Imagine a world where the strength and stability of your projects hinge on a simple yet powerful component: the through bolt fastener. Whether you’re an intermediate enthusiast seeking to deepen your understanding or a professional aiming to refine your skills, this article is your gateway to mastering the intricacies of through bolt fasteners.

We’ll delve into the working mechanism of these essential fasteners, breaking down their design and functionality step-by-step. You’ll discover how they work, the key components involved, and their various applications, from heavy-duty construction to precision machinery assembly. By the end, you’ll not only know how to install them correctly but also how to choose the right materials and understand their load-bearing capacities.

Are you ready to uncover the secrets behind through bolt fasteners and elevate your projects to new heights? Let’s get started!

Through bolt fasteners are essential components used in various industrial and structural applications to create strong and reliable connections. These fasteners are characterized by their ability to pass completely through the materials being joined, with a nut and washer tightened on the opposite end to create a secure and load-bearing joint.

Through bolt fasteners consist of three main components – the bolt, nut, and washer – and their installation involves a few critical steps:

The working principle involves:

Through bolt fasteners come in various types, each designed for specific applications and materials:

Through bolt fasteners are widely used in industries where strong and durable joints are essential:

Through bolt fasteners are engineered to provide strong, secure connections in various materials, including concrete, metal, and wood. Key design features include:

The main component of a through bolt fastener is the fully threaded rod or bar, typically made from high-strength materials such as alloy steel or stainless steel. This design allows for secure tightening and efficient load distribution, ensuring durability and resistance to corrosion.

A critical feature of through bolt fasteners is the expansion sleeve. When the nut at the end of the bolt is tightened, the sleeve expands radially, pressing against the walls of the drilled hole in the substrate. This expansion creates a frictional hold, enhancing the stability and holding power of the fastener.

One end of the through bolt features a tapered wedge. As the nut is tightened, this wedge forces the sleeve to expand. This mechanism ensures a secure grip within the substrate, preventing the fastener from loosening under dynamic forces such as vibrations or shocks.

To distribute the clamping force evenly across the surface being fastened, a bearing plate is used at the opposite end of the bolt. This plate helps prevent localized damage and improves the overall load capacity of the fastener.

The functionality of a through bolt fastener involves a series of actions that ensure a secure and reliable connection:

This mechanism ensures that through bolt fasteners can effectively resist both tensile and shear forces, providing robust and reliable fastening in various applications.

Through bolts can handle high tensile and shear forces, making them perfect for heavy-duty tasks like structural supports and machinery anchoring.

These fasteners can be used in both solid and hollow substrates, including concrete, metal, and wood. This versatility makes them suitable for a wide range of engineering and construction projects.

Unlike some fasteners that require curing or adhesive bonding, through bolts provide immediate load-bearing capability upon installation. This feature is particularly beneficial in fast-paced construction environments or for emergency repairs.

Through bolts made from stainless steel variants, such as A4 stainless steel or HCR 1.4529 stainless steel, offer excellent corrosion resistance. This ensures durability and longevity, especially in outdoor or harsh environments.

Through bolt fasteners are used extensively in industries requiring secure, heavy-duty fastening solutions:

Through bolt fasteners combine robust design with an effective expansion mechanism, offering unmatched strength, versatility, and reliability for critical fastening applications across diverse industrial, construction, and engineering environments.

Through bolt fasteners use a torque-controlled expansion mechanism to secure medium to heavy loads to solid substrates like concrete. This process involves several key components working together to ensure a strong and reliable connection.

Through bolt fasteners are essential in applications requiring reliable and durable connections, such as anchoring heavy machinery, securing structural components, and installing critical fixtures. Their robust design and immediate load-bearing capabilities make them ideal for demanding industrial and construction environments.

Through bolt fasteners are frequently utilized in heavy-duty applications that require strong, dependable connections. Their ability to withstand high tensile and shear forces makes them ideal for demanding environments.

In the construction industry, through bolts are used to secure structural elements such as beams, columns, and trusses. They are also effective in fixing medium to heavy weight fixtures to concrete or masonry, even in situations involving cracked substrates. This dual capability ensures the integrity and safety of buildings and infrastructure.

Industrial settings need secure anchoring for heavy machinery and equipment that undergo significant vibrations and dynamic forces. Through bolts offer the necessary tensile and shear strength to keep these installations firmly in place, preventing movement or loosening over time. Their immediate load-bearing capacity is particularly beneficial in high-demand operational settings.

Through bolts are indispensable in both construction and machinery assembly, providing reliable fastening solutions in various scenarios.

In architectural applications, through bolts are used to attach facade panels and cladding systems to building envelopes. They provide a strong anchoring point that can endure environmental pressures like wind and thermal expansion, ensuring the durability and safety of exterior finishes.

Through bolts are popular in DIY projects that require secure fastening to concrete, masonry, or stone. Their easy installation and strong hold make them perfect for mounting heavy fixtures, reinforcing structures, or making urgent repairs needing instant support.

In a structural renovation project, through bolts were used to reinforce aging concrete columns. The bolts were inserted through pre-drilled holes and tightened with nuts and washers, providing immediate load-bearing support and enhancing the structural integrity of the columns.

During the installation of heavy industrial machinery, through bolts were employed to anchor the equipment to a concrete floor. The bolts’ high tensile and shear strength ensured that the machinery remained stable and secure, even under intense operational vibrations.

In the construction of a commercial building, through bolts were used to attach aluminum cladding panels to the exterior walls. The bolts provided a secure and durable attachment that could withstand environmental forces, ensuring the long-term stability of the facade.

Through bolts are versatile and can be used with a wide range of substrates, including solid and hollow materials. They are manufactured in various materials such as steel, stainless steel, and titanium, allowing them to be tailored for specific environmental conditions. For example, stainless steel through bolts are preferred in outdoor or corrosive environments due to their enhanced resistance to rust and degradation.

Through bolt fasteners stand out for their combination of strength, versatility, and immediate load-bearing capability, making them essential in applications requiring secure, stable, and durable connections across construction, industrial, and DIY sectors.

To properly install through bolt fasteners, you will need the following tools:

Begin by measuring and marking the exact points where you need to drill holes in the base material. This ensures precise alignment and load distribution. Using the drill and the correctly sized drill bit, drill the hole perpendicular to the surface. Follow the manufacturer’s specifications for the hole’s diameter and depth. Ensure the hole is drilled at least six times the bolt diameter from any edge to prevent weakening the substrate.

Clean the drilled hole thoroughly using a dust blower pump or compressed air, followed by a wire brush to ensure no remnants are left that could interfere with the anchor’s expansion or alignment.

Position the fixture or material to be fastened over the drilled hole. Insert the through bolt anchor through the fixture and into the hole, ensuring the bolt is inserted at the correct angle, perpendicular to the surface. Ensure the black marking on the anchor is flush with the concrete surface, indicating it is inserted to the correct depth. Use a hammer to gently tap the chamfered head of the bolt until the nut and washer sit flush against the fixture, being careful not to deform the anchor during this process.

Using a torque wrench, tighten the nut to the manufacturer’s specified torque setting. This ensures the metal shield within the anchor expands correctly inside the hole. Be careful not to overtighten, as this can damage the anchor or substrate and reduce its holding capacity.

After tightening, gently tug on the fixture to ensure the bolt has expanded properly and is securely fixed, with no movement indicating stability.

Always drill and install bolts perpendicular to the surface to optimize load distribution and anchor performance. Maintain required minimum distances from edges and between anchors to prevent substrate cracking or weakening. Thorough hole cleaning is essential to ensure proper anchor expansion and load transfer. Use a calibrated torque wrench and follow manufacturer torque values exactly to avoid installation faults. Do not place any sealing materials or layers between the washer and the fixture, which can impair clamping.

Through bolt fasteners operate by expanding a metal shield inside the drilled hole in the substrate. When the nut is tightened, this expansion creates a frictional and mechanical interlock between the bolt and the base material. The black marking on the anchor indicates the correct embedment depth to ensure optimal expansion. This mechanism provides a reliable fixing suitable for both cracked and non-cracked concrete, depending on the assessment standards.

Through bolt fasteners are crucial for forming strong, durable connections across a wide range of applications. These fasteners typically consist of a long threaded rod that passes completely through the materials being joined, a bearing plate at one end to distribute the clamping force, and an expansion mechanism. The expansion mechanism, which often includes a tapered wedge and sleeve system, is activated when the nut is tightened, causing the sleeve to expand and grip the walls of the hole. This design enables through bolts to handle significant tensile and shear forces right after installation.

Selecting the right material for through bolt fasteners is crucial for ensuring their performance, durability, and reliability. The main considerations include:

The material must have sufficient tensile strength to resist pulling forces and shear strength to withstand lateral loads. This ensures that the fastener can handle the stresses it will encounter in its application.

For fasteners in outdoor or harsh environments, corrosion resistance is essential to prevent rust and deterioration over time. This helps maintain the fastener’s integrity and longevity.

Balancing performance with cost is essential for widespread industrial use. The selected material should provide the necessary strength and durability without being prohibitively expensive.

The material must be suitable for the specific environmental conditions it will be exposed to, such as extreme temperatures, chemicals, or moisture. This ensures that the fastener maintains its integrity and performance under these conditions.

Several materials are commonly used for through bolt fasteners, each offering different properties:

Choosing the appropriate material involves considering the specific requirements of the application:

The load-bearing capacity of through bolt fasteners is crucial for determining their suitability in different applications. This capacity is influenced by several factors, including the material of the fastener, the design of its components, and the quality of installation.

Through bolts are designed to withstand significant tensile forces, which are the pulling forces along the axis of the bolt. The tensile strength is primarily determined by the material and diameter of the bolt. High-strength alloy steels are commonly used to ensure the fasteners can handle heavy loads without elongation or failure, making them ideal for structural applications and heavy machinery.

Shear strength refers to the ability of through bolts to resist sideways forces. While generally lower than tensile strength, shear strength is vital for maintaining joint integrity under side loads, such as those caused by wind or vibrations in structures and vehicles. Through bolts with higher shear strength are particularly valuable in applications where lateral forces are prevalent.

One of the significant advantages of through bolt fasteners is their ability to bear loads immediately after installation. Unlike chemical anchors or adhesives that need time to set, through bolts provide immediate structural stability. This feature is especially beneficial in fast-paced construction environments or emergency repairs where structural stability cannot be delayed.

Through bolt fasteners are versatile and can be installed in various substrates, including solid concrete, hollow masonry, and steel frameworks. They are available in different materials such as high-strength alloy steel, stainless steel, and high-corrosion-resistant steels. This versatility allows them to be used in diverse environments, including harsh outdoor and industrial settings where corrosion resistance is essential.

Several factors influence the load-bearing capacity of through bolt fasteners:

The quality of materials used in through bolts directly impacts their load capacity. High-strength alloy steels and corrosion-resistant stainless steels are preferred for their superior mechanical properties and durability.

Proper installation is crucial for achieving the desired load-bearing capacity. This includes drilling the correct hole size, cleaning the hole thoroughly, and tightening the nut to the specified torque. Inaccurate installation can lead to reduced load capacity and potential failure of the fastener.

The condition of the substrate, such as concrete or masonry, plays a significant role in the performance of through bolts. Factors like the presence of cracks, moisture content, and the overall strength of the substrate can affect the bolt’s load-bearing capacity.

To illustrate the load-bearing capacity, consider a through bolt fastener made from high-strength alloy steel with a diameter of 12 mm. Assuming the tensile strength of the material is 800 MPa and the cross-sectional area of the bolt is approximately 113 mm², the maximum tensile load can be calculated as follows:

This calculation shows that the through bolt can withstand a maximum tensile load of 90.4 kN. Similar calculations can be performed for shear strength based on the material properties and design specifications.

The load-bearing capacity of through bolt fasteners, combined with their robust design and immediate load-bearing capabilities, make them indispensable in applications demanding high performance and reliability.

Knowing the differences between through bolts and other fasteners helps in choosing the right one for different tasks. Through bolt fasteners create a direct load path by passing completely through the materials being joined. This design ensures a consistent and reliable transfer of loads, minimizing lateral movement and enhancing stability. Other fasteners, such as cast-in or epoxy anchors, rely on adhesion or embedment, which can create indirect load paths and less stable connections.

Through bolts are known for their high tensile and shear strength, making them suitable for heavy-duty applications. The mechanical expansion mechanism ensures that they can handle substantial loads immediately upon installation. In contrast, the load capacity of other fasteners can vary widely. For example, epoxy anchors need curing time to achieve their full strength, and screws generally have lower load capacities, especially for lateral loads.

The expansion mechanism of through bolt fasteners involves a mechanical expansion (wedge and sleeve) that provides a strong grip within the substrate. This frictional hold enhances the stability and holding power of the fastener. Other fasteners may use different methods: epoxy anchors rely on chemical bonding, while screws may depend solely on friction or embedment without any expansion mechanism.

Through bolts can bear loads immediately after tightening, making them ideal for applications needing instant structural integrity. This is a significant advantage over fasteners like epoxy anchors, which require curing time before they can bear loads. Screws and cast-in anchors may offer quicker installation but often lack the precision and immediate load-bearing capabilities of through bolts.

Through bolts are effective on both solid and hollow substrates, such as concrete, metal, and wood. This versatility allows them to be used in a wide range of applications. Other fasteners might be limited to specific materials or conditions. For instance, epoxy anchors are often best suited for solid substrates, while screws may struggle with heavy loads in softer materials.

Through bolts can be reused if undamaged, which is useful for applications needing adjustments or replacements. In contrast, many other fasteners, particularly chemical anchors, are often permanent and cannot be reused after removal.

Through bolt fasteners stand out for their robust design, high load-bearing capacity, and versatility across different materials and applications. These characteristics make them indispensable in heavy-duty construction, machinery assembly, automotive, and other high-stress industrial applications.

Below are answers to some frequently asked questions:

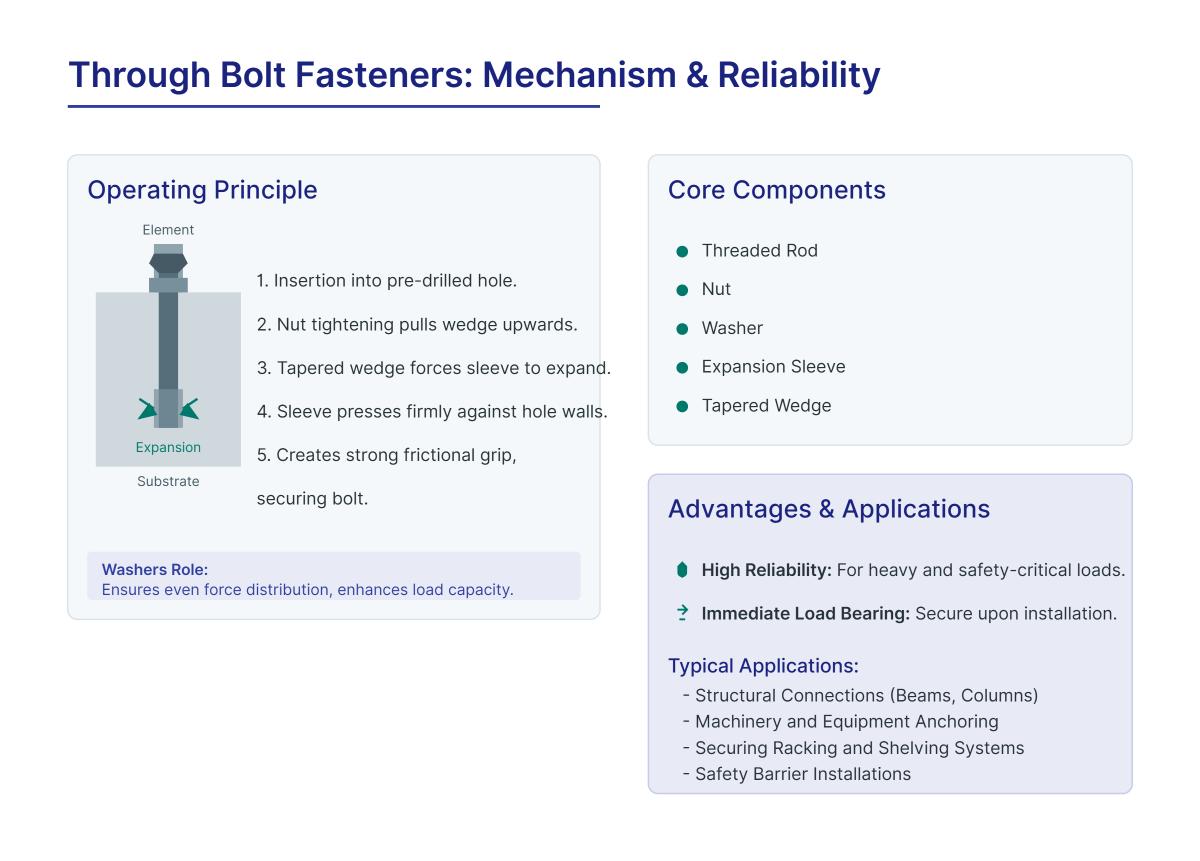

A through bolt fastener operates by utilizing a controlled expansion mechanism to secure heavy and safety-critical components to solid substrates, such as concrete. The primary components include a threaded rod, nut, washer, expansion sleeve, and tapered wedge. The process begins by inserting the through bolt into a pre-drilled hole in the substrate. Upon tightening the nut, the threaded rod pulls the tapered wedge into the expansion sleeve, causing the sleeve to expand radially and generate significant frictional grip against the hole walls. This frictional force clamps the bolt securely, ensuring it remains firmly in place and can bear substantial loads immediately. The washer helps distribute the clamping force evenly, enhancing the overall load capacity and protecting the attached element. This mechanism makes through bolt fasteners highly reliable for heavy-duty applications such as structural connections and machinery anchoring.

Through bolt fasteners are commonly used in various applications due to their robust load-bearing capabilities and versatility. They are essential in structural connections, stabilizing beams, columns, and trusses within building frameworks to ensure integrity under environmental stresses like wind loads. In heavy equipment anchoring, through bolts secure industrial machinery, generators, and production line equipment to concrete floors, preventing displacement from vibrations or operational forces. They are also used in facade and cladding systems, providing reliable attachment points for exterior cladding, curtain walls, and solar panel mounts. Additionally, through bolt fasteners are ideal for residential and commercial fixtures, such as anchoring TV screens, mirrors, or shelving to brick or concrete walls, and securing ledger boards to masonry foundations in deck construction. Their ability to provide immediate load-bearing capacity makes them valuable for emergency repairs, enabling rapid stabilization of compromised structures.

Through bolt fasteners are primarily made from materials such as steel and stainless steel, chosen for their high strength and durability. Steel through bolts are commonly used in heavy-duty applications like construction and machinery assembly due to their robust load-bearing capacity. Stainless steel variants are favored for environments exposed to moisture because of their superior corrosion resistance, making them suitable for outdoor settings, bathrooms, and basements.

Additionally, zinc-plated and electro-galvanized steel through bolts are utilized in indoor or dry environments, offering sufficient corrosion resistance and cost efficiency. Specialty materials such as silicon bronze and brass are used in specific applications requiring excellent corrosion resistance and aesthetic appeal, though they are less common due to higher costs and mechanical limitations. The material choice for through bolt fasteners significantly impacts their performance and suitability for various applications.

To select the right through bolt for your project, consider several key factors to ensure a reliable and strong connection. First, assess the application environment. For indoor projects in dry conditions, zinc-plated or electro-galvanized bolts are typically sufficient. For outdoor or moisture-prone areas, stainless steel bolts offer better corrosion resistance. In marine environments, opt for materials with high corrosion resistance, such as stainless steel or specialized coatings.

Next, determine the appropriate bolt dimensions. Ensure the diameter matches the required drill bit size, and that the length is sufficient to pass through all materials with adequate threads exposed for secure fastening. Additionally, select a thread pitch that matches the specifications for a secure connection.

Material choice is crucial; stainless steel is ideal for corrosive environments, while other materials may be suitable for less demanding conditions. Ensure the bolt’s load capacity meets the expected stresses and consult experts for safety-critical applications.

Consider installation specifics, such as maintaining the recommended edge distance to prevent compromising structural integrity and adhering to the manufacturer’s torque specifications to avoid over-tightening.

By carefully evaluating these factors, you can choose the right through bolt to ensure a strong and reliable connection for your project.

When installing through bolt fasteners, several safety considerations must be observed to ensure proper installation and performance. Firstly, maintain adequate edge distance to prevent damage to the substrate; typically, a minimum of six times the bolt diameter is recommended. Proper hole preparation and alignment are crucial, ensuring holes are drilled to the correct depth and alignment to avoid uneven load distribution. Applying the correct torque is essential; under-tightening can lead to loosening, while over-tightening can damage the bolt or substrate. Using locking devices like locknuts or washers helps prevent loosening due to vibration. Additionally, selecting bolt materials suitable for environmental conditions, such as corrosion-resistant finishes, enhances durability. Personal protective equipment (PPE) such as safety glasses, gloves, and hard hats should be used to ensure worker safety. Lastly, compliance with industry standards such as BS 8539 and relevant ISO standards ensures the installation meets safety and performance benchmarks.

Through bolt fasteners are distinct in their design and application compared to other fasteners. They consist of a threaded shaft that passes entirely through the materials being joined and is secured with a nut on the opposite side. This ensures even load distribution, enhancing tensile strength and stability, making them ideal for heavy-duty and structural applications.

Compared to other fasteners like carriage bolts, lag bolts, and anchor bolts, through bolts generally offer superior load-bearing capacity and durability. They are particularly suited for projects requiring high tensile and shear strength, such as construction, heavy machinery, and automotive assembly. However, through bolts require access to both sides of the assembly and precise pre-drilling, which can make installation more complex and time-consuming. They are also typically more expensive due to their higher-strength materials and additional components. Despite these limitations, through bolts’ removability and immediate load-bearing capabilities make them highly valuable for permanent, heavy-duty installations.