In the world of metals, zinc and tin might seem interchangeable to the untrained eye, but these two elements have distinct properties and applications that set them apart. Have you ever wondered why some metals are more suitable for jewelry casting, while others excel in corrosion resistance? This comparative analysis will delve into the unique characteristics of zinc and tin, exploring their strengths and weaknesses in various industrial applications. From understanding their roles in metal coatings to discovering the intriguing properties of tin-zinc alloys, we will guide you through a comprehensive comparison. So, which metal holds the edge in durability and versatility? Let’s dive in and find out.

Zinc and tin are two essential metals utilized in various industries due to their unique properties and applications. Comparing these metals helps in choosing the right one for different applications.

Zinc, with an atomic number of 30, is represented by the symbol Zn, while tin, with an atomic number of 50, is denoted by Sn. The difference in atomic structure contributes to their distinct physical and chemical behaviors.

Tin is slightly denser than zinc (7.31 g/cm³ vs. 7.14 g/cm³), but zinc is harder (Mohs hardness 2.5 vs. 1.5). This difference in hardness influences their suitability for various applications, particularly where wear resistance is a critical factor.

Zinc melts at 419.53°C and boils at 907°C. In contrast, tin melts at a lower temperature of 232°C and boils at a significantly higher temperature of 2602°C. These thermal properties are vital for processes like soldering, casting, and alloy formation.

Zinc primarily exhibits a +2 oxidation state, making it relatively straightforward in its chemical reactions. Tin, on the other hand, can exist in both +2 and +4 oxidation states, allowing for a broader range of chemical behaviors and applications.

Zinc has an electronegativity of 1.65, which is lower than tin’s 1.96 on the Pauling scale. This difference affects their chemical bonding and reactivity. In terms of electrical conductivity, zinc outperforms tin, with a conductivity of about 17,000,000 S/m compared to tin’s 9,100,000 S/m. This makes zinc more suitable for applications requiring efficient electrical conduction.

Zinc is commonly used to coat steel or iron in a process called galvanizing, which prevents rust. Its anti-corrosion properties make it indispensable in construction and automotive industries. Additionally, zinc is used in batteries, die-casting, and as an essential trace element in human health, influencing immune function and enzyme activity.

Tin is primarily used in soldering due to its low melting point and excellent malleability. It is also utilized in the production of corrosion-resistant coatings for steel cans and other packaging materials. Tin’s role in precision instruments and specialty alloys highlights its importance in advanced manufacturing sectors.

Zinc is more eco-friendly and recyclable, though its extraction and processing can cause environmental waste. Tin, being less toxic than some other heavy metals, poses fewer health risks but still involves environmental challenges during extraction and plating processes.

The cost of tin is higher than zinc, primarily due to its relative scarcity and the complexity of its extraction and refinement processes. This makes zinc a more cost-effective option for large-scale industrial applications, while tin is reserved for specialized uses where its unique properties justify the higher expense.

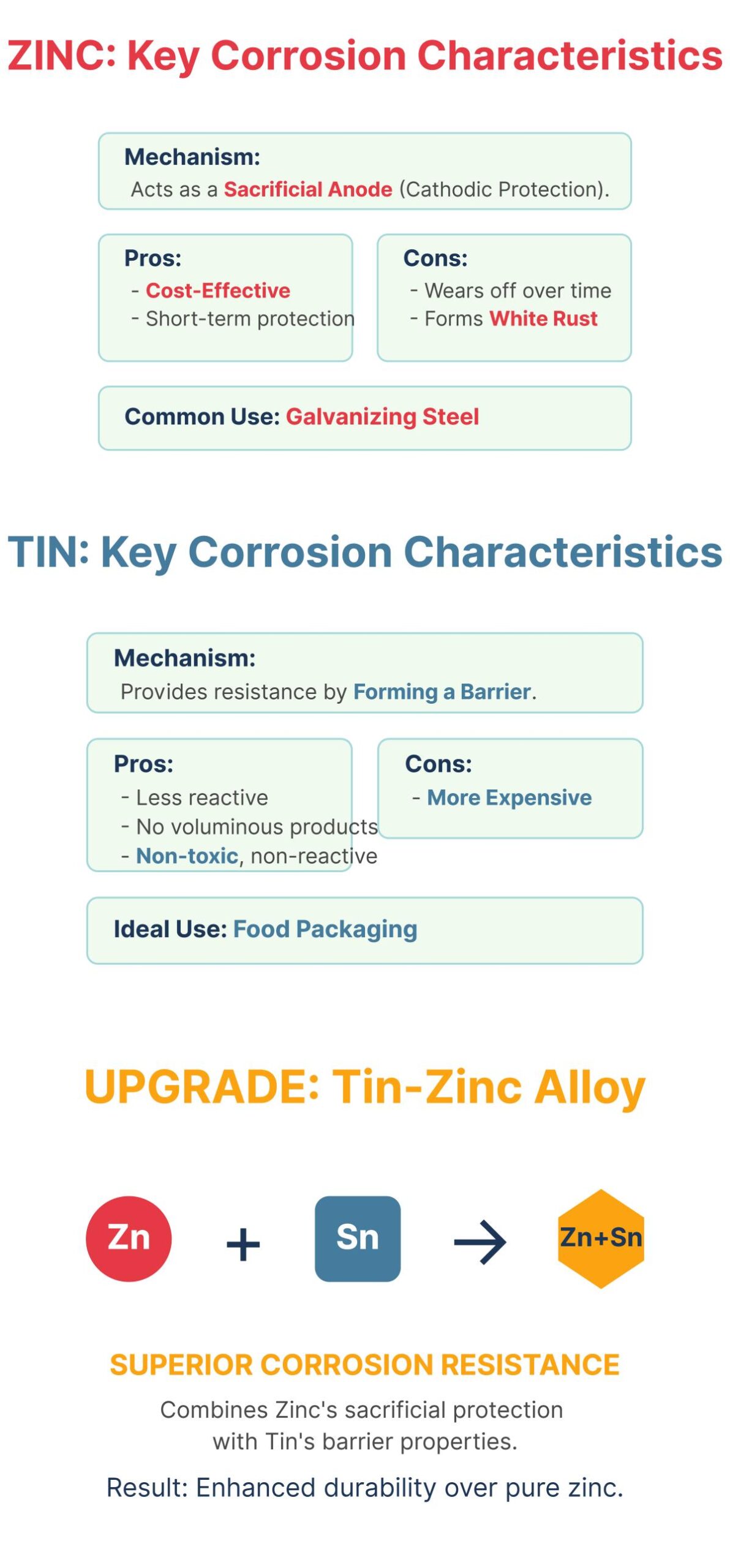

Zinc protects steel by acting as a sacrificial anode, meaning it corrodes more quickly than steel and thus prevents the steel from rusting. This corrosion process leads to the formation of a protective zinc oxide layer, which further slows down the corrosion rate. Additionally, zinc can form a patina that shields the underlying metal from moisture and oxygen, enhancing its protective effectiveness.

Tin acts as a barrier coating, isolating the steel surface from the environment and, due to its noble nature, corrodes more slowly than steel. However, if the tin layer is damaged, the exposed steel can rust. Its malleability and non – toxicity make it well – suited for applications such as food packaging.

Zinc coatings provide excellent corrosion resistance, especially in harsh environments, with thicker coatings offering better protection. Zinc can also form alloys, like zinc – cobalt, which can boost its corrosion resistance up to five times compared to pure zinc.

In industrial settings, tin is less corrosion – resistant than zinc. Nevertheless, it offers sufficient protection for applications like food cans, where the environmental conditions are less severe. Tin – zinc alloys present a balanced solution, combining the sacrificial protection of zinc with the barrier effect of tin.

Zinc is widely used in galvanized steel for construction and automotive industries due to its high corrosion resistance, but its toxicity and reactivity with acidic foods limit its use in food packaging.

Tin’s non – toxicity and non – reactivity make it an ideal choice for food contact applications. In environments with controlled humidity and temperature, tin provides adequate protection against corrosion.

The corrosion resistance of zinc coatings is frequently evaluated through salt spray tests. The American Society for Testing and Materials (ASTM) has established classifications for zinc coatings based on their protection level.

Tin – zinc alloys are tested for corrosion resistance using methods like ASTM B117, and optimal compositions (around 75 – 80% tin) show better performance than pure zinc under certain conditions.

One of the primary uses of zinc is in galvanizing, where it coats steel or iron to prevent corrosion. This process is crucial in the construction and automotive industries, ensuring long-lasting protection from rust. Galvanized steel is widely used in building structures, roofing, and car bodies.

Zinc plays a vital role in battery production, especially in zinc-carbon and zinc-air batteries. Its high reactivity and ability to store energy make zinc an excellent material for these applications, providing efficient and reliable power sources for various electronic devices.

Zinc is extensively used in die-casting, a process that shapes molten metal into precise industrial parts. Zinc’s ability to create detailed and complex shapes with high precision makes it ideal for the automotive, electrical, and hardware industries.

Zinc is important in creating various alloys, such as brass (zinc and copper) and nickel silver (zinc, copper, and nickel). These alloys are valued for their strength, corrosion resistance, and aesthetic appeal, making them suitable for musical instruments, decorative items, and industrial machinery.

Tin is predominantly used in soldering due to its low melting point and excellent malleability. It is a key component of solder alloys, which often combine tin with lead or silver to join electronic components. This application is critical in electronics manufacturing, ensuring strong and conductive joints.

Tin’s non-toxicity and corrosion resistance make it ideal for food packaging. Tin coatings on steel cans prevent corrosion and preserve the quality of the food inside. This application is vital in the food industry, where maintaining the integrity and safety of products is paramount.

In electronics, tin is used for plating and coating electronic components, providing corrosion resistance and ensuring reliable electrical connections. Its ductility and non-reactivity are particularly beneficial in protecting sensitive electronic parts from environmental damage.

Tin is essential in creating various alloys, such as bronze (tin and copper) and pewter (tin, antimony, and copper). These alloys are appreciated for their strength, workability, and resistance to corrosion, finding applications in art, sculpture, bearings, and other mechanical parts.

Zinc’s versatility is evident in its use across multiple industries, from construction to electronics. Its ability to provide robust corrosion protection and form complex shapes through die-casting underscores its industrial significance. In contrast, tin’s applications are more specialized, focusing on areas where its non-toxic nature and low melting point are advantageous, such as food packaging and electronics.

Zinc is generally more abundant and cost-effective than tin, making it the preferred choice for large-scale applications like galvanizing and die-casting. Tin, while more expensive, justifies its cost in specialized applications where its unique properties, such as non-toxicity and malleability, are crucial.

Both metals have environmental considerations; zinc’s extraction and processing can lead to ecological concerns, while tin, although less toxic, also poses environmental challenges during mining and refining. However, zinc’s wider use in galvanizing and battery production highlights its broader environmental footprint compared to tin.

Zinc coatings are a popular choice for protecting metal surfaces due to their ability to provide sacrificial protection. Zinc corrodes instead of the metal it covers, extending the life of the object.

Tin coatings, while less commonly used than zinc, offer distinct advantages, especially in environments that require non-toxic and non-reactive surfaces.

Combining zinc and tin can leverage the advantages of both metals. Tin-zinc alloys provide balanced protective properties and are particularly useful in electrical applications where both solderability and corrosion resistance are needed. These hybrid coatings can be tailored to specific needs, offering enhanced performance over pure zinc or tin coatings alone.

Tin-zinc alloys are engineered to improve mechanical strength, resist corrosion, and enhance solderability. These alloys typically consist of a combination of tin (Sn) and zinc (Zn) in varying proportions, which can be adjusted to achieve specific properties for different applications. The addition of zinc to tin not only increases the hardness and tensile strength of the alloy but also provides a protective layer that helps prevent oxidation and corrosion. This makes tin-zinc alloys particularly useful in the electronics industry for soldering components, as well as in the automotive and aerospace industries where durability and resistance to environmental factors are crucial.

One of the standout features of tin-zinc alloys is their superior corrosion resistance. The combination of zinc’s sacrificial protection and tin’s barrier properties results in alloys that offer excellent protection against various environmental conditions. This makes them particularly valuable in marine and industrial applications where corrosion resistance is paramount.

Tin-zinc alloys exhibit a balance of strength and ductility. Zinc contributes to the alloy’s strength and hardness, while tin provides ductility and malleability. This combination allows tin-zinc alloys to be used in applications that require both durability and the ability to undergo deformation without cracking. These mechanical properties make them suitable for use in coatings, connectors, and various components in the automotive and electronics industries.

Tin-zinc alloys provide excellent electrical conductivity, making them ideal for applications where electrical performance is crucial. The presence of tin, known for its excellent conductivity, helps maintain the electrical integrity of components made from these alloys.

In the automotive sector, tin-zinc alloys are used for components that require both corrosion resistance and electrical conductivity. These alloys are ideal for parts exposed to harsh environmental conditions, such as connectors and fasteners.

Tin-zinc alloys are extensively used in the electronics industry. Their good solderability and electrical properties make them suitable for various electronic components, ensuring reliable performance and longevity.

Tin-zinc alloys are perfect for decorative uses due to their appealing look and durability. They are used in producing various decorative items that require a combination of visual appeal and functional performance.

Finding alternatives to zinc and tin is essential for various reasons, including cost efficiency, environmental impact, and specific performance requirements. Here, we explore several viable alternatives that can meet diverse needs in different sectors.

Aluminum is lightweight and versatile, with excellent corrosion resistance and conductivity.

Nickel is hard and ductile, offering excellent corrosion resistance and high-temperature stability.

Copper, a highly conductive metal with good corrosion resistance as its natural patina forms protection, is widely used in electrical wiring, plumbing, heat exchangers, and as a base for alloys like brass and bronze.

Stainless steel, an alloy of iron with chromium and other elements, offers exceptional strength, durability, and corrosion resistance.

Titanium is a high-performance metal known for its remarkable strength-to-weight ratio and excellent corrosion resistance.

Zinc-nickel alloys blend zinc’s sacrificial protection with nickel’s better corrosion resistance and durability.

Composite materials, made from two or more constituent materials, provide tailored properties that can surpass those of traditional metals.

Below are answers to some frequently asked questions:

Zinc and tin differ in corrosion resistance mechanisms and properties. Zinc acts as a sacrificial anode, corroding in place of the underlying steel through cathodic protection. It’s effective for short – term protection, but wears off over time and can form white rust. Zinc is cost – effective and used in galvanizing steel. Tin, on the other hand, provides corrosion resistance by forming a barrier. It’s less reactive, doesn’t form voluminous corrosion products, and is ideal for non – reactive, non – toxic applications like food packaging. Tin is more expensive than zinc. A tin – zinc alloy combines the benefits of both, offering better corrosion resistance than pure zinc.

Tin-zinc alloys are employed in various industries due to their unique combination of properties, which enhance the benefits of both metals. In the electronics and automotive sectors, these alloys are prized for their excellent solderability and electrical conductivity. Their ductility allows components to be shaped without compromising the coating, which is crucial for intricate parts.

In electroplating, tin-zinc alloys offer superior corrosion resistance by combining zinc’s galvanic protection with tin’s barrier properties, making them ideal for use in marine and chemical environments. Additionally, these alloys are used in decorative applications, such as architectural hardware and ornaments, due to their aesthetic appeal and good castability.

For jewelry casting, tin alloys are generally more suitable than zinc alloys. Tin alloys, such as pewter and Britannia, are favored due to their excellent fluidity and ductility, which allow for intricate and detailed designs. They have a lower melting point (between 475°F and 750°F), making them easier to work with and enabling precise detailing. Additionally, tin alloys are cost-effective and relatively soft, simplifying the shaping and molding processes.

In contrast, zinc alloys offer higher tensile strength and better corrosion resistance, making them suitable for durable jewelry. However, they require higher casting temperatures (between 735°F and 875°F) and may not be as easy to work with for intricate designs. Zinc alloys can also be more expensive.

In industrial applications, several alternatives to zinc and tin are utilized, driven by factors such as environmental impact, cost, and specific material properties.

For zinc, alternatives include aluminum plating, zinc-nickel alloys, and zinc-aluminum alloys. Aluminum plating offers excellent corrosion resistance and is lightweight, making it suitable for aerospace and automotive industries. Zinc-nickel alloys provide superior corrosion resistance and electrical conductivity, often replacing cadmium plating in harsh environments. Zinc-aluminum alloys combine the benefits of both metals, offering enhanced corrosion resistance and cost-effectiveness.

For tin, alternatives include zinc-iron alloys, nickel-PTFE, and silver plating. Zinc-iron alloys are cost-effective and environmentally friendly, suitable for applications where tin is too expensive. Nickel-PTFE combines wear resistance with corrosion protection, ideal for low friction and high durability requirements. Silver plating, although more expensive, provides excellent electrical conductivity for high-frequency electronic applications, despite its susceptibility to tarnishing.

These alternatives help industries meet regulatory standards, reduce environmental impact, and achieve specific performance requirements.

Both zinc and tin have environmental impacts that need to be considered when used in industrial applications. Zinc, while essential for life, can be harmful to ecosystems in high concentrations. It often originates from industrial activities such as mining and manufacturing, and improper disposal can lead to contamination of water sources, affecting marine and terrestrial life. However, zinc is highly recyclable, which can mitigate some of its environmental footprint due to lower energy consumption during recycling processes.

Tin is relatively non-toxic compared to other heavy metals but still presents environmental challenges. The tin plating process is energy-intensive and generates hazardous waste, necessitating careful management of chemicals to avoid environmental contamination. Technological advancements are improving the efficiency and sustainability of tin plating, but it remains less recyclable than zinc.

Zinc and tin coatings both provide corrosion protection, but their durability differs based on their specific properties and application environments. Zinc coatings are known for their sacrificial nature, meaning they corrode over time to protect the underlying metal. This results in good durability in moderate environments, with potential longevity of up to 50 years, but shorter in harsh conditions such as marine settings.

In contrast, tin coatings form a stable, non-sacrificial oxide layer, offering superior durability in harsh environments. They are also non-toxic and provide excellent solderability, making them ideal for electronics and food packaging applications. However, tin coatings are generally more expensive than zinc.

Overall, zinc coatings are cost-effective for moderate environments, while tin coatings offer long-term protection and are better suited for harsh conditions and applications requiring non-toxicity.