Imagine a world where every metal surface gleams with a protective, durable shine, standing resilient against the harshest environments. This is the promise of zinc metal plating, a process that not only enhances the appearance of metals but also significantly extends their lifespan. Whether you’re an intermediate hobbyist or a seasoned professional in the manufacturing or engineering fields, mastering the art of zinc plating can elevate your projects to new heights.

In this comprehensive guide, we will delve into the intricacies of zinc plating, starting with the fundamentals and moving through detailed, step-by-step instructions. You’ll learn how to prepare surfaces meticulously, set up your electroplating bath, and execute the plating process with precision. We’ll also explore the essential materials and equipment needed, along with critical safety considerations.

Are you ready to transform your metalwork with a robust, corrosion-resistant finish? Let’s dive in and uncover the secrets of zinc metal plating.

Zinc plating involves applying a thin layer of zinc to metal components, such as steel and iron, to protect them from corrosion. This process is crucial in industries like automotive, aerospace, and construction because it makes metal parts more durable and long-lasting.

In manufacturing and engineering, zinc plating is vital for ensuring metal components can withstand harsh conditions, as the zinc layer corrodes preferentially, protecting the underlying metal. This protective mechanism is essential for components exposed to moisture, salt, and other corrosive elements.

In the automotive industry, zinc plating is used extensively for parts such as bolts, nuts, and brackets. These components face exposure to road salt and moisture, making corrosion resistance essential for vehicle safety and longevity.

Aerospace applications demand high standards of durability and corrosion resistance. Zinc plating is utilized for various fasteners and structural components, ensuring they can withstand extreme conditions without compromising performance.

Construction materials, such as steel beams and rebar, benefit significantly from zinc plating. It prevents rust, extends the lifespan of structures, and lowers maintenance costs.

Zinc plating is an electroplating process where a thin layer of zinc is applied to the surface of metal workpieces, typically steel or iron, to protect them from corrosion. This process involves using electrical current to transfer zinc ions from a zinc anode to the metal cathode, forming a protective coating.

Electroplating is a method that uses electrical current to reduce dissolved metal cations so that they form a coherent metal coating on an electrode. In zinc plating, the workpiece acts as the cathode and the zinc metal as the anode in an electrolytic cell. The electrolyte solution contains zinc ions, which are deposited onto the workpiece when an electrical current is applied.

Zinc is used for plating because it provides excellent corrosion resistance. It serves as a sacrificial layer, corroding in place of the underlying metal. Zinc anodes ensure the quality and effectiveness of the protective layer.

The electroplating setup includes a power supply, electrolyte solution, anodes and cathodes, and a plating tank.

Zinc plating involves the use of chemicals and electrical equipment, which necessitates adherence to environmental and safety protocols. Key considerations include:

Acid zinc solutions are known for their fast deposition rates and high efficiency. They are suitable for high-volume production but may result in uneven thickness distribution and lower throwing power.

Alkaline zinc solutions offer better ductility and uniform thickness distribution. Although they have slower deposition rates and lower plating efficiency, they are preferred for applications requiring consistent coating quality.

Before plating, the workpiece must be thoroughly cleaned to remove any contaminants that could affect the adhesion and quality of the zinc coating. This can be achieved using alkaline detergent solutions.

Choose the zinc plating solution according to the desired properties of the final coating. Acid zinc solutions provide rapid deposition, while alkaline zinc solutions offer superior uniformity.

Two primary methods are used in zinc plating:

Connect the workpiece to the cathode and the zinc anode to the anode of the power source. Apply a direct current to initiate the deposition of zinc ions onto the workpiece.

The electrical current causes zinc ions to move from the anode to the cathode, forming a protective layer on the workpiece.

After plating, the workpiece should be rinsed to remove any residual plating solution and contaminants. Dry the workpiece thoroughly before use to ensure optimal performance and longevity of the zinc coating.

Proper surface preparation is essential for zinc plating because it cleans the metal substrate, removes contaminants, and prepares it to bond with the zinc coating. Without thorough preparation, the plating process can result in poor adhesion, uneven coating, and reduced corrosion resistance.

Start by immersing the substrate in an alkaline detergent bath heated to around 150°F (65°C) for 5–10 minutes to remove oils, grease, and dirt. Next, use electrocleaning to remove microscopic contaminants by applying electric current in a cleaning solution, generating bubbles that lift away residues. After each cleaning stage, rinse the substrate thoroughly with clean water.

Remove rust and oxides from the metal surface, exposing a clean area for zinc to bond. Treat the substrate with an acid solution, commonly referred to as pickling. Typical acids used include dilute hydrochloric acid or sulfuric acid. Immerse the metal in the acid bath just long enough to dissolve rust and oxides without etching or damaging the base metal. After pickling, rinse thoroughly with water to remove all acid residues, preventing contamination of subsequent plating baths.

Further refine the surface texture using a mild acid or alkaline solution to enhance bonding and plating uniformity. After etching, rinse thoroughly with clean water, often using deionized water, and dry the substrate quickly to prevent rusting.

Properly preparing the surface of the metal substrate is essential for achieving high-quality zinc plating. By following these detailed steps, manufacturers can ensure a clean, active surface ready for zinc electrodeposition, resulting in improved adhesion, uniformity, and corrosion resistance of the zinc coating.

Zinc plating requires several essential steps to achieve a high-quality protective coating.

To remove all contaminants such as grease, oil, dirt, and oxides, immerse the metal part in a hot alkaline solution at around 150°F for 5–10 minutes. This breaks down and removes organic impurities. Additionally, subject the part to an electrical current in a cleaning solution, generating gases that lift off microscopic contaminants from the surface.

Submerge the part in an acidic solution like sulfuric or hydrochloric acid to dissolve oxides and prepare a clean, reactive surface.

Prepare an electrolyte solution with water, zinc salts (such as zinc sulfate or zinc chloride), and additives to improve coating quality. The bath composition must be carefully formulated to achieve the desired properties of the zinc layer.

Immersing the cleaned and activated metal part in the plating bath, an electrical current is passed through the bath, causing zinc ions to reduce and deposit onto the metal surface. Control parameters such as current density, bath temperature, and electrolyte composition closely to ensure consistent coating thickness and quality.

Enhance the protective qualities and appearance of the zinc coating by treating the plated part with a chromate or chemical solution for increased corrosion resistance and color options. Thoroughly rinse and dry the part to remove any residual chemicals.

Verify coating thickness, adhesion, and overall quality through visual inspection, thickness measurement, and adhesion and corrosion testing, ensuring the coating meets specifications.

Surface preparation, the foundation of successful zinc plating, involves cleaning the metal substrate to remove contaminants that could interfere with the process. Mechanical cleaning, like abrasive blasting, removes rust, scale, and other impurities, while chemical cleaning uses alkaline or acidic solutions to dissolve oils, grease, and oxides. Proper surface preparation ensures good adhesion and uniformity of the zinc coating.

Preparing the electroplating bath involves dissolving zinc salts (like zinc sulfate or zinc chloride) in water and adding additives to improve the coating’s quality. Maintaining the correct bath composition, temperature, and pH is crucial for consistent zinc deposition.

Zinc plating processes must adhere to industry standards to ensure quality and performance. Compliance with standards like ASTM B633 is essential for meeting specific requirements regarding coating thickness, adhesion, and corrosion resistance. Regular testing and inspection verify compliance with these standards.

Effective zinc plating means addressing common issues like poor adhesion, uneven coating, and bath contamination by identifying and correcting their root causes. Poor adhesion is often caused by inadequate surface preparation or contamination. Uneven coating thickness can result from improper bath composition or inconsistent current density. Regular monitoring and maintenance of the plating bath are necessary to prevent contamination.

Zinc plating provides excellent corrosion resistance by acting as a sacrificial barrier. Applying chromate conversion coatings or passivation layers to the zinc surface can significantly improve corrosion resistance and provide various aesthetic finishes.

Advanced zinc plating techniques, such as high-efficiency solutions and eco-friendly processes, enhance performance and sustainability. Real-world case studies offer valuable insights into future trends in zinc plating technology.

Pulse plating uses pulsed electrical currents instead of a constant current during electroplating, offering several benefits. Pulsed current can enhance the distribution of zinc ions for a more uniform coating thickness, while also reducing internal stresses within the zinc layer, minimizing the risk of cracking or peeling. Additionally, pulse plating can produce a brighter and more aesthetically pleasing finish compared to traditional constant current methods.

Precise temperature control during the plating process is crucial for achieving optimal zinc coating characteristics. The bath temperature significantly affects the zinc crystal structure, with higher temperatures promoting larger crystals and lower temperatures favoring finer ones. Temperature variations can also influence the morphology of the zinc deposit, affecting its mechanical properties and corrosion resistance. Maintaining a stable temperature ensures consistent plating results, reducing variability and improving overall coating quality.

Incorporating specialized additives into the plating bath can significantly enhance the quality of the zinc coating. Brighteners improve the brightness and smoothness of the zinc layer, resulting in a more visually appealing finish. Leveling agents help achieve a uniform coating by minimizing surface roughness and imperfections. Grain refiners control the zinc crystal size, enhancing the mechanical properties and durability of the coating.

Automated process control systems optimize the zinc plating process by reducing human error. Utilizing sensors and programmable logic controllers (PLCs) allows for real-time monitoring and adjustments of plating parameters such as current density, bath composition, and temperature. These automated systems ensure consistent and reproducible plating results, improving efficiency and reducing the likelihood of human error. Continuous data logging facilitates process analysis and optimization, enabling manufacturers to refine their plating operations based on historical performance data.

Adopting sustainable practices in zinc plating can reduce environmental impact and enhance process efficiency by using eco-friendly chemicals and minimizing hazardous waste. Implementing energy-efficient equipment and optimizing process parameters can lower energy consumption and operational costs. Proper treatment and disposal of plating waste, including recycling of spent electrolytes and recovery of zinc, contribute to environmental sustainability.

Examining real-world case studies provides valuable insights into advanced zinc plating techniques. In the automotive industry, innovations in zinc plating have led to enhanced corrosion resistance and durability of automotive components, improving vehicle safety and longevity. Advanced zinc plating methods have enabled the production of high-performance aerospace parts that withstand extreme environmental conditions. Sustainable zinc plating practices have contributed to the development of long-lasting and corrosion-resistant construction materials, reducing maintenance costs and extending the lifespan of structures.

Below are answers to some frequently asked questions:

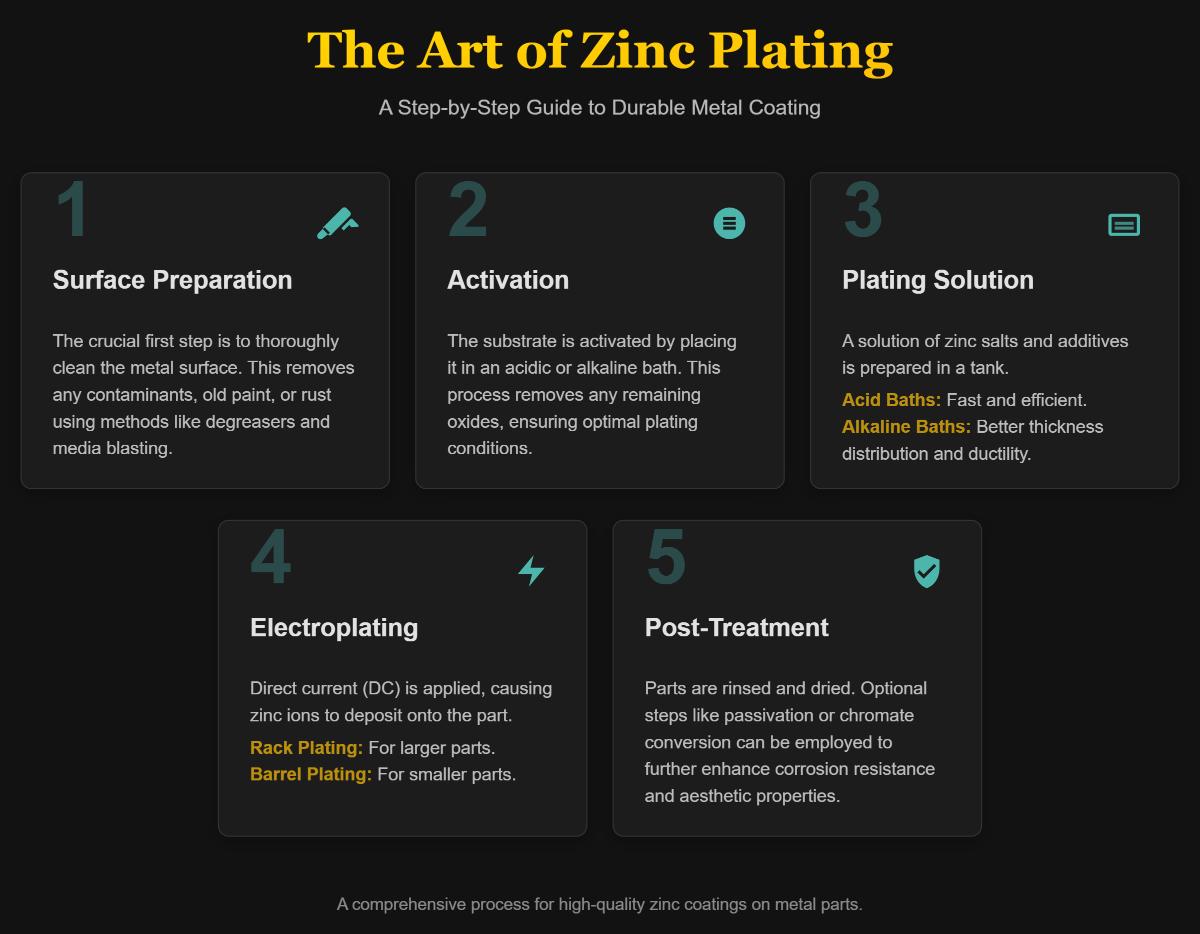

Zinc plating is a process used to coat metal parts with a thin layer of zinc to enhance corrosion resistance and aesthetic appeal. The procedure involves several key steps. First, surface preparation is crucial; the metal surface must be thoroughly cleaned using degreasers, cleaning solutions, and sometimes media blasting to remove any contaminants, old paint, or rust. Next, the substrate is activated in an acidic or alkaline bath to remove remaining oxides, ensuring optimal plating conditions.

Following activation, the plating solution is prepared by mixing zinc salts and additives in a tank. There are two main types of zinc baths: acid zinc baths, which are fast and efficient, and alkaline zinc baths, which offer better thickness distribution and ductility. The electroplating process then begins, where a direct current (DC) is applied to the anode, causing zinc ions to deposit onto the cathode, the metal part being plated. Methods such as rack plating for larger parts and barrel plating for smaller parts are used to ensure a uniform finish.

After plating, the parts are rinsed and dried thoroughly to prevent water spots. Additional steps like passivation or chromate conversion may be employed to further enhance corrosion resistance and achieve desired aesthetic properties. This comprehensive process ensures high-quality zinc coatings on metal parts.

Surface preparation is critical in zinc plating to ensure proper adhesion, durability, and corrosion resistance of the zinc coating. Here’s a detailed step-by-step guide for preparing metal surfaces before zinc plating:

By following these steps, you ensure that the surface is optimally prepared for zinc plating, leading to high-quality, durable coatings.

To perform zinc plating, several essential materials are required. The base metal or substrate, commonly steel, iron, brass, or copper, must be thoroughly cleaned and prepared. Cleaning supplies include alkaline detergents for grease removal, acid pickling solutions (hydrochloric or sulfuric acid) for rust and oxide removal, degreasers, abrasives, and distilled water for rinsing.

The plating bath components are crucial. Zinc anodes made of pure zinc metal bars or plates are used. Zinc salts, such as zinc chloride, zinc sulfate, or cyanide-based salts, are dissolved in the bath, along with electrolyte additives like brighteners and levelers. Depending on the method, acid or alkaline solutions are used to control the plating characteristics.

A DC power source is necessary to supply the electrical current, with the base metal connected to the negative terminal (cathode) and zinc anodes to the positive terminal (anode). Optional materials include chemicals for chromate conversion coatings, barrels or racks for holding parts during plating, and safety gear like gloves and goggles.

Electroplating in zinc plating works by using an electrochemical process to deposit a thin layer of zinc onto a metal substrate, typically steel or iron. This process involves several key steps:

This controlled deposition process ensures a uniform and durable zinc coating that provides corrosion protection and improves the substrate’s appearance.

Common issues in zinc plating include dull or dark plating, slow plating speed and poor coverage, blistering or bubbling, rough or coarse plating, hydrogen embrittlement, and floweriness or blooming.

Dull or dark plating often results from insufficient brighteners, low zinc concentration, or high impurities. Troubleshooting involves adjusting brightener levels and maintaining proper zinc and temperature levels, typically 80–85°F (26–30°C).

Slow plating speed and poor coverage can be due to an imbalance of brighteners, low zinc or caustic soda, or high carbonates. Ensuring zinc and caustic soda levels are within the recommended range and regularly analyzing the bath can help.

Blistering or bubbling usually stems from poor substrate preparation or high impurity levels. Thorough cleaning, proper additive adjustment, and impurity removal are necessary.

Rough or coarse plating is generally caused by high current density or contamination. Adjusting current density and ensuring proper bath filtration can resolve this.

Hydrogen embrittlement and cracking arise from excessive hydrogen absorption during plating. Reducing current density and performing post-plating baking can mitigate this issue.

Floweriness or blooming is often due to dirty cleaning water or poor pickling. Using clean water and improving the cleaning process will help.

By following these troubleshooting steps, the quality of zinc plating can be significantly improved.

Zinc plating significantly contributes to corrosion protection through several mechanisms. Firstly, it provides a physical barrier that isolates the underlying ferrous metal (such as steel or iron) from exposure to moisture, oxygen, and other corrosive elements. This barrier slows down the initiation of corrosion by preventing direct contact between the metal and environmental agents.

More critically, zinc plating offers galvanic protection. Zinc is more anodic than steel, meaning it corrodes preferentially when exposed to an electrolytic environment. This sacrificial corrosion of zinc protects the steel underneath, preventing rusting and pitting.

Additionally, as zinc corrodes, it forms zinc oxide, which further reacts to create zinc carbonate. This compound adheres to the surface, creating a passive layer that enhances corrosion resistance. Conversion coatings applied after zinc plating, such as chromate treatments, can further improve protection by forming an additional protective film.