Imagine a material that combines the strength of steel with the versatility of cast iron, a material that revolutionizes engineering and manufacturing across various industries. Ductile iron is that remarkable alloy, offering unparalleled mechanical properties and a wide range of applications. In this article, we delve into the intricate composition of ductile iron, exploring the chemical elements and microstructure that give it its unique characteristics. You will discover how its elasticity and toughness make it an ideal choice for construction, automotive components, and heavy machinery. We will also compare ductile iron with other materials, highlighting its advantages in terms of cost efficiency and sustainability. As we navigate through the standards and compliance requirements, you’ll gain a comprehensive understanding of why ductile iron is a preferred material in engineering. Ready to uncover the secrets behind ductile iron’s impressive performance and diverse uses? Let’s dive in.

Ductile iron, also known as spheroidal graphite iron or nodular cast iron, is a type of cast iron engineered to provide exceptional mechanical properties through the presence of spherical graphite inclusions. Unlike the flake-like graphite in gray cast iron, these spherical nodules give ductile iron its unique blend of high strength, flexibility, and toughness. This material is widely used across various industries due to its versatility and cost-effectiveness.

Ductile iron was developed in 1943 by Keith Millis, who discovered that adding magnesium to molten iron transformed graphite flakes into spheroids, significantly enhancing the iron’s mechanical properties and leading to its commercial production in the 1950s. Over the decades, ductile iron has evolved with advancements in metallurgical techniques, becoming a preferred material for numerous applications, including automotive components, pipelines, and heavy machinery.

Ductile iron is primarily composed of iron, with carbon and silicon being the main alloying elements. The typical composition includes:

Ductile iron is renowned for its impressive tensile strength, which can range from 60,000 psi to over 100,000 psi, depending on the grade and heat treatment. This makes it suitable for applications requiring materials to withstand high loads and stresses.

Ductile iron offers superior corrosion resistance compared to traditional gray cast iron, making it an excellent choice for applications exposed to harsh environments, such as underground pipelines and outdoor machinery.

The presence of spherical graphite nodules enhances the impact resistance of ductile iron, allowing it to absorb energy without fracturing. This property makes it ideal for components that must endure significant stress and shock.

Ductile iron exhibits excellent wear resistance due to the nodular graphite structure, which reduces friction and wear on the material. This is particularly beneficial for parts like gears, bearings, and other components subjected to continuous contact and movement.

Producing ductile iron involves several crucial steps:

Thanks to its versatile mechanical properties, ductile iron is used in a wide variety of applications:

Ductile iron is classified into different grades based on its tensile strength, yield strength, and elongation. Common grades include:

Each grade is tailored to specific applications, ensuring that the material properties meet the requirements of the intended use.

Ductile iron is primarily composed of iron, with several key alloying elements that significantly influence its properties and performance.

The microstructure of ductile iron is characterized by spherical graphite nodules within a matrix of soft ferrite and harder pearlite. Adding magnesium ensures the graphite forms in spheres rather than flakes, as seen in gray cast iron. This unique microstructure provides ductile iron with its notable mechanical properties.

Ductile iron is renowned for its superior mechanical properties compared to traditional cast irons. These properties make it ideal for demanding applications such as automotive components, pipes, and heavy machinery.

These mechanical properties, combined with the material’s unique composition and microstructure, make ductile iron a highly versatile and reliable material for various industrial applications.

Ductile iron is essential in construction because of its strength, flexibility, and versatility. Its high strength, toughness, and ductility make it ideal for various structural applications.

Ductile iron is used in the construction of buildings and bridges where high strength and durability are essential. Components such as beams, columns, and girders benefit from the material’s ability to withstand significant loads and stresses without deforming or failing.

In infrastructure projects, ductile iron is preferred for manhole covers, storm drains, and sewer systems due to its excellent wear resistance and capacity to handle heavy traffic loads.

Ductile iron is extensively used in the manufacturing of pipes and fittings, particularly for water and sewage systems.

Ductile iron pipes are favored for water distribution due to their high tensile strength and corrosion resistance. These pipes can handle high-pressure conditions and are less prone to leakage, ensuring a reliable water supply.

The material’s resistance to corrosion and wear makes ductile iron an excellent choice for sewage and wastewater systems. It can withstand the harsh chemical environments often found in these systems, providing long-term durability.

The automotive industry uses ductile iron for parts that need strength, flexibility, and durability.

Ductile iron is used in critical engine parts such as crankshafts, camshafts, and connecting rods. Its high tensile strength and fatigue resistance ensure these components can endure the intense operational stresses of internal combustion engines.

In suspension systems, ductile iron is utilized for parts like control arms, steering knuckles, and brackets. The material’s toughness and ability to absorb impacts make it ideal for these components, which must withstand constant dynamic loads.

Heavy machinery often uses ductile iron for parts that face high stress and wear.

Ductile iron is commonly used in agricultural machinery for parts such as plowshares, brackets, and clamps. Its wear resistance and strength ensure these components can withstand the rigorous demands of farming operations.

In construction equipment, ductile iron is employed for gears, pulleys, and other mechanical parts. The material’s durability and toughness make it suitable for use in heavy-duty machinery like bulldozers, cranes, and excavators.

Ductile iron’s versatile properties make it suitable for a wide range of general engineering applications.

In the machine tool industry, ductile iron is used for manufacturing complex machine parts due to its excellent machinability and mechanical properties. Components such as lathe beds, milling machine tables, and drilling machine columns are often made from ductile iron.

Ductile iron is also used in the paper manufacturing industry for parts like pressure drums and drying drums. The material’s high strength and elastic modulus make it suitable for these applications, where precision and durability are critical.

Ductile iron is increasingly used in renewable energy, especially for wind power.

Ductile iron is used for hubs and structural parts of wind turbines. The material’s strength and fatigue resistance are essential for these components, which must endure constant stress and environmental exposure.

In the oil and gas industry, ductile iron is valued for its durability and ability to withstand high pressures.

Ductile iron is used in oil well pumps and other high-pressure applications due to its toughness and corrosion resistance. The material ensures reliable performance in the demanding conditions of oil extraction and processing.

Ductile iron offers several advantages over other materials commonly used in similar applications. These benefits arise from its unique blend of strength, affordability, and ease of manufacturing.

Compared to traditional cast iron, ductile iron exhibits significantly higher strength and ductility. The spherical graphite nodules in its microstructure reduce stress concentrations, enhancing its ability to withstand tensile and impact forces without fracturing. This makes it a preferred choice for applications requiring a balance of strength and flexibility, such as automotive components and structural supports.

Ductile iron outperforms mild steel in terms of corrosion resistance, primarily due to the presence of graphite nodules, which form a protective layer against environmental factors. This property is particularly beneficial for pipelines and fittings exposed to harsh environments, such as underground water and sewage systems.

The graphite nodules in ductile iron offer great wear resistance. This makes it suitable for applications where components are subjected to continuous friction and wear, such as gears, bearings, and agricultural machinery parts. The lubricating effect of graphite helps reduce wear and prolong the lifespan of these components.

Ductile iron costs less to produce than steel because it melts at a lower temperature and is easier to cast. The ability to cast complex shapes with high precision reduces the need for extensive machining and finishing, further lowering production costs.

The durability and corrosion resistance of ductile iron contribute to lower maintenance costs over the lifespan of the component. In water supply and sewage treatment, needing fewer replacements and repairs saves significant costs.

Ductile iron has a favorable environmental profile compared to many other materials. Its production process is energy-efficient, and the material is highly recyclable. The long service life of ductile iron components also reduces the environmental impact associated with frequent replacements and waste generation.

While ductile iron is highly ductile at room temperature, it can become brittle at very low temperatures. This limitation must be considered in applications exposed to extreme cold, where materials like certain grades of steel may be more suitable.

Ductile iron is heavier than some alternative materials, such as aluminum and certain high-strength plastics. This can be a drawback in applications where weight reduction is critical, such as in aerospace and certain automotive components.

The production of ductile iron involves precise control of the alloying elements and the casting process to achieve the desired mechanical properties. This complexity can result in higher initial production costs and the need for specialized foundries.

Standards are crucial for ensuring the quality, safety, and performance of ductile iron products. Various organizations have established specific standards to govern the manufacturing, testing, and use of ductile iron in different applications. These standards ensure that ductile iron products meet specific criteria for quality, safety, and performance.

ASTM International provides widely recognized standards for ductile iron, focusing on its mechanical properties, testing methods, and application guidelines.

The International Organization for Standardization (ISO) also provides comprehensive standards for ductile iron, ensuring global consistency in quality and performance.

Compliance with established standards is essential for manufacturers and engineers to ensure the reliability and safety of ductile iron products. Several certification programs and audits are in place to verify adherence to these standards.

Accredited organizations regularly conduct audits to ensure manufacturing processes comply with specified standards. These audits typically include:

Compliance with industry standards is further supported by specific certification programs designed to ensure the highest quality and reliability of ductile iron products.

The National Association of Pipe Fabricators (NAPF) offers the QualityPlus Certification Program, which provides independent third-party certification for ductile iron pipe fabricators. This program ensures that manufacturers meet stringent industry standards and guidelines.

This standard ensures that materials in drinking water systems do not impart harmful contaminants, crucial for ductile iron pipes and fittings in water distribution networks.

Addressing lead content in drinking water system components, this standard ensures compliance with the U.S. Safe Drinking Water Act (SDWA). Certified products must have a weighted average lead content of ≤0.25%.

This standard specifies the requirements for flanged ductile iron pipes used in water supply systems. It includes audit-based certification to ensure compliance with wall thickness and flange specifications.

Covering grooved and shouldered joints for ductile iron pipes, this standard provides minimum requirements for materials, dimensions, and testing procedures.

This standard sets the criteria for testing and certification of ductile iron pipe and fittings used in underground fire protection mains. It ensures products meet performance, safety, and quality standards through rigorous testing and manufacturing audits.

Below are answers to some frequently asked questions:

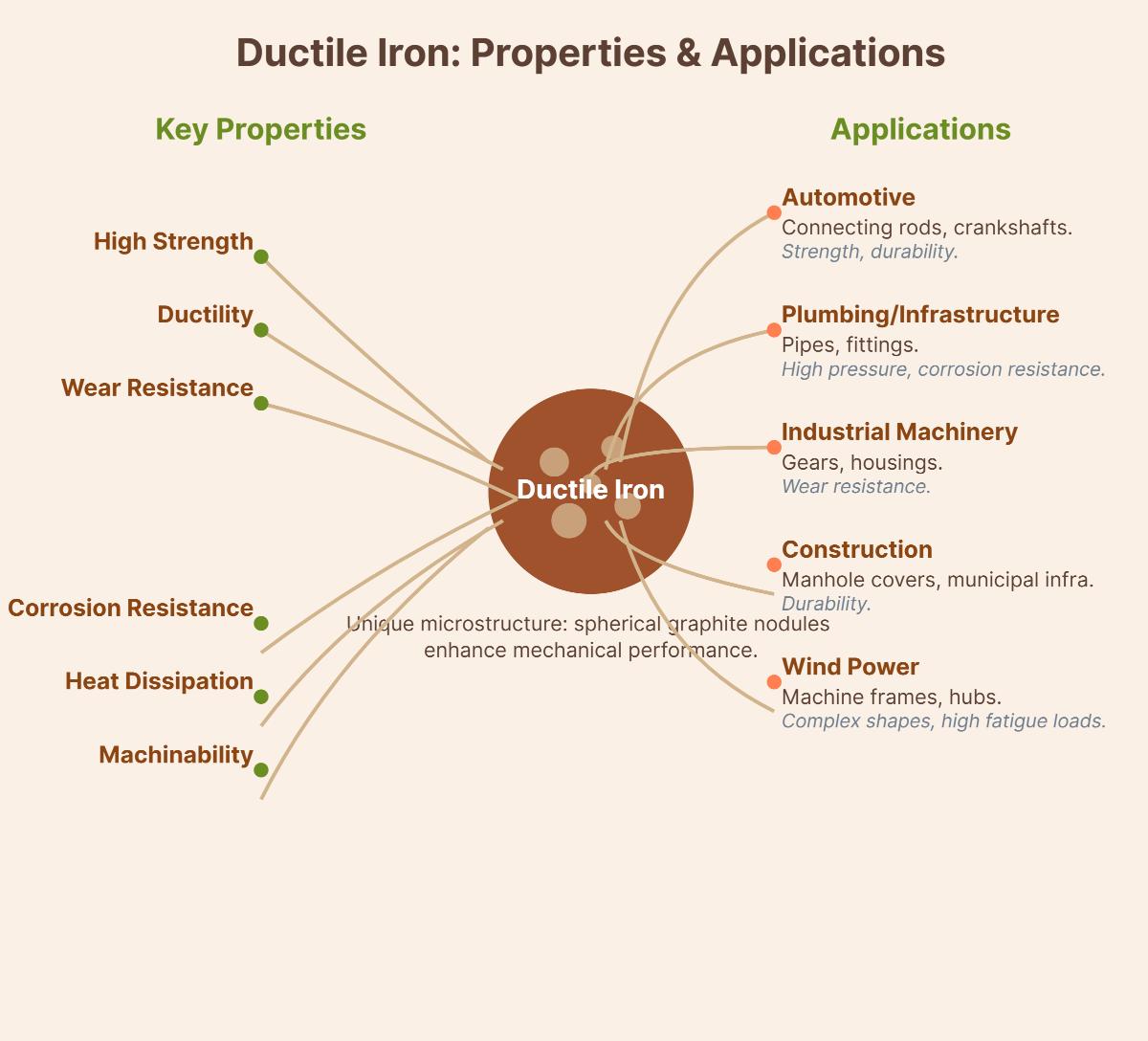

Ductile iron, also known as nodular cast iron, is characterized by its high strength, ductility, wear resistance, corrosion resistance, heat dissipation, and machinability. These properties stem from its unique microstructure, featuring spherical graphite nodules that enhance its mechanical performance.

In terms of applications, ductile iron is extensively used across various industries. In the automotive sector, it is employed for engine components like connecting rods and crankshafts due to its strength and durability. For plumbing and infrastructure, ductile iron pipes and fittings are preferred for water and sewage systems because they can withstand high pressures and corrosive environments. Industrial machinery benefits from ductile iron’s wear resistance, making it suitable for gears and housings. In construction, it is used for manhole covers and municipal infrastructure components owing to its durability. Additionally, ductile iron is used in the wind power industry for machine frames and hubs, which require handling complex shapes under high fatigue loads.

Ductile iron, also known as spheroidal graphite cast iron, is composed primarily of iron (about 94%), carbon (3.2% to 3.6%), silicon (2.2% to 2.8%), manganese (0.1% to 0.2%), and magnesium (0.03% to 0.04%). Minor elements such as phosphorus, sulfur, and copper are also present. The key characteristic of ductile iron is the presence of spherical graphite nodules, formed by the addition of magnesium, which significantly enhances its mechanical properties.

Compared to other materials, ductile iron offers several advantages:

These properties make ductile iron a preferred material in various industries, including automotive, infrastructure, and heavy machinery.

Ductile iron is widely used in construction, automotive, and heavy machinery sectors due to its excellent mechanical properties, such as high strength, ductility, and corrosion resistance.

In construction, ductile iron is primarily used for water pipes, valves, and fittings, crucial for municipal water distribution and sewage systems. Its durability and ability to withstand heavy loads make it ideal for manhole covers and grates in urban infrastructure.

In the automotive industry, ductile iron is essential for manufacturing critical engine components like crankshafts, connecting rods, and camshafts. Its strength and fatigue resistance are also valuable for gears, bushings, suspension systems, brake components, and steering parts, where it helps absorb vibrations and endure mechanical stress.

In the heavy machinery sector, ductile iron is used for gears, gearboxes, pump housings, and other high-stress components in mining, manufacturing, and power generation equipment. Its durability and vibration-dampening properties make it suitable for agricultural machinery and wind power applications.

Ductile iron, often referred to as nodular or spheroidal graphite iron, offers several advantages over traditional cast iron in terms of performance and cost. In terms of performance, ductile iron is significantly less brittle than traditional cast iron. This is due to its nodular graphite structure, which allows it to bend without fracturing, making it ideal for high-stress applications such as pipes, automotive parts, and heavy machinery. Ductile iron also exhibits superior tensile strength, nearly matching that of steel, and has better corrosion resistance, making it suitable for outdoor and water-based applications.

In contrast, traditional cast iron, while strong in compressive applications, is more brittle and prone to cracking under stress. It does have superior vibration damping properties, which can be advantageous in applications like machinery bases where vibration control is crucial.

From a cost perspective, ductile iron is generally more expensive to produce than traditional cast iron due to its more complex chemical composition and manufacturing process. However, its higher initial cost can be offset by lower long-term maintenance and replacement expenses, thanks to its enhanced durability and corrosion resistance. Traditional cast iron, being less costly to produce, may be more economically viable for applications where its brittleness is not a critical issue.

Several standards are relevant for the manufacturing and engineering of ductile iron, ensuring that its products meet stringent quality and performance criteria. Among these, the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide comprehensive guidelines.

Key ASTM standards include:

ISO standards also play a crucial role:

Compliance with these standards ensures that ductile iron products are reliable and suitable for various applications, including construction, automotive, and heavy machinery sectors.

Ductile iron significantly impacts sustainability and the environment positively through several key aspects. Firstly, ductile iron is highly recyclable, containing at least 90% recycled materials and being 100% recyclable itself, which minimizes the need for new raw materials and reduces environmental impact. Its long service life, often exceeding 100 years, decreases the frequency of replacements, further reducing production and disposal impacts.

Additionally, ductile iron pipes have a smooth interior that enhances water flow efficiency, leading to lower pumping costs and up to a 38% reduction in energy consumption compared to other materials. This efficiency translates to lower greenhouse gas emissions during both production and operation phases.

Moreover, ductile iron does not release hazardous chemicals, ensuring safety for both public health and the environment. Its corrosion resistance also contributes to an extended lifespan and reduced maintenance needs, lowering its In various applications, such as utility poles and automotive components, ductile iron’s durability and recyclability offer sustainable alternatives to traditional materials, making it a responsible choice in terms of environmental conservation.