Imagine a world where your smartphone never runs out of battery, and electric vehicles can travel for days without needing a recharge. At the heart of these technological marvels are two contenders vying for supremacy in the energy storage arena: vanadium and lithium batteries. As we delve into this comprehensive comparison, you’ll discover the unique advantages and disadvantages of each type, their energy densities, and how they measure up in terms of cost-effectiveness and environmental impact. Whether you’re a tech enthusiast or a professional seeking deeper insights into these cutting-edge technologies, this article will equip you with the knowledge to understand the strengths and weaknesses of vanadium and lithium batteries. Which one will emerge as the ultimate choice for future energy solutions? Let’s explore.

Energy storage involves capturing energy produced at one time and using it later. This technology is crucial for balancing supply and demand, especially with renewable sources like solar and wind that are intermittent. By storing excess energy when production is high and releasing it when production is low, energy storage systems help stabilize the grid, improve energy security, and enhance the efficiency of the energy system.

Several energy storage technologies are currently in use or development, each with its unique advantages and applications.

Mechanical storage technologies, such as pumped hydroelectric storage and flywheels, store energy through mechanical means. Pumped hydroelectric storage involves moving water between two reservoirs at different elevations, while flywheels store energy by spinning a rotor.

Thermal storage systems capture energy in the form of heat or cold, using materials like molten salt or ice. These systems are effective for storing large amounts of energy that can be released when needed.

Chemical storage includes various battery technologies, such as lead-acid and nickel-cadmium batteries. Advanced options like lithium-ion and vanadium redox flow batteries are also part of this category. For instance, lithium-ion batteries are commonly used in smartphones and electric vehicles due to their high energy density.

Vanadium and lithium batteries are notable among energy storage technologies due to their distinct properties and applications. Vanadium Redox Flow Batteries (VRFBs) store energy in liquid electrolytes within external tanks, making them scalable and ideal for industrial use. They have a long lifespan and can handle many charge-discharge cycles without significant degradation. On the other hand, lithium-ion batteries are prevalent in consumer electronics, electric vehicles, and portable devices due to their high energy density and compact size. Though they have a shorter lifespan compared to VRFBs, lithium-ion batteries offer high performance and efficiency in various applications.

Vanadium batteries, primarily Vanadium Redox Flow Batteries (VRFBs), are a type of rechargeable flow battery that uses vanadium ions in different oxidation states to store energy.

VRFBs consist of two separate tanks, each filled with vanadium-based electrolytes in different oxidation states. These electrolytes are pumped through a cell stack that contains a membrane. This membrane allows ions to pass through while keeping the electrolytes apart. During the charging process, vanadium ions in the electrolyte change their oxidation state to store energy. Conversely, during discharge, these ions revert to their original state, releasing the stored energy.

VRFBs use a water-based electrolyte, which is non-flammable and operates at room temperature, greatly reducing the risk of fire hazards compared to lithium-ion batteries. This makes them particularly safe for large-scale energy storage.

A major benefit of VRFBs is their long cycle life. They can handle more than 20,000 charge-discharge cycles with minimal degradation, resulting in a lifespan of 15-25 years. This far exceeds the typical lifespan of lithium-ion batteries, which usually last around 10,000 cycles or 10-15 years.

The modular design of VRFBs allows for easy expansion. Increasing the size of the electrolyte tanks can boost energy capacity without changing the cell stack. This flexibility is ideal for grid-scale energy storage, where capacity requirements can evolve over time.

Vanadium electrolytes are highly recyclable, reducing waste and environmental impact. This makes VRFBs a more sustainable option compared to lithium-ion batteries, which are harder to recycle.

The initial cost of VRFBs may be higher. However, their longer lifespan and the ability to reuse the electrolyte can lead to a lower total cost of ownership over time, making them a cost-effective solution for long-term energy storage needs.

VRFBs are well-suited for grid-scale energy storage due to their scalability, safety, and long cycle life. They can store excess energy from renewable sources like wind and solar, releasing it during periods of high demand or low generation, thereby stabilizing the grid.

The consistent and reliable energy storage provided by VRFBs makes them ideal for integrating with renewable energy sources. They help manage the intermittency of renewable generation and ensure a steady supply of electricity.

Industries and commercial establishments requiring large-scale, reliable, and safe energy storage can benefit from VRFBs. Their long lifespan and minimal maintenance needs make them a cost-effective choice for these applications.

VRFBs are suitable for off-grid and remote locations where reliable energy storage is crucial. Their robustness and ability to operate under various environmental conditions ensure a consistent power supply in these areas.

Ongoing research aims to improve the efficiency, energy density, and cost-effectiveness of VRFBs. Advances in membrane technology and electrolyte formulations are expected to enhance their overall performance.

The demand for VRFBs is expected to grow as the need for sustainable and reliable energy storage solutions increases. Investments in renewable energy projects by governments and organizations worldwide will drive the adoption of VRFBs.

Integrating VRFBs with smart grid technologies can enhance grid management and energy distribution. Efficient storage and dispatch of energy will play a crucial role in developing modern, resilient energy systems.

Lithium-ion (Li-ion) batteries are the most widely used type of lithium batteries. They consist of an anode, cathode, separator, electrolyte, and two current collectors. During discharge, lithium ions move from the anode to the cathode and back when charging, facilitated by the electrolyte. This movement allows for efficient energy storage and release, making Li-ion batteries highly reliable.

Lithium batteries are celebrated for their high energy density and rapid charging capabilities, allowing them to store substantial energy in a compact space. These features are crucial for applications where size and weight matter, such as portable electronics, electric vehicles, and aerospace technologies. The ability to deliver high power quickly sets lithium batteries apart from many other energy storage solutions, making them suitable for consumer electronics and electric vehicles where fast recharge times are expected without compromising battery life or performance.

Lithium-ion batteries usually last up to 10,000 cycles or 10-15 years. Despite eventual degradation due to electrode material wear and tear, they maintain a balance between longevity and performance, providing reliable energy storage over extended periods.

Lithium-ion batteries are essential for consumer electronics like smartphones, laptops, and tablets due to their high energy density and compact size. The demand for lightweight and efficient power sources in these products underscores the widespread use of lithium batteries.

In the automotive industry, lithium batteries are crucial for electric vehicles (EVs). Their high energy density and fast charging support modern EVs, aiding the move towards sustainable transportation.

In aerospace and defense applications, lithium batteries provide the necessary power for advanced systems while adhering to stringent weight and space constraints. Their reliability and efficiency make them suitable for powering drones, satellites, and other high-tech equipment.

Lithium batteries play a role in energy storage systems, particularly for applications requiring quick discharge and recharge cycles. They are used in grid stabilization and renewable energy integration, where their performance characteristics complement the fluctuating nature of energy production from sources like solar and wind.

Ongoing research and development in lithium battery technology focus on enhancing energy density, safety, and cost-effectiveness. Innovations in electrode materials and battery management systems aim to improve overall performance and sustainability.

The demand for lithium batteries continues to grow, driven by advancements in electric vehicles, consumer electronics, and renewable energy projects. Their widespread application across industries highlights the importance of continued innovation and investment in lithium battery technology.

Lithium batteries are prized for their high energy density, which ranges from 100 to 265 Wh/kg, making them ideal for applications where space and weight are crucial, like portable electronics and electric vehicles (EVs). In contrast, vanadium batteries, specifically Vanadium Redox Flow Batteries (VRFBs), have a much lower energy density, typically between 12 to 40 Wh/kg. This means that vanadium batteries require significantly more volume to store the same amount of energy, making them less suitable for space-constrained applications.

While lithium batteries generally last between 2,000 to 5,000 cycles, VRFBs can endure between 15,000 to 20,000 charge-discharge cycles, translating to a lifespan of 15-25 years. This makes vanadium batteries more reliable for long-term storage solutions where longevity is crucial.

Lithium batteries typically have a lower upfront cost per kilowatt-hour (kWh) compared to vanadium batteries. However, the shorter lifespan of lithium batteries means they need to be replaced more frequently, which can increase long-term costs. Vanadium batteries, while having a higher initial installation cost due to the price of vanadium minerals, offer lower lifetime costs because of their extended longevity and minimal degradation over time.

The levelized cost of energy storage for vanadium batteries is competitive, often reaching a few tens of cents per kWh. This is close to the U.S. Department of Energy’s target of $0.05 per kWh. In comparison, lithium batteries tend to have higher long-term costs due to the need for frequent replacements and more intensive thermal management systems to prevent overheating.

Vanadium batteries are highly recyclable. The vanadium electrolyte can be reused indefinitely, and other components like carbon and plastics can also be recycled. Lithium batteries, however, are more challenging to recycle and often result in hazardous waste.

While vanadium in its V(V) oxidation state is toxic, it is contained within closed systems in VRFBs, minimizing environmental risks. In contrast, the mining and processing of lithium and associated metals can have detrimental impacts on ecosystems and communities, making the sustainability of lithium batteries more contentious.

Vanadium batteries excel in grid-scale energy storage due to their scalability and long cycle life. They efficiently store and release large amounts of energy, making them ideal for stabilizing the grid and integrating renewable energy sources.

Lithium batteries dominate the market for portable electronics and electric vehicles. Their high energy density and compact size make them perfect for devices and vehicles where space and weight are at a premium. The ability to provide high power quickly is another advantage, essential for applications requiring rapid charging and discharging.

Lithium batteries typically offer a round-trip efficiency of 85–95%, making them highly effective for short-term energy transfer. Vanadium batteries have a lower efficiency of 70–80%, better suited to long-duration storage where capacity and longevity matter more than efficiency.

Vanadium batteries operate efficiently across a wide temperature range (-5°C to 40°C) without the need for active cooling or heating systems. This passive cooling capability enhances their reliability and reduces maintenance costs. In contrast, lithium batteries require active thermal management to maintain optimal performance, especially in extreme climates, which can reduce their overall efficiency and increase operational costs.

A study conducted by the University of Sheffield found that VRFBs offer notable benefits in certain environments, especially for long-term energy storage. The research demonstrated VRFBs’ ability to maintain consistent performance and capacity retention over extended periods, making them suitable for large-scale energy storage solutions where longevity is crucial.

Invinity Energy Systems’ projects highlighted the reliability and robustness of VRFBs, which operate without fire hazards unlike lithium-ion batteries, reinforcing their suitability for secure energy storage. This safety aspect makes them ideal for large-scale installations where safety is paramount.

The Tesla Powerwall stores solar energy and provides backup power, showcasing the high energy density and quick discharge capabilities of lithium-ion batteries. Homeowners benefit from the compact size and efficiency of the Powerwall, ensuring reliable power during outages and optimizing solar energy usage.

The Nissan Leaf electric vehicle (EV) utilizes lithium-ion batteries to deliver efficient and sustainable transportation. With a focus on high energy density and quick recharge times, the Leaf’s battery system supports extended driving ranges and fast charging capabilities. This case study highlights the critical role of lithium-ion batteries in the automotive industry, enabling the transition to greener, more sustainable mobility solutions.

Ongoing research in VRFB technology aims to address traditional limitations such as cost and complexity. Innovations in electrolyte formulations and membrane technology are enhancing efficiency and reducing costs, making VRFBs more competitive with lithium-ion batteries. Companies like StorEn Tech are leading these advancements, focusing on improving performance and scalability for broader adoption in renewable energy systems.

Lithium-ion batteries continue to dominate the energy storage market, driven by their widespread application in consumer electronics, electric vehicles, and renewable energy projects. Technological improvements in electrode materials and battery management systems are further enhancing their performance, safety, and cost-effectiveness. The market for lithium batteries is expected to grow as demand for efficient, high-capacity energy storage solutions increases globally.

Vanadium batteries are increasingly being integrated into renewable energy systems, particularly in solar and wind power installations. Their ability to provide long-duration energy storage enhances grid stability and self-sufficiency, addressing the intermittency challenges of renewable energy sources. The focus is on optimizing VRFB performance in varying environmental conditions, ensuring reliable energy storage across diverse climates.

Lithium batteries play a significant role in renewable energy integration, offering quick discharge and recharge capabilities that complement the fluctuating nature of solar and wind energy production. Their high energy density and compact size make them suitable for residential and commercial energy storage systems, contributing to the overall efficiency and stability of renewable energy grids.

Safety remains a critical focus in battery technology advancements. VRFBs offer major safety benefits due to their non-flammable electrolyte and low risk of electrical faults. Innovations in lithium battery design are addressing thermal runaway risks, with improved battery management systems and safer electrode materials enhancing overall safety.

Both vanadium and lithium battery technologies are advancing towards more sustainable practices. VRFBs are highly recyclable due to their reusable electrolytes, and similar efforts are being made to enhance the recyclability of lithium batteries. Sustainable sourcing of materials and environmentally friendly manufacturing processes are becoming priorities in the industry, driving the development of greener energy storage solutions.

Below are answers to some frequently asked questions:

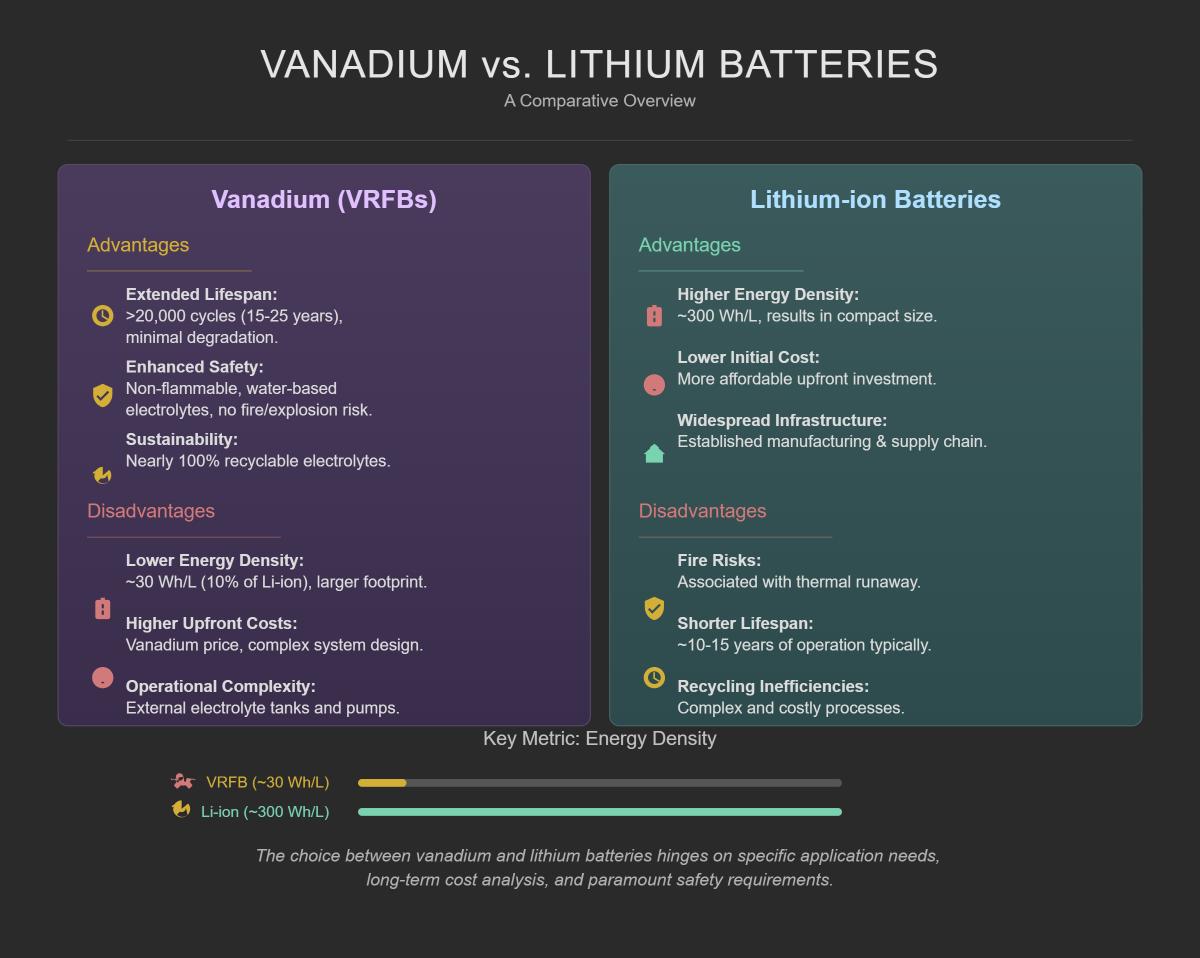

Vanadium batteries, particularly vanadium redox flow batteries (VRFBs), have several advantages over lithium batteries. VRFBs offer an extended lifespan, exceeding 20,000 charge-discharge cycles, which translates to 15-25 years of operation with minimal degradation. They also enhance safety by using non-flammable, water-based electrolytes, eliminating the fire and explosion risks associated with lithium batteries. Additionally, vanadium electrolytes are nearly 100% recyclable, making them more sustainable.

However, vanadium batteries have some disadvantages. They have a lower energy density (~30 Wh/L), only about 10% of lithium-ion batteries (~300 Wh/L), requiring a larger physical footprint for the same storage capacity. They also have higher upfront costs due to the price of vanadium and complex system design. Moreover, their operational complexity is increased by the need for external electrolyte tanks and pumps.

Lithium batteries, in contrast, are compact, have a lower initial cost, and benefit from widespread infrastructure. However, they come with fire risks, a shorter lifespan (~10-15 years), and recycling inefficiencies. Therefore, the choice between vanadium and lithium batteries depends on specific use cases, cost considerations over time, and safety requirements.

When comparing the energy densities of vanadium and lithium batteries, lithium-ion batteries significantly outperform vanadium redox flow batteries (VRFBs). Lithium-ion batteries typically have high energy densities, ranging from 100 to 265 Wh/kg, making them ideal for applications where compactness and efficiency are crucial, such as consumer electronics and electric vehicles. In contrast, vanadium batteries have much lower energy densities, generally between 12 to 40 Wh/kg. Despite this, vanadium batteries excel in large-scale energy storage applications due to their ability to deliver consistent power over extended periods and their long cycle life. Therefore, while lithium batteries are preferred for portable applications requiring high energy density, vanadium batteries are more suited for grid-scale power systems and other large-scale energy storage needs.

Vanadium batteries, specifically Vanadium Redox Flow Batteries (VRFB), boast impressive longevity with lifespans ranging from 25 to 30+ years, and can endure over 20,000 charge/discharge cycles with minimal degradation. This is largely due to the stability of vanadium electrolytes, which can be replenished and recycled indefinitely.

In contrast, Lithium-ion batteries typically last between 5 to 15 years, depending on the specific chemistry (e.g., Lithium Iron Phosphate (LFP) tends to last longer than Nickel Manganese Cobalt (NMC)). These batteries can handle approximately 2,000 to 5,000 cycles before their capacity diminishes to 70-80% of the original. Lithium-ion batteries suffer from irreversible degradation of their cathode and anode materials, which accelerates capacity loss over time.

For long-term energy storage, vanadium batteries are generally more cost-effective than lithium batteries. Although vanadium batteries have a higher initial cost due to their larger size and infrastructure requirements, they offer significant advantages in terms of lifespan, scalability, safety, and environmental impact. Vanadium batteries can handle over 20,000 charge-discharge cycles and last between 15-25 years with minimal performance degradation, whereas lithium batteries typically last around 10,000 cycles or 10-15 years and exhibit gradual capacity loss over time. Additionally, vanadium batteries are non-flammable and allow for easy recovery and reuse of their electrolyte, reducing environmental disposal costs. In contrast, lithium batteries pose safety risks due to their flammable electrolyte and have higher disposal costs. Therefore, despite the higher upfront costs, vanadium batteries provide a lower total cost of ownership over their lifecycle, making them a more economical choice for long-term, large-scale energy storage applications.

Vanadium redox flow batteries (VRFBs) and lithium-ion batteries have distinct environmental impacts. VRFBs are generally considered more environmentally friendly due to their nearly 100% recyclability and lower carbon footprint over their lifespan. The vanadium electrolyte in VRFBs can be reused, significantly reducing waste and the need for new materials. Additionally, VRFBs use non-toxic, non-flammable electrolytes, which enhance safety and minimize environmental hazards.

In contrast, lithium-ion batteries have a higher carbon footprint primarily due to the extraction and processing of lithium and other materials like cobalt and nickel. These processes are energy-intensive and environmentally damaging. Furthermore, lithium-ion batteries pose safety risks, including potential fires and explosions from their flammable electrolytes, which can lead to significant environmental damage in the event of accidents. Their lower recyclability rates and shorter lifespan contribute to higher waste and environmental impact compared to VRFBs.