Imagine a world where every connection in a complex piping system is both reliable and adaptable. This is where Van Stone flanges come into play, offering a unique solution for industries ranging from chemical processing to HVAC systems. With their distinctive design, these flanges provide advantages that standard flanges simply cannot match, such as enhanced flexibility and ease of alignment. But what exactly sets Van Stone flanges apart, and how do they fare in various applications compared to their conventional counterparts? In this comprehensive guide, we will delve deep into the types, uses, and technical specifications of Van Stone flanges. You’ll discover their benefits in dynamic conditions and understand how they integrate with PTFE-lined pipe systems. Ready to unlock the full potential of your piping connections? Let’s dive in.

Van Stone flanges, also known as Lap Joint flanges, are a type of flange assembly used in piping systems. Their two-piece design includes a stub end and a loose backing flange, allowing the backing flange to rotate for easier alignment during installation.

The stub end is welded to the pipe. It has a flange face that matches the pipe material and a lap that fits into the backing flange. Typically, the stub end is made from the same material as the piping to ensure compatibility and prevent corrosion.

The backing flange, or loose flange, fits over the stub end without being welded to the pipe. It is usually made from materials such as carbon steel, stainless steel, or other alloys, depending on the application requirements. The backing flange’s ability to rotate around the stub end simplifies bolt hole alignment during assembly.

Van Stone flanges comply with various industry standards to ensure quality, compatibility, and safety:

The pressure rating of Van Stone flanges depends on the materials used and the specific design. Commonly, these flanges are rated for a maximum pressure of 150 psi at 73°F (23°C). For higher pressure applications, flanges made from more robust materials, like stainless steel or reinforced fiberglass, can achieve higher ratings.

Van Stone flanges come in various sizes to meet different piping needs, typically ranging from 1/2 inch to 36 inches in diameter. The specific configuration, including the type of stub end and backing flange, can be customized for different applications.

Socket flanges are designed for slip-on connections and are available in sizes from 1/2 inch to 18 inches. They are commonly used in systems requiring quick assembly and disassembly.

Threaded flanges are used for threaded connections and are available in sizes from 1/2 inch to 4 inches. These flanges are ideal for systems where welding is not feasible or where disassembly is needed for maintenance.

Spigot flanges are available in sizes from 1/2 inch to 12 inches. They are used in applications requiring a spigot connection.

Van Stone flanges offer several benefits over traditional one-piece flanges:

Van Stone flanges come in various types, each tailored to specific applications and environments. Understanding these types is crucial for selecting the right flange for your piping system.

Van Stone flanges are manufactured from different materials, each with its own benefits:

Van Stone flanges are available in a wide range of sizes, typically from 1/2 inch to 36 inches in diameter. This versatility makes them suitable for a wide range of uses, from small residential systems to large industrial pipelines.

Van Stone flanges are employed in diverse applications due to their unique design and material flexibility. Here are some common uses:

In industrial settings, Van Stone flanges are favored for their ease of installation and disassembly. The rotating backing flange simplifies bolt alignment, cutting labor costs and minimizing maintenance downtime. These flanges can handle the transport of gases and fluids under varying conditions.

Heating, ventilation, and air conditioning (HVAC) systems benefit from the precise bolt alignment provided by Van Stone flanges. This ensures the integrity of duct and piping connections, which is vital for system efficiency and reliability.

Van Stone flanges are used in agricultural irrigation systems because they can handle high pressure and resist environmental challenges such as UV exposure and soil chemicals. This makes them ideal for long-term use in demanding agricultural environments.

Marine environments require materials that can resist saltwater corrosion. Van Stone flanges made from stainless steel or PTFE-lined options are commonly used in shipbuilding and marine pipeline systems, ensuring durability and longevity.

In chemical processing plants, Van Stone flanges are essential due to their ability to withstand corrosive environments. PTFE-lined flanges provide superior chemical resistance, making them suitable for handling aggressive chemicals safely.

Water treatment plants utilize Van Stone flanges for their chemical resistance and ease of maintenance. These flanges ensure reliable connections in systems that process and treat water, contributing to the overall efficiency and safety of the operation. By providing a secure and leak-proof seal, Van Stone flanges help prevent contamination and ensure that the treated water meets regulatory standards.

A large-scale agricultural irrigation project required flanges that could handle high pressure and resist chemical exposure from fertilizers and pesticides. Van Stone flanges made from PVC were chosen for their cost-effectiveness and durability, resulting in a reliable and efficient irrigation system.

A chemical processing plant faced challenges with corrosion in their pipeline connections. The plant significantly increased the lifespan and safety of their piping system by using PTFE-lined Van Stone flanges, reducing maintenance costs and downtime.

An HVAC installation in a commercial building utilized Van Stone flanges to connect ductwork and piping. The rotating backing flange allowed for precise alignment, ensuring system integrity and reducing installation time.

By understanding the types and uses of Van Stone flanges, engineers and technicians can make informed decisions about selecting the right flange for their specific application, ensuring efficiency, reliability, and cost-effectiveness in their piping systems.

Van Stone flanges are highly beneficial in environments where piping systems face frequent changes in pressure, temperature, and flow rates. Their two-piece design, consisting of a rotating ring and a stub-end, offers significant advantages.

The rotating ring allows for flexible bolt alignment, which is crucial under dynamic loads. This flexibility helps absorb and distribute the stress caused by pressure and temperature changes, reducing the risk of leaks and mechanical failures.

Van Stone flanges eliminate the need for welding, which avoids creating a heat-affected zone that can weaken the metal. This ensures the flange maintains its integrity even under varying operational conditions.

Van Stone flanges come in various materials, including PVC, stainless steel, and carbon steel. Each material offers specific benefits:

The design of Van Stone flanges makes disassembly and reassembly straightforward. This is particularly advantageous in systems requiring frequent maintenance or adjustments, minimizing downtime and ensuring the system can quickly adapt to changing requirements.

In a bustling chemical processing plant, Van Stone flanges connected pipelines transporting highly corrosive chemicals. The PTFE-lined flanges provided exceptional chemical resistance and handled frequent pressure changes without compromising the connection’s integrity. This demonstrated their reliability in a dynamic, corrosive environment.

An HVAC system in a large commercial building used Van Stone flanges to connect various ductwork sections. The rotating ring allowed for precise bolt alignment, ensuring airtight connections despite changes in air pressure and temperature. This ease of adjustment and maintenance contributed to the system’s overall efficiency and reliability. By minimizing air leaks and ensuring consistent airflow, the HVAC system maintained optimal performance, reducing energy consumption and operational costs.

In a vast agricultural irrigation project, Van Stone flanges were chosen for their ability to handle high pressure and resist environmental challenges like UV exposure and soil chemicals. The rotating ring facilitated quick and precise alignment during installation, while the material options provided the necessary durability for long-term use in dynamic field conditions.

Van Stone flanges offer significant benefits in dynamic conditions, including enhanced performance under fluctuating loads, adaptability to changing pressures and temperatures, and ease of maintenance. These features make them an ideal choice for various industrial applications where reliability and efficiency are paramount.

PTFE (Polytetrafluoroethylene) lined pipe systems offer exceptional resistance to corrosion and chemicals, making them essential in industries like chemical processing, pharmaceuticals, and food production. The lining serves as a protective barrier, preventing aggressive chemicals from coming into contact with the metal pipe, thereby preserving the pipe’s integrity and extending its service life.

PTFE is renowned for its excellent chemical resistance, which allows it to withstand a wide range of aggressive substances, including acids, bases, and solvents. This makes PTFE lined pipes ideal for applications where chemical compatibility is critical.

PTFE can endure high temperatures without degrading, making it suitable for processes involving extreme heat. Its ability to maintain structural integrity at elevated temperatures ensures reliable performance in demanding conditions.

PTFE’s non-stick properties prevent material build-up inside pipes, reducing blockages and making cleaning and maintenance easier. This feature is particularly beneficial in industries where cleanliness and hygiene are paramount, such as food processing and pharmaceuticals.

There are various types of PTFE lined fittings, including tees, reducers, flanges, crosses, and valves, each serving a specific function within the piping system.

These fittings are used to split or merge the flow of fluids within a piping system. They are available in equal and reducing configurations to accommodate different flow rates and system requirements.

Reducers connect pipes of varying diameters, ensuring a smooth transition and maintaining the chemical resistance of the system. They come in concentric and eccentric designs to suit different piping layouts.

Flanges with PTFE linings provide secure, leak-proof connections between pipes and other components. Types include slip-on, weld neck, and blind flanges, each designed for specific installation needs.

These fittings allow for multi-directional fluid flow by intersecting four pipes, making them suitable for complex piping systems that require fluid distribution in multiple directions.

Valves lined with PTFE are used to control fluid flow within a system. Common types include ball, butterfly, and diaphragm valves, all of which benefit from PTFE’s corrosion-resistant properties.

Ensuring chemical compatibility is crucial when integrating Van Stone flanges with PTFE lined pipe systems. The integration process should focus on preserving the integrity of the PTFE lining to prevent any exposure of the metal pipe to corrosive substances. Proper installation techniques and the use of compatible materials are essential to achieve this.

In chemical processing plants, PTFE lined pipe systems are essential for handling corrosive substances safely. Their chemical inertness ensures that the integrity of the piping system is maintained, reducing the risk of leaks and contamination. The non-stick and chemically inert properties of PTFE lined pipes are also vital in maintaining purity standards in pharmaceutical and food processing applications, preventing contamination and ensuring high-quality products.

PTFE lined pipe systems are well-suited for high-temperature applications, such as those found in chemical processing plants. Their ability to withstand extreme temperatures without degrading ensures reliable and continuous operation.

Selecting the appropriate PTFE lining material is critical for ensuring compatibility with the chemicals being handled. Different grades of PTFE offer varying levels of resistance to specific substances, so careful consideration is necessary.

Proper installation is essential to maintain the integrity of the PTFE lining. This includes ensuring that the lining is not damaged during installation and that all connections are secure and leak-proof.

Regular maintenance and inspection of PTFE lined pipe systems are necessary to detect any signs of wear or damage early. This proactive approach helps prevent potential failures and extends the service life of the system.

Van Stone flanges differ significantly from regular flanges in terms of design, installation, material flexibility, and cost.

Van Stone flanges have a two-piece design with a lap joint stub end and a rotating backing flange. This design allows for easy alignment of bolt holes without the need for welding, simplifying the installation process. Regular flanges, on the other hand, are typically single-piece units that usually need welding or threading for connection. This can increase installation complexity and labor costs.

Van Stone flanges offer greater material flexibility compared to regular flanges. The stub end and backing flange can be made from different materials like PVC, stainless steel, or carbon steel, based on application needs. This flexibility makes Van Stone flanges ideal for dynamic systems needing frequent maintenance, unlike regular flanges which are typically made from a single material and are less adaptable.

Regular flanges are generally more cost-effective and robust for high-pressure applications. They provide strong, secure connections and can handle significant pressure loads. However, the installation process may require more labor and time due to the need for welding or threading. Van Stone flanges, while typically more expensive, offer ease of installation and maintenance, making them a preferred choice for systems requiring frequent adjustments and lower labor costs.

Van Stone flanges and slip-on flanges both offer unique advantages and are suited for different applications.

Van Stone flanges are well-suited for higher pressure applications due to their robust design and material options. The rotating backing flange helps distribute stress evenly, reducing the risk of leaks and mechanical failures under varying pressure conditions. Slip-on flanges, while easier to install, may not provide the same level of pressure handling and are typically used in lower pressure systems.

The rotating ring design of Van Stone flanges allows for precise bolt alignment, making installation straightforward and reducing labor time. Slip-on flanges also offer ease of installation as they slip over the pipe and are then welded in place. However, the lack of a rotating component means that bolt alignment can be more challenging, especially in complex systems.

Welded neck flanges and Van Stone flanges differ in terms of material flexibility, installation complexity, and application suitability.

Van Stone flanges allow different materials for the stub end and backing flange, providing greater adaptability for various applications. This is particularly beneficial in environments requiring high corrosion resistance or varying mechanical properties. Welded neck flanges are typically made from a single material, which may limit their suitability for diverse applications.

Van Stone flanges simplify the installation process compared to welded neck flanges. The rotating backing flange eliminates the need for precise welding, reducing labor costs and installation time. Welded neck flanges require welding to connect to the piping system, which can create a heat-affected zone and increase the risk of material degradation. This complexity makes welded neck flanges less ideal for systems needing frequent maintenance or adjustments.

In chemical processing industries, the corrosion resistance and ease of maintenance provided by Van Stone flanges are crucial. The rotating backing flange allows for quick and precise alignment, reducing downtime and ensuring reliable connections in systems handling aggressive chemicals.

Van Stone flanges are beneficial in HVAC systems due to their ability to maintain airtight connections despite changes in air pressure and temperature. The rotating component facilitates easy alignment and adjustment, ensuring system efficiency and reliability.

Marine environments require materials that can resist saltwater corrosion. Van Stone flanges made from stainless steel or PTFE-lined options are commonly used in shipbuilding and marine pipeline systems, providing durability and longevity.

Water treatment plants utilize Van Stone flanges for their chemical resistance and ease of maintenance. These flanges ensure reliable connections in systems that process and treat water, contributing to By understanding the differences between Van Stone flanges and other flange types, engineers and technicians can make informed decisions about selecting the right flange for their specific application, ensuring efficiency, reliability, and cost-effectiveness in their piping systems.

Below are answers to some frequently asked questions:

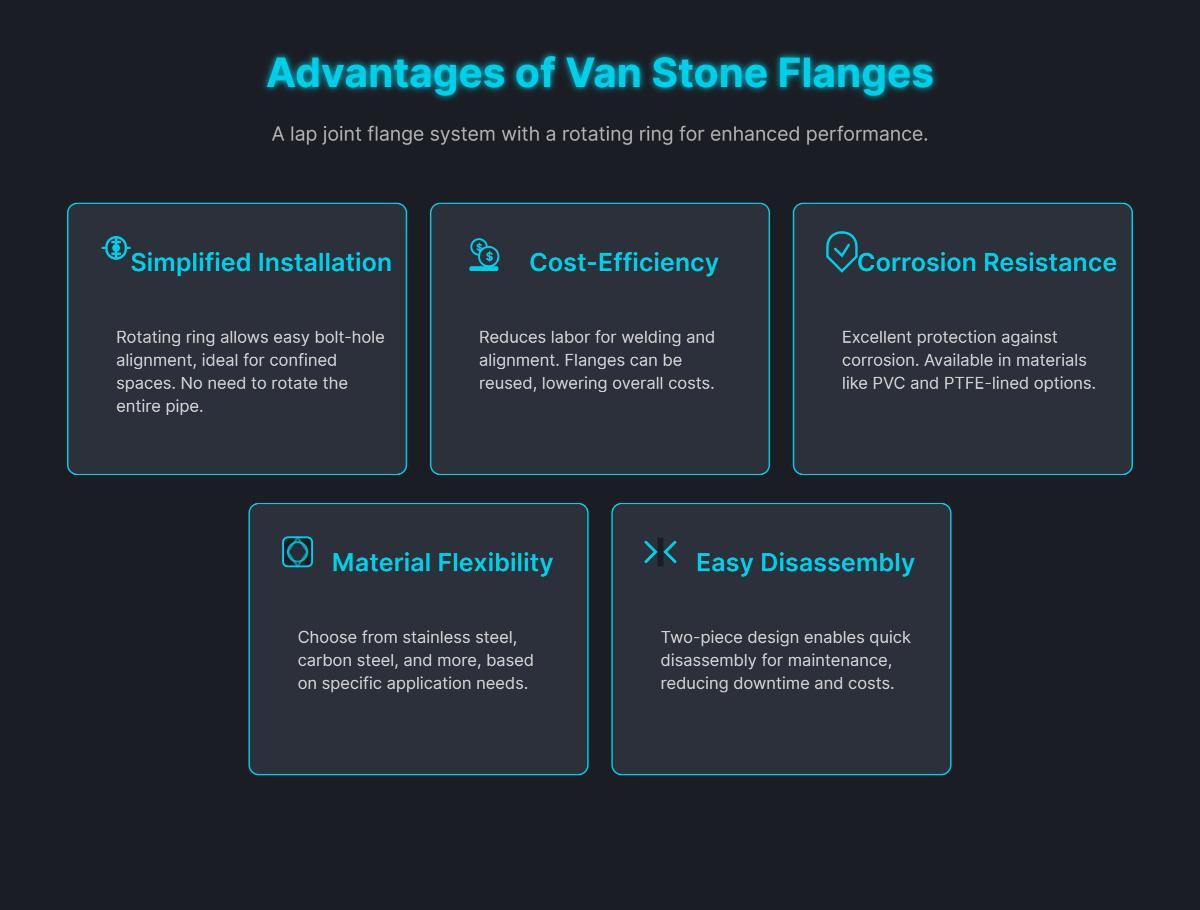

Van Stone flanges, a type of lap joint flange system with a rotating ring, offer several advantages. They simplify installation as the rotating ring allows easy bolt – hole alignment without rotating the whole pipe, useful in confined spaces. Cost – efficiency is enhanced by reducing labor for welding and alignment, and they can be reused. They provide excellent corrosion resistance, available in materials like PVC and PTFE – lined options. Material flexibility allows selection from stainless steel, carbon steel, etc., based on application needs. Their two – piece design enables easy disassembly for maintenance, reducing downtime and costs.

Van Stone flanges, also known as lap joint flanges, feature a two-piece design that includes a rotating ring, which facilitates easy bolt alignment during installation. This design contrasts with regular flanges, which are typically single-piece and can be more challenging to align. The rotating feature of Van Stone flanges simplifies the installation process, making them ideal for applications requiring frequent disassembly or reconfiguration.

In terms of materials and versatility, Van Stone flanges are available in various materials such as PVC, stainless steel, and carbon steel, making them suitable for corrosive environments. Regular flanges are also available in multiple materials but are generally associated with metal and high-pressure applications.

From a cost perspective, Van Stone flanges are generally more expensive upfront due to their specialized design. However, they offer long-term cost savings through reduced maintenance needs and ease of installation. Regular flanges are more cost-effective initially but may incur higher labor costs for installation and maintenance.

Van Stone flanges are highly suitable for various applications due to their unique two-piece design, which includes a rotating ring that simplifies bolt alignment and installation. They are extensively used in industrial piping systems, particularly in chemical processing and water treatment plants, where their chemical resistance and ease of maintenance are critical. In HVAC systems, they facilitate the connection of ductwork due to their ease of installation. Agricultural and irrigation systems benefit from their high-pressure rating and adaptability to changing layouts. Additionally, they are employed in the food and beverage industry for their hygienic properties, in marine environments for their corrosion resistance, and in residential and commercial plumbing for applications such as pool and spa installations and fire sprinkler systems.

Yes, there are specific standards for Van Stone flanges. The most common is ANSI B16.5, which covers pipe flanges and flanged fittings from 1/2 inch to 24 inches, with a typical Class 150 pressure rating (150 PSI at 73°F). For PVC or plastic Van Stone flanges, ASTM standards are relevant: ASTM D1784 for PVC material classification, ASTM D2467 for socket dimensions, ASTM D4024 for bolt hole patterns, and ASTM F1498 for threaded configurations. These standards ensure material quality, dimensional accuracy, and compatibility, making Van Stone flanges reliable for various applications.

PTFE lining significantly enhances the performance of Van Stone flanges. Van Stone flanges, known for their two – piece design facilitating easy alignment and installation, benefit from PTFE (Polytetrafluoroethylene) lining. PTFE offers high chemical resistance, protecting the flanges in chemical processing systems from aggressive substances. It also guards the underlying metal against corrosion, extending the flange’s lifespan, which is especially useful in marine settings. Moreover, PTFE – lined flanges are easier to clean, crucial for high – hygiene applications. They ensure smooth bolt alignment during installation and offer long – term cost savings due to reduced maintenance.

Van Stone flanges perform well in dynamic conditions due to several features. Their design flexibility, with a rotating ring, allows for free movement and easier alignment during installation, reducing misalignment and leak risks, especially in confined spaces. The two – piece design provides a robust seal, essential for systems with common pressure fluctuations. They also offer material versatility, being made from materials like PVC, stainless steel, and carbon steel, adapting to different environmental demands. Additionally, their ease of disassembly and reassembly reduces downtime and maintenance costs, which is advantageous in industrial setups requiring frequent maintenance.