Imagine holding a perfectly forged sword, its blade gleaming with the promise of power and precision. The choice of metal for crafting such a masterpiece can make all the difference between an enduring weapon and a fragile showpiece. For beginners venturing into the world of sword making, understanding the nuances of different metals is crucial. This guide delves into the properties of carbon steel, spring steel, and tool steels—each with its unique strengths and weaknesses. How does carbon content influence the hardness and flexibility of your blade? Why might spring steel be your go-to for a resilient, flexible sword? Join us as we explore these options and more, helping you make an informed decision for your next sword crafting project. Ready to discover the secrets behind the best metals for sword making? Let’s dive in!

Sword making is a fascinating process that combines artistry and metallurgy to create a weapon of both beauty and functionality. This ancient craft has evolved over centuries, incorporating various techniques and materials to create swords that are both battle-effective and culturally treasured.

Sword making dates back thousands of years, with early examples found in ancient civilizations such as Egypt, Greece, and Japan. Each culture developed its unique methods and styles, influenced by available materials and the specific needs of their warriors. For instance, Japanese swordsmiths are renowned for their katana, which combines exceptional sharpness and flexibility.

While traditional techniques are still valued, modern sword making has also embraced new technologies and materials. For instance, modern swordsmiths may use power hammers and precision grinders to enhance efficiency and consistency. Additionally, advanced metallurgical knowledge allows for the creation of alloys that were not possible in ancient times, offering new possibilities for performance and durability.

The carbon content of the steel used in sword making significantly affects the blade’s properties. Higher carbon content typically increases hardness and edge retention but can also make the blade brittle if not properly tempered. Conversely, lower carbon content results in a softer, more flexible blade that may not hold an edge as well. Finding the right balance is key to creating a high-quality sword.

Carbon Steel, widely used for its strength and affordability, and Spring Steel, known for its flexibility and resilience, are popular choices among sword makers. Each type requires specific handling techniques during forging and heat treatment to maximize its potential. Tool steels are also prized for their hardness and durability, making them suitable for high-performance blades.

Forging is the essential technique in sword crafting that involves heating and shaping metal. The process begins by heating the metal to a high temperature, typically between 2,100 and 2,200 degrees Fahrenheit, until it reaches a yellow heat, making it malleable for hammering into the desired shape. The hammering process aligns the metal’s grain structure, enhancing its strength and durability. An anvil and tongs are essential tools for handling and shaping the metal during forging.

After the sword is forged, it undergoes quenching and tempering to achieve the desired hardness and toughness. Quenching involves rapidly cooling the hot blade in a medium such as oil or water. This sudden cooling hardens the steel but can also make it brittle. To counteract brittleness, tempering is performed. The tempered blade is reheated to a lower temperature and held there for a specific period. This process reduces internal stresses and ensures the sword is both hard and flexible.

Sharpening is the final stage in sword crafting, where the blade is honed to a sharp edge. This involves using various tools such as files, sandpaper, or high-grit sanders to refine the edge. Proper sharpening improves the sword’s cutting ability and overall performance.

Handles are usually made from wood, bone, or metal and often wrapped in leather or cord for better grip. The guard, placed between the blade and handle, protects the hand during use. Crafting the handle and guard involves careful design to ensure comfort, balance, and aesthetic appeal.

Several tools and materials are essential for sword crafting:

Understanding these techniques and mastering their application allows one to craft swords that are both functional and visually striking.

Carbon steel is a popular material for sword making due to its versatility and affordability. It is an alloy primarily composed of iron and carbon, with the carbon content playing a crucial role in determining the steel’s characteristics.

Higher carbon steels, such as 1090, are known for their exceptional hardness and ability to maintain a sharp edge, making them ideal for swords that require superior cutting performance and durability. However, increased hardness can also make the steel more brittle, necessitating careful heat treatment to balance these properties.

Lower carbon steels, like 1055, are tough and less likely to crack or chip, making them suitable for swords that need to withstand heavy use. The toughness of carbon steel allows it to absorb shock and resist breaking, which is essential for combat and practice swords.

Mid-range carbon steels, like 1060, provide a good mix of durability and strength while maintaining a reasonable edge. These steels are flexible enough to endure bending and twisting without breaking, which is particularly important for functional swords that may encounter various stresses during use.

While carbon steel is not inherently resistant to corrosion, proper maintenance can help prevent rust and other forms of deterioration. High-carbon steels are more prone to rusting, so regular cleaning, oiling, and proper storage are essential to preserve the blade’s integrity and appearance.

Carbon steel’s ability to respond well to heat treatment processes like quenching and tempering is a significant advantage in sword making. These processes allow the steel to achieve the desired balance of hardness and flexibility. Proper heat treatment can enhance the performance of the sword, ensuring it is both sharp and resilient.

1055 carbon steel contains approximately 0.55% carbon. It is noted for its toughness and ability to withstand impact, making it a popular choice for swords that need to be durable and reliable.

With about 0.60% carbon content, 1060 carbon steel is appreciated for its excellent balance of hardness and pliability. This makes it suitable for swords that require both strength and the ability to maintain a sharp edge.

These high carbon steels, with carbon content ranging from 0.70% to 0.80%, offer better edge retention while maintaining sufficient resilience. They are ideal for swords that need to be both sharp and durable.

1090 carbon steel, containing approximately 0.90% carbon, is favored for its exceptional hardness and sharpness. It is used in high-performance swords that require superior cutting ability and resistance to bending under stress.

Selecting the appropriate carbon steel for sword making depends on the intended use of the sword. For general durability and strength, mid-range carbon steels like 1060 are often the best choice. For superior sharpness and resilience, higher carbon content steels like 1090 are preferred. The choice should consider factors such as the desired hardness, toughness, and maintenance requirements to ensure the sword meets the specific needs of the user.

Spring steel is a type of steel specifically designed to be flexible, resilient, and durable. Its unique properties make it an excellent choice for crafting swords that can endure significant stress and maintain their shape even under harsh conditions. As a result, spring steel is highly valued by martial arts practitioners and collectors alike.

One of the primary advantages of spring steel is its remarkable elasticity. This material can absorb impacts and return to its original shape after being bent or flexed. This characteristic is crucial for swords, which often encounter high-impact forces during use, as it allows them to endure rigorous training and combat while maintaining their structural integrity.

Spring steel swords are known for their exceptional durability and wear resistance. These swords can maintain their edge and overall condition longer than those made from softer materials. Spring steel’s durability makes it ideal for heavy use, as it can withstand the repeated stress and strain of frequent training or combat.

Another significant advantage of spring steel is its resistance to fatigue. Fatigue resistance refers to the material’s ability to withstand repetitive stress without failing. This property makes spring steel an ideal material for swords that need to be both flexible and durable, ensuring that the blade remains reliable and does not suffer from metal fatigue over time.

Compared to traditional materials like tamahagane (a type of Japanese steel used in samurai swords), spring steel is more accessible and cost-effective. This affordability does not compromise the quality of the sword, making spring steel an attractive option for modern sword makers. The cost-effectiveness of spring steel allows swordsmiths to produce high-quality blades without the need for expensive materials.

Spring steel comes in various grades, each with its own set of properties that enhance its performance. Two popular grades used in sword making are:

These grades offer sword makers the flexibility to choose the best material for their specific needs, ensuring that the final product meets the desired performance criteria.

When compared to other materials like carbon steel, spring steel offers a unique set of advantages:

Spring steel’s elasticity, durability, and cost-effectiveness make it a top choice in modern sword making. Its advantages make it suitable for creating swords that are not only functional but also reliable and resilient.

Tool steels contain various alloying elements like tungsten, manganese, and silicon, which boost their performance. These elements significantly enhance the steel’s properties, making them ideal for sword making.

Tool steels are known for their remarkable toughness, allowing them to absorb impacts without chipping or breaking. This toughness is crucial for swords used in combat or heavy-duty applications, where the blade must endure significant stress. Additionally, the inclusion of elements like tungsten and silicon improves their wear resistance, enabling the sword to retain its sharp edge for a longer period, even under continuous use. Wear resistance is particularly important for swords that are frequently used for cutting and slashing.

Tool steels can achieve very high hardness levels, often exceeding HRC 60 when properly heat-treated. This high hardness contributes to excellent edge retention, ensuring that the sword remains sharp over extended periods. Moreover, tool steels maintain their structural integrity at high temperatures, reducing the risk of deformation during forging and heat treatment. This stability is beneficial for creating blades with precise and consistent shapes.

Several types of tool steels are commonly used in sword making, each offering unique advantages:

Tool steels and high-carbon steels differ in several key ways:

| Property | Tool Steels (T10, L6) | High-Carbon Steels (1095, 65Mn) |

|---|---|---|

| Hardness | HRC 60+ | HRC 58–62 |

| Toughness | Superior (L6 Bainite) | Moderate (prone to chipping in 1095) |

| Edge Retention | Excellent | High (1095 excels in sharpness) |

| Flexibility | Moderate (T10) to High (L6) | High (65Mn spring steel) |

Tool steels generally offer superior toughness and edge retention compared to high-carbon steels. However, high-carbon steels like 1095 are known for their excellent sharpness, making them suitable for specific applications where a razor-sharp edge is critical.

While tool steels provide numerous benefits, there are some considerations to keep in mind:

Tool steels are highly resistant to wear but can be prone to rust if not properly maintained. Regular oiling and cleaning are necessary to prevent corrosion and ensure the longevity of the blade.

Producing tool steels is more complex and costly than making standard carbon steels. However, the investment is often justified by the superior performance and durability they offer.

Forging and heat-treating tool steels require precise control and expertise, especially for complex steels like L6. Achieving the best results often depends on the skill and experience of the swordsmith.

Carbon steel is a popular choice for sword making due to its balance of strength, durability, and edge retention. It is particularly favored for functional swords used in combat or martial arts practice.

Spring steel is highly valued for its flexibility and resilience, making it ideal for swords that need to endure significant stress without breaking.

Tool steels, such as T10 and L6, are chosen for their exceptional hardness and edge retention, making them suitable for high-performance swords.

Stainless steel is often used for decorative swords due to its corrosion resistance and low maintenance requirements.

Titanium is a modern material used in sword making for its lightweight and corrosion-resistant properties.

Below are answers to some frequently asked questions:

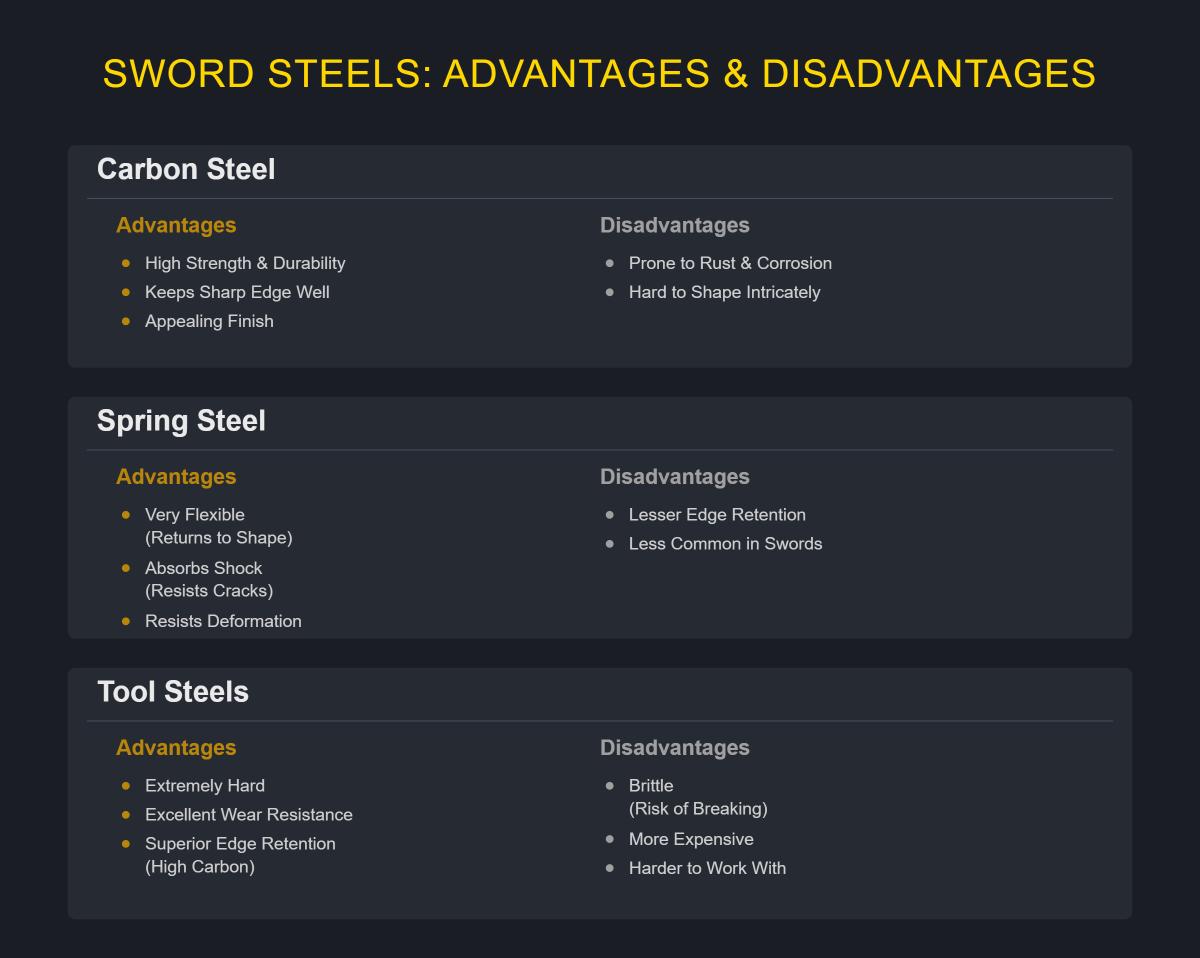

Carbon steel, spring steel, and tool steels each offer distinct advantages and disadvantages in sword making.

Carbon steel is known for its strength and durability, making it ideal for combat and martial arts training. It maintains a sharp edge well, allowing for precise cuts, and often has an appealing finish. However, it is prone to rust and corrosion, requiring regular maintenance, and its strength can make it difficult to shape into intricate designs.

Spring steel is valued for its flexibility and ability to return to its original shape after bending, which makes it resistant to deformation and excellent at absorbing shocks. This reduces the likelihood of cracking under impact. On the downside, it may not retain its edge as well as carbon steel, necessitating more frequent sharpening, and it is less commonly used in sword making.

Tool steels are extremely hard and offer excellent wear resistance, with some variants having high carbon content for enhanced hardness and edge retention. However, this hardness can make them brittle, increasing the risk of cracking or breaking under impact. They are also more expensive and harder to work with, requiring specialized tools.

Carbon content significantly affects the properties of steel used in swords. Steel is an alloy primarily made of iron and carbon, and the amount of carbon can influence the blade’s hardness, strength, and flexibility.

Higher carbon content typically results in harder steel, which is advantageous for maintaining a sharp edge. However, this also makes the steel more brittle, increasing the risk of chipping or cracking if not properly tempered. For example, high carbon steel (above 0.60% carbon) offers excellent hardness but must be carefully treated to avoid brittleness.

Medium carbon content, ranging from 0.3% to 0.6%, provides a balance of strength and hardness, making it ideal for swords. This range allows the blade to be strong and retain a sharp edge while maintaining some flexibility to prevent breaking under stress. A popular choice among sword makers is 1060 carbon steel, which strikes a good balance between hardness and flexibility.

Sword crafting involves several fundamental techniques to create a strong, functional, and aesthetically pleasing sword. Firstly, design and planning are crucial, where you decide on the type of sword and its intended use. Material selection follows, with high-carbon steel being a popular choice due to its strength and ability to hold a sharp edge.

The forging and shaping process includes heating the steel to a malleable state and using tools like a hammer and anvil to shape the blade. Techniques such as drawing out and beveling help form the sword’s shape and cutting edges. Heat treatment is essential, involving normalization, quenching, and tempering to achieve the desired hardness and relieve brittleness.

Sanding and sharpening smooth out and refine the blade, while hilt construction ensures a comfortable and secure grip. Additional features like crafting a fuller and deciding on the blade’s cross-section shape can enhance functionality and appearance. These steps collectively ensure the creation of a high-quality sword.

Different metals significantly impact the sword crafting process due to their unique properties, which affect the blade’s strength, flexibility, hardness, and overall performance. High-carbon steel is commonly used for its excellent balance between hardness and ductility. It can be hardened through heat treatment processes like quenching and tempering, making it durable and flexible.

Spring steel is favored for its high flexibility and resistance to breaking under stress, making it ideal for swords that need to withstand heavy impacts. Tool steels are known for their durability and edge retention, making them suitable for high-performance blades that require a sharp edge over prolonged use.

Traditional metals like Japanese tama-hagane require specialized folding techniques to homogenize carbon content and remove impurities, enhancing toughness and creating a distinctive layered pattern. Pattern-welded steel (Damascus steel) involves forge-welding multiple layers of different steels, resulting in a strong, flexible blade with a unique appearance.

Each metal’s specific properties dictate the necessary crafting techniques, such as heat treatments, folding, and forge-welding, ultimately determining the sword’s quality and suitability for different uses. Choosing the right metal depends on the desired balance of strength, flexibility, and hardness for the sword type.

To choose the right metal for your sword type, consider the intended use and the specific properties of different steels. For functional swords used in cutting or martial arts, high-carbon steels such as 1045, 1060, and 1095 are recommended due to their durability and edge retention. These steels are harder but can be brittle if not properly tempered. For flexibility, especially in swords used for combat reenactments, spring steel like 5160 is ideal as it absorbs shock well.

If your sword is primarily decorative, stainless steel or titanium may be suitable as they offer good corrosion resistance and require less maintenance, though they lack the strength needed for combat. Tool steels like T10 are excellent for edge retention in tactical or modern swords but require careful heat treatment.

Balancing cost, maintenance, and historical accuracy is crucial. Carbon steels need regular oiling to prevent rust, while stainless and titanium are easier to maintain but are not suitable for heavy use. Always prioritize the quality of heat treatment, as even the best steel can underperform if improperly tempered.

When crafting a sword, beginners should avoid several common mistakes to ensure a high-quality result. One key mistake is improper heat treatment, which can cause the blade to warp, become brittle, or develop soft spots. It’s crucial to heat and quench the blade evenly to maintain its integrity. Overambitious projects are another pitfall; starting with large blades without mastering basic techniques can lead to poor symmetry and heat treatment issues. Inadequate tools can also hinder the process; using small grinders or forges can result in uneven bevels and warping. Neglecting the normalizing process, which involves stress-relieving the metal, can create inconsistent grain structure and weak points. Lastly, poor symmetry control, especially in double-edged swords, can compromise the blade’s balance and effectiveness. Beginners should focus on perfecting these aspects with smaller projects before attempting more complex designs.