In the intricate dance of forces that govern the physical world, shear stress plays a pivotal role, shaping the integrity and behavior of materials in ways often unseen but profoundly impactful. As engineers and material scientists delve into the complexities of this fundamental concept, understanding shear stress becomes not just an academic exercise, but a crucial aspect of innovation and design. This article embarks on a technical deep dive, unraveling the definition and calculation of shear stress, and exploring its significant applications across various engineering disciplines. From the equations that quantify it to the real-world scenarios where it alters material properties, shear stress is a force to be reckoned with. How does this hidden force influence the strength and durability of the materials we rely on every day? Join us as we explore its mysteries and practical implications.

Shear stress, symbolized by τ (tau), refers to the force per unit area acting parallel to a material’s surface. This internal force results from applied forces that cause portions of a material to slide past each other, parallel to their plane of contact. Imagine pushing the top card of a deck sideways—this action illustrates shear stress.

Shear stress is crucial in engineering and material science due to its impact on material deformation and potential failure. Grasping the concept of shear stress is crucial for designing and analyzing structures and materials. Engineers must ensure that materials can endure shear forces without excessive deformation or catastrophic failure. In material science, studying shear stress helps predict how materials behave under various loads, aiding in creating stronger materials.

Materials respond differently to shear stress, and their behavior under such stress is key to their application in engineering. Here are some common engineering materials and their characteristics related to shear stress:

Understanding the properties of these materials in relation to shear stress is crucial for their application in engineering designs. Selecting the appropriate material based on its shear characteristics ensures the safety, reliability, and longevity of structures and components.

Shear stress is important in engineering and materials science; it measures the force per unit area parallel to a material’s surface. Accurate calculation is essential for predicting material behavior under various loads, ensuring structural integrity and safety. The fundamental formula for shear stress (τ) is given by:

where ( F ) is the applied force, and ( A ) is the area over which the force is distributed.

In more complex scenarios, like irregular shapes, shear stress calculation can use a more detailed formula:

where:

This approach is particularly useful in engineering applications involving beams and structural components with varying cross-sectional shapes.

Understanding maximum shear stress in common shapes is crucial for designing safe and effective structures. For rectangular sections, the maximum shear stress is calculated as:

where ( A ) is the cross-sectional area (depth × breadth).

For hollow circular shafts, the formula is more complex:

where ( R ) and ( Ri ) are the outer and inner radii, respectively.

In I-beams, maximum shear stress typically occurs at the web-flange junction, requiring careful consideration of the flange width and web thickness in calculations.

In fluid dynamics, shear stress relates to viscosity (μ) and the change in velocity within a fluid. It’s defined by:

where ( du/dy ) is the velocity change perpendicular to the flow direction. This equation helps understand forces in pipelines and around aerodynamic surfaces.

Shear stress significantly affects how materials behave and what characteristics they display. When materials are subjected to shear stress, they undergo deformation due to the sliding of their internal layers. This deformation can be elastic, allowing the material to return to its original shape after the stress is removed, or plastic, leading to permanent changes. The extent of deformation depends on properties like the modulus of rigidity, which measures a material’s ability to resist shear deformation.

Shear strength is crucial for understanding a material’s ability to withstand shear stress without failing. It’s the highest shear stress a material can handle before it breaks down. This property is vital in selecting materials for engineering applications where high shear forces are anticipated. Metals such as steel, known for their high shear strength, are often used in structural applications.

Yield strength in shear is important for ductile materials, representing the stress level at which a material begins to deform plastically. Beyond this point, permanent deformation occurs. Understanding this property helps engineers design components that can withstand operational loads without irreversible shape changes.

Shear stress significantly influences the durability and performance of materials. Fatigue is damage that builds up over time when a material faces repeated loads, eventually causing failure even at lower stress levels. This is especially critical in components subjected to dynamic loads, such as in rotating machinery and structural elements in buildings and bridges.

Work hardening, or strain hardening, occurs in materials, particularly metals, under shear stress. While work hardening increases strength, it also makes the material less flexible and more prone to breaking. This process enhances hardness and strength through plastic deformation but reduces ductility.

The stress-strain relationship under shear stress reveals how materials deform and fail. For many materials, this relationship is linear up to the yield point, followed by a nonlinear region where plastic deformation occurs. The slope of the linear portion is defined by the shear modulus, indicating the material’s rigidity. Engineers use this relationship to predict material behavior under various conditions and to design components that can withstand expected stresses.

Temperature variations can alter mechanical properties under shear stress. High temperatures can lower shear strength and make materials more flexible, while low temperatures can make them brittle and easier to break. These temperature-dependent behaviors are crucial for applications in environments with extreme temperature fluctuations, such as in aerospace and automotive industries.

Shear stress can induce microstructural changes in materials, such as the rearrangement of grains in metals or the alignment of polymer chains in plastics. These changes can enhance or degrade the material’s properties, depending on the nature and extent of the stress. For instance, in metals, shear stress can cause grain refinement, improving strength and toughness. In polymers, shear-induced alignment can increase stiffness and strength in the direction of alignment but may reduce properties in other directions. Understanding the impact of shear stress on material properties is essential for selecting the right materials and designing components that can withstand operational demands. This knowledge helps ensure the safety, reliability, and longevity of engineering structures and systems.

Shear stress (τ) is the force applied parallel to a material’s surface, divided by the area over which the force is applied. It occurs when forces are applied in opposite directions on different parts of an object, causing the material to experience a sliding deformation. The basic formula for calculating shear stress is:

where ( F ) is the applied force, and ( A ) is the area over which the force is distributed.

In structural engineering, shear stress is crucial for designing and analyzing load-bearing elements. Components like beams, columns, and shear walls must withstand lateral forces from wind, earthquakes, and other loads to maintain structural integrity. Engineers use shear stress calculations to ensure these elements can handle expected loads throughout the structure’s lifespan.

Aerospace engineering relies heavily on shear stress analysis to ensure the structural integrity of aircraft and spacecraft. Engineers use advanced models to predict material behavior under high shear stress, optimizing designs for weight, strength, and fuel efficiency. This analysis is critical for the safety and performance of aerospace vehicles.

In materials science, understanding shear stress is vital for developing and testing new materials. In the automotive industry, materials are rigorously tested to ensure they can withstand operational shear forces. This testing helps create materials with enhanced performance characteristics, such as higher strength and better durability.

Shear stress plays a significant role in biomedical engineering, particularly in the study of blood flow and cardiovascular health. The interaction between blood flow and arterial walls is influenced by shear stress, impacting conditions like atherosclerosis. This knowledge aids in designing medical devices, such as stents and artificial heart valves, that function effectively under shear forces within the body.

In mechanical engineering, shear stress is crucial for processes like metal forming and machining. Shear stress analysis is also crucial for designing gears and fasteners that must endure operational loads without failing. Understanding how metals respond to these forces helps optimize techniques such as forging, rolling, and cutting.

Engineers employ various strategies to mitigate the negative effects of shear stress:

By understanding and effectively managing shear stress, engineers can design structures and components that are safer, more efficient, and more durable across various engineering disciplines.

Below are answers to some frequently asked questions:

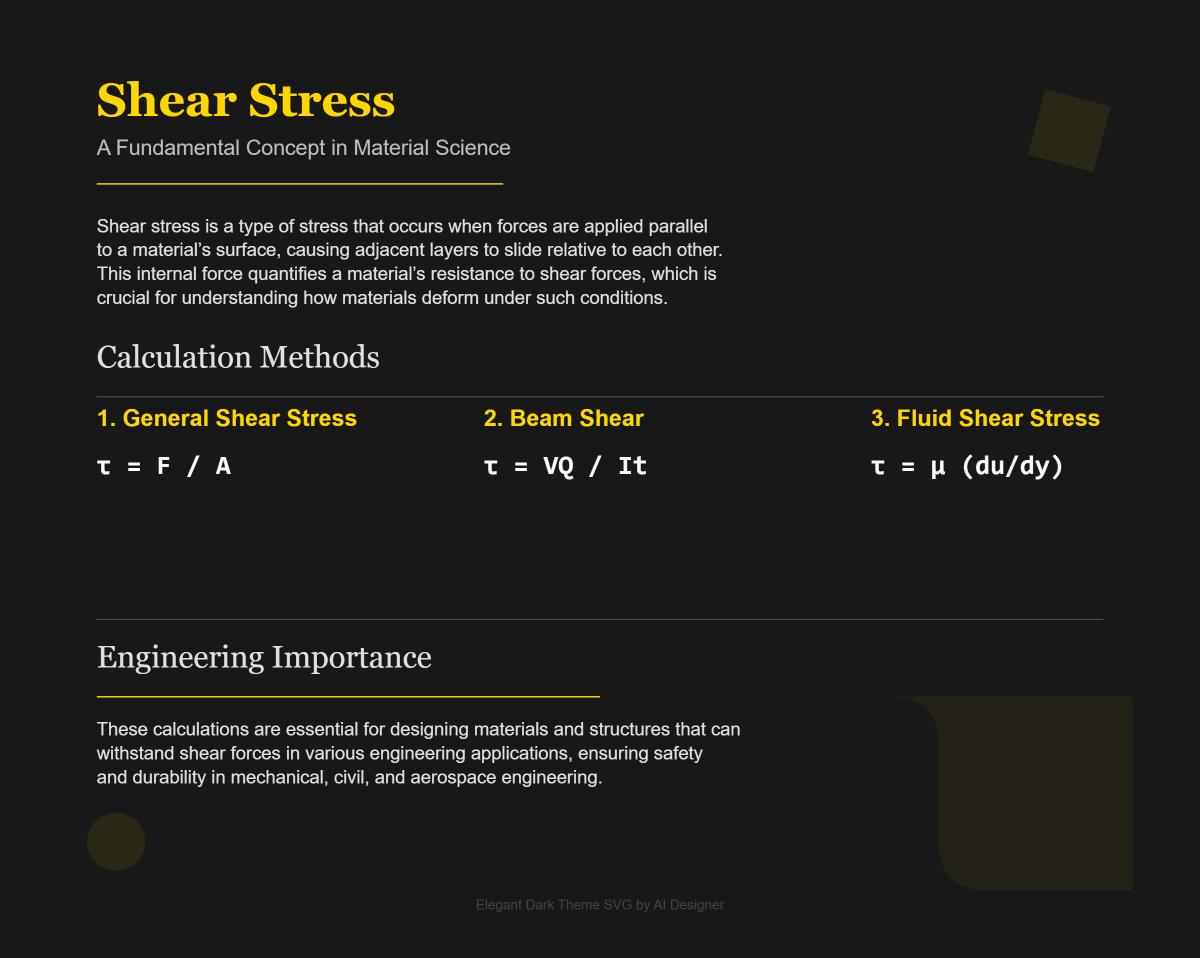

Shear stress is a type of stress that occurs when forces are applied parallel to a material’s surface, causing adjacent layers to slide relative to each other. This internal force quantifies a material’s resistance to shear forces, which is crucial for understanding how materials deform under such conditions. Shear stress is calculated using different methods depending on the application:

These calculations are essential for designing materials and structures that can withstand shear forces in various engineering applications.

Shear stress has several practical applications in engineering, crucial for the design, safety, and efficiency of various structures and components. In civil engineering, shear stress is vital for structural design, helping engineers assess the load-carrying capacity and stability of bridges, buildings, and dams. It also plays a key role in the design of foundations and retaining walls by evaluating the shear strength of soil to prevent sliding or instability.

In mechanical engineering, shear stress is significant in rotating components such as shafts that transmit torque, ensuring they can withstand torsional forces without twisting or fracturing. Fastening components like bolts and rivets must also resist shear forces to maintain the durability and reliability of joints under dynamic conditions.

Aerospace engineering relies on shear stress to design lightweight, strong aircraft structures like wings and fuselages, which must distribute and withstand aerodynamic forces during flight. In material science, understanding shear stress is crucial for analyzing material deformation and failure, aiding in material selection and structural design. These applications underscore the importance of accurately assessing and managing shear stress in engineering to ensure the safety and performance of structures and components.

Shear stress significantly impacts material properties by influencing their deformation behavior and overall performance. Defined as the force per unit area applied parallel to a material’s surface, shear stress can cause layers within the material to slide over each other. This stress can lead to both elastic (temporary) and plastic (permanent) deformation, depending on the magnitude of the force and the material’s inherent properties.

High shear stress can result in plastic deformation, where the material undergoes a permanent change in shape. Additionally, it accelerates surface wear and abrasion, thereby reducing the material’s lifespan. Shear stress also affects the internal structure and stability of materials, altering their strength and durability. These effects make it crucial for engineers to understand and mitigate shear stress through strategies like using lubricants to minimize friction and selecting materials with higher resistance to shear stress, such as high-strength alloys or composites.