When it comes to engineering and material science, understanding the yield strength of carbon steel is paramount. Yield strength serves as a critical measure of a material’s ability to withstand deformation under stress, a vital factor in ensuring structural integrity and safety in various applications. But what exactly influences this property in carbon steel? From the carbon content’s role to the differences among mild, medium, and high carbon steels, and the impact of manufacturing processes like heat treatment, this article delves into the intricate details. How do we measure and test yield strength to ensure reliability? Join us as we explore these questions and more, offering a comprehensive technical deep dive into the fascinating world of carbon steel yield strength.

Yield strength is a key material property that indicates the maximum stress a material can handle before it begins to deform permanently. When a material is subjected to stress, it initially deforms elastically, returning to its original shape upon unloading. Yield strength marks the point where this elastic behavior transitions to plastic deformation, resulting in permanent changes in shape.

Yield strength is crucial in engineering because it defines how much load a material can handle without deforming permanently. Understanding yield strength helps engineers design safer, more reliable structures, preventing failures and extending their lifespan.

Structural integrity is the ability of a structure to withstand its intended load without experiencing failure or excessive deformation. Yield strength plays a pivotal role in maintaining structural integrity by:

Yield strength is usually measured with a tensile test, applying a uniaxial force to a sample until it deforms. The stress at which the material transitions from elastic to plastic deformation is recorded as the yield strength. This value is often determined from the stress-strain curve obtained during the test, specifically at the point where noticeable plastic deformation begins.

Carbon steel is highly valued in various industries due to its mechanical strength, affordability, and versatility. It is primarily composed of iron and carbon, with the carbon content significantly influencing its characteristics. The carbon content in carbon steel can range from less than 0.1% to more than 2%, determining its classification into different types.

Carbon steel is generally classified into three main categories based on the carbon content: low carbon steel (mild steel), medium carbon steel, and high carbon steel. Each type has distinct properties and applications, making them suitable for various engineering and industrial purposes.

Low carbon steel, also known as mild steel, contains up to 0.3% carbon. This type of steel is known for its excellent ductility, toughness, and weldability. Its lower carbon content results in a softer, more malleable material, making it ideal for applications that require significant forming and bending.

Properties of Low Carbon Steel:

Applications:

Medium carbon steel contains between 0.3% and 0.6% carbon. It offers a balance between strength and ductility, making it suitable for applications that require higher strength than low carbon steel, while still retaining some formability.

Properties of Medium Carbon Steel:

Applications:

High carbon steel, with over 0.6% carbon, is much harder and stronger. However, this also makes it more brittle and less ductile than the other types of carbon steel. High carbon steel is typically used in applications that require high wear resistance and minimal deformation.

Properties of High Carbon Steel:

Applications:

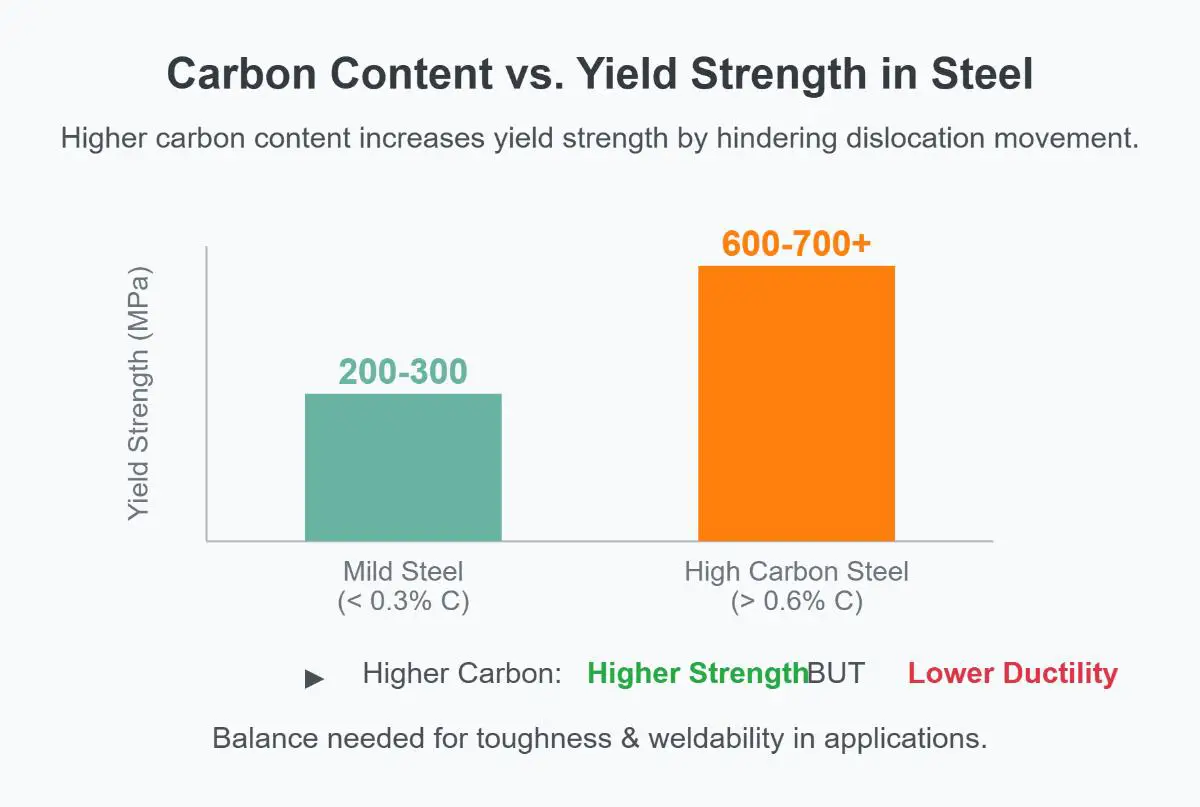

The properties of carbon steel vary significantly with the carbon content, influencing their suitability for different applications. A comparison of the key properties of low, medium, and high carbon steel is summarized below:

| Property | Low Carbon Steel | Medium Carbon Steel | High Carbon Steel |

|---|---|---|---|

| Carbon Content | Up to 0.3% | 0.3% – 0.6% | More than 0.6% |

| Yield Strength | 200-300 MPa | 350-450 MPa | 600-700 MPa |

| Tensile Strength | 400-550 MPa | 600-800 MPa | 800-1000 MPa |

| Ductility | High | Moderate | Low |

| Toughness | High | Moderate | Low |

| Weldability | Good | Moderate | Poor |

| Machinability | Good | Moderate | Poor |

| Cost | Low | Moderate | High |

Knowing the distinct properties of each type of carbon steel is essential for choosing the right material for various engineering needs. This ensures optimal performance, cost-effectiveness, and reliability in the final product.

Carbon content is a key factor that affects the yield strength of carbon steel. Carbon atoms in steel interfere with the movement of dislocations within the crystal structure, increasing the material’s resistance to deformation. Generally, as the carbon content increases, the yield strength of the steel also increases. However, higher carbon content can reduce the ductility and weldability of the steel, making it more brittle and harder to work with.

In addition to carbon, other alloying elements can significantly affect the yield strength of carbon steel. Common alloying elements include manganese, chromium, nickel, and molybdenum. These elements change the steel’s structure, affecting its strength and suitability for different uses.

Heat treatment processes play a crucial role in determining the yield strength of carbon steel. Key heat treatment techniques include quenching and tempering, and normalizing.

Work hardening, also known as strain hardening, is the process of increasing the yield strength of a material through plastic deformation. Techniques such as rolling, drawing, and forging introduce dislocations into the steel’s crystal structure, making it harder and stronger. However, work hardening also reduces ductility, making the material less capable of further deformation.

The grain size of carbon steel significantly affects its yield strength. According to the Hall-Petch relationship, smaller grain sizes result in higher yield strength. Grain boundaries act as barriers to dislocation movement, and finer grains increase the number of these barriers, enhancing the material’s resistance to deformation.

Several environmental factors can influence the yield strength of carbon steel:

Understanding these factors is essential for optimizing the yield strength of carbon steel in various engineering applications. Proper selection and treatment of materials can ensure that they meet the required performance standards while maintaining structural integrity and safety.

Manufacturing processes are essential in determining the yield strength of carbon steel, as they can alter its microstructure and mechanical properties. Key manufacturing processes include heat treatment techniques, cold working, and specific forming methods.

Heat treatment is a controlled process used to modify the physical and sometimes chemical properties of carbon steel. By applying heat and then cooling the material, the internal structure of the steel is changed, affecting its yield strength.

Quenching involves heating the carbon steel to a high temperature and then rapidly cooling it in water or oil. This process creates martensite, a hard and brittle phase, which significantly boosts yield strength. However, this can also make the steel too brittle for many applications. To mitigate this, tempering is performed, where the quenched steel is reheated to a lower temperature and then cooled again. This process reduces brittleness while retaining much of the increased yield strength.

Normalizing involves heating carbon steel above its critical point and then air cooling it, resulting in a more uniform and refined grain structure that enhances yield strength and improves toughness. Normalized steel exhibits a balance of strength and ductility, making it suitable for many structural applications.

Cold working, also known as work hardening, involves deforming the steel at room temperature. This process increases the dislocation density within the metal’s crystal structure, which blocks further dislocation movement and thus increases yield strength.

Cold rolling is a process where steel is passed through a pair of rollers at a temperature below its recrystallization point. This process not only reduces the thickness of the steel but also improves its yield strength through strain hardening. Cold rolling results in a smooth finish and precise dimensions, which are beneficial for applications requiring high strength and surface quality.

Cold drawing involves pulling the steel through a die to reduce its diameter. This process aligns the grain structure and further increases dislocation density, enhancing yield strength. Cold-drawn steel is used in applications requiring high strength and tight dimensional tolerances, such as in wire and tubing.

Examining real-world applications can provide valuable insights into how different manufacturing processes impact yield strength.

In the automotive industry, components such as drive shafts and suspension parts are often made from medium carbon steel that has undergone quenching and tempering. This process gives the components high yield strength to endure the stresses of vehicle operation while also preventing brittleness.

Structural beams and columns used in construction are typically made from low carbon steel that has been cold rolled. The cold rolling process increases the yield strength of the steel, ensuring that the structural components can support the loads imposed by buildings and other structures without excessive deformation.

Tensile testing is the most common method used to measure the yield strength of carbon steel, involving a straightforward process where the steel specimen is pulled apart until it deforms. In this process, a carefully prepared specimen of the steel is placed in a testing machine. The machine then applies a uniaxial force, gradually pulling the specimen until it deforms. As the force is applied, the machine records both the force and the corresponding deformation of the specimen. The yield point, which marks the transition from elastic to plastic deformation, is determined from the data collected. This is the stress level at which the material will no longer return to its original shape once the force is removed.

The stress-strain curve shows how a material stretches and deforms when force is applied. Initially, the curve is straight, meaning the material will return to its original shape when the force is removed. As the force increases, the stress on the specimen rises proportionally, and the material begins to deform. In the initial stage, the relationship between stress and strain is linear, which is the elastic region.

As the stress continues to increase, the material reaches the yield point. The yield point is the stage at which the material starts to permanently deform, entering the plastic region where changes in shape remain even after removing the force. The shape of the stress-strain curve can vary depending on the type of carbon steel, its heat treatment, and other factors.

In the 0.2% Offset Method, a line is drawn parallel to the initial straight section of the curve, starting at a small strain of 0.2%. Where this line crosses the curve indicates the yield strength. This method is particularly useful when the yield point is not clearly defined on the curve.

Proof stress measures how much force is needed to cause a specific amount of permanent change in the material’s shape. It’s useful when the yield point isn’t clear, showing stress levels for different amounts of strain like 0.1%. This method is often used when dealing with materials that do not have a well-defined yield point.

Yield strength is a fundamental consideration in various practical applications due to its impact on the performance and safety of materials. In the construction, automotive, and industrial equipment sectors, selecting the right carbon steel with appropriate yield strength is crucial.

Carbon steel is commonly used for structural elements like beams, columns, and reinforcing bars in construction due to its high yield strength. The robustness of carbon steel ensures that these structures can withstand significant loads without permanent deformation. Low carbon steel is often used in building frames for its excellent ductility and weldability, making it easier to fabricate and assemble on-site. Medium carbon steel, with its higher yield strength, is utilized in applications requiring additional load-bearing capacity, such as bridges and high-rise buildings.

The automotive industry uses carbon steel for parts that need a balance of strength, ductility, and wear resistance. Medium carbon steel is commonly employed in manufacturing engine components, drive shafts, and suspension systems. The yield strength of these materials ensures that the parts can endure the stresses and strains encountered during vehicle operation without failing. High carbon steel, with its superior hardness and wear resistance, is used for cutting tools and other high-stress components within the vehicle.

In the industrial sector, machinery, tools, and heavy-duty components often need materials with high yield strength for durability and performance under demanding conditions. Medium and high carbon steels are chosen for their ability to withstand high loads and resist wear. For instance, gears, axles, and shafts are often made from medium carbon steel, which provides the necessary strength and toughness. High carbon steel is used for making cutting tools, dies, and springs, where hardness and wear resistance are paramount.

Selecting the right type of carbon steel for a project involves considering several factors, including yield strength, ductility, weldability, and the specific requirements of the application.

Higher yield strength typically results in lower ductility. For applications requiring significant deformation or bending, such as in forming operations, low carbon steel is preferred due to its higher ductility. Conversely, for applications where higher strength is necessary, medium or high carbon steel may be more suitable.

While carbon steel is not inherently corrosion-resistant, various treatments and coatings can enhance its durability in corrosive environments. For example, galvanization or painting can protect structural components from rust and degradation, extending their service life.

Carbon steel is generally more cost-effective and readily available compared to other materials like stainless steel or alloy steels. This makes it an attractive option for large-scale projects and applications where budget constraints are a consideration.

When selecting carbon steel for a specific application, it is essential to balance yield strength with other material properties to ensure optimal performance and safety.

Each application has unique requirements that dictate the choice of material. For instance, components subjected to high impact loads require materials with both high yield strength and toughness. In contrast, applications involving extensive welding might prioritize materials with good weldability, even if it means compromising on yield strength.

Environmental conditions such as temperature, humidity, and exposure to chemicals can affect the performance of carbon steel. Materials must be chosen with these factors in mind to ensure they can withstand the specific conditions they will be exposed to during their service life.

In bridge construction, the choice of carbon steel with appropriate yield strength is critical to ensuring the structure can support traffic loads without deforming. Medium carbon steel is often used for its balance of strength and toughness, providing the necessary support while resisting fatigue and wear.

Automotive suspension systems require materials that can absorb shocks and stresses while maintaining structural integrity. Medium carbon steel is commonly used for these components, offering the required yield strength to withstand dynamic loads and ensure vehicle safety and performance.

Yield strength plays a crucial role in the practical applications and material selection of carbon steel across various industries. By understanding the specific requirements of each application, engineers can make informed decisions to optimize performance, safety, and cost-effectiveness.

Below are answers to some frequently asked questions:

Carbon content significantly impacts the yield strength of carbon steel by altering its microstructure. Yield strength, the stress at which a material begins to deform plastically, increases with higher carbon content. This is because carbon atoms hinder dislocation movement within the steel’s crystal lattice, making deformation more difficult.

In practical terms, mild steel (with less than 0.3% carbon) typically has a yield strength of around 200-300 MPa, while high carbon steel (over 0.6% carbon) can exhibit yield strengths between 600-700 MPa or more. However, increasing carbon content also reduces ductility, making the steel more brittle. Thus, while higher carbon content enhances yield strength, it necessitates a balance with other properties, such as toughness and weldability, for optimal material performance in various engineering applications.

The yield strength of carbon steel varies significantly among mild, medium, and high carbon steels due to differences in carbon content.

Mild carbon steel, with a carbon content below 0.3%, typically has a yield strength ranging from 200 to 300 MPa (30,000 to 45,000 psi). It is known for excellent formability and weldability, making it suitable for applications where ease of fabrication is essential, such as building structures and automotive body repair.

Medium carbon steel, containing 0.3% to 0.6% carbon, generally exhibits a yield strength between 350 to 450 MPa (50,000 to 65,000 psi). It offers a balance between strength and ductility and often requires heat treatments like quenching and tempering to enhance its properties. This type is used in automotive parts and machinery components.

High carbon steel, with more than 0.6% carbon, has a yield strength ranging from 600 to 700 MPa (87,000 to 101,500 psi) or more. It is characterized by high hardness, tensile strength, and wear resistance but is more brittle and difficult to work with. It is ideal for high-stress applications such as cutting tools and springs.

Yield strength in carbon steel is measured using tensile testing, a standard method to determine the material’s resistance to deformation. During tensile testing, a prepared sample of carbon steel is subjected to increasing tensile stress until it yields or deforms plastically. The test generates a stress-strain curve, which plots stress against strain as the material is stretched. The yield strength is identified on this curve, often using the 0.2% offset method for materials without a distinct yield point. This involves drawing a line parallel to the initial linear portion of the curve at a strain of 0.2%, and where this line intersects the curve indicates the yield strength. Accurate measurement of yield strength is essential for ensuring the structural integrity and appropriate selection of materials for engineering applications.

Manufacturing processes, particularly heat treatment, significantly impact the yield strength of carbon steel. Heat treatment involves controlled heating and cooling of the steel to alter its microstructure, which directly affects its mechanical properties.

Quenching is a process where steel is rapidly cooled from a high temperature, transforming its structure into martensite. This results in a substantial increase in yield strength but also makes the steel more brittle. To counteract this brittleness, tempering is performed by reheating the quenched steel to a lower temperature and then cooling it, which reduces brittleness while maintaining enhanced strength.

Annealing involves heating the steel to a specific temperature and then slowly cooling it, which softens the material, increases ductility, but decreases yield strength. Cold working, another manufacturing process, increases yield strength through work hardening, as it introduces dislocations in the steel’s crystal structure that impede further deformation.

When selecting carbon steel for a project, several critical factors must be considered to ensure optimal performance and suitability for the intended application. First, the carbon content significantly influences the mechanical properties such as yield strength, hardness, and ductility. Low-carbon steels (less than 0.3% carbon) are more ductile and easier to weld, while medium-carbon steels (0.3-0.6% carbon) provide a balance of strength and toughness, and high-carbon steels (above 0.6% carbon) offer higher strength but are less ductile.

Alloying elements like manganese, chromium, and nickel can enhance yield strength and other properties. Additionally, heat treatment processes, such as quenching and tempering, can modify the yield strength and ductility of the steel. Weldability and formability are also essential considerations, with low-carbon steels being easier to weld and shape.

Environmental conditions and corrosion resistance are important, as some applications may require additional protection or the use of alloys for better durability. Cost and availability should be evaluated to ensure the material fits within budget constraints and is readily accessible.

Yes, yield strength can vary between different batches of the same type of carbon steel. Yield strength is the stress at which a material begins to deform plastically, and carbon steel is an alloy of iron and carbon with small amounts of other elements. Variations occur due to factors like slight differences in carbon content, which can enhance strength as it increases; fluctuations in alloying elements that influence microstructure; inconsistencies in heat treatment processes affecting the final microstructure; variations in impurities and inclusions acting as stress concentrators; and differences in manufacturing conditions such as rolling and cooling rates. Engineers should account for these variations in design, implement strict quality control, and consider them during material selection.