In the realm of industrial materials, PC-ABS stands out as a versatile and high-performing alloy. Comprising Polycarbonate and Acrylonitrile Butadiene Styrene, it combines the best of both worlds. Key mechanical properties like high impact resistance and tensile strength make it a go – to for many industries. The ratio of PC to ABS significantly influences these properties, tailoring the material for specific needs.

This guide will take you through a step – by – step exploration of PC-ABS, from its properties and applications to processing techniques. So, are you ready to uncover how this remarkable material can revolutionize your projects?

PC-ABS (Polycarbonate-Acrylonitrile Butadiene Styrene) is a hybrid thermoplastic that merges the strengths of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS). This engineered material is designed to leverage the properties of both base polymers, resulting in a versatile and high-performance plastic suited for a variety of industrial applications.

Polycarbonate is known for its high impact strength, optical clarity, and excellent thermal resistance, making it ideal for high-performance applications under stress and heat. It maintains its mechanical properties across a wide temperature range and has inherent flame retardancy. ABS, on the other hand, is valued for its toughness, ease of processing, and good impact resistance even at low temperatures. It offers a balance of mechanical properties, making it widely used in consumer products for its ease of fabrication and aesthetic versatility. Additionally, ABS enhances the material’s ductility and energy absorption upon impact.

The mix of PC and ABS in PC-ABS offers a unique set of properties, making it ideal for demanding applications. Here are some key reasons why PC-ABS is important in industrial contexts:

The specific composition of PC-ABS can vary depending on the desired balance of properties. Typically, the blend consists of 60-90% polycarbonate and 10-40% ABS. The precise ratio is adjusted to optimize characteristics such as:

Thanks to the polycarbonate, PC-ABS has high tensile strength and stiffness, making it ideal for parts that must endure heavy loads without deforming. The ABS adds excellent impact resistance, helping the material absorb high-energy impacts without cracking, which is crucial for durable applications.

PC-ABS is known for its exceptional mechanical properties, which result from combining the strengths of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS).

PC-ABS exhibits a tensile strength of approximately 5,900 psi (41 MPa). This value indicates the material’s ability to resist breaking under tension. With a higher tensile strength than ABS alone, PC-ABS offers better performance in applications requiring robust and durable materials.

The tensile modulus of PC-ABS is about 278,000 psi. This parameter reflects the stiffness of the material, indicating its ability to deform elastically when a force is applied. A higher tensile modulus means the material is stiffer and can withstand higher stresses without significant deformation.

One of the standout features of PC-ABS is its high impact resistance, a critical property for applications subject to sudden forces or shocks. The ABS component contributes to this property, providing excellent toughness and the ability to absorb energy without cracking or breaking.

PC-ABS boasts impressive thermal properties, making it suitable for applications exposed to various temperatures. It offers excellent heat resistance, primarily due to the polycarbonate component, and can maintain its structural integrity up to 110°C under moderate pressure. This is essential for applications that operate in high-temperature environments.

The heat deflection temperature (HDT) of PC-ABS is typically higher than that of standard ABS. This property measures the temperature at which the material deforms under a specified load, indicating its ability to retain shape and mechanical properties under thermal stress.

The specific properties of PC-ABS can be tailored by adjusting the ratio of polycarbonate to ABS in the blend. Common ratios range from 60-90% PC and 10-40% ABS, allowing customization for various applications.

PC-ABS stands out by combining the best of both polycarbonate and ABS. Polycarbonate provides high strength and thermal resistance, while ABS offers excellent impact resistance and ease of processing. By combining these materials, PC-ABS delivers enhanced performance, making it a versatile choice for a wide range of industrial applications.

In the automotive industry, PC-ABS is used for components that require both high impact resistance and thermal stability, such as glove boxes and dashboard components. These parts must endure constant mechanical stress and temperature variations without compromising safety or performance.

Similarly, PC-ABS is widely used in the electronics sector for products like laptop monitor enclosures and phone exteriors. These applications benefit from the material’s strength, heat resistance, and ability to achieve high-quality finishes, ensuring durability and aesthetic appeal.

The combination of mechanical robustness, thermal performance, and customizable properties makes PC-ABS an invaluable material in various demanding industrial applications.

Injection molding is a primary method for processing PC-ABS, enabling the production of high-quality, complex parts with excellent mechanical properties. Molten material is injected into a mold cavity, where it cools and hardens into the desired shape.

3D printing, especially Fused Deposition Modeling (FDM), is popular for processing PC-ABS due to its ability to create complex geometries and rapid prototypes. Similar to injection molding, drying the filament before printing is crucial to avoid moisture-induced defects like bubbling and poor layer adhesion.

Both injection molding and 3D printing are effective techniques for processing PC-ABS, each with unique advantages and challenges. Proper handling and optimization of processing parameters are essential to achieve high-quality results.

PC-ABS is widely used in the automotive industry for its impact resistance, heat resistance, and dimensional stability, making it ideal for both interior and exterior components.

The electrical insulation properties, heat resistance, and flame retardancy of PC-ABS make it a preferred material for electronic housings and enclosures.

PC-ABS is favored for household appliances and consumer products because of its attractive surface finish, durability, and heat resistance.

PC-ABS’s resistance to chemicals, disinfectants, and its ability to maintain shape under stress make it suitable for medical device housings and equipment.

PC-ABS’s mechanical strength, flame retardancy, and chemical resistance make it ideal for industrial protective equipment and machinery components, ensuring durability and safety in harsh conditions.

In the aerospace sector, PC-ABS is valued for its lightweight nature, flame resistance, and dimensional stability.

PC-ABS is gaining traction in advanced manufacturing sectors such as 3D printing. Its strength, heat resistance, and flow characteristics make it suitable for producing strong, functional prototypes and end-use parts.

When comparing PC-ABS to other common materials, several key performance attributes need consideration: impact resistance, heat resistance, mechanical strength, dimensional stability, and ease of processing. These properties significantly affect a material’s suitability for specific applications.

PC-ABS stands out for its exceptional impact resistance and toughness, particularly at low temperatures. It’s ideal for applications needing durability and mechanical stress resistance. In contrast:

The polycarbonate component of PC-ABS significantly enhances its heat resistance. PC-ABS can maintain its properties at temperatures up to around 110°C, making it suitable for applications exposed to elevated temperatures. Comparatively:

The blend of PC and ABS results in a material with high tensile strength and stiffness. This ensures that PC-ABS can withstand significant mechanical loads without deforming. In comparison:

PC-ABS maintains its dimensions and mechanical properties across a range of temperatures and humidities better than many other plastics, making it ideal for precision parts requiring tight tolerances. By comparison:

Processing PC-ABS can be more challenging due to the higher molding temperatures required by polycarbonate. However, the blend retains good processability, allowing it to be molded using standard injection molding techniques. In contrast:

The cost of PC-ABS is generally higher than ABS and many common plastics but lower than pure polycarbonate. This cost difference is often justified by the enhanced performance characteristics of PC-ABS.

PC-ABS is particularly well-suited for industries requiring materials that can endure mechanical stress, thermal conditions, and precise manufacturing tolerances. These include automotive, electronics, consumer goods, and medical devices.

PC-ABS has limited chemical resistance, which can be a drawback in certain applications. The material is particularly susceptible to degradation when exposed to acids, bases, and various volatile compounds. This limitation restricts its use in environments where it might come into contact with aggressive chemicals, leading to potential material failure.

To address this issue, manufacturers often incorporate reinforcing agents such as glass fibers or fillers into the PC-ABS blend. These additives enhance the material’s chemical resistance, although they do not completely eliminate its vulnerability to harsh chemicals. Despite these enhancements, PC-ABS remains less effective in highly corrosive environments compared to materials specifically designed for chemical resistance.

UV resistance is another limitation of PC-ABS. Although the polycarbonate in the blend offers some UV protection, it is generally insufficient for prolonged outdoor use. Over time, UV radiation can cause the material to degrade, leading to discoloration, loss of mechanical properties, and surface cracking.

Enhancements to UV resistance can be achieved through the use of additives and coatings. UV stabilizers and absorbers can be incorporated into the PC-ABS formulation to improve its resistance to UV radiation. Additionally, surface treatments and coatings can provide a protective barrier against UV light. However, these measures are often external treatments rather than intrinsic improvements to the material itself, which means their effectiveness can diminish over time.

PC-ABS is sensitive to moisture, which can cause defects like surface blemishes, degradation, and compromised mechanical properties during processing. Proper drying of PC-ABS before use is crucial to maintaining the quality and performance of the final product.

To mitigate moisture-related issues, PC-ABS must be thoroughly dried before processing. Typical drying conditions involve heating the material at temperatures between 80°C and 110°C for several hours to reduce moisture content to acceptable levels. This step is essential to prevent processing defects and ensure the material performs as expected.

Various additives can be used to enhance the properties of PC-ABS, making it more suitable for specific applications.

Thermoplastic additives can improve the processability, dimensional stability, and mechanical strength of PC-ABS. These additives help tailor the material’s properties to meet the demands of different manufacturing processes and applications.

Incorporating reinforcing agents like glass fibers or fillers can significantly improve the mechanical properties of PC-ABS. These agents enhance the material’s strength, stiffness, and impact resistance, making it more suitable for structural applications.

Despite its limitations, PC-ABS is popular in various industries due to its balance of strength, impact resistance, and heat tolerance. By understanding and mitigating its limitations, manufacturers can effectively leverage the material’s strengths. For instance, in automotive and electronics applications, components are typically designed to avoid direct exposure to harsh chemicals or prolonged UV light, ensuring the longevity and reliability of the parts.

Ongoing research aims to further enhance the properties of PC-ABS, including the development of new additives and processing techniques. These advancements are expected to improve the material’s recyclability and environmental impact, making it a more sustainable option for various applications.

Below are answers to some frequently asked questions:

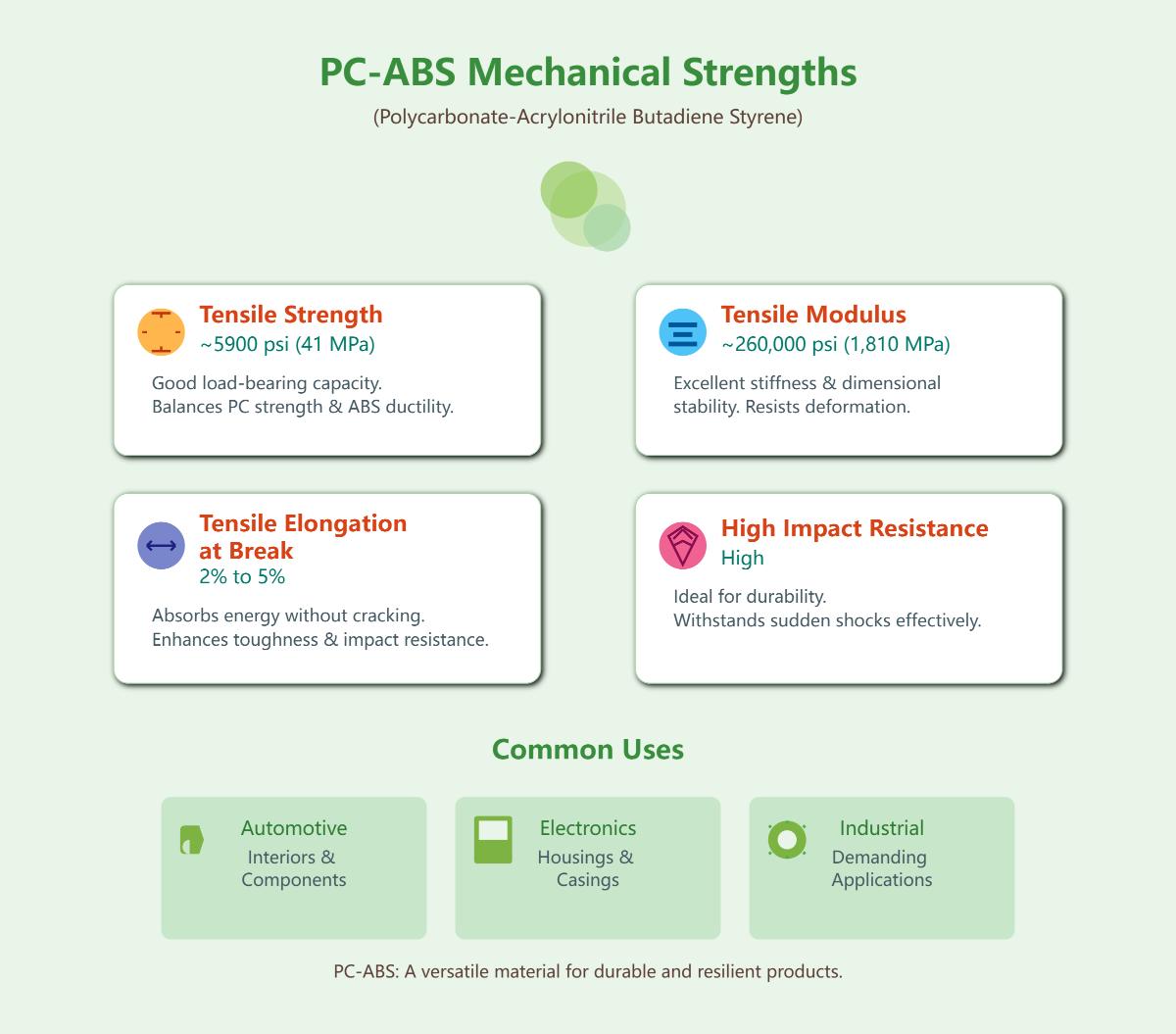

PC-ABS (Polycarbonate-Acrylonitrile Butadiene Styrene) exhibits several key mechanical properties that make it valuable for industrial applications. Firstly, it has a tensile strength of approximately 5900 psi (41 MPa), which is a balance between the higher strength of polycarbonate and the ductility of ABS. This ensures good load-bearing capacity. Secondly, the tensile modulus, around 260,000 psi (1,810 MPa), indicates that PC-ABS has excellent stiffness and dimensional stability, resisting deformation under stress. Additionally, its tensile elongation at break, ranging from 2% to 5%, reflects its ability to stretch and absorb energy without cracking, enhancing its toughness and impact resistance. Lastly, PC-ABS has a high impact resistance, making it suitable for applications that require durability and the ability to withstand sudden shocks. These properties collectively make PC-ABS an ideal material for automotive interiors, electronic housings, and other demanding applications.

The ratio of polycarbonate (PC) to acrylonitrile butadiene styrene (ABS) in PC-ABS blends significantly affects the material’s properties. Increasing the PC content generally enhances tensile strength and heat resistance due to PC’s inherently higher strength and thermal stability. Conversely, higher ABS content improves impact resistance and flexibility, making the material better suited for applications requiring toughness and energy absorption.

A balanced ratio, often around 70:30 or 75:25 (PC:ABS), is typically used to optimize both mechanical strength and processability. Higher PC ratios result in better performance in high-temperature environments, while higher ABS ratios facilitate easier molding and better flow characteristics during injection molding. This ratio-dependent property adjustment allows engineers to tailor PC-ABS blends for specific industrial applications, ensuring optimal performance and manufacturability.

PC-ABS, a blend of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS), is widely used in various industries. In automotive, it’s used for interior and exterior parts like instrument panels, door liners, and exterior trims due to its impact resistance and dimensional stability. For electronics, it’s found in laptop/desktop housings, phone cases, and control panels, leveraging its heat resistance and surface finish. Consumer appliances such as vacuum cleaners and personal care devices also use PC-ABS for its durability. In medical and safety equipment, it meets hygiene and safety standards for device housings and protective gear.

PC-ABS is highly suitable for both plastic injection molding and 3D printing due to its advantageous material properties. For plastic injection molding, PC-ABS offers excellent heat resistance, mechanical strength, impact resistance, and dimensional stability. These attributes allow the production of complex, high-quality parts, making it ideal for automotive, electronics, and consumer goods industries. The material requires proper drying and precise control of processing temperatures to avoid defects.

In 3D printing, PC-ABS provides strong, durable parts with good thermal resistance, suitable for functional prototypes and end-use applications. However, it also demands careful handling, such as ensuring the filament is dry and using a heated bed and enclosed chamber to minimize warping and ensure dimensional accuracy.

PC-ABS (polycarbonate-acrylonitrile butadiene styrene) has some notable limitations regarding chemical and UV resistance that can affect its performance in certain environments. Chemically, PC-ABS is vulnerable to alkalis, aromatic and halogenated hydrocarbons, ketones, esters, and strong solvents. Additionally, it is sensitive to hydrolysis due to the polyester nature of polycarbonate, making it less durable in moist, alkaline, or acidic conditions over time. Exposure to these chemicals can lead to degradation or damage.

Regarding UV resistance, PC-ABS has limited inherent UV stability. Prolonged exposure to ultraviolet radiation can cause yellowing, discoloration, surface embrittlement, and a loss of mechanical properties. While polycarbonate offers some UV resistance, it is insufficient to fully protect PC-ABS blends. To mitigate these issues, UV stabilizers, special UV-absorbing additives, or protective coatings are often required. However, these measures only partially improve the material’s UV resistance, and the problem remains significant, especially for outdoor applications.

PC-ABS (Polycarbonate-Acrylonitrile Butadiene Styrene) stands out in the market due to its unique blend of properties derived from its constituent materials. It combines the high tensile strength and stiffness of polycarbonate (PC) with the toughness and ductility of ABS, resulting in a material that is up to 60% stronger than ABS alone and more ductile than pure PC. This makes PC-ABS highly resistant to impact, even at low temperatures, and capable of withstanding higher temperatures (up to ~110°C) than ABS.

Compared to other common thermoplastics like HDPE and PP, PC-ABS offers superior mechanical strength and heat resistance, although it is more expensive. Its moderate chemical and UV resistance can be enhanced with additives, but it generally performs better than ABS alone in these areas. Additionally, PC-ABS processes well in injection molding and 3D printing, providing excellent surface finishes and dimensional stability.

Overall, PC-ABS provides a balanced combination of strength, toughness, heat resistance, and processability, making it a preferred choice for demanding applications in automotive, electronics, and other industries requiring high-performance materials.