When it comes to selecting the right aluminum alloy for your project, understanding the differences between 6065 and 7075 can make all the difference. These two alloys, while both popular and highly regarded, offer distinct properties that can significantly impact their performance in various applications. Are you wondering which alloy boasts superior tensile strength, or which one provides better corrosion resistance? Perhaps you need to know which is more cost-effective for large-scale manufacturing. This article dives deep into the comparative analysis of 6065 and 7075 aluminum alloys, exploring their chemical compositions, mechanical properties, and suitability for specific uses. By the end, you’ll have a clearer picture of which alloy aligns best with your project’s needs and why. So, let’s unravel the mysteries behind these two formidable materials.

Aluminum alloys are essential in modern engineering and manufacturing due to their unique combination of properties such as lightweight, high strength, and excellent corrosion resistance. These alloys are categorized into several series based on their primary alloying elements, each offering distinct characteristics and applications.

Aluminum alloys are divided into series, each defined by its major alloying element:

Aluminum alloys are praised for their high strength-to-weight ratio. This makes them ideal for applications where reducing weight without sacrificing strength is crucial, such as in aerospace and automotive industries.

Aluminum alloys are highly resistant to corrosion. This is particularly beneficial in marine environments and applications where exposure to harsh weather conditions is common.

Aluminum alloys generally exhibit good machinability and formability, allowing for complex shapes and designs through processes like extrusion, rolling, and forging. This versatility makes them suitable for a wide range of industrial applications.

Aluminum alloys also offer high thermal and electrical conductivity, making them suitable for applications in heat exchangers and electrical transmission lines.

Aluminum alloys are utilized in various industries due to their advantageous properties:

When comparing specific alloys such as 6065 and 7075, it is essential to consider their respective properties and applications:

Each alloy has unique advantages, and the choice depends on the specific application requirements.

6065 aluminum alloy is part of the 6000 series, mainly composed of aluminum, magnesium, and silicon. The typical chemical composition includes:

These elements enhance the alloy’s properties, contributing to its strength, corrosion resistance, and weldability.

6065 aluminum alloy typically exhibits a tensile strength ranging from 310 MPa to 450 MPa, making it suitable for applications requiring moderate strength.

The yield strength of 6065 aluminum alloy ranges from 270 MPa to 310 MPa. This yield strength is lower than that of 7075 aluminum alloy, which is approximately 480 MPa. The lower yield strength of 6065 makes it less suitable for high-stress applications but more formable and easier to work with.

6065 aluminum alloy has an elongation at break of about 11%, indicating good ductility. This property allows the alloy to undergo significant deformation before fracturing, making it ideal for applications requiring bending and forming.

The density of 6065 aluminum alloy is approximately 2.70 g/cm³, which is typical for aluminum alloys. This lightweight nature is beneficial for reducing the overall weight of structures and components, making it a popular choice in industries such as aerospace, automotive, and construction. The reduced weight contributes to improved fuel efficiency in vehicles and aircraft, easier handling and installation in construction projects, and overall cost savings in material transportation and usage.

6065 aluminum alloy offers good thermal conductivity, making it suitable for applications where heat dissipation is important. Its thermal conductivity is comparable to other 6000 series alloys and supports its use in heat exchangers and similar applications.

6065 aluminum alloy is known for its excellent corrosion resistance due to the presence of magnesium and silicon, which form a protective oxide layer on the surface when exposed to air or water. This makes 6065 ideal for marine environments and applications where exposure to moisture is common.

6065 aluminum alloy is highly regarded for its weldability and machinability. It can be easily welded using standard welding techniques, including TIG and MIG welding. The alloy also exhibits good machinability, allowing for precise and complex shapes to be formed through processes such as extrusion and milling.

6065 aluminum alloy complies with several ASTM standards, ensuring its quality and suitability for various applications. These standards specify the chemical composition, mechanical properties, and manufacturing processes required to produce high-quality aluminum alloy products.

7075 aluminum alloy, part of the 7000 series, is primarily alloyed with zinc. Its typical chemical composition includes aluminum, zinc (approximately 5.6%), magnesium (approximately 2.5%), copper (approximately 1.6%), chromium (up to 0.23%), silicon (up to 0.4%), and iron (up to 0.5%). This blend grants 7075 aluminum its exceptional strength and other beneficial properties, making it suitable for demanding applications.

7075 aluminum alloy exhibits remarkable tensile strength, reaching up to 572 MPa in the T6 temper. It also has a yield strength of at least 430 MPa in the T6 temper, indicating its ability to withstand substantial loads without permanent deformation. Additionally, it has an elongation at break of approximately 11% in the T6 temper, showing that the alloy can endure some degree of deformation before fracturing, although it is less ductile compared to other aluminum alloys like 6065.

7075 aluminum alloy has a density of 2.81 g/cm³, providing a good strength-to-weight ratio, which is beneficial in applications where weight reduction is critical. Its thermal conductivity ranges from 130 to 150 W/m*K, adequate for applications requiring efficient heat dissipation.

While 7075 aluminum alloy has decent corrosion resistance, it may be susceptible to stress corrosion cracking due to its copper content, requiring protective coatings and treatments to enhance its durability in harsh environments.

Welding 7075 aluminum alloy can significantly reduce strength, making it less desirable. Specialized techniques and treatments are needed to maintain integrity. On the other hand, the alloy is known for its excellent machinability, though its high strength and hardness can pose challenges, requiring specialized tools and techniques to achieve precise and clean cuts. Despite these challenges, it remains a preferred material for machining high-strength components.

7075 aluminum alloy complies with several ASTM standards, including ASTM B209 for sheet and plate, ASTM B211 for bar and rod, and ASTM B221 for extruded products. These standards ensure the alloy’s quality and suitability for various high-performance applications.

When comparing 6065 and 7075 aluminum alloys, it is essential to understand their distinct properties and applications. These alloys are popular in various industries because of their unique characteristics that suit different applications.

In the aerospace industry, both 6065 and 7075 aluminum alloys are critical due to their unique properties.

6065 aluminum is used in aircraft interiors and non-critical structural parts, while 7075 aluminum is used in critical load-bearing structures and military applications where extreme performance is needed.

6065 aluminum is popular with hobbyists for its durability and affordability, while 7075 aluminum is preferred by professionals for its high performance and precision.

In the automotive industry, the choice between 6065 and 7075 aluminum alloys depends on the specific application requirements.

6065 aluminum provides reliable structural integrity and corrosion resistance for vehicle safety, whereas 7075 aluminum offers superior strength for high-stress components in performance vehicles.

6065 aluminum is used in the manufacturing of lightweight, corrosion-resistant automotive parts, improving fuel efficiency and reducing emissions. 7075 aluminum is applied in the construction of high-stress components in racing and high-performance vehicles, demonstrating significant improvements in strength and durability under extreme conditions.

Several factors affect the costs of 6065 and 7075 aluminum alloys, such as material composition, manufacturing complexity, and market availability.

Prices for 6065 aluminum are generally more stable and predictable, with shorter lead times due to its widespread use. In contrast, 7075 aluminum costs can fluctuate significantly based on market demand and availability.

6065 aluminum is easier to manufacture, keeping production costs lower. Its simpler composition allows for efficient fabrication using standard techniques. Manufacturing 7075 aluminum is more complex and costly. The alloy’s higher strength requires specialized processing and heat treatment to achieve optimal properties, adding to the overall production expenses.

The widespread use and availability of 6065 aluminum contribute to its lower cost and shorter lead times. It is readily stocked by suppliers, making it a more economical choice for many applications. Due to its specialized nature, 7075 aluminum is less commonly available, which can increase costs and lead times. Suppliers may stock less of this high-strength alloy, impacting its availability.

6065 aluminum is easier to machine because it’s softer and more ductile, leading to smoother processes and less tool wear. In contrast, 7075 aluminum’s harder, stronger composition requires specialized tools and techniques, making machining more challenging. Additionally, 6065 aluminum is more formable, making it suitable for applications that require bending or shaping, such as automotive body panels. 7075 aluminum’s lower formability limits its use in applications requiring extensive shaping or bending.

6065 aluminum offers moderate strength suitable for a wide range of applications where extreme durability is not the primary concern. On the other hand, 7075 aluminum provides superior tensile and yield strength, making it ideal for high-stress applications where durability is critical.

While 6065 aluminum offers decent fatigue and impact resistance, it is not as robust as 7075 aluminum. The latter exhibits better performance in high-impact environments due to its hardness and slight ductility.

7075 aluminum is preferred for applications requiring high strength and fatigue resistance, such as aerospace or high-performance sports equipment. For projects where cost is a significant factor and moderate strength is sufficient, 6065 aluminum is more economical and provides a good balance of strength and corrosion resistance.

Choosing between 6065 and 7075 aluminum alloys often involves balancing performance and cost. While 7075 offers superior strength, it comes at a premium. Projects with tight budgets may need to opt for 6065 for its cost-effectiveness without compromising on moderate strength requirements.

Below are answers to some frequently asked questions:

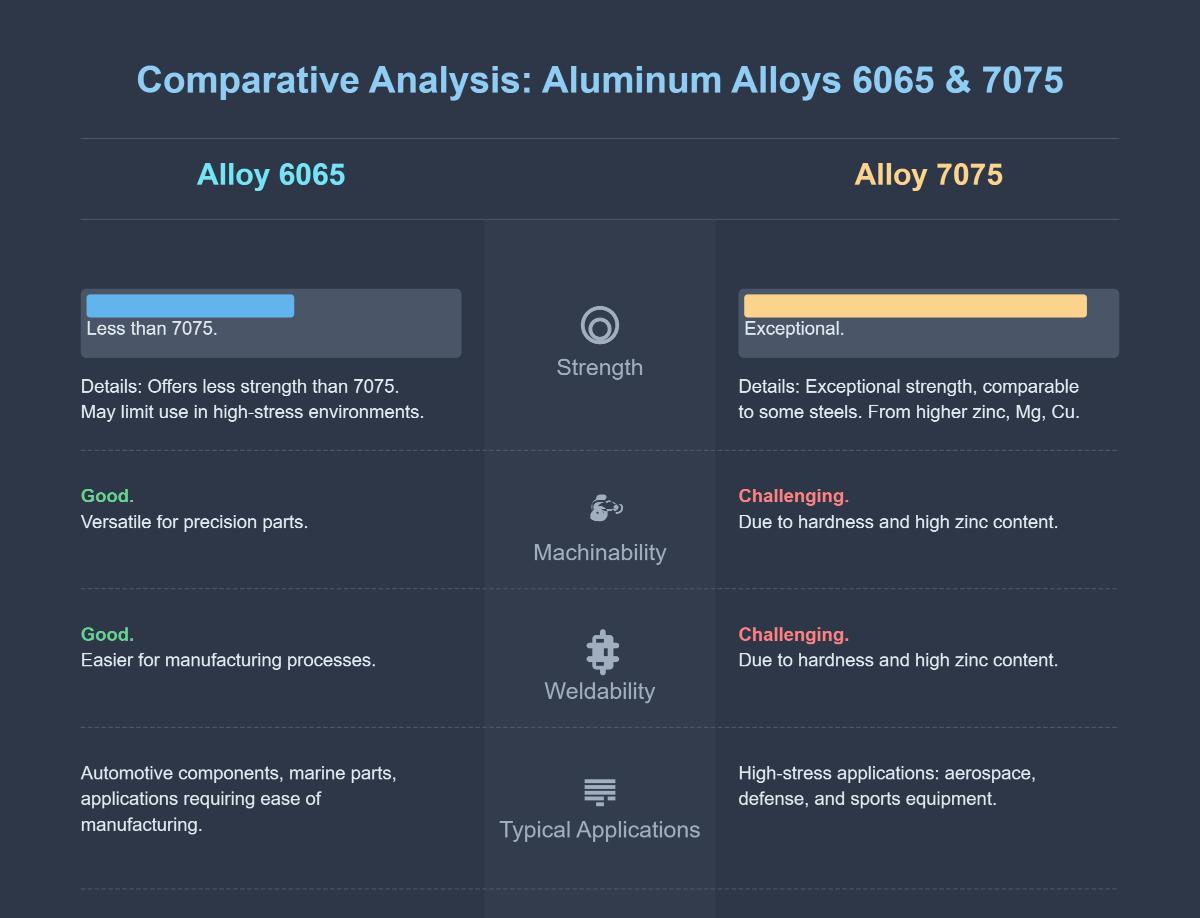

The primary differences between 6065 and 7075 aluminum alloys lie in their strength, machinability, weldability, and typical applications.

7075 aluminum alloy is known for its exceptional strength, comparable to some steels, making it suitable for high-stress applications in aerospace, defense, and sports equipment. This strength comes from its higher zinc content, along with magnesium and copper. However, 7075 is more challenging to machine and weld due to its hardness and high zinc content.

In contrast, while specific data on 6065 is limited, it is generally considered to have good machinability and weldability, making it more versatile for precision parts and applications requiring ease of manufacturing, such as automotive and marine components. However, it offers less strength than 7075, which may limit its use in high-stress environments.

When selecting between 6065 and 7075 aluminum alloys for specific applications, the decision hinges on the distinct properties of each alloy and the requirements of the application in question.

6065 aluminum, part of the 6000 series, is primarily composed of aluminum, magnesium, and silicon. It offers moderate strength, excellent formability, and superior corrosion resistance, making it ideal for applications where complex shapes and resistance to environmental factors are crucial, such as automotive parts, marine components, and building structures. Additionally, its excellent machinability and weldability make it a cost-effective choice for projects requiring extensive forming and joining.

On the other hand, 7075 aluminum, belonging to the 7000 series, is alloyed with zinc, copper, and magnesium. Known for its high strength, durability, and fatigue resistance, it is best suited for demanding applications where these attributes are critical, such as aerospace and military components. Despite its higher cost, the exceptional strength-to-weight ratio and resistance to stress corrosion cracking make 7075 aluminum invaluable in these high-performance fields.

The mechanical properties of 6065 and 7075 aluminum alloys differ significantly, reflecting their suitability for various applications.

7075 aluminum boasts a much higher tensile and yield strength compared to 6065, making it ideal for high-stress applications such as aerospace and military equipment. Additionally, 7075 has superior fatigue resistance and hardness, which contribute to its durability under repeated stress and high-load conditions. However, these benefits come with the trade-off of more challenging machinability due to its increased hardness.

In contrast, 6065 aluminum, while having lower tensile and yield strengths, offers better formability and machinability. This makes it more suitable for applications requiring complex shapes and designs, such as automotive parts. Moreover, 6065 generally provides better corrosion resistance than 7075 due to its magnesium content, although 7075 has some resistance to stress corrosion cracking due to its copper content.

When comparing the cost implications of using 6065 vs 7075 aluminum, it’s important to consider several factors. Generally, 7075 aluminum is more expensive than 6065 due to its higher content of alloying elements like zinc and copper, which contribute to its superior strength and durability. The complex processing requirements for 7075 to achieve its high mechanical properties further increase its production cost.

In contrast, 6065 aluminum, while less commonly referenced, is likely closer in cost to 6061 aluminum, which is known for its cost-effectiveness and ease of production. Alloys like 6061 (and by extension, potentially 6065) are generally less expensive and easier to machine, making them more suitable for projects where budget and manufacturability are key considerations.

However, for applications requiring high strength, such as aerospace and high-performance sports equipment, the additional cost of 7075 is often justified by its enhanced mechanical properties. On the other hand, for projects that prioritize cost-efficiency and ease of machining, 6065 or similar alloys would be more economical choices.

When comparing the corrosion resistance of 6065 and 7075 aluminum alloys for marine applications, 6065 is generally the better choice. This is due to its composition, primarily involving magnesium and silicon, which provides excellent resistance to environmental degradation such as saltwater exposure. On the other hand, 7075 aluminum alloy, which contains significant amounts of zinc and copper, offers only average corrosion resistance. While 7075 excels in mechanical strength and resistance to stress corrosion cracking, it is more susceptible to corrosion and typically requires additional protective coatings in marine environments. Therefore, for applications where corrosion resistance is critical, 6065 aluminum alloy is preferred.

In high-temperature environments, both 6065 and 7075 aluminum alloys exhibit certain limitations. The 7075 aluminum alloy, known for its exceptional strength and durability, has a melting point ranging from 477°C to 635°C and a thermal conductivity of about 130 W/m-K. While it maintains its strength better than some alloys at moderate temperatures, it can lose significant strength as temperatures rise above its optimal range. On the other hand, the 6065 aluminum alloy, with a melting point around 530°C, offers moderate strength with good formability and machinability. However, it is generally more suited to moderate temperature applications due to its lower strength compared to 7075. Overall, 7075 is more suitable for applications requiring high stress resistance at moderate temperatures, while neither alloy is ideal for extremely high-temperature environments.