Imagine stepping into a workshop filled with the hum of machines and the promise of creation, where raw metal transforms into precision-crafted components. At the heart of this transformation lies the Bridgeport milling machine, a cornerstone of the metalworking world. For beginners eager to understand its magic, this guide is your gateway. We’ll unravel the history and mechanics of the iconic Bridgeport mill, renowned for its knee mill design that revolutionized machining. You’ll learn not only how to operate this engineering marvel safely but also how to harness its full potential through step-by-step techniques. Whether you’re crafting intricate parts for aerospace or simply curious about milling’s role in industry, this guide will illuminate your path. Ready to discover why the Bridgeport mill stands out among its peers? Let’s dive in and explore the art of milling.

Bridgeport milling machines are famous for their versatile and robust design, making them essential in metalworking shops worldwide. Originating from Bridgeport, Connecticut, these machines have become synonymous with high-quality machining since their introduction in the 1930s. The innovation of adjustable heads and flexible movement along multiple axes set the standard for vertical milling machines.

Milling is a machining process that involves the removal of material using rotary cutters. It is one of the most common methods in manufacturing and metalworking. Milling machines, such as the Bridgeport, are used to shape and cut solid materials like metal, wood, or plastic. The versatility of milling allows for a variety of operations, including drilling, slotting, and contouring, making it essential for creating precise components.

The Bridgeport milling machine is often referred to as a “knee mill” due to its unique design. The knee mill design features a worktable that can be raised or lowered on a knee-shaped support, providing enhanced flexibility and control. The adjustable head of the Bridgeport milling machine further enhances its capability, enabling angled cuts and complex maneuvers.

Bridgeport milling machines are crucial in the metalworking industry due to their reliability and versatility. Their ability to handle a wide range of tasks, from simple drilling to complex contouring, makes them ideal for both small workshops and large-scale manufacturing. The precision offered by Bridgeport mills ensures high-quality output, which is crucial in industries where exact specifications are necessary, such as aerospace and automotive manufacturing. Their durable construction ensures a long-lasting solution for metalworking needs.

To operate a Bridgeport milling machine effectively, you need to understand its parts and learn essential techniques. Ensuring the machine is ready is the first step toward a successful milling project.

Power up the machine, ensuring it’s connected to the power source and all safety switches are correctly positioned. Inspect components like the spindle, table, and knee for any wear or damage, and ensure they are clean and free from obstructions.

Select the appropriate tool for your milling operation. Secure the chosen tool in the spindle with a collet or holder, and tighten it using the drawbar. Position the workpiece securely on the table using clamps or a vise to prevent movement during milling.

Determine the correct RPM and feed rates based on the material and tool, then adjust the machine settings accordingly. Turn the handwheels to move the workpiece left and right (X-axis), front to back (Y-axis), and up and down (Z-axis) to position it precisely for milling.

Always wear goggles, gloves, and suitable clothing to protect yourself. Familiarize yourself with the location of emergency stop buttons and ensure all machine guards are in place to protect against moving parts.

Start with conventional milling, where the workpiece feeds against the cutter’s rotation. This method requires less force and is ideal for rough cuts. For a smoother finish, use climb milling, where the workpiece moves with the cutter’s rotation, ensuring it is securely fastened to prevent slipping.

Regularly clean the machine after each use to remove chips and dust that can cause wear. Apply lubrication to moving parts to prevent friction and extend the machine’s life. Conduct routine inspections and address any necessary repairs promptly to maintain optimal performance.

Bridgeport milling machines are celebrated for their ability to handle intricate machining tasks, thanks to their versatile design and precise control mechanisms. Mastering advanced milling operations is essential for tackling complex projects.

Achieving the desired shape and finish in complex projects often requires combining various milling operations. These processes include sequential milling, which involves performing multiple operations in a specific order, and layered approaches, which gradually remove material in stages.

Using specialized tools can greatly enhance a Bridgeport mill’s capabilities for complex projects. Boring heads are essential for creating precise holes and enlarging existing ones with high accuracy. Edge finders help determine the exact position of the workpiece, crucial for setting reference points and ensuring alignment.

Precision milling depends on optimizing machine settings. Adjusting feed rates and setting optimal RPM are vital to ensure smooth cuts and prevent tool wear. Different materials require specific spindle speeds for efficient cutting and finishing.

Modern Bridgeport mills often come equipped with digital readouts (DROs) and other electronic aids. DRO systems provide real-time data on the position of the machine’s axes, aiding in precision adjustments. Utilizing CAD software can help in planning and visualizing complex projects before machining.

Real-world examples offer valuable insights into advanced milling techniques. Bridgeport mills are frequently used to manufacture intricate parts for the aerospace industry, requiring high precision and exact tolerances. Projects often involve milling intricate shapes with tight tolerances, such as turbine blades and engine components.

In the automotive sector, Bridgeport mills play a crucial role in prototyping and developing new parts. Milling machines are used to create custom components and prototypes, which demand precise dimensions and smooth finishes.

Bridgeport milling machines continue to find novel applications across various industries, pushing the boundaries of traditional machining. Artists and sculptors are increasingly using milling machines to create complex, detailed works from metal and other materials. The precision of Bridgeport mills allows for detailed engraving and complex designs, enhancing artistic projects.

The precision of Bridgeport mills is vital in producing components for medical devices, where exact specifications are crucial for functionality and safety. Milling machines are used to create custom implants and surgical instruments, requiring meticulous attention to detail and accuracy.

By mastering these advanced techniques, users can expand the capabilities of their Bridgeport milling machines and tackle increasingly complex projects with confidence and precision.

Bridgeport milling machines are renowned for their versatility and reliability, making them ideal for diverse applications across various industries.

Bridgeport mills excel at producing precise components needed in industries like aerospace, automotive, and medical devices. Their capability to meet exact specifications ensures that parts integrate seamlessly into larger systems, which is crucial for maintaining performance and safety standards.

Bridgeport mills are essential in product development, offering quick prototyping capabilities. Their flexibility allows engineers to swiftly modify designs and test various configurations, accelerating the development process and enabling rapid refinement of prototypes before moving to production.

Industries often rely on Bridgeport mills for maintenance and repair tasks. They efficiently produce custom parts for repairs, minimizing equipment downtime. This adaptability makes them vital in workshops servicing a wide range of industries.

Bridgeport milling machines offer several advantages that make them a preferred choice in machining environments.

These machines perform a variety of milling operations, such as face milling, side milling, slot milling, plunge milling, and pocketing. Their adaptability supports both manual and CNC operations, enhancing usability in diverse settings.

Bridgeport mills are celebrated for their precision. They allow for fine adjustments, crucial when working with detailed components, ensuring high-quality finishes and exact dimensions.

Constructed from durable materials, Bridgeport mills are built to last, provided they are well-maintained. Their sturdy construction withstands the demands of intensive machining processes, offering reliability for workshops focused on long-term use.

Understanding the basic features of Bridgeport milling machines is essential for successful operation.

Knowledge of machine parts like the XYZ axis, quill feed, and spindle is vital for effective operation. Familiarity with these components ensures accurate milling tasks.

Beginners should learn essential operational steps, including powering up the machine, moving and locking axes, setting RPMs, and installing cutting tools correctly. This foundational knowledge ensures safe and efficient use of the machine.

It’s important to become acquainted with conventional and climb milling techniques. Understanding these methods allows beginners to choose the appropriate approach for each project, optimizing both efficiency and quality.

Milling machines are vital in metalworking for shaping and cutting materials precisely. Understanding the differences between various types of milling machines can help beginners choose the right tool for their needs.

Bridgeport milling machines are renowned for their versatility and manual control. These vertical mills feature a spindle that moves vertically and are equipped with a knee that supports the worktable, allowing for precise manual adjustments. Ideal for small to medium-sized workpieces, Bridgeport mills excel in prototyping and general machining tasks. Their design is user-friendly, making them a popular choice for beginners.

CNC (Computer Numerical Control) milling machines offer automated control, allowing for complex and precise machining tasks. CNC machines use computer programs to move cutting tools across multiple axes. This capability makes them suitable for high-volume production and intricate designs. However, operating CNC machines requires programming knowledge, which can be challenging for beginners.

Horizontal milling machines differ from vertical mills like Bridgeport machines in terms of the spindle orientation. Their spindle is mounted horizontally, making them ideal for heavy-duty cutting and large workpieces. These machines are often used for specific tasks that require significant material removal, such as cutting grooves or slots.

When selecting a milling machine, consider the specific tasks you need to perform, the complexity of the operations, and your level of expertise. Bridgeport milling machines are excellent for beginners due to their simplicity and versatility. For those looking to tackle more advanced projects or require automation, CNC machines offer greater capabilities. Meanwhile, horizontal milling machines are best for specialized applications that benefit from their unique design. Understanding these differences will help you choose the most appropriate machine for your needs.

Below are answers to some frequently asked questions:

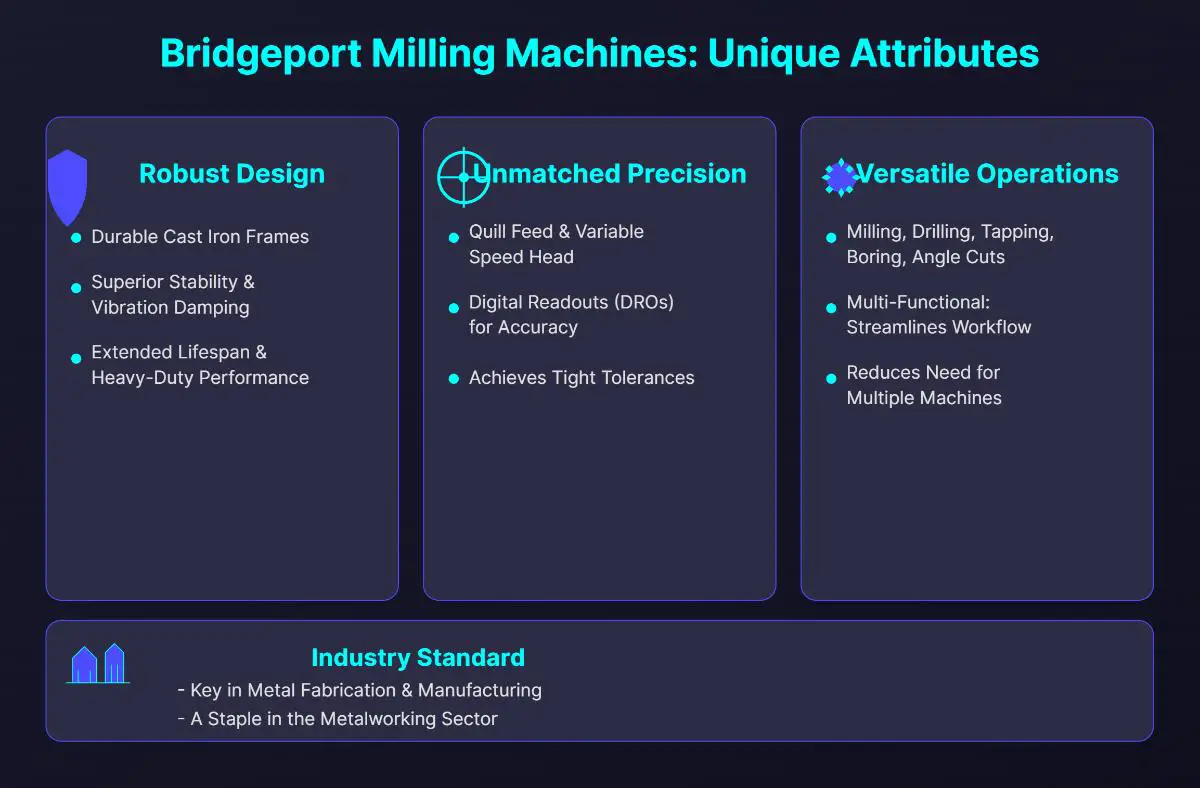

Bridgeport milling machines are unique due to their robust design, precision, and versatility. Known for their durable cast iron frames, these machines provide excellent stability and vibration-damping qualities, which contribute to their long lifespan. Their heavy-duty structure allows them to handle demanding tasks efficiently. Bridgeport mills are highly versatile, capable of performing various operations such as milling, drilling, tapping, boring, and angle cuts. This multi-functionality streamlines workflow by reducing the need for additional equipment. Additionally, they feature a quill feed and variable speed head, enhancing their capability to perform precise tasks like drilling and tapping. The inclusion of digital readouts (DROs) further enhances accuracy by providing precise axis positions. Bridgeport machines are widely used in industries like metal fabrication and manufacturing due to their reliability and ability to achieve tight tolerances, making them a staple in the metalworking sector.

Bridgeport milling machines offer several key benefits that make them appealing to both beginners and experienced machinists. Firstly, they are renowned for their durability and stability, constructed from high-quality cast iron, which minimizes vibrations and leads to precise machining. This robust build also contributes to a longer machine lifespan. Secondly, Bridgeport mills provide exceptional precision and versatility, handling a wide array of tasks from simple drilling to complex shaping. The adjustable knee feature allows for varied cutting operations, enhancing their adaptability.

Ease of use is another significant advantage. Bridgeport mills are user-friendly, requiring no complex programming, making them ideal for beginners and small workshops. Their compact footprint fits well in limited spaces, adding practicality for smaller shops. Furthermore, these machines are productive and efficient, with advanced models offering features like quick tool changes and coolant systems for specific metals, improving workflow.

To safely operate a Bridgeport milling machine, it’s important to follow several key safety practices. Begin by consulting the manufacturer’s manual for specific instructions related to your model. Always wear appropriate safety gear, including safety glasses and a dust mask, and ensure all machine guards are in place. Only operate the machine if you are trained and authorized, as this knowledge helps you understand its capabilities and limitations. Secure the workpiece firmly in the vice to prevent accidents and ensure precision. Avoid distractions, such as using phones or wearing loose clothing, which can get caught in the machine’s moving parts. During maintenance, adhere to lockout/tagout procedures to prevent accidental start-up. Regularly lubricate and clean the machine to maintain performance and extend its lifespan. By adhering to these guidelines, beginners can operate a Bridgeport milling machine effectively and safely.

Advanced techniques for complex milling projects on Bridgeport milling machines can significantly enhance precision and efficiency. High-Speed Milling (HSM) uses faster spindle speeds to improve productivity and surface finish, though managing heat and tool wear is essential. Micromilling is ideal for creating ultra-precise features necessary in electronics and medical devices, requiring specialized tools for microscopic dimensions. Cryogenic Milling involves using liquid nitrogen to make tough materials like titanium more brittle, enhancing machinability. Flow Milling generates accurate toolpaths for tiny features, beneficial for mold makers. Multi-Axis Milling utilizes multiple axes to efficiently machine intricate parts, demanding advanced software for toolpath generation. Plunge and Ramp Milling techniques minimize tool stress and extend tool life by controlling vertical and gradual tool entry. These techniques broaden the capabilities of Bridgeport mills in handling complex projects, offering improved precision and productivity.

Bridgeport milling machines are renowned for their performance in the metalworking industry, offering a blend of versatility and reliability. Compared to other milling machines, Bridgeport mills, especially the Series I and Series II models, stand out due to their robust knee mill design, which provides stability and flexibility. These machines are equipped with a tilting head, allowing operators to perform a variety of machining tasks with ease, which is a feature not as common in other models.

While Bridgeport mills excel in versatility and affordability, they may not match the heavy-duty capabilities of more industrial-grade machines. For instance, their R8 taper is suitable for light to moderate-duty machining but is less ideal for heavy loads. Despite this, Bridgeport mills are favored in many sectors, including aerospace and automotive, due to their reliable performance and adaptability to a range of applications. Overall, they offer a balanced approach to milling, making them a popular choice for both professionals and hobbyists.

Bridgeport milling machines are widely used across various industries due to their precision, versatility, and reliability. Key industries that commonly utilize Bridgeport mills include:

These industries benefit from the precision, durability, and flexibility that Bridgeport milling machines offer, making them a valuable asset in various manufacturing environments.