Imagine a world where the surfaces of everyday objects are not only visually appealing but also incredibly durable and resistant to corrosion. Welcome to the fascinating realm of anodizing. This intricate electrochemical process transforms aluminum and other metals into robust materials with enhanced properties. In this article, we’ll dive deep into the anodizing process, exploring its technical aspects, various types, and the impressive benefits it offers. Whether you’re curious about how anodizing can fortify aluminum against wear and tear, or eager to learn about its applications across different industries, we’ve got you covered. Join us as we uncover the secrets behind anodizing and its transformative impact. Ready to elevate your understanding of this essential technique? Let’s get started.

Anodizing is a highly regarded surface treatment process primarily used to enhance the properties of aluminum. This process creates a durable oxide layer on aluminum, enhancing its resistance to corrosion, wear, and abrasion. This process not only improves durability but also enhances the aesthetic appeal of aluminum, making it essential in industries like aerospace, automotive, and consumer electronics.

The anodizing process begins with the preparation of the aluminum surface. This step includes thorough cleaning and deoxidizing to remove contaminants and existing oxide layers. Etching in a chemical bath, such as caustic soda, is often performed to achieve a uniform surface texture, which is crucial for effective anodizing.

Once the aluminum surface is properly prepared, the component is immersed in an electrolyte bath. Sulfuric acid is the most common electrolyte, but other acids like chromic acid can be used based on specific needs. In the electrolyte bath, the aluminum part serves as the anode, while a cathode, typically made of lead or stainless steel, completes the electrical circuit.

A direct current (DC) is applied to the electrolyte bath, causing the aluminum to release electrons. These electrons react with oxygen ions from the electrolyte to form a layer of aluminum oxide on the surface of the aluminum part. This aluminum oxide layer is integral to the anodizing process as it provides the enhanced surface properties.

The initial aluminum oxide layer formed is non – porous and acts as a barrier. As the anodizing process continues, the oxide layer grows thicker and becomes more porous. This porosity is beneficial as it allows for further treatments, such as dyeing, to impart various colors to the anodized aluminum. The oxide layer’s thickness is controlled by adjusting the anodizing time and electrical settings.

After achieving the desired oxide layer thickness, the anodized aluminum part undergoes a sealing process. Sealing typically involves immersing the part in hot water or a sealing agent, which closes the pores in the oxide layer. This step is crucial as it enhances the corrosion resistance of the anodized aluminum and ensures the longevity of the surface treatment.

Anodized aluminum finds applications across numerous industries due to its enhanced properties:

By understanding the intricacies of the anodizing process and its benefits, manufacturers and engineers can effectively utilize this surface treatment to enhance the performance and appearance of aluminum components.

Anodizing is an electrolytic treatment that transforms the metal surface into a durable, corrosion-resistant oxide layer. This process involves several key technical aspects:

The choice of electrolyte is crucial for the anodizing process. Sulfuric acid is the most commonly used electrolyte due to its effectiveness and cost-efficiency, though chromic acid and phosphoric acid are also used depending on specific application needs. The concentration of the acid and the presence of additives can significantly influence the properties of the anodized layer.

The application of direct current (DC) is fundamental to the anodizing process. Parameters such as current density, voltage, and duration of the current application must be carefully controlled. These parameters determine the thickness and quality of the oxide layer. Higher current densities can create thicker oxide layers but also increase the risk of burning or pitting if not properly controlled.

The temperature of the electrolyte bath plays a critical role in the anodizing process. Lower temperatures (0-5°C) are used for hard anodizing (Type III) to create thicker, more durable coatings. In contrast, higher temperatures (20-25°C) are suitable for standard sulfuric acid anodizing (Type II), which results in a more uniform and aesthetically pleasing finish.

Compliance with industry standards is essential to ensure the quality and performance of anodized components. Several standards govern the anodizing process, including:

This military specification outlines the requirements for anodizing aluminum and aluminum alloys. It covers various types of anodizing, including Type I (chromic acid anodizing), Type II (sulfuric acid anodizing), and Type III (hard anodizing). The standard specifies the thickness, corrosion resistance, and wear resistance criteria that anodized components must meet.

The International Organization for Standardization (ISO) provides guidelines for anodizing aluminum and its alloys in ISO 7599. This standard specifies the methods for producing anodic oxidation coatings, including the preparation, anodizing, coloring, and sealing processes. It also outlines the testing methods to assess the quality of the anodized layer.

The American Society for Testing and Materials (ASTM) standard B580 covers the requirements for anodic oxidation coatings on aluminum. It includes specifications for the thickness, hardness, adhesion, and corrosion resistance of the anodized layer. ASTM B580 also provides guidelines for quality control and inspection procedures.

Effective process control and quality assurance are essential for achieving consistent, high-quality anodized coatings. Key aspects include:

Proper surface preparation is essential for successful anodizing. This involves cleaning, etching, and deoxidizing the aluminum surface to remove contaminants and achieve a uniform texture. Inadequate surface preparation can lead to defects such as uneven coating thickness, poor adhesion, and reduced corrosion resistance.

Regular maintenance of the electrolyte bath is crucial to ensure consistent results. This includes monitoring the acid concentration, temperature, and contamination levels. Periodic replacement of the electrolyte and cleaning of the anodizing tank help maintain optimal conditions for the process.

Quality control measures include visual inspection, thickness measurement, and testing for corrosion resistance and adhesion. Non-destructive testing methods, such as eddy current testing, can be used to measure the thickness of the anodized layer. Corrosion resistance is typically assessed using salt spray tests, while adhesion can be evaluated through peel or scratch tests.

By adhering to these technical aspects and standards, manufacturers can ensure that anodized aluminum components meet the required performance and quality criteria for their specific applications.

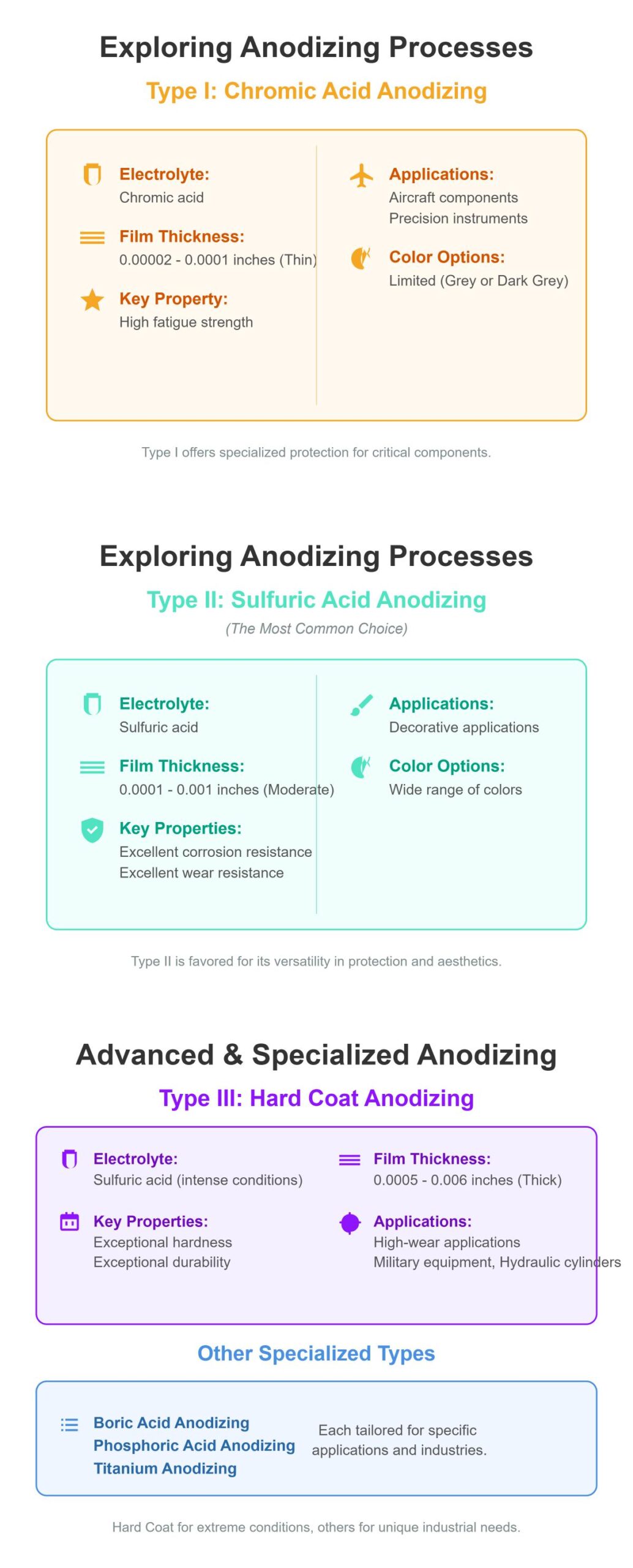

Type I anodizing, also known as chromic acid anodizing, uses chromic acid as the electrolyte. This process creates a thin oxide layer, typically ranging from 0.00002” to 0.0001” in thickness. Chromic acid anodizing is known for producing a very thin, non-porous film. It offers excellent corrosion resistance and maintains the fatigue strength of the aluminum substrate.

Characteristics and Benefits:

Applications:

Type II anodizing is the most common anodizing process, using sulfuric acid as the electrolyte. The oxide layer formed is thicker than in Type I, typically ranging from 0.0001” to 0.001”. This process is valued for its ability to produce a wide range of colors through dyeing, offering both aesthetic and functional benefits.

Characteristics and Benefits:

Applications:

Type III anodizing, or hard anodizing, employs sulfuric acid but with higher current densities and lower temperatures. This results in a much thicker and harder oxide layer, typically between 0.0005” and 0.006”. The hard anodized layer is highly durable, offering exceptional wear resistance and is suitable for heavy-duty applications.

Characteristics and Benefits:

Applications:

Thin-Film Sulfuric Acid Anodizing (TFSAA) is a variation of Type II anodizing but uses a lower concentration of sulfuric acid. This means the acid is diluted more than in standard sulfuric acid anodizing. The oxide layer produced is thinner than standard Type II but offers enhanced fatigue strength, making it suitable for high-stress applications.

Characteristics and Benefits:

Applications:

Integral color anodizing uses organic acids to produce colors within the oxide layer without the need for dyes. The organic acids react with the aluminum to create a range of natural colors, including pale yellow, gold, deep bronze, brown, grey, and black.

Characteristics and Benefits:

Applications:

Clear anodizing involves sealing the anodized layer in a hot water bath after the anodizing process. This method produces a transparent finish that showcases the natural color of the aluminum.

Characteristics and Benefits:

Applications:

Anodizing significantly enhances the durability and corrosion resistance of aluminum and other non-ferrous metals.

Anodized aluminum exhibits superior wear and tear resistance, making it ideal for industries that require high durability. This includes sectors such as military, construction, and consumer goods, where components are subject to intense mechanical stress and abrasion.

The anodizing process creates an oxide layer that provides excellent protection against corrosion. This layer acts as a barrier to environmental factors such as moisture and chemicals, significantly extending the lifespan of aluminum parts. This makes anodized aluminum suitable for harsh environments, including marine and industrial applications.

Anodizing not only enhances the functional properties of aluminum but also improves its aesthetic appeal.

Anodized finishes maintain their color over time, even when exposed to UV light. This keeps anodized products looking consistent and vibrant, which is particularly important for architectural and decorative applications.

The anodizing process allows for a wide range of colors and finishes. This is achieved through dyeing the porous oxide layer before sealing, enabling manufacturers to produce aluminum components that meet specific aesthetic requirements. This versatility is highly valued in consumer electronics, automotive, and architectural industries.

Anodizing is an environmentally friendly process with several safety advantages.

The anodizing process does not produce harmful or toxic by-products, making it a safer option for both the environment and the workforce. This non-toxic process meets growing demands for sustainable manufacturing.

Anodized surfaces are chemically stable and non-reactive. This makes them suitable for applications where exposure to chemicals is a concern, such as in medical equipment and food processing industries.

The cost-effectiveness of anodizing is another significant benefit.

Anodized surfaces need minimal upkeep, lowering long-term costs. The sealed oxide layer is easy to clean and resistant to stains and scratches, leading to lower maintenance efforts and costs.

While the initial cost of anodizing might be higher than other surface treatments, the long-term benefits, including extended product lifespan and reduced maintenance needs, justify the investment. This long-term value is particularly beneficial in industries where durability and reliability are paramount.

Anodizing is widely used across various industries due to its combined benefits of durability, aesthetic appeal, and environmental friendliness.

In the aerospace industry, anodizing is used for structural parts that require thin coatings and high corrosion resistance. This enhances the longevity and reliability of critical components.

Anodizing enhances the durability and aesthetics of electronic components, making them more resistant to wear and tear while providing a sleek, modern finish.

Anodized aluminum’s corrosion resistance makes it ideal for medical equipment, including surgical instruments, where hygiene and durability are essential.

Anodized aluminum is used in vehicle components such as wheels and trim, where both durability and aesthetic appeal are important. The ability to produce various colors and finishes also allows for customization in automotive design.

Anodizing offers a combination of enhanced durability, aesthetic appeal, and environmental benefits, making it a preferred surface treatment in multiple industries.

Anodizing is vital in the aerospace industry because it helps materials withstand extreme conditions and meet strict safety standards. The anodized aluminum components offer enhanced corrosion resistance, which is essential for aircraft operating in diverse and often harsh environments.

Anodized aluminum is extensively used for structural components in aircraft, including wing skins, fuselage panels, and internal support structures. The anodic layer provides a durable, corrosion-resistant surface that ensures the longevity and reliability of these critical parts.

In avionics and satellite applications, anodized aluminum is favored for its excellent thermal and electrical insulating properties. The anodic coating helps manage heat dissipation in electronic components and protects against electromagnetic interference.

Anodized aluminum wheels, trim pieces, and engine components are popular due to their resistance to wear, corrosion, and environmental factors. The anodic layer improves the durability and aesthetic appeal of cars, while engine parts benefit from reduced friction and extended lifespan.

In the building and architectural sector, anodized aluminum is prized for its weather resistance, low maintenance, and aesthetic versatility.

Anodized aluminum is widely used for building facades and curtain walls. The anodic layer protects against weather, ensuring durability with little maintenance. Additionally, the ability to produce various colors and finishes allows architects to achieve desired aesthetic effects.

Window frames and roofing systems benefit from anodizing due to its corrosion resistance and durability. Anodized aluminum frames maintain their appearance and functionality over time, even in harsh climates.

Anodizing is a preferred surface treatment in the consumer electronics industry, where both durability and appearance are critical.

Smartphones, laptops, and tablets often feature anodized aluminum housings. The anodic layer creates a scratch-resistant surface, protecting devices from daily wear while providing a sleek, modern look.

Heat sinks in electronic devices are anodized to enhance their thermal conductivity and corrosion resistance. The anodic coating helps in efficient heat dissipation, improving the performance and lifespan of electronic components.

Anodized aluminum is used in medical devices for its biocompatibility, corrosion resistance, and ease of sterilization. Surgical instruments and medical equipment housings benefit from the non-reactive, durable surfaces that can withstand regular cleaning and sterilization.

The marine and military sectors utilize anodized aluminum for its robust performance in harsh conditions.

Anodized aluminum is used for various marine hardware, including fittings, rails, and structural components. The anodic layer provides excellent protection against saltwater corrosion, ensuring long-term durability in marine environments.

Military equipment, such as vehicles and weapon systems, benefits from anodizing due to the enhanced wear resistance and corrosion protection. The anodic coating ensures that these critical components can withstand the rigors of military use.

In the food service industry, anodized aluminum is valued for its non-reactive surface and ease of cleaning.

High-end cookware, such as pots and pans, is often anodized to create a hard, non-stick surface that is resistant to scratches and chemical reactions with food. This ensures safe and efficient cooking while extending the lifespan of the cookware.

Anodized aluminum kitchenware, including utensils and appliances, benefits from the enhanced durability and easy maintenance provided by the anodic coating. The non-reactive surface ensures that the kitchenware remains safe for food contact.

Anodizing is crucial in aerospace for enhancing the longevity and performance of components under extreme conditions. Chromic acid anodizing (Type I) is widely used due to its thin, flexible coating that offers excellent corrosion resistance while maintaining the fatigue strength of aluminum substrates. This type of anodizing is particularly suitable for aircraft components, military equipment, and precision instruments. The thin layer, typically ranging from 0.00002 to 0.0001 inches (0.5 to 2.5 microns), minimizes weight, which is a critical factor in aerospace applications.

Moreover, as of 2025, there is a growing trend towards using boric – sulfuric acid anodizing in the aerospace industry. This method provides a more environmentally friendly alternative to traditional chromic acid anodizing while maintaining efficiency and effectiveness for corrosion protection and paint adhesion. It helps meet the industry’s increasing focus on sustainability without sacrificing the high – performance requirements of aerospace components.

Agricultural and heavy machinery often face harsh environments, making hard anodizing (Type III) the preferred technique due to its superior wear resistance and electrical insulation. It creates a thicker, denser oxide layer, typically ranging from 0.0005 to 0.006 inches, which provides superior wear resistance and electrical insulation.

Components such as hydraulic cylinders, military vehicles’ parts, and heavy machinery components benefit from the extreme durability offered by hard anodizing. The thick layer can withstand the constant friction, abrasion, and impact that these parts experience during operation, ensuring a longer service life and reduced maintenance costs.

Sulfuric acid anodizing (Type II) is widely used in automotive and architectural industries for its good corrosion resistance and variety of color options. In the automotive sector, it is used for various vehicle parts, including wheels, trim, and engine components. The moderately thick layer, typically 0.0001 to 0.001 inches, offers good corrosion resistance and a wide range of color options through dyeing. This allows for both aesthetic customization and functional protection of automotive parts.

In architecture, anodized aluminum is used for building facades, curtain walls, window frames, and roofing systems. The weather resistance, low maintenance, and aesthetic versatility of sulfuric acid anodized aluminum make it an ideal choice. Architects can achieve a variety of colors and finishes to meet the design requirements of different buildings while ensuring the long – term durability of the structures.

The medical industry requires materials that are safe, corrosion-resistant, and easy to sterilize, making titanium anodizing a common choice. It provides a durable, biocompatible surface that can withstand the harsh cleaning and sterilization processes required in medical settings.

Anodized titanium is used in surgical instruments, medical equipment housings, and other medical devices. The anodic layer not only protects the metal from corrosion but also prevents the leaching of metal ions into the body, ensuring the safety and reliability of medical products.

In the consumer electronics industry, anodizing is used to enhance both the durability and aesthetics of devices. Sulfuric acid anodizing (Type II) is the primary method employed. Device housings like those of smartphones, laptops, and tablets are anodized to create a scratch-resistant surface, protecting them from daily wear while providing a sleek, modern look.

Heat sinks in electronic devices are also anodized to enhance their thermal conductivity and corrosion resistance. The anodic coating helps in efficient heat dissipation, which is crucial for the performance and lifespan of electronic components. The ability to dye the anodized layer in various colors also allows for customization, meeting the diverse aesthetic preferences of consumers.

To apply anodizing in the aerospace industry, start by selecting the appropriate type of anodizing. Chromic acid anodizing (Type I) is suitable for components where maintaining fatigue strength and a thin coating are crucial, such as aircraft structural parts. Ensure strict adherence to environmental regulations when handling chromic acid.

For parts requiring high wear resistance and tight tolerances, consider Type III hard anodizing or boric-sulfuric acid anodizing (BSAA). Pay close attention to the electrolyte composition and electrical parameters when using BSAA to achieve the desired corrosion protection and paint adhesion.

Before anodizing, thoroughly clean the aluminum components to remove any machining residues or contaminants. During the anodizing process, control the temperature, current density, and anodizing time precisely to meet the industry’s high-quality standards, like MIL-A-8625.

In the agricultural and heavy machinery sector, hard anodizing (Type III) is the preferred option. Assess the specific requirements of the machinery components, such as the level of wear and abrasion they will face.

Prepare the metal surface carefully by sandblasting or chemical etching to ensure good adhesion of the anodic layer. Use higher current densities and lower temperatures during the anodizing process to create a thick, dense oxide layer.

Monitor the thickness of the oxide layer regularly, as it directly affects the wear resistance and electrical insulation properties. After anodizing, conduct thorough quality checks, including hardness testing and corrosion resistance tests, to ensure the components can withstand harsh operating conditions.

For automotive and architectural applications, sulfuric acid anodizing (Type II) is widely used. In the automotive industry, anodize parts like wheels, trim, and engine components. Start with a proper cleaning process to remove oil, grease, and dirt.

Choose the appropriate dye if color customization is required. The dyeing process should be carried out after anodizing but before sealing. Control the dye concentration, temperature, and immersion time to achieve uniform coloration.

In architecture, anodize building facades, curtain walls, window frames, and roofing systems to meet the required weather resistance standards. Conduct long-term weathering tests to verify the durability of the anodized aluminum.

When applying anodizing in the medical industry, titanium anodizing is a common choice. Ensure the titanium components are biocompatible and free from impurities.

Clean the titanium parts using specialized medical-grade cleaning agents that remove contaminants without leaving residues that could affect the anodizing process or the final product’s safety.

During the anodizing process, control the parameters to create a durable, biocompatible anodic layer. This layer must withstand the harsh cleaning and sterilization processes in medical settings. After anodizing, conduct strict quality control measures, including biocompatibility testing, to ensure the safety and reliability of medical products.

In the consumer electronics industry, sulfuric acid anodizing (Type II) is mainly used. For device housings, focus on creating a scratch-resistant surface. Use a fine-grained polishing process before anodizing to achieve a smooth finish.

Optimize the anodizing process when dealing with heat sinks to enhance thermal conductivity. Adjust the electrolyte composition and anodizing parameters to ensure efficient heat dissipation.

If color customization is needed, select high-quality dyes resistant to fading and capable of withstanding the normal use of electronic devices. Conduct wear and color-fastness tests on the anodized components to meet consumer expectations.

Below are answers to some frequently asked questions:

The main types of anodizing processes are:

Other types include Boric Acid Anodizing, Phosphoric Acid Anodizing, and Titanium Anodizing, each tailored for specific applications and industries.

Anodizing aluminum offers several significant benefits. Firstly, it enhances durability by forming a hard, protective oxide layer on the surface, making the aluminum resistant to scratches and wear. This layer also increases corrosion resistance, shielding the material from moisture and chemicals, which is particularly beneficial in harsh environments like aerospace and marine applications. Additionally, anodized aluminum provides excellent electrical insulation due to the non-conductive nature of the oxide layer. It also improves paint adhesion and adhesive bonding, allowing for more durable and even finishes. Moreover, anodized aluminum requires low maintenance and offers vibrant, fade-resistant aesthetics with a variety of color options.

Anodizing enhances the properties of aluminum by creating a durable and corrosion-resistant surface through an electrochemical process. This process forms a thick, porous oxide layer on the aluminum, significantly increasing its hardness and wear resistance. The anodic layer provides excellent protection against environmental factors such as moisture and chemicals, reducing the likelihood of corrosion. Additionally, anodized aluminum can be dyed to achieve vibrant colors, enhancing its aesthetic appeal. The porous nature of the anodized surface also improves the adhesion of paints and sealants, ensuring a more durable and consistent finish.

The anodizing process must meet several standards to ensure quality and durability of anodic coatings. Key standards include those from the Aluminum Association (e.g., SSA – 46 for architectural use), MIL – A – 8625 for military requirements, various ASTM standards (like ASTM B244 for testing coating thickness), ISO standards (e.g., ISO 10074 for thick sulfuric acid anodizing), and NASA specifications (PRC – 5006 for aluminum alloys). Process parameters such as time, voltage, electrolyte composition, current density, and temperature are also strictly controlled, along with quality control measures and environmental considerations.

In the aerospace industry, anodizing is applied to aluminum components to enhance their durability, corrosion resistance, and Various types of anodizing are used in aerospace applications, including Type I Chromic Acid Anodizing (CAA), Type II Sulfuric Acid Anodizing (SAA), and Type III Hardcoat Anodizing. These processes provide different levels of oxide layer thickness and properties, tailored to meet specific requirements such as lightweight, wear resistance, and maximum durability.

Anodizing is crucial for protecting structural components, fasteners, and electronics against harsh environmental conditions, extending their lifespan, and reducing maintenance needs. Additionally, the process allows for aesthetic enhancements and better adhesion for coatings and surface treatments. Recent advancements have also made anodizing more environmentally friendly, aligning with sustainable practices in the aerospace industry.

Anodizing consumer electronics involves specialized techniques to enhance both the durability and aesthetic appeal of metal components, primarily aluminum. The process begins with pre-treatment steps such as cleaning, degreasing, etching, and desmutting to ensure a clean and textured surface that promotes uniform oxide formation.

The anodizing process itself typically uses sulfuric acid (Type II anodizing) in an electrolytic bath, where voltage and current are carefully controlled to achieve the desired oxide layer thickness and properties. Temperature control is also crucial, with lower temperatures producing harder coatings.

For consumer electronics, Type II anodizing is common due to its suitability for dyeing and decorative purposes. The porous oxide layer can be dyed in various colors before sealing, which helps prevent color fading and enhances corrosion resistance. This combination of dyeing and sealing not only improves the aesthetic appeal but also contributes to the wear resistance and durability of the electronic devices.

Overall, these anodizing techniques are designed to balance functionality, design, and environmental considerations, making them ideal for high-quality consumer electronics.