provides a smooth and controlled braking mechanism without physical contact or wear.

Lenz’s Law is utilized in induction heating, where an alternating magnetic field is used to induce currents in a metal workpiece, such as aluminum. These currents generate heat due to the metal’s resistance, allowing for efficient and precise heating applications in various industrial processes.

Magnetic levitation (Maglev) trains use the principles of Lenz’s Law to achieve frictionless travel. Magnets on the train induce currents in the aluminum tracks, creating a repulsive force that lifts the train off the tracks. This reduces friction and allows for high-speed travel.

Understanding Lenz’s Law and its application to aluminum provides valuable insights into how non-magnetic materials can still interact significantly with magnetic fields through induced currents. This interaction is the basis for many innovative technologies and practical applications in modern engineering and industry.

Aluminum’s paramagnetic nature is particularly advantageous in the electronics and telecommunications industries. Its weak magnetic response preserves electromagnetic signal integrity, ensuring devices perform optimally. Aluminum enclosures are commonly used for smartphones, tablets, and laptops for several reasons:

In aerospace and automotive industries, aluminum’s paramagnetic properties play a vital role in applications where magnetic interference could have serious consequences:

Aluminum is essential in medical technologies that involve strong magnetic fields, particularly MRI (Magnetic Resonance Imaging) machines:

Aluminum’s magnetic and conductive properties are utilized in energy generation and cutting-edge research:

Aluminum’s interaction with magnetic fields is exploited in magnetic levitation (Maglev) systems:

Aluminum’s paramagnetic properties find practical applications across various industries:

Aluminum’s unique magnetic behavior—being paramagnetic and nearly non-magnetic—makes it indispensable in many modern technologies where magnetic field integrity and minimal interference are critical. This understanding helps appreciate why aluminum is more than just a lightweight metal; it is a key material in maintaining the functionality and safety of advanced devices and systems.

Below are answers to some frequently asked questions:

Aluminum is not magnetic in the way that materials like iron or nickel are. Instead, aluminum is classified as a paramagnetic material. This means it does not exhibit strong magnetic properties under normal conditions. However, when exposed to a strong magnetic field, aluminum can show weak magnetic behavior. This is due to the presence of unpaired electrons in its atomic structure, which align with the magnetic field.

When a magnet is brought near aluminum, it induces small electric currents within the metal, as explained by Lenz’s Law. These currents create their own magnetic field that opposes the external magnetic field, leading to a repelling effect. This phenomenon is particularly noticeable when a strong magnet falls through an aluminum tube, as the induced currents slow down the magnet’s descent.

Aluminum, classified as a paramagnetic material, exhibits weak attraction to magnetic fields, which leads to several practical applications. In electronics and telecommunications, aluminum is used in device encasements and for electromagnetic interference (EMI) shielding, ensuring stable performance by minimizing magnetic interference. In aerospace and transportation, aluminum’s lightweight and non-magnetic properties make it ideal for aircraft and vehicles, preventing disruptions in navigational instruments and control systems. In the medical field, aluminum is critical in constructing MRI machines, as it does not distort magnetic fields, enabling accurate imaging. Additionally, aluminum’s conductivity and paramagnetic behavior are useful in magnetohydrodynamic (MHD) generators, which convert kinetic energy into electrical energy. Emerging research also focuses on developing aluminum alloys with enhanced magnetic properties for specialized applications, such as sensors and advanced composites. These applications underscore aluminum’s versatility and importance in various technological fields.

Aluminum is classified as a paramagnetic material, meaning it exhibits weak magnetic properties. Unlike ferromagnetic metals such as iron, nickel, and cobalt, which are strongly magnetic and can retain permanent magnetism, aluminum does not retain magnetism once it is removed from a magnetic field. This makes aluminum only weakly attracted to magnetic fields, and this attraction is generally unnoticeable in everyday situations.

In comparison to ferromagnetic metals, aluminum’s magnetic response is much weaker and temporary. Ferromagnetic metals can be strongly magnetized and are used in applications like magnets in speakers and motors. On the other hand, diamagnetic metals such as copper, silver, and gold are weakly repelled by magnetic fields and do not exhibit significant magnetism.

Aluminum’s unique interaction with magnetic fields, as per Lenz’s Law, allows it to induce currents that oppose changes in magnetic fields, leading to applications in magnetic levitation systems and induction heating. This property is particularly useful in technologies such as maglev trains, where aluminum tracks help reduce friction and enable high-speed travel.

Yes, aluminum can be used in magnetic levitation systems, despite not being inherently magnetic. This is achieved through the application of electromagnetic principles. When electromagnetic coils generate alternating currents, they induce eddy currents in the aluminum. These eddy currents create their own magnetic fields, which interact with the external magnetic fields produced by the coils, allowing the aluminum to levitate. Additionally, configurations like Halbach arrays, which use permanent magnets to generate strong magnetic fields, can precisely control the levitation of aluminum. These advanced techniques enable the use of aluminum in various magnetic levitation applications, even though it is not a ferromagnetic material.

Lenz’s Law is significant in understanding aluminum’s magnetic behavior because it explains why aluminum, despite being non-magnetic, interacts with magnets. Lenz’s Law states that when there is a change in the magnetic field around a conductor, such as aluminum, it induces an electric current in that conductor. This induced current creates its own magnetic field that opposes the change in the original magnetic field.

When a magnet moves near or through aluminum, the changing magnetic field induces currents (called eddy currents) within the aluminum. These eddy currents generate a magnetic field that opposes the magnet’s field, creating a repelling force. For instance, if you drop a magnet through an aluminum tube, the magnet falls slower than expected due to this opposing force.

This principle is crucial for understanding how aluminum can be used in applications like magnetic levitation, where the repelling force is harnessed to reduce friction and enable smooth movement. Lenz’s Law connects aluminum’s electrical conductivity with its interactions with magnetic fields, providing a foundational understanding of its behavior in electromagnetic contexts.

Paramagnetism affects the use of aluminum in industry by making it suitable for applications where magnetic neutrality is crucial. Aluminum’s paramagnetic properties mean it exhibits a weak attraction to magnetic fields due to unpaired electrons. This attraction is minimal, allowing aluminum to be used in electronic components without causing interference with magnetic fields, ensuring efficient operation. In aerospace and engineering, aluminum’s non-magnetic nature prevents unwanted magnetic interactions, enhancing safety and precision. Additionally, when exposed to changing magnetic fields, aluminum induces eddy currents that generate opposing magnetic fields, useful in dynamic applications. Overall, aluminum’s paramagnetism ensures minimal interaction with magnetic fields, making it a preferred choice in various industries.