Ever wondered why that shiny copper wire in your toolbox suddenly turned black? It’s a common issue that puzzles many, especially beginners. The culprit behind this mysterious transformation is oxidation—a natural process where copper reacts with oxygen in the air, forming a dark, tarnished layer. But what does this mean for the wire’s functionality? Can it still be used safely, or does it need to be replaced? In this article, we’ll explore the science behind copper wire blackening, the effects of oxidation, and provide practical solutions to restore and maintain your copper wire in top condition. Curious to learn more? Let’s dive in and uncover the secrets to keeping your copper wire bright and reliable.

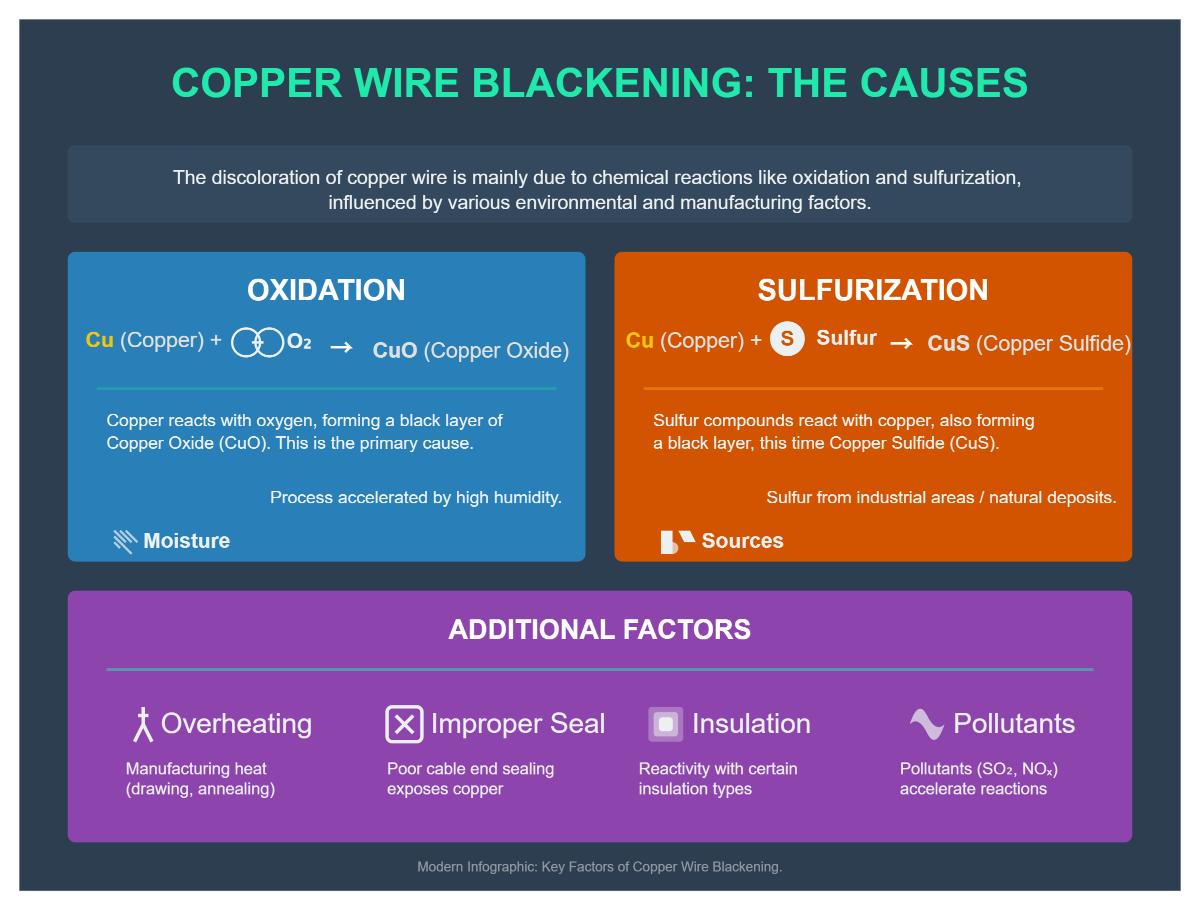

Copper wire blackening is a common issue that can impact the performance and longevity of electrical systems. Here are the primary causes:

Copper reacts with oxygen in the air to form copper oxide, which is black in color, and this process is further accelerated in humid environments.

Copper wire can also turn black when it reacts with insulation materials like PVC. When heated, PVC releases gases that cause a black, corrosive layer on the wire.

Galvanic corrosion happens when copper wire touches another metal in the presence of moisture, causing the copper to corrode and turn black.

Exposure to pollutants like sulfur dioxide and nitrogen oxides, combined with high humidity and heat, can speed up the blackening of copper wire.

The manufacturing process can also contribute to copper wire blackening. If the wire is overheated during production or if the annealing process (a heat treatment to make the metal more ductile) is not properly controlled, the wire can develop a black surface.

Blackened copper wire can have several detrimental effects on its performance:

Copper wire is essential in electrical engineering because of its excellent conductivity and durability.

Oxidation is a chemical reaction that occurs when copper wire is exposed to oxygen and moisture, forming copper oxide, a non-conductive black layer. This process is typically accelerated in the presence of moisture, which provides a conducive environment for oxidation.

Several factors can accelerate the oxidation of copper wire. Environmental conditions like high humidity and pollutants can speed up copper wire oxidation. Insulation materials, such as PVC, may release sulfur compounds when heated, which react with copper and promote oxidation. Improper handling during the wire drawing or annealing processes can expose the wire to excessive heat, increasing its susceptibility to oxidation.

Copper oxide reduces the wire’s conductivity, leading to higher electrical resistance and increased heat generation. This can affect the efficiency of the electrical system and pose safety risks, including potential electrical fires.

To address oxidation issues, clean lightly oxidized wires with abrasive materials to restore conductivity, store wires in airtight and dry conditions, and apply protective coatings. Ensuring high manufacturing standards can also reduce oxidation risks during production.

Copper wire often turns black due to oxidation, which happens when copper reacts with oxygen to form copper oxide. This reaction is accelerated by the presence of moisture, making humid environments particularly conducive to the blackening process. The formation of copper oxide reduces the wire’s conductivity, which can impair its performance in electrical systems.

The processes involved in manufacturing copper wire, such as annealing and wire drawing, can also contribute to blackening. During annealing, the wire is heated to high temperatures to increase its ductility. If the temperature is not properly controlled or if there is insufficient cooling, oxidation can occur. Additionally, the lack of antioxidants in the cooling water can exacerbate the problem, leading to the formation of a blackened surface on the wire.

Copper wire can turn black because of chemical reactions with certain insulation materials. For example, sulfur compounds in rubber insulation react with copper to form black copper sulfide. Similarly, PVC insulation can release hydrogen chloride gas when heated, which reacts with copper to create a black layer. These reactions compromise the wire’s integrity and can affect its electrical performance.

Pollutants in the air, like sulfur dioxide and nitrogen oxides, can speed up the blackening of copper wire. High humidity and heat make these reactions happen faster, leading to a quicker formation of the blackened layer.

Galvanic corrosion occurs when copper wire comes into contact with dissimilar metals in the presence of moisture. This type of corrosion is particularly problematic because it not only causes blackening but also deteriorates the copper, potentially leading to failure in electrical systems. The presence of moisture acts as an electrolyte, facilitating the corrosion process.

Improper storage and handling can expose copper wire to moisture and pollutants, causing oxidation and corrosion. To prevent these issues, it’s crucial to store copper wire in a dry, clean environment.

Oxidation significantly impacts the electrical conductivity of copper wire. The formation of copper oxide on the wire’s surface creates a non-conductive layer, which increases the wire’s resistance and requires more energy to transmit electrical currents. This reduces the efficiency of the electrical system, leading to higher energy consumption and potential overheating.

The higher resistance causes the wire to heat up more than usual, which can degrade the insulation material surrounding the wire, potentially leading to short circuits or even electrical fires. The compromised insulation can allow moisture to penetrate further, worsening the oxidation problem.

Oxidation also makes the copper wire more brittle, reducing its flexibility and making it more likely to break under stress. This brittleness is particularly problematic in applications where the wire needs to be bent or twisted, such as in tight spaces or during installation.

Oxidized copper wire can cause issues with electrical connections and create aesthetic concerns. The non-conductive layer of copper oxide can interfere with forming secure connections, leading to intermittent electrical faults, reduced performance, and increased maintenance. Additionally, the blackened appearance of oxidized copper can be undesirable in visible applications.

To prevent oxidation, use protective coatings like tin or silver, control the storage environment, regularly inspect and clean the wire, and ensure high manufacturing standards. By understanding the effects of oxidation and implementing these strategies, the performance and longevity of copper wire can be preserved, ensuring reliable and safe electrical systems.

To address issues with blackened copper wire, start by cleaning the wire to remove the oxidized layer. Cleaning restores the wire’s conductivity by removing the superficial layer of copper oxide.

Wire wool or abrasive pads can be used to scrub the blackened surface of the copper wire. This method is effective for exposed connections where the blackening is not too severe. You can also use commercial copper cleaners, which typically contain acids that dissolve the oxide layer. Always follow the manufacturer’s instructions and safety precautions when using chemical cleaners.

Moisture and pollutants can speed up the blackening of copper wire. Improving the conditions in which the wire is used and stored can help prevent further oxidation.

Good ventilation reduces humidity levels, which slows down the oxidation process. Ensuring that electrical installations are in well-ventilated areas can help maintain the integrity of the copper wire.

Using dehumidifiers in areas where copper wire is stored or installed can help keep moisture levels low. This is particularly important in environments prone to high humidity.

In cases where the blackening is extensive or has penetrated the insulation, cleaning may not be sufficient. In such scenarios, replacing the blackened copper wire is the best solution.

Before replacing the wire, it is important to assess the extent of the blackening. If the wire is only superficially blackened, cleaning might suffice. However, if the blackening has compromised the wire’s performance, replacement is necessary.

When replacing the wire, opt for high-quality insulation materials that are less likely to react with copper. This can help prevent future blackening.

Taking preventive measures can help avoid the recurrence of black copper wire problems.

Store copper wire in airtight containers or use plastic wraps to prevent exposure to air and moisture. Proper sealing can significantly reduce the chances of oxidation.

Regularly inspecting copper wire for signs of blackening can help catch oxidation early. Early detection allows for timely cleaning or replacement, preventing more severe issues.

Coating copper wire with tin or silver can protect it from oxidation. These coatings are especially useful in harsh environments where the wire is exposed to moisture and pollutants.

Below are answers to some frequently asked questions:

Copper wire turns black primarily due to chemical reactions involving oxidation and exposure to environmental factors. When copper reacts with oxygen in the air, it forms copper oxide (CuO), which appears as a black layer. This process is accelerated by moisture, particularly in humid environments. Additionally, sulfur compounds present in industrial settings or areas with natural sulfur deposits can react with copper to form copper sulfide (CuS), also contributing to blackening. Other factors include overheating during manufacturing processes like drawing or annealing, improper sealing of cable ends, and interactions with certain insulation materials. Environmental pollutants such as sulfur dioxide and nitrogen oxides can further exacerbate these reactions.

Oxidation affects copper wire by causing it to turn black, primarily due to the formation of copper oxide (CuO) or copper sulfide (CuS). This process impacts the wire’s electrical conductivity and overall performance. The oxidation layer increases the electrical resistance of the copper wire, which can lead to poor conductivity and increased heat generation during use. This can compromise the efficiency of electrical systems and potentially cause overheating problems, reducing the lifespan of the wire.

Blackened copper wire can still be used since the blackening is mainly a surface phenomenon caused by oxidation or chemical reactions. This blackening does not significantly affect the wire’s conductivity, although it may slightly increase resistance. To ensure optimal performance, it is advisable to clean the blackened copper wire with fine sandpaper or emery cloth to remove the oxidation layer.

However, the presence of blackened copper wire can indicate issues such as poor connections or exposure to moisture, which could lead to overheating or unreliable connections. Regular inspection and maintenance are essential, and in severe cases, replacing the wire may be necessary to ensure safety and efficiency.

To clean blackened copper wire, you can use a simple and effective method involving household items. First, strip the insulation from the affected section of the wire. Prepare a cleaning solution by mixing 1 tablespoon of salt with vinegar in a container until the salt dissolves. Dip the stripped end of the wire into the vinegar and salt solution, ensuring the blackened area is fully submerged. Stir the wire in the solution until it becomes shiny, which typically takes a few minutes. Next, neutralize the wire by submerging it in a baking soda solution (1 tablespoon of baking soda mixed with water) for about 10 seconds to neutralize any remaining acid.

To prevent copper wire from turning black, it is essential to understand and mitigate the primary causes of oxidation and corrosion. Here are some effective practices:

By following these best practices, you can significantly reduce the likelihood of copper wire blackening, maintaining their efficiency and longevity.

The annealing process is a heat treatment used to alter the properties of metals like copper, making them more malleable and ductile. This process involves heating the copper wire to a specific temperature and then allowing it to cool slowly. Annealing helps copper wire in several ways:

Overall, annealing improves the mechanical and electrical properties of copper wire, making it suitable for various practical applications.