When it comes to optimizing thermal systems, understanding the heat transfer characteristics of materials is crucial. Stainless Steel 304, renowned for its corrosion resistance and durability, is a staple in industries ranging from manufacturing to food processing. But what about its thermal properties? How does temperature impact its thermal conductivity, and what are the typical values for its heat transfer coefficient? This article dives deep into the intricacies of Stainless Steel 304, exploring its thermal behavior, factors influencing its heat transfer performance, and its comparative advantages over other materials. Ready to uncover the secrets of this versatile alloy? Let’s get started.

Stainless Steel 304, often referred to as SS304, is a popular type of stainless steel known for its excellent resistance to corrosion and strong mechanical properties. It belongs to the austenitic family, meaning it has a face-centered cubic crystal structure—a type of atomic arrangement that enhances its ductility, weldability, and toughness even at extremely low temperatures.

The chemical composition of SS304 typically includes:

These elements work together to provide SS304 with its notable characteristics.

SS304 is widely favored for its superior corrosion resistance. The chromium content forms a passive layer of chromium oxide on the surface, protecting the material from oxidation and corrosion. This property is crucial in heat transfer applications where the material may be exposed to moisture, chemicals, or other corrosive environments.

Thermal conductivity and specific heat capacity are critical properties for heat transfer materials. SS304 has a moderate thermal conductivity, around 16.2 W/m·K at room temperature, increasing to about 21.5 W/m·K at 500°C. Although lower than metals like aluminum and copper, SS304’s thermal conductivity is adequate for applications requiring a balance between thermal performance and mechanical strength.

The specific heat capacity of SS304 is approximately 500 J/(kg·K). This property indicates the amount of heat energy needed to raise the temperature of a given mass of the material by one degree Celsius. A higher specific heat capacity means the material can absorb more heat before its temperature rises significantly, beneficial for maintaining stable temperatures in heat transfer applications.

The coefficient of linear thermal expansion for SS304 is about 17.2 × 10-6/K. This property describes the extent to which the material expands or contracts with temperature changes. Understanding thermal expansion is crucial for designing systems that experience significant temperature variations, ensuring that components fit together properly without causing mechanical stress or deformation.

SS304 has a density of about 8.00 g/cm3. Density influences the material’s thermal performance in applications involving mass transfer and energy storage. A higher density typically means the material can store more energy, advantageous in certain heat transfer systems.

In manufacturing, SS304 shines due to its robust properties, making it indispensable in crafting durable storage tanks and piping systems. Its combination of mechanical properties and corrosion resistance ensures reliability in a wide range of equipment.

SS304 is frequently used in pipelines that transport fluids at various temperatures. Its thermal properties ensure efficient heat transfer while maintaining structural integrity and resistance to corrosion, making it suitable for industries such as petrochemicals, water treatment, and food processing.

Heat exchangers are critical components in many industrial processes, and SS304 is often the material of choice. Its ability to withstand high temperatures and corrosive environments, coupled with moderate thermal conductivity and excellent mechanical properties, makes it effective in transferring heat between fluids without compromising durability.

The heat transfer coefficient, denoted as ( h ), is a key parameter in thermal engineering that measures how effectively heat is transferred between a surface and a fluid. Its unit is typically watts per square meter per kelvin (W/m²·K), and it is crucial for designing and analyzing systems where heat exchange occurs, such as heat exchangers, boilers, and cooling systems. This parameter is fundamental in evaluating thermal performance and efficiency across various applications.

A higher value of ( h ) means more efficient heat transfer, which is vital for optimizing energy use and reducing losses in industrial and mechanical applications. By understanding and controlling the heat transfer coefficient, engineers can design systems that meet specific thermal requirements while ensuring cost-effectiveness and reliability.

Several factors influence the heat transfer coefficient, making it a dynamic and context-dependent property:

Material Properties

The thermal conductivity of a material significantly impacts the heat transfer coefficient. For example, metals like copper, which have high thermal conductivity, generally have higher heat transfer coefficients than materials like stainless steel. Stainless Steel 304, while less conductive than copper, offers a balance of moderate thermal conductivity and superior mechanical properties, making it suitable for various applications.

Surface Conditions

The condition of the surface—whether polished, rough, or coated—can affect thermal resistance. Polished surfaces reduce thermal resistance, improving the heat transfer coefficient, while rough or corroded surfaces tend to lower it. Surface treatments and coatings are often employed to enhance heat transfer performance in specific applications.

Fluid Properties and Flow Regime

The type of fluid and its properties, such as viscosity and density, directly affect the heat transfer coefficient, as does whether the flow is laminar or turbulent. Turbulent flow disrupts the thermal boundary layer, increasing ( h ), while laminar flow results in lower coefficients due to limited mixing.

Temperature and Pressure

Temperature and pressure conditions also influence heat transfer. For example, higher temperatures can alter a fluid’s viscosity and thermal conductivity, impacting heat transfer efficiency. Changes in pressure, particularly in gases, can similarly affect fluid properties and the resulting heat transfer coefficient.

Different types of heat transfer coefficients are defined based on specific conditions and mechanisms of heat transfer:

The heat transfer coefficient (( h )) of Stainless Steel 304 (SS304) plays a crucial role in the design and evaluation of thermal systems. SS304, known for its good balance of strength, corrosion resistance, and thermal properties, has specific heat transfer characteristics that make it suitable for various industrial applications.

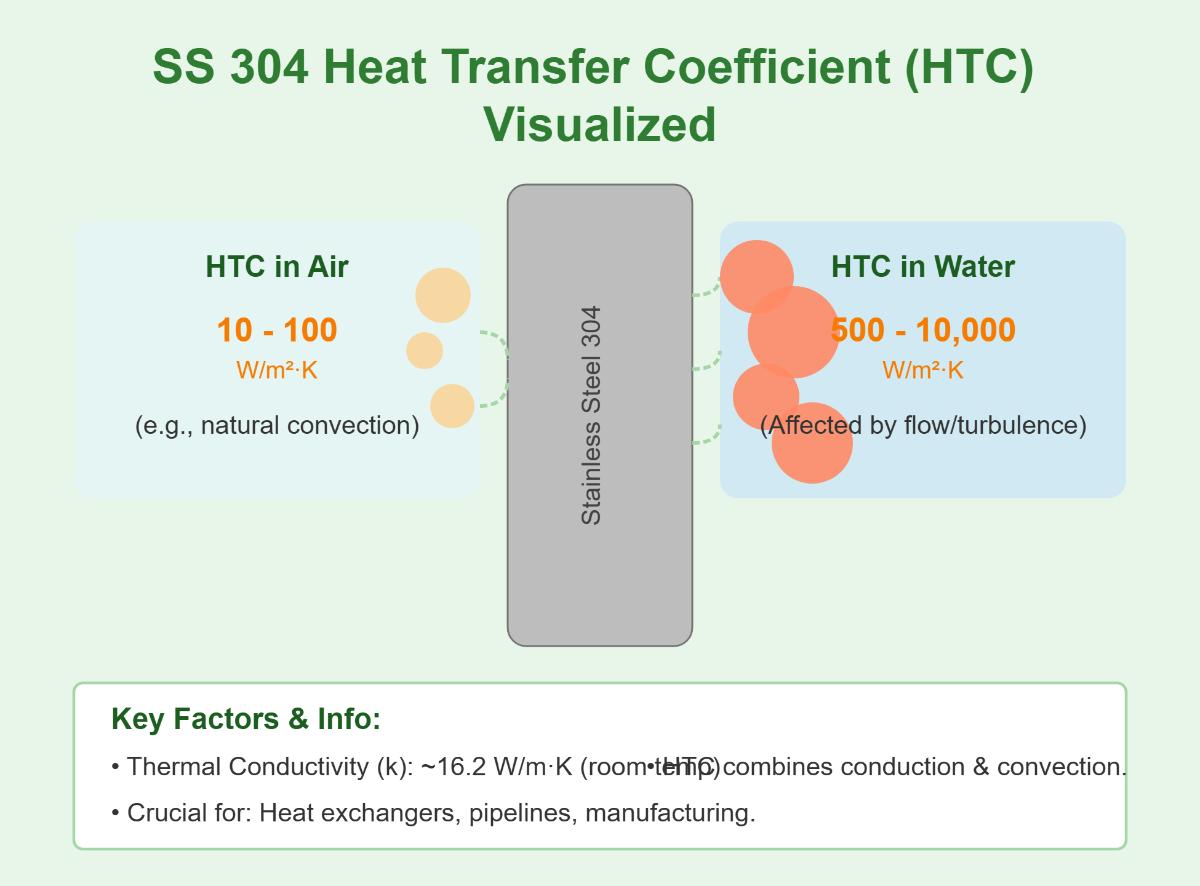

In applications involving fluid flow over SS304 surfaces, the convective heat transfer coefficient, which depends on factors such as the type of fluid, flow velocity, and surface conditions, is of primary interest. For SS304, typical values of the convective heat transfer coefficient in water can range from 500 to 10,000 W/m²·K, while in air, the values are generally lower, ranging from 10 to 100 W/m²·K. These values are influenced by the nature of the fluid and the specific application conditions.

Compared to other materials used in heat transfer applications, SS304 shows moderate thermal performance. Here are some comparisons:

Adhering to industry standards, like those from ASTM International, is crucial for ensuring the safety, reliability, and performance of thermal systems using SS304. Standards such as ASTM A240 specify the requirements for SS304 sheets and plates, ensuring they meet the necessary mechanical and thermal properties for industrial use.

Thermal conductivity is a key property that determines how well a material conducts heat. For Stainless Steel 304 (SS304), this property starts at approximately 16.2 W/m·K at 20°C and rises to about 21.5 W/m·K at 500°C. This gradual increase enhances the material’s efficiency in transferring heat as the operating temperature rises, making SS304 suitable for applications requiring stable thermal performance across varying temperatures.

The condition of the surface of SS304 plays a significant role in determining its heat transfer efficiency. Clean, smooth surfaces are essential for optimal heat transfer, as any fouling, scaling, or oxidation layers can significantly increase thermal resistance. Techniques such as femtosecond laser surface processing can create micro and nano structures on the surface, enhancing pool boiling heat transfer and improving the overall thermal performance. These micro and nano structures increase the surface area and create nucleation sites for bubble formation, which enhances the boiling process.

The convection heat transfer coefficient is influenced by the properties of the fluid in contact with the SS304 surface and the flow rate of that fluid. Higher fluid flow rates and favorable fluid properties, such as higher specific heat and lower thickness, enhance convective heat transfer. This coefficient is crucial in applications involving fluid flow, such as heat exchangers and cooling systems, where the efficiency of heat transfer depends significantly on the nature and behavior of the fluid.

The thickness of SS304 impacts its ability to conduct heat. Thicker materials create more resistance to heat flow, thereby reducing the heat transfer coefficient. Conversely, thinner materials allow for better heat conduction. In practical applications, using thin-walled tubes or components can reduce thermal resistance and increase the efficiency of heat exchangers or other thermal systems.

SS304 maintains relatively stable thermal properties across a wide range of temperatures, but extreme conditions can slightly alter its behavior. Understanding the impact of temperature gradients is essential for applications involving high or fluctuating temperatures, as these conditions can affect the material’s thermal conductivity and, consequently, its heat transfer performance. Engineers must consider these effects when designing systems to ensure reliable and efficient operation under varying thermal conditions.

SS304 stands out for its excellent corrosion resistance, ensuring efficient heat transfer over time. The material’s inherent resistance to corrosion helps prevent fouling or degradation that can occur in other metals, ensuring long-term stability and performance. This property is particularly beneficial in environments exposed to moisture, chemicals, or other corrosive elements, making SS304 a preferred choice for heat transfer applications in harsh conditions.

Stainless Steel 304 (SS304) is a widely used material in industrial applications, valued for its unique combination of thermal and mechanical properties. Its versatility and durability make it a reliable choice for demanding environments.

At room temperature, SS304 has a thermal conductivity of about 16.2 W/m·K, which is lower than that of copper or aluminum. While its heat conduction capabilities are moderate, its other qualities, such as corrosion resistance and mechanical strength, make it a preferred material in applications where durability and environmental resilience are critical.

One of the standout features of SS304 is its excellent corrosion resistance due to its high chromium content, making it particularly beneficial in heat transfer applications exposed to corrosive fluids or environments. This property ensures long-term performance and reliability, even in challenging conditions where other materials might degrade over time.

SS304 is a common choice for heat exchangers in chemical processing plants. Its ability to resist corrosion in harsh environments ensures that it remains structurally intact over prolonged use, even when exposed to aggressive chemicals. While its thermal conductivity is moderate, its durability and resistance to environmental damage compensate for this limitation, making it a practical solution for long-term operations.

In food processing and brewing, SS304’s non-reactive nature keeps the quality of foods and beverages high. Its corrosion resistance ensures longevity, even in environments with high moisture and frequent exposure to cleaning agents. Moreover, its smooth surface and ease of cleaning make it ideal for maintaining strict hygiene standards essential in these industries.

Though SS304 isn’t mainly used for heat transfer in automotive and aerospace, its strength, corrosion resistance, and good looks make it ideal for structural parts and trim. These attributes allow it to withstand the demanding conditions of these industries while also offering an aesthetic appeal for visible components.

SS304 is a popular choice for kitchen appliances and equipment due to its durability, corrosion resistance, and ease of cleaning. Its ability to maintain its appearance and structural integrity under constant exposure to water, heat, and cleaning chemicals makes it suitable for sinks, countertops, and cookware, meeting both functional and aesthetic demands.

Several strategies can improve the heat transfer efficiency of SS304 in industrial applications:

Stainless Steel 304 (SS304) is widely used for its moderate thermal conductivity and excellent resistance to corrosion. Its thermal conductivity ranges from 16.2 W/m·K at room temperature to 21.5 W/m·K at 500°C. This makes it suitable for various heat transfer applications where durability is essential, although it is less efficient than materials like aluminum and copper in high-speed heat transfer scenarios.

| Material | Thermal Conductivity (W/m·K) |

|---|---|

| Stainless Steel 304 | 16.2 (20°C), 21.5 (500°C) |

| Aluminum | 205-250 |

| Copper | 386-394 |

| Stainless Steel 316 | Similar to SS304 |

Aluminum and copper have significantly higher thermal conductivities compared to SS304, making them more efficient for heat transfer applications. Aluminum’s thermal conductivity ranges between 205-250 W/m·K, while copper boasts a thermal conductivity of around 386-394 W/m·K. These materials are preferred in applications where rapid heat transfer is essential. Stainless Steel 316, which is similar to SS304 in thermal conductivity, offers better corrosion and heat resistance, making it suitable for more demanding environments where SS304 might not suffice.

Heat transfer efficiency depends on surface conditions (clean and smooth surfaces are better), material thickness (thinner is more efficient), and the convection heat transfer coefficient (higher fluid flow rates improve efficiency).

While materials like aluminum and copper offer superior thermal conductivity, SS304 provides a balance of thermal properties, mechanical strength, and corrosion resistance. This balance makes it cost-effective for applications where both durability and moderate heat transfer efficiency are required. In environments with high temperatures and corrosive conditions, SS316 might be a preferable choice due to its enhanced resistance properties.

SS304 is ideal for applications needing both moderate thermal conductivity and high durability, including heat exchangers, pipelines, and various manufacturing processes. For high-speed heat transfer applications, aluminum or copper would be more efficient. In more demanding environments, SS316 offers better performance due to its superior resistance to corrosion and heat.

Improving the heat transfer efficiency of Stainless Steel 304 (SS304) can be significantly influenced by various material processing techniques. These techniques can alter the microstructure and surface properties, thereby enhancing thermal conductivity and overall performance.

Annealing involves heating the SS304 to a specific temperature and then allowing it to cool slowly. This process reduces internal stresses and removes crystal defects, which enhances the material’s thermal conductivity. By creating a more uniform and refined microstructure, annealing can improve heat transfer efficiency, making SS304 more effective in thermal applications.

Cold rolling increases material density and slightly improves thermal conductivity, though it may introduce defects that negatively impact heat transfer. Conversely, hot rolling can lead to a coarser grain structure, which might reduce thermal conductivity. Balancing these processes to optimize the microstructure is crucial for achieving the desired thermal properties.

Quenching involves rapid cooling after heating, followed by tempering, which involves reheating to a lower temperature and then cooling again. This combination can relieve internal stresses and enhance the material’s toughness, ductility, and strength. The quenching process typically results in a hard but brittle structure, while tempering helps to reduce brittleness and improve mechanical properties, making the material more suitable for practical applications.

Surface treatments play a vital role in optimizing the heat transfer efficiency of SS304. These treatments can modify the surface properties, enhancing thermal performance and extending the material’s lifespan.

A smooth surface reduces thermal resistance and enhances heat transfer efficiency. Polished surfaces provide better thermal contact with fluids, improving convective heat transfer. Regular maintenance to remove oxidation and scaling is crucial for maintaining smooth surfaces and optimal thermal performance.

Applying surface coatings can improve heat transfer efficiency by enhancing thermal conductivity and protecting against corrosion. Coatings such as nickel or ceramic can provide a smoother, more conductive surface while adding a layer of protection against environmental factors that might degrade SS304 over time.

Advanced techniques like femtosecond laser surface processing can create micro and nano structures on the SS304 surface. These structures significantly enhance the heat transfer coefficient by increasing the surface area and improving fluid interaction. This method is particularly effective in applications involving boiling or high heat flux conditions.

Optimizing the design of SS304 components can lead to significant improvements in heat transfer efficiency. These modifications can include changes in geometry, flow dynamics, and material thickness.

Designing components with larger surface areas, such as fins and corrugations, can enhance heat transfer efficiency by increasing contact with fluids and improving convective heat transfer. This approach is widely used in heat exchangers and cooling systems to maximize thermal performance.

Improving the flow dynamics of fluids over SS304 surfaces can enhance heat transfer. Turbulent flow conditions, as opposed to laminar flow, disrupt the thermal boundary layer, increasing the convective heat transfer coefficient. Designing systems to promote turbulence, such as using baffles or swirl generators, can significantly boost heat transfer efficiency.

Thinner SS304 components can reduce thermal resistance, improving heat conduction. While maintaining structural integrity is essential, using thin-walled tubes or plates can enhance thermal performance by allowing heat to pass through more readily. This approach is particularly useful in applications where space and weight are critical constraints.

Developing composite materials that combine SS304 with high thermal conductivity materials, such as aluminum or copper, can significantly enhance heat transfer efficiency. These composites maintain the desirable properties of SS304, such as corrosion resistance and mechanical strength, while benefiting from the superior thermal conductivity of the added materials.

Incorporating high-conductivity particles into SS304 metal matrix composites (MMCs) can enhance thermal performance. For example, embedding copper or aluminum particles into the SS304 matrix can create a composite material with improved thermal conductivity, making it suitable for more demanding heat transfer applications.

Additive manufacturing, or 3D printing, allows for the creation of complex geometries and customized designs that maximize heat transfer efficiency. By precisely controlling the material distribution and incorporating high-conductivity elements, additive manufacturing can produce SS304 components optimized for specific thermal applications, such as heat sinks and energy systems.

Implementing these optimization techniques can significantly enhance the heat transfer efficiency of SS304 in various industrial applications. From heat exchangers and cooling systems to advanced energy solutions, these methods ensure that SS304 remains a reliable and efficient material in thermal management.

In heat exchangers, optimizing SS304 through material processing, surface treatments, and design modifications can lead to improved thermal performance and longer service life. These enhancements make SS304 an excellent choice for demanding applications in chemical processing, energy production, and HVAC systems.

For advanced energy systems, such as solar thermal collectors and nuclear reactors, the ability to customize SS304 components through additive manufacturing and composite material development offers significant advantages. These innovations provide enhanced heat transfer efficiency, ensuring reliable and efficient energy conversion and management.

The heat transfer coefficient (( h )) is a crucial parameter used to quantify the efficiency of heat transfer between a surface and a fluid. This coefficient is essential in designing and analyzing thermal systems, such as heat exchangers, boilers, and cooling systems. Accurate calculation of the heat transfer coefficient ensures that thermal systems operate efficiently and meet the desired performance criteria.

Thermal conductivity (( k )) measures a material’s ability to conduct heat. For Stainless Steel 304 (SS304), thermal conductivity changes with temperature, ranging from 16.2 W/m·K at room temperature to 21.5 W/m·K at approximately 500°C. Accurate knowledge of thermal conductivity is crucial for calculating heat transfer coefficients.

The convective heat transfer coefficient (( h_c )) depends on the nature of the fluid and the flow conditions around the SS304 surface. Factors such as fluid velocity, viscosity, and temperature gradients affect this coefficient. Typical values for the convective heat transfer coefficient in SS304 range from 10 to 100 W/m²·K for air and 500 to 10,000 W/m²·K for water.

Empirical formulas, like the Dittus-Boelter equation, use dimensionless numbers (Nusselt, Reynolds, and Prandtl) to estimate heat transfer efficiency. For example, the Dittus-Boelter equation for turbulent flow in pipes is given by:

where:

From the Nusselt number, the convective heat transfer coefficient ( hc ) can be calculated:

where:

Assume the following conditions for a practical calculation:

The U = 1/(0.02 + 0.00067 + 0.01) resulting in approximately 32.6 W/m²·K.

You can improve the heat transfer performance of SS304 using methods such as surface modification, material processing, or heat treatment.

By understanding and applying these methods, engineers can optimize the heat transfer performance of SS304 in various industrial applications, ensuring efficient and reliable thermal systems.

Below are answers to some frequently asked questions:

The typical values for the heat transfer coefficient (HTC) of Stainless Steel 304 can vary significantly based on the application and environmental conditions. For convective heat transfer, the HTC for Stainless Steel 304 when exposed to air generally ranges from 10 to 100 W/m²·K, whereas in water, it can be much higher, ranging between 500 to 10,000 W/m²·K, depending on factors such as flow rate and turbulence. These values are influenced by the thermal conductivity of Stainless Steel 304, which is approximately 16.2 W/m·K at room temperature and increases with temperature. The HTC is crucial for designing efficient thermal systems and combines both conductive and convective resistances, making it a key parameter in applications such as heat exchangers, pipelines, and manufacturing processes.

The thermal conductivity of Stainless Steel 304 decreases as temperature rises, which impacts its heat transfer efficiency. At room temperature (around 20°C), SS304 has a thermal conductivity of approximately 16.2 W/m·K. However, as the temperature increases, this value typically declines—for example, to about 15.1 W/m·K at 100°C and 13.8 W/m·K at 300°C. This reduction is due to the alloy’s microstructure and the scattering of heat-carrying electrons and phonons at higher temperatures. Interestingly, at very high temperatures (e.g., 500°C), the thermal conductivity can increase slightly, reaching around 21.5 W/m·K, though it remains lower compared to materials like copper or aluminum.

These variations are influenced by the alloy’s composition, which includes elements like chromium and nickel that reduce thermal conductivity. Understanding this relationship is critical for optimizing SS304 in heat transfer applications, particularly where stable thermal performance and corrosion resistance are prioritized.

Stainless Steel 304 (SS304) is extensively utilized in industries requiring efficient heat transfer due to its corrosion resistance, mechanical strength, and moderate thermal conductivity. Key industries include:

These applications highlight SS304’s versatility and reliability in demanding thermal environments.

Yes, there are several tools available for calculating heat transfer coefficients, particularly for materials like Stainless Steel 304. These tools help engineers and designers assess the thermal performance of systems involving this material.

Omni Calculator: Offers a dedicated heat transfer coefficient calculator that allows users to input parameters such as wall thickness, thermal conductivity, and contact area to compute the overall heat transfer coefficient.

ChemEnggCalc: Focuses on systems with multiple layers, allowing for a detailed analysis of thermal resistances. It uses the formula below to estimate heat transfer rates and temperature profiles.

Duratherm Fluids Calculator: Helps determine heat transfer rates for both conduction and convection by allowing users to input thermal conductivity, surface area, and temperature differentials.

Heat Exchanger Data from Engineering Toolbox: Provides average values for These tools and methodologies provide accurate and practical means to calculate and optimize the heat transfer coefficients for Stainless Steel 304 in various thermal applications.

Stainless Steel 304 is commonly used in heat exchangers due to its excellent corrosion resistance, mechanical strength, and cost-effectiveness. However, it has a lower thermal conductivity (approximately 16.2 W/m·K) compared to materials like copper (401 W/m·K) and aluminum (235 W/m·K), which means it is less efficient at heat transfer. Despite this, Stainless Steel 304 is favored in many applications for its durability and ability to withstand various environmental conditions.

In comparison to copper and aluminum, which are superior in heat transfer efficiency due to their higher thermal conductivity, Stainless Steel 304 excels in environments where corrosion resistance is crucial. While titanium and higher alloys like 316L stainless steel offer specialized benefits, such as high strength-to-weight ratios and enhanced corrosion resistance, they are typically more expensive.

The use of Stainless Steel 304 in thermal applications is governed by several industry standards to ensure consistent quality and performance. Key standards include ASTM A240 and ASME SA-240. ASTM A240 specifies the requirements for annealed and pickled stainless steel plate, sheet, and strip, including mechanical properties such as tensile strength, yield strength, and elongation. ASME SA-240, similar to ASTM A240, applies to materials used in the construction of boilers and other pressure vessels, ensuring the material meets specific mechanical and physical properties. These standards are critical for maintaining the integrity and efficiency of thermal systems where Stainless Steel 304 is utilized.