In the world of metallurgy, low carbon steel stands out as a versatile and widely used material, yet its full potential often remains under – explored. With a unique chemical composition that sets it apart from other steel types, it offers remarkable ductility, malleability, and cost – effectiveness. Low carbon steel is not only a staple in the construction of high – rise buildings but also finds its way into everyday consumer goods.

As we embark on this technical deep – dive, have you ever wondered how the manufacturing process of low carbon steel impacts its properties and applications? Let’s find out.

Low carbon steel, commonly referred to as mild steel, is a type of carbon steel with a relatively low carbon content, typically ranging from 0.05% to 0.3%. This composition gives low carbon steel valuable properties like high ductility, malleability, and ease of welding. These characteristics make it a preferred choice for numerous industrial applications, including construction, automotive manufacturing, and consumer goods production.

Low carbon steel is primarily composed of iron with a small percentage of carbon. The carbon content is crucial because it directly affects the steel’s properties. In addition to carbon, low carbon steel may contain trace amounts of other elements such as:

Medium carbon steel has a carbon content between 0.3% and 0.6%. This higher carbon content results in increased hardness and strength but reduces ductility and weldability compared to low carbon steel. Medium carbon steel is often used in applications requiring a balance of strength and toughness, such as automotive components and machinery parts.

High carbon steel has a carbon content ranging from 0.6% to 1.0%, making it much harder and stronger than both low and medium carbon steels. However, this increased hardness comes at the expense of ductility and weldability. High carbon steel is commonly used in applications where high wear resistance is essential, such as cutting tools and springs.

Low carbon steel’s unique composition offers several benefits:

Low carbon steel’s versatility makes it ideal for many applications:

Low carbon steel is highly ductile and malleable, meaning it can be easily deformed without breaking. Its low carbon content allows the steel to stretch and bend under stress. These properties are particularly beneficial in applications requiring extensive forming and shaping, such as automotive body panels and various structural components.

The tensile strength of low carbon steel typically ranges between 400 to 550 MPa. While this is lower than the tensile strength of higher carbon steels, it is sufficient for many structural and machinery applications. This moderate strength, combined with its other favorable properties, makes low carbon steel a versatile material in numerous industries.

Low carbon steel has moderate thermal conductivity. This makes it suitable for applications where heat needs to be efficiently dissipated, like in heat exchangers and radiators. The material can transfer heat effectively without losing its structural integrity.

Low carbon steel is known for its excellent weldability. The low carbon content reduces the risk of weld cracking, a common issue in higher carbon steels. This makes it ideal for projects involving extensive welding, such as in construction and fabrication, where strong and reliable joints are crucial.

The density of low carbon steel is about 7.85 g/cm³, which is consistent with many other ferrous alloys. This property is important for calculating the weight and load-bearing capacity of steel components in structural applications. Additionally, low carbon steel has a melting point ranging from 1420 to 1460 °C. This high melting point is advantageous in welding and forging processes, as it allows the steel to withstand high temperatures without losing its structural properties.

The shear modulus of low carbon steel is between 70 and 80 GPa. This measure of rigidity indicates the material’s ability to resist deformation under shear stress. It is an important factor in applications where the steel must maintain its shape and integrity under load.

Low carbon steel is known for its cost-effectiveness. Its production process is relatively simple due to the minimal carbon content, which simplifies the refining and alloying processes. Additionally, the widespread availability of raw materials makes it an economical choice for many applications. This affordability, combined with its favorable properties, ensures that low carbon steel provides excellent value for money.

Low carbon steel is highly recyclable, which contributes to its sustainability. Recycling steel reduces the need for raw material extraction and lowers energy consumption in production. For example, the automotive industry often uses recycled steel to manufacture new vehicles, reducing the environmental impact. Similarly, the construction industry repurposes steel beams from old buildings to create new structures. This environmental benefit makes low carbon steel a preferred material in industries focused on sustainability and reducing their carbon footprint.

The BOS method starts by collecting and preparing raw materials, mainly iron ore and scrap steel. These materials are charged into a blast furnace, where they are melted to produce molten iron. Additives such as limestone are often introduced to remove impurities during the melting process.

Once the molten iron is produced, it is transferred to a basic oxygen furnace. In this furnace, high-purity oxygen is blown through the liquid iron at high pressure. This starts a chemical reaction that reduces carbon content by oxidizing impurities, transforming the iron into low carbon steel.

During the oxygen blowing process, alloying elements like manganese and silicon are added to enhance the steel’s properties. This step ensures that the final product has the desired characteristics, such as enhanced strength, ductility, and weldability.

After the primary steelmaking process, techniques such as vacuum degassing and argon stirring are used. These methods further refine the chemical composition and improve the quality of the steel, ensuring it meets specific standards required for various applications.

The refined molten steel is then cast into various shapes, such as slabs, billets, and blooms, using continuous casting machines. This process allows for efficient mass production and reduces the need for further processing, making it a cost-effective method.

The cast steel products undergo rolling and forging operations to achieve desired dimensions and mechanical properties. Rolling is used to reduce the thickness of the steel, while forging shapes the material under compressive forces. These processes enhance the structural integrity and usability of the steel.

The EAF method primarily utilizes recycled steel scrap as the raw material. Electric arcs are generated between electrodes to melt the scrap steel, which may include direct reduced iron (DRI) and other iron sources. This method is highly efficient and environmentally friendly due to the recycling of materials.

During the melting process, the carbon content is carefully managed to achieve low carbon levels. Precise control of input materials and operational parameters ensures that the final product has the desired carbon content, typically less than 0.3%.

Similar to the BOS method, the melted steel undergoes secondary refining processes to remove impurities and achieve the required chemical composition. Continuous casting is then used to form the steel into various shapes, ensuring consistent quality and dimensions.

Low carbon steel exhibits excellent ductility and formability, making it ideal for applications that require extensive shaping and bending. Its lower carbon content contributes to these favorable properties.

The good weldability of low carbon steel, due to its low carbon content, minimizes the risk of brittle fractures during welding. This makes it suitable for reliable construction and maintenance of structural components.

The manufacturing processes of low carbon steel are generally more economical compared to higher carbon steels. The use of recycled materials in EAF further enhances cost-effectiveness and sustainability, reducing the overall production costs and minimizing the environmental impact.

New methods, like hydrogen-based reduction and carbon capture, are being developed to cut greenhouse gas emissions. These innovations contribute to the environmental sustainability of low carbon steel manufacturing.

Low carbon steel is highly versatile and used in numerous applications across various industries. Its ductility, weldability, and affordability make it ideal for many structural and functional uses.

The construction industry relies on low carbon steel for structural elements like beams, columns, and girders due to its mechanical properties and ease of fabrication.

The automotive industry benefits greatly from the properties of low carbon steel, utilizing it in various components to enhance performance and safety.

In the consumer goods industry, low carbon steel is utilized for its ease of fabrication and cost-effectiveness.

The machinery and equipment sector leverages the properties of low carbon steel for various mechanical components.

Low carbon steel is extensively used in the fabrication of pipes and tubes for various fluid transport and structural applications.

Beyond the primary industries, low carbon steel finds use in several other areas due to its advantageous properties.

Comparing the performance of low-carbon steel to medium-carbon, high-carbon, and alloy steels reveals distinct differences in their properties and applications.

Low-carbon steel has less than 0.3% carbon, making it more flexible. Medium-carbon steel, with 0.3% to 0.6% carbon, offers a balance of strength and flexibility.

Low-carbon steel is highly ductile and malleable, which means it can be easily shaped and formed. It’s commonly used in construction, like for structural beams and rebar, and in the automotive industry, for body panels. Next, let’s look at how medium-carbon steel compares.

Medium-carbon steel has a balanced combination of strength and flexibility, making it suitable for more demanding mechanical applications. It’s often used to manufacture heavy – duty machinery parts such as gears, axles, and crankshafts.

High-carbon steel has a carbon content ranging from 0.6% to 1.0%. High-carbon steel is much harder and stronger than low-carbon steel. However, it is also more brittle and less ductile.

High-carbon steel is the go-to choice for applications that demand high wear resistance, such as cutting tools, springs, and high – strength wires. Low-carbon steel, on the other hand, is used when ease of forming and welding are more critical.

Alloy steel contains additional alloying elements like chromium, nickel, and vanadium, which boost its mechanical properties. Alloy steel offers superior strength, hardness, and corrosion resistance compared to low-carbon steel. These enhanced properties make alloy steel suitable for high – stress and high – wear applications.

Alloy steel is utilized in critical components like drivetrain parts, high – performance gears, and industrial machinery. Low-carbon steel, with its excellent weldability and formability, is preferred for general construction and less demanding applications.

Low-carbon steel is generally more cost – effective. Its simpler manufacturing process and the lower cost of raw materials contribute to its affordability. Also, its wide availability and ease of fabrication make it a budget – friendly option.

The increased carbon content and additional processing requirements make medium – carbon steel more expensive than low – carbon steel. However, the enhanced mechanical properties justify the higher cost for specific applications.

The specialized applications and higher processing costs associated with high – carbon steel result in a higher price point. The need for additional heat treatment and the material’s brittleness also add to the cost.

The inclusion of alloying elements and the complexity of the manufacturing process make alloy steel the most expensive among the types compared. But the superior properties justify the cost in high – performance and high – stress applications.

Low – carbon steel is highly recyclable, which makes it environmentally friendly and supports sustainability initiatives. Its production often involves a significant amount of recycled material, reducing the need for raw material extraction and lowering energy consumption.

While medium – carbon steel is also recyclable, the higher carbon content and specific applications may limit the extent of recycling compared to low – carbon steel. However, it still offers environmental benefits through recyclability.

Recycling high – carbon steel is more challenging due to its brittleness and specialized applications. Nevertheless, efforts to recycle and reuse high – carbon steel components continue to improve.

The recycling process for alloy steel is more complex because of the presence of alloying elements. But advancements in recycling technology are improving the efficiency and feasibility of recycling alloy steel, contributing to its sustainability.

Material characterization, especially of low carbon steel, has advanced significantly in recent years. These advancements have enhanced our understanding of its metallurgical and mechanical properties, particularly in applications such as laser autogenous welding, which does not use filler material. This technique has been shown to improve the mechanical properties of low carbon steel joints, and post-weld heat treatment further enhances their strength and stability, making them suitable for high-stress applications.

Characterizing low carbon steel requires sophisticated analysis techniques to understand its microstructure and composition. These techniques provide insights into how different elements and phases are distributed within the steel, which is crucial for optimizing its performance in various applications.

EDS, used with scanning electron microscopy (SEM), is a powerful tool for analyzing the elemental composition of low carbon steel. By detecting the X-rays emitted from the material when it is bombarded with electrons, EDS can identify and quantify the presence of alloying elements such as manganese, silicon, copper, and nickel. This information is vital for controlling the steel’s properties and ensuring consistency in production.

X-ray Diffraction (XRD) is another essential technique for characterizing low carbon steel. It involves directing X-rays at the steel and measuring the angles and intensities of the diffracted beams. This data helps identify the crystalline phases present in the steel, providing insights into its microstructure. Understanding the phase composition is important for predicting the steel’s mechanical properties and behavior under different conditions.

Electron Backscatter Diffraction (EBSD) is used to examine the crystallographic orientation of grains in low carbon steel. This technique, also coupled with SEM, provides detailed information about the grain structure and texture of the steel. Analyzing grain orientation helps in understanding how the material deforms under stress and can guide the development of processes to enhance its mechanical properties.

Characterizing low carbon steel is crucial for its application in various industries, ensuring that it meets the required performance standards.

In construction, advanced characterization techniques ensure that low carbon steel in beams and reinforcement bars meets safety and durability standards. Understanding its microstructure and mechanical properties helps in designing components that can withstand high loads and harsh environmental conditions.

For the automotive industry, characterizing low carbon steel is essential for developing body panels, chassis, and other components that require a balance of strength, ductility, and impact resistance. Techniques like EBSD and XRD help in optimizing the steel’s properties to improve vehicle safety and performance.

In the consumer goods industry, advanced characterization ensures that low carbon steel used in appliances, utensils, and furniture meets quality and performance standards. Techniques like EDS provide detailed compositional analysis, ensuring the steel’s consistency and reliability.

In heat exchangers and radiators, understanding the thermal properties and corrosion resistance of low carbon steel is essential. Advanced characterization techniques help in tailoring the steel’s composition and microstructure to enhance its thermal conductivity and longevity in these applications.

Below are answers to some frequently asked questions:

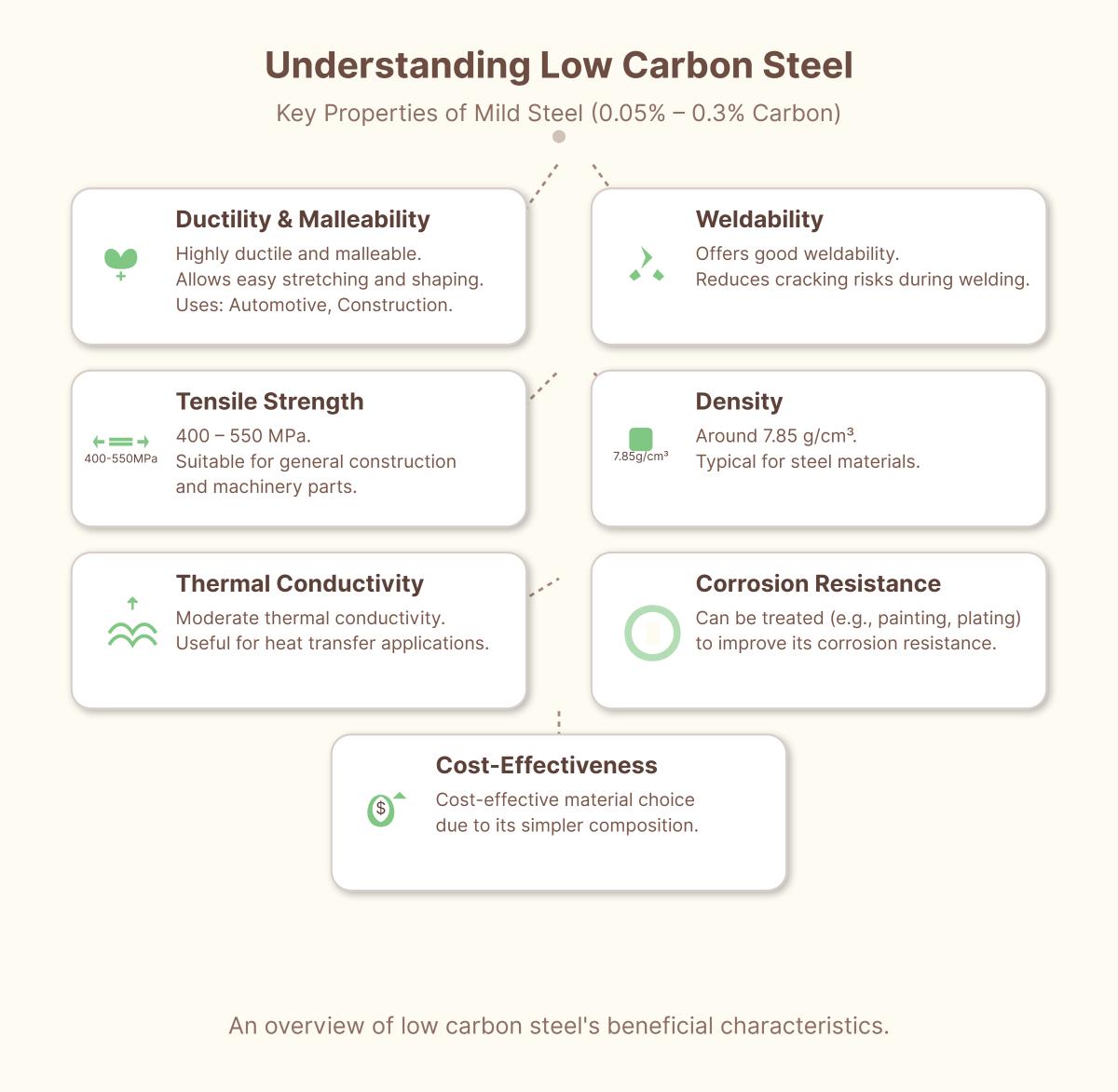

Low carbon steel, or mild steel, with a carbon content of 0.05% – 0.3% by weight, has several key properties. It is highly ductile and malleable, allowing for easy stretching and shaping, suitable for automotive and construction uses. It offers good weldability, reducing cracking risks during welding. With a tensile strength of 400 – 550 MPa, it’s fit for general construction and machinery. It has a density around 7.85 g/cm³, moderate thermal conductivity useful for heat transfer, and can be treated for corrosion resistance. It’s also cost – effective due to its simpler composition.

Low carbon steel, also known as mild steel, is primarily manufactured using two methods: the Basic Oxygen Furnace (BOF) and the Electric Arc Furnace (EAF).

In the BOF method, pure oxygen is blown into molten iron, reducing the carbon content and removing impurities. This process begins with the melting of iron ore and recycled steel, with carbon monoxide introduced to reduce iron ore to liquid steel while controlling the carbon content within the desired range of 0.05% to 0.32%.

The EAF method involves using electrical energy to melt steel scraps, achieving similar refinement through precise control over carbon content and alloying elements.

After initial steel making, the steel undergoes secondary refining to meet specific composition standards, using techniques such as argon stirring and vacuum degassing to adjust chemical composition and eliminate impurities. The refined steel is then cast into slabs, billets, or blooms using continuous casting machines.

These intermediate forms are further processed through rolling or forging to achieve the desired thickness and shape, with precise temperature control crucial for achieving the desired mechanical properties.

Final stages involve heat treatments like normalizing or controlled cooling to enhance properties like ductility and strength, followed by finishing processes to achieve the required surface quality and dimensions.

Recent developments aim at more sustainable production methods, such as hydrogen-based direct reduction, which reduces iron ore to iron using hydrogen gas, emitting only water vapor.

Low carbon steel, with carbon content below 0.3%, is widely used due to its weldability, ductility, and cost – effectiveness. In construction, it’s used for beams, frames, and reinforcement bars. The automotive industry employs it for body panels and engine components. For machinery, it’s utilized in shafts, gears, and fasteners. In consumer goods, it can be found in household appliances and furniture frames. It’s also common in low – pressure piping and fluid transport in the oil and gas sector.

Low carbon steel, with its carbon content typically below 0.3%, is known for its excellent ductility, malleability, and weldability. Compared to medium carbon steel, which contains 0.3% to 0.6% carbon, low carbon steel is less strong and hard but offers superior ductility and ease of fabrication. Medium carbon steel is often used in automotive parts and machinery where a balance between strength and ductility is required, often involving heat treatment processes.

High carbon steel, with carbon content above 0.6%, is the strongest and hardest but also the most brittle among the three. It is commonly used in applications requiring high wear resistance, such as cutting tools and springs, but it is less ductile and more challenging to work with.

Low carbon steel is advantageous in terms of cost-effectiveness due to its simpler production processes and lower carbon content. It is widely used in construction, automotive, and consumer goods industries. Additionally, its environmental benefits include high recyclability and reduced production emissions, making it a sustainable choice for various applications.

Low carbon steel, often referred to as mild steel, presents significant cost and sustainability benefits. Economically, its production is less energy-intensive and involves simpler processes, which lowers operational costs and results in a more affordable final product. Additionally, its ease of machining reduces wear on cutting tools and maintenance costs for machinery, enhancing its cost-effectiveness in industries like automotive and construction. The high demand for low carbon steel also allows for large-scale production, leveraging economies of scale to further reduce per-unit costs.

From a sustainability perspective, low carbon steel has a lower environmental impact due to reduced carbon emissions during production. This is particularly beneficial in regions with carbon pricing mechanisms and stringent environmental regulations, helping manufacturers comply with standards at lower costs. Moreover, ongoing investments in cleaner technologies and optimized production methods continue to decrease energy consumption and emissions, aligning with global trends toward eco-friendly materials. These advancements are expected to reduce the “green premium” associated with low carbon steel, making it a more competitive and sustainable choice in the long term.

Low carbon steel, also known as mild steel, complies with several industry standards to ensure its quality and suitability for various applications. Key standards include those set by ASTM International (formerly the American Society for Testing and Materials), the American Iron and Steel Institute (AISI), and SAE International.

ASTM standards such as ASTM A36 specify a minimum yield strength of 36 ksi and a maximum carbon content of around 0.25%, making it one of the most commonly used standards. ASTM A572 Grades 42 and 50, offering higher yield strengths of 42 ksi and 50 ksi respectively, are used in construction for building frames and bridges. ASTM A830-1020 is another specification for low carbon steel plates used in machinery parts and structural components.

AISI and SAE standards also play a significant role. AISI 1010 and AISI 1020 are popular grades with low carbon content, suitable for general manufacturing and construction applications. SAE J403 includes various grades with specific carbon content requirements to meet different mechanical properties.

These standards ensure that low carbon steel meets the necessary physical and mechanical properties for its intended applications, providing consistency and reliability in its performance.