When it comes to precision engineering, the devil is often in the details—specifically, in the depths of threads. Understanding how to accurately measure thread depth is crucial for ensuring the integrity and functionality of any threaded assembly. But what if you don’t have access to specialized tools? And how do you differentiate between functional depth and physical depth? This comprehensive guide is designed to demystify these concepts, offering intermediate-level insights into the nuances of thread measurement. Through step-by-step instructions and expert tips, you’ll learn not only how to measure thread depth using various tools but also how to interpret depth notches on thread plug gages and solve common measurement challenges. Are you ready to dive into the intricacies of thread measurement and ensure your projects meet industry standards? Let’s get started.

Measuring thread depth is crucial for maintaining the integrity and functionality of threaded connections. Accurate thread depth ensures proper engagement between mating components, such as screws and bolts, preventing mechanical failures and maintaining structural stability.

There are two primary types of thread depth: physical and functional. Physical thread depth refers to the actual depth of the threads in the material, measured from the top surface to the bottom of the threaded hole. Functional thread depth is the depth at which the threads effectively engage with the mating component, ensuring the threaded parts achieve the desired mechanical strength and reliability.

Thread depth gauges are specialized tools designed to measure the depth of threads with high precision. They come in various forms, including digital gauges, which offer enhanced accuracy and ease of use.

Depth micrometers are highly accurate tools used to measure the depth of threaded holes. They provide precise readings and are ideal for applications where high accuracy is required.

Digital calipers can measure thread depth by reaching the bottom of the threaded hole. While practical for general use, they may not offer the same level of precision as depth gauges or micrometers.

Direct measurement involves inserting the chosen tool into the hole until it reaches the bottom of the threads. The measurement is then read directly from the tool, providing an immediate and accurate reading.

The wire method involves inserting a wire of known diameter into the threaded hole and measuring the exposed part of the wire. This measurement is used to calculate the thread depth. This method is useful for applications where direct measurement is challenging or less precise.

Selecting the right tool ensures precise and dependable thread depth measurements. Consider the precision required for the application and select tools like thread depth gauges or depth micrometers accordingly.

Regular calibration of measurement tools is essential to maintain their accuracy. Ensure that tools are calibrated according to manufacturer guidelines and industry standards to prevent measurement errors.

Technical drawings often specify the required thread depth. It is important to accurately interpret these drawings to ensure compliance with design specifications and achieve the desired thread engagement.

Misalignment of measurement tools can lead to inaccurate readings. Ensure that tools are properly aligned with the threaded hole to obtain precise measurements.

Failure to calibrate measurement tools can result in erroneous readings. Regular calibration and maintenance of tools are necessary to ensure their reliability. Additionally, misinterpreting measurement readings can lead to incorrect thread depth. Familiarize yourself with the measurement tools and their operation to accurately interpret the results.

Compliance with industry standards, such as ASME B1.1 and ISO 68-1, ensures that thread depth measurements meet the required specifications for mechanical assembly and quality control. Understanding these standards is crucial for achieving consistent and reliable thread depth measurements.

Thread depth gauges are specialized tools designed specifically to measure the depth of threads in a hole. Available in both analog and digital versions, digital gauges offer enhanced precision and ease of use. To measure thread depth, insert the gauge into the threaded hole until it contacts the bottom. You can easily read the measurement directly from the gauge, ensuring quick and accurate results.

Depth micrometers are highly accurate tools used for measuring the depth of threaded holes. They consist of a micrometer head attached to a base that can be adjusted to contact the bottom of the threads. Ideal for applications requiring high accuracy and reliability, depth micrometers provide precise measurements by inserting the micrometer into the hole until it reaches the bottom.

Calipers are versatile measuring tools that can be used to measure thread depth. Calipers are practical for general use, although they may not be as precise as specialized gauges or micrometers. To measure thread depth with calipers, insert the caliper into the threaded hole until it reaches the bottom, then read the measurement from the caliper’s scale.

Thread plug gages are primarily used to determine if threads are within specification, but they can also assist in measuring thread depth. Use a thread plug gage to quickly assess thread quality by measuring the distance before and after screwing it in. This method provides a quick assessment of whether the threads meet the required standards.

The wire method involves inserting a wire of known diameter into the threaded hole and measuring the exposed part of the wire. This approach is handy when you don’t have access to specialized tools, allowing you to calculate the thread depth with minimal equipment.

Using off-the-shelf screws that fit the thread can also be effective. Measure the full length of the screw, then measure how much is engaged when fully inserted into the part. The difference between these measurements gives the thread depth.

For critical applications, it is recommended to take multiple measurements across the thread length to ensure accuracy. Precision tools help prevent errors and ensure reliable measurements.

Choosing the right precision tools for the application is essential to avoid errors and ensure dependable measurements. Tools like thread depth gauges and depth micrometers are ideal for high-stakes applications.

Select the measurement method based on the required precision and available tools. For high-accuracy needs, tools like depth micrometers and thread depth gauges are preferred, while alternative methods can be used for less critical applications.

Accurate measurement and mechanical compatibility depend on a clear understanding of thread dimensions. Threads have three critical diameters: the Major Diameter (the largest diameter), the Minor Diameter (the smallest diameter), and the Pitch Diameter (an imaginary cylinder’s diameter halfway between the major and minor diameters).

Thread depth is the difference between the major and minor diameters for external threads and the difference between the nominal and minor diameters for internal threads.

Thread pitch and TPI are essential indicators of thread density and spacing. In metric threads, thread pitch refers to the distance between two adjacent threads, measured in millimeters. Larger pitch values indicate fewer threads per unit length, often referred to as coarse threads. In imperial threads, TPI measures the number of threads within one inch. Higher TPI values indicate finer threads, which are denser and more precise.

Accurate thread measurement requires specific techniques and tools. Calipers can measure diameter and pitch. To measure pitch, place calipers across multiple threads and divide the total distance by the number of threads. Rulers can provide approximate measurements of pitch or TPI. For imperial threads, count the number of thread peaks over a one-inch span to determine TPI.

The thread angle is the angle between the sides (flanks) of a thread, measured in a cross-sectional view. Standard thread angles vary depending on the type of thread, such as UN or ISO.

Understanding and adhering to thread standards and terminology is crucial for consistency and reliability in thread measurement. Threads are defined by various international standards, including ASME (American Society of Mechanical Engineers) for imperial threads and ISO (International Organization for Standardization) for metric threads. Familiarity with terms like “coarse” vs. “fine” threads is essential. Coarse threads have a larger pitch and are generally easier to assemble but provide less holding power compared to fine threads.

Identify the thread type to determine if it is internal or external and whether it follows imperial or metric standards. Use calipers to measure the major and minor diameters directly for external threads. For internal threads, use a depth gauge or caliper to measure the depth from the surface of the threaded hole to the bottom of the thread. For imperial threads, use the formula:

For metric threads, calculate similarly but ensure units are consistent. In high-precision applications, use micrometers or specialized thread measuring instruments for accurate results.

Accurately interpreting technical drawings is crucial for ensuring that threaded components are manufactured and assembled correctly. These drawings provide critical information about the dimensions and specifications required for proper thread engagement.

Technical drawings should specify the required thread depth clearly, including dimensions, tolerances, and relevant notes, often indicated as a vertical measurement from a defined reference point. Tolerances define the permissible variation in thread depth and are crucial for ensuring parts fit together correctly. These may be expressed in the drawing as a range or a specific value with a tolerance band. Thread depth measurements are typically taken from the start of the first full thread at the bottom of the hole, ensuring consistency and accuracy in both manufacturing and inspection processes.

Tools like thread plug gages with depth notches allow for quick visual checks, while depth micrometers provide precise measurements to verify thread depth. These tools are inserted into the threaded hole to ensure that the depth aligns with the drawing specifications.

Start by carefully examining the technical drawing, noting all specified dimensions, tolerances, and special instructions regarding thread depth. Identify the starting point for depth measurement as indicated on the drawing, which is often the surface or the first full thread. Use appropriate measurement tools to verify that the actual thread depth matches the specified dimensions on the drawing, ensuring that the measurements fall within the given tolerances. Record measurements and any deviations from the specifications for quality control purposes, maintaining manufacturing standards and ensuring product reliability.

Choosing the right tool is crucial for accurate thread depth measurement. Depending on the precision required and the thread size, different tools may be more suitable. Here are some methods to consider:

To streamline your measurement process, follow these steps using either a thread depth gauge or a depth micrometer:

This method is useful when specialized tools are unavailable. Follow these simplified steps for clarity:

Accurate thread depth measurement requires knowing the reference point. Measure from the crest of the last full thread to the thread root bottom. Confirm these points against standards or specifications, and use thread plug gages for verification, simulating the engagement of mating parts.

By adhering to these guidelines, you can ensure that thread depth measurements are accurate and consistent, meeting engineering requirements and supporting the performance and reliability of threaded assemblies.

Accurate thread depth measurement is essential for ensuring the functionality and reliability of threaded components. However, various challenges can arise during the measurement process. Here are some common measurement problems and their solutions:

Cause: Inaccurate measurements often result from improper tool selection, misalignment, or incorrect usage of the measurement tool.

Solution: Choose the appropriate tool for the specific thread size and pitch, ensuring it is properly aligned with the threaded hole. Maintain a perpendicular position to avoid skewed readings and follow the manufacturer’s guidelines for correct usage. Practice the correct insertion technique and take multiple readings to verify accuracy.

Cause: Deep or narrow threaded holes can be difficult to measure accurately.

Solution: Use extension rods or adapters with your measuring tools to access hard-to-reach areas. Consider using specialized tools designed for measuring deep or narrow threads, such as long-reach depth micrometers or custom-made gauges.

Cause: Inconsistent thread depths can occur due to variations in the manufacturing process, leading to discrepancies in measurements.

Solution: Implement regular quality control checks and measure at multiple points to ensure consistent thread depths.

Cause: Debris and contamination within the threaded hole can interfere with accurate measurements, leading to false readings.

Solution: Clean the threads thoroughly before measuring and inspect for debris to prevent false readings.

Cause: Measurement errors can occur if the tools used are not properly calibrated or have worn out over time.

Solution: Regularly calibrate your measurement tools according to the manufacturer’s recommendations. Use certified calibration standards to maintain accuracy. Perform routine maintenance on your measurement tools to ensure they remain in good working condition. Replace worn or damaged tools promptly to avoid inaccurate readings.

Cause: Misinterpreting the specifications on technical drawings can lead to incorrect thread depth measurements.

Solution: Ensure that personnel are trained to read and interpret technical drawings accurately. Familiarize yourself with common symbols, dimensions, and tolerances used in thread specifications. Always double-check the thread depth specifications on the technical drawings before taking measurements. Confirm the reference points and measurement criteria specified in the drawings.

By addressing these common measurement problems, you can improve the accuracy and reliability of your thread depth measurements, ensuring the proper performance and assembly of threaded components.

Thread depth gauges measure the depth of threads in holes with precision. These tools, available in both analog and digital versions, offer accuracy and ease of use. Digital gauges, in particular, provide clear displays for quick readings. However, they tend to be more expensive and require regular calibration to maintain their precision.

Depth micrometers are highly accurate tools for measuring thread depth. They consist of a micrometer head attached to a base, which users adjust to contact the bottom of the threads. These devices consistently perform well, offering exceptional accuracy and reliability. Despite their precision, depth micrometers require careful handling and regular maintenance to ensure accuracy.

Calipers, including digital versions, are versatile tools that can quickly measure thread depth by being inserted into the threaded hole. While practical and cost-effective, calipers offer less precision compared to specialized thread depth gauges or micrometers. They are best suited for general applications where extreme accuracy is not critical.

The wire method involves inserting a known diameter wire into a hole and measuring the exposed part to calculate depth. This approach is accessible and cost-effective when specialized tools are unavailable. However, it is less precise and can be time-consuming compared to other methods.

When selecting a tool for measuring thread depth, consider the required accuracy, the type of thread, and ease of use. High-precision tasks benefit from thread depth gauges and depth micrometers, while calipers and the wire method are suitable for less critical measurements.

Variations in thread depth can significantly impact the performance of high-precision sensors, emphasizing the importance of accurate measurement. Accurate depth measurement can also be hindered by the features of parts and gauges, underscoring the need for careful tool selection and technique.

Thread measurement standards, such as the Unified Thread Standard (UTS) for imperial threads and ISO metric standards for metric threads, are essential for ensuring the compatibility and reliability of threaded components. These standards define key geometric parameters like major and minor diameters, pitch, and thread angle, which are critical for proper fitting.

Compliance involves understanding major and minor diameters, which define the outermost and innermost thread points, and the pitch diameter, crucial for proper engagement. Thread pitch and angle are also specified to maintain mechanical compatibility.

To verify compliance with thread measurement standards, several methods and tools are used:

Go/No-Go gauges are quick tools to check thread tolerances. A “Go” gauge should fit without force, while a “No-Go” gauge should not fit if the thread is within limits, ensuring the threads are sized correctly.

The three-wire method involves using three precision wires placed in the thread grooves to measure the effective pitch diameter. This method is highly accurate and widely used for critical applications where precision is paramount.

Ensuring compliance can be challenging due to measurement uncertainty from tool wear, operator error, or environmental factors, requiring regular tool calibration. Threads that don’t meet specs may need costly rework or replacement. Keeping up with evolving standards is also necessary.

To ensure compliance, regularly calibrate tools, control the measurement environment to prevent errors, use multiple verification methods, and ensure personnel are well-trained in both tools and standards.

Below are answers to some frequently asked questions:

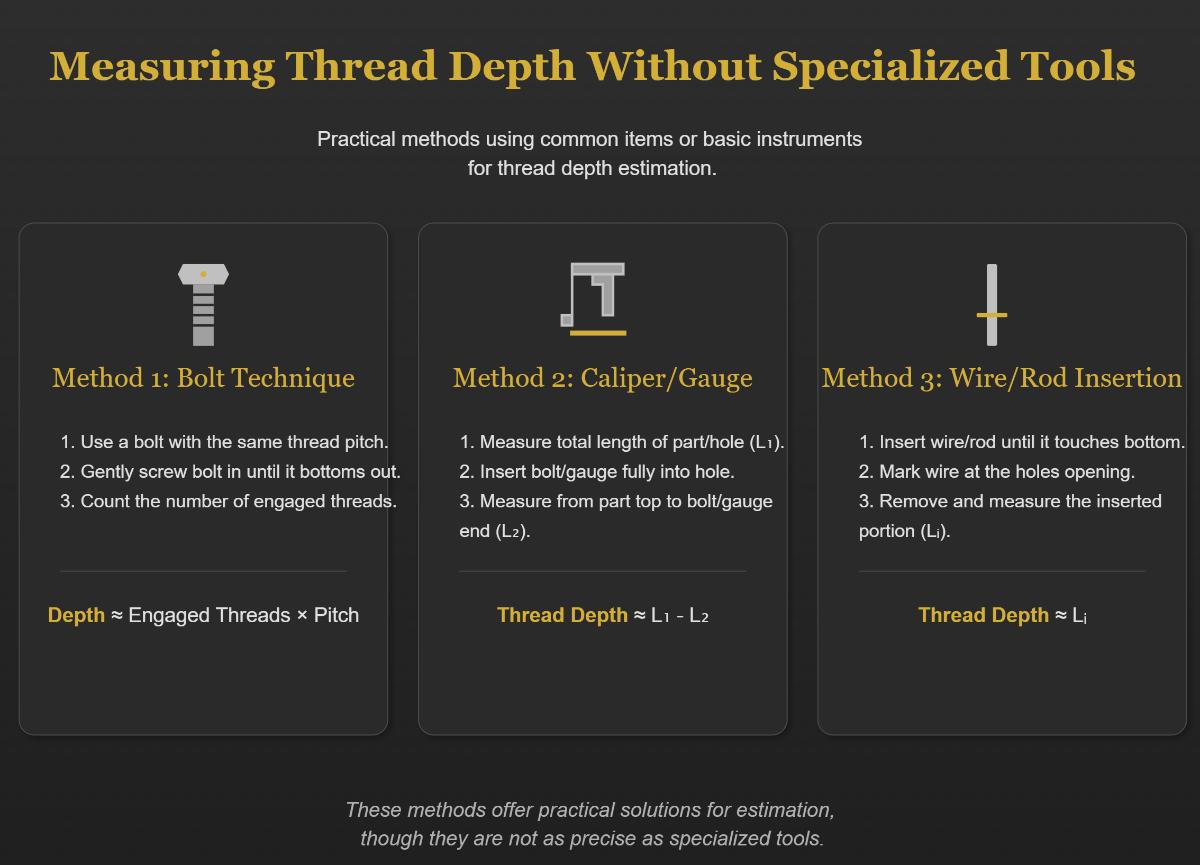

To measure thread depth without specialized tools, you can employ practical methods using common items or basic measuring instruments. One method involves using a bolt with the same thread pitch as the hole. Gently screw the bolt into the hole until it bottoms out, then count the number of engaged threads. Multiply this count by the thread pitch to estimate the depth.

Another approach uses a caliper or depth micrometer. Measure the total length of the part or hole, insert a bolt or plug gauge fully into the hole, and measure the distance from the top of the part to the end of the bolt or gauge. Subtract this measurement from the total length to determine the thread depth.

Alternatively, you can insert a wire or thin rod of known diameter into the threaded hole until it touches the bottom. Measure the exposed length of the wire, then subtract the wire diameter or apply thread pitch-related calculations to find the thread depth.

These methods, while not as precise as specialized tools, offer practical solutions for measuring thread depth in various situations.

Functional depth refers to the effective engagement length of the threads that ensure a secure fastening. It is measured from the first full thread at the bottom of the hole to the point where the mating threads achieve full mechanical strength. This depth is critical for ensuring that the threaded connection meets design specifications and provides the necessary holding power.

Physical depth, on the other hand, represents the total axial length of the threaded hole, including any non-functional sections such as incomplete threads, chamfers, or debris. This measurement extends from the surface entry point to the bottom of the hole and includes areas that do not contribute to the mechanical engagement of the threads.

The primary difference lies in their purposes: functional depth focuses on the part of the thread that actively engages and supports the load, while physical depth accounts for the entire length of the threaded hole, including sections that do not contribute to the thread’s functional performance.

Thread plug gages are essential tools for measuring the depth of threaded holes, and understanding the interpretation of depth notches on these gages is crucial for accurate assessment. Depth notches on Go plug gages serve the purpose of verifying that the threaded hole meets the minimum required thread depth. When using a Go plug gage, the notch should be fully engaged and disappear below the surface of the part; this indicates that the thread depth is sufficient. If the notch remains visible, it suggests that the thread depth is inadequate.

For National Pipe Threads (NPT) and similar standards, a single notch on the L1 gage is used to indicate the depth at which the thread is considered within tolerance. The notch should be within +/- 1 full turn of being flush with the starting point of the threads. Special considerations must be taken if a counterbore or spot face is present above the thread, as this may obscure the visibility of the notch even when the gage is fully seated. In such cases, adjustments to the notch location or measurement technique may be necessary to ensure accurate interpretation.

When measuring thread depth without specialized tools, several alternative methods can be employed depending on the level of accuracy needed. Calipers are a common choice due to their versatility and ease of use, though they offer less precision than dedicated gauges. The wire method involves placing a wire of a known diameter into the thread and calculating the depth based on the wire’s position, providing a rough estimate when other tools aren’t available. The three-wire method, while primarily for pitch diameter measurement, can help infer thread depth through accurate pitch calculations. Additionally, thread plug gages serve as an indirect method to assess depth by verifying thread size compliance with go/no-go criteria. Each of these methods offers varying degrees of accuracy and convenience, making them suitable for different applications in thread depth measurement.